Automobile windshield cleaning fluid

A glass cleaning and car windshield technology, which is applied in the field of cleaning fluid, can solve the problems of personnel injury in the car, unstable performance of sodium metasilicate, and affecting the anti-corrosion performance of product metal, so as to avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

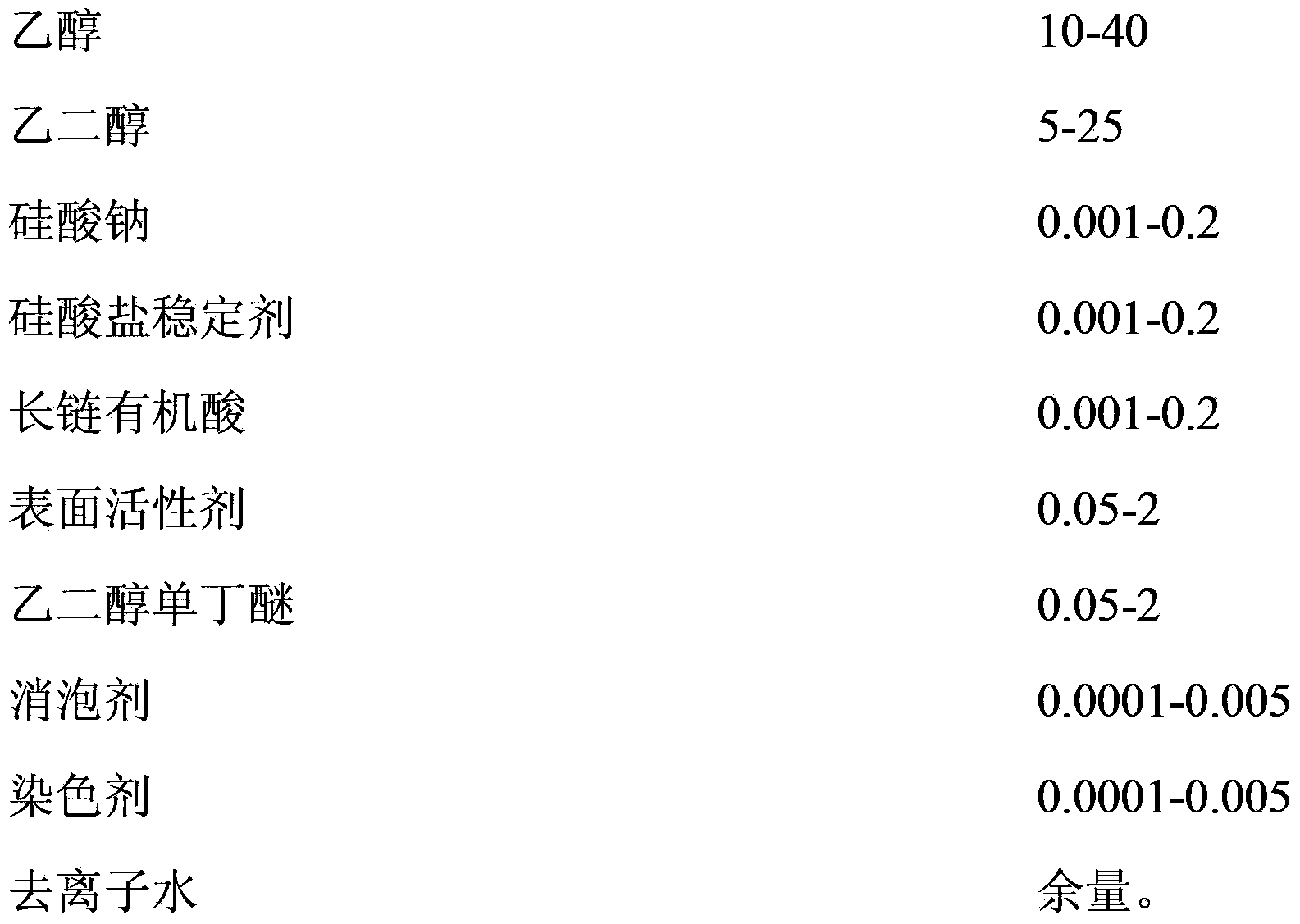

Method used

Image

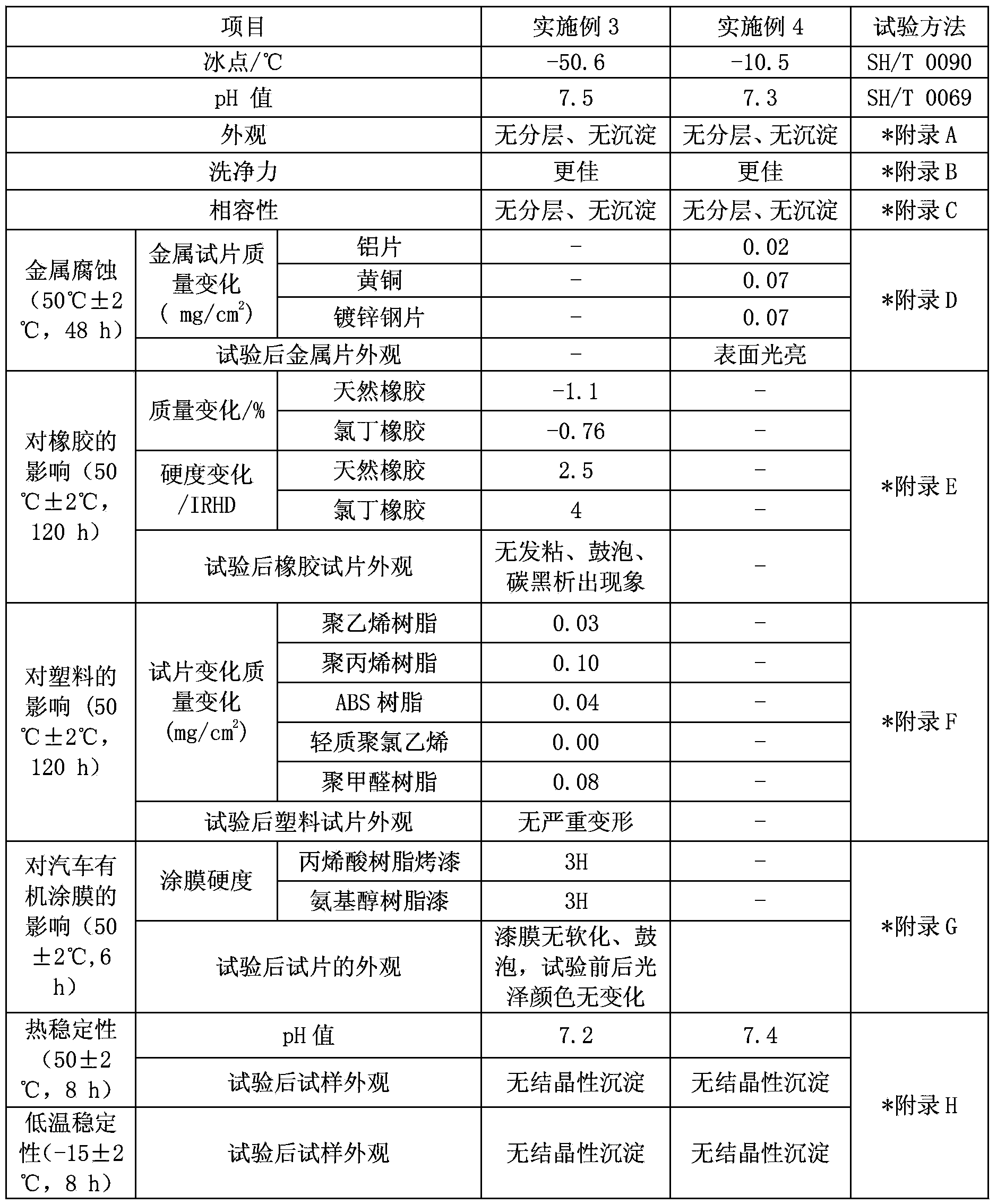

Examples

Embodiment 1

[0014] Take 40kg of ethanol, 25kg of ethylene glycol, the balance of deionized water, 0.05kg of sodium metasilicate pentahydrate, 0.05kg of silicate stabilizer, 0.05kg of adipic acid, and 0.8 kg of fatty alcohol polyoxyethylene ether (AEO-9) kg, 0.2 kg of sodium dodecylbenzene sulfonate, 0.3 kg of ethylene glycol monobutyl ether, 0.002 kg of silicone defoamer, and 0.0005 kg of bright blue pigment, which are blended and formulated into automobile windshield cleaning fluid products according to conventional processes.

Embodiment 2

[0016] Take 10kg of ethanol, 5kg of ethylene glycol, the balance of deionized water, 0.1kg of sodium metasilicate pentahydrate, 0.1kg of silicate stabilizer, 0.08kg of adipic acid, and alkylphenol polyoxyethylene ether (OP-10) 0.7kg, sodium dodecylbenzene sulfonate 0.3kg, ethylene glycol monobutyl ether 0.4kg, silicone defoamer 0.002kg, bright blue pigment 0.0005kg, according to the conventional process to blend and prepare the car windshield cleaning fluid products .

Embodiment 3

[0018] Take 38kg of ethanol, 19kg of ethylene glycol, the balance of deionized water, 0.1kg of sodium metasilicate pentahydrate, 0.1kg of silicate stabilizer, 0.1kg of sebacic acid, and nonylphenol polyoxyethylene ether (NP-10) 1.0kg, 0.5kg of ethylene glycol monobutyl ether, 0.003kg of silicone defoamer, and 0.0005kg of bright blue pigment are blended according to conventional processes to make automobile windshield cleaning fluid products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com