Composition for producing waterborne coating and coating system prepared from composition

A water-based coating and composition technology, which is applied in the field of producing water-based coating compositions, can solve the problems of inability to use a double-coating system, poor paint film compactness, and poor anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

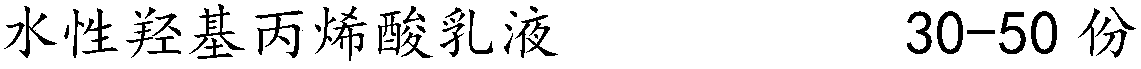

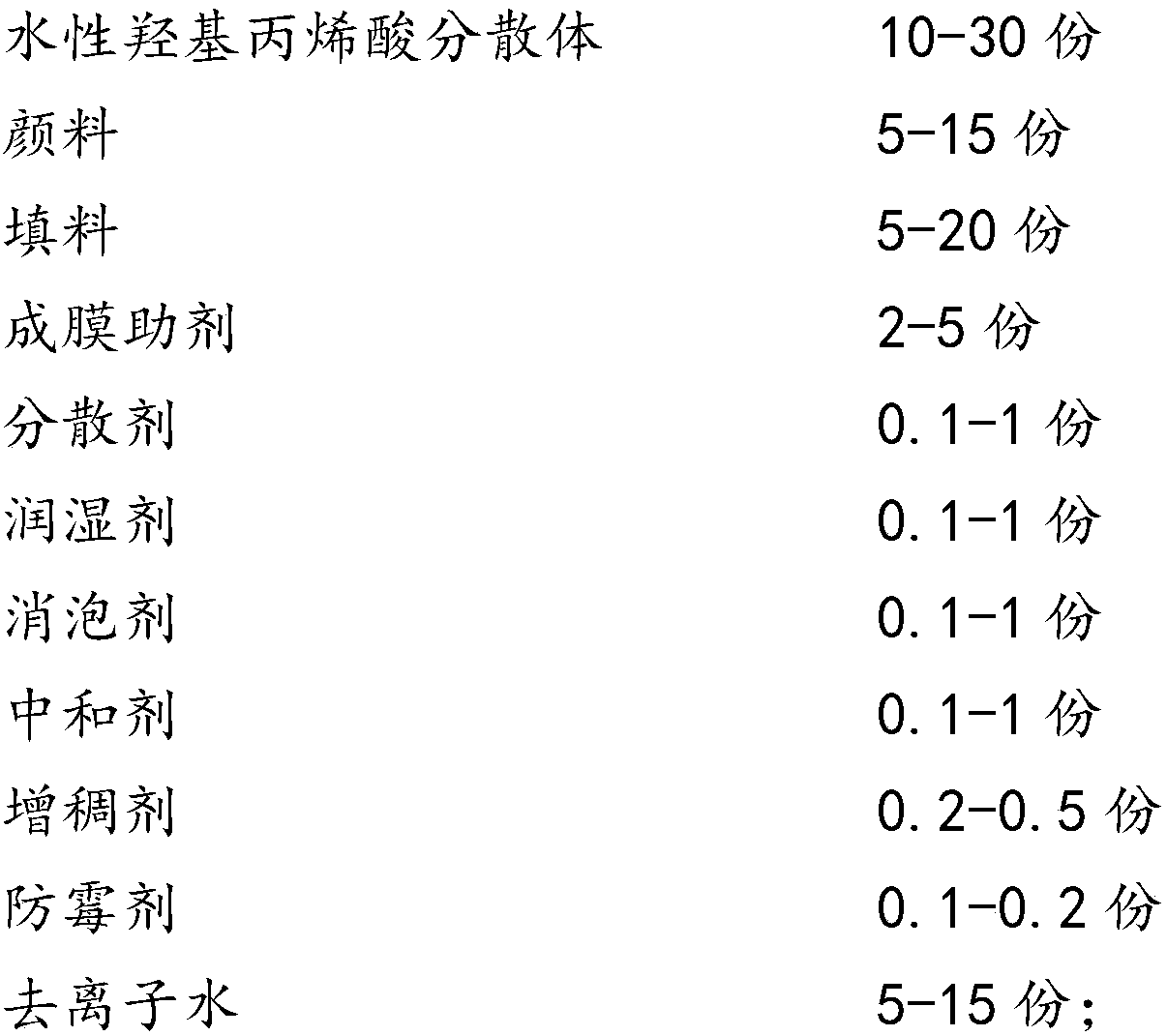

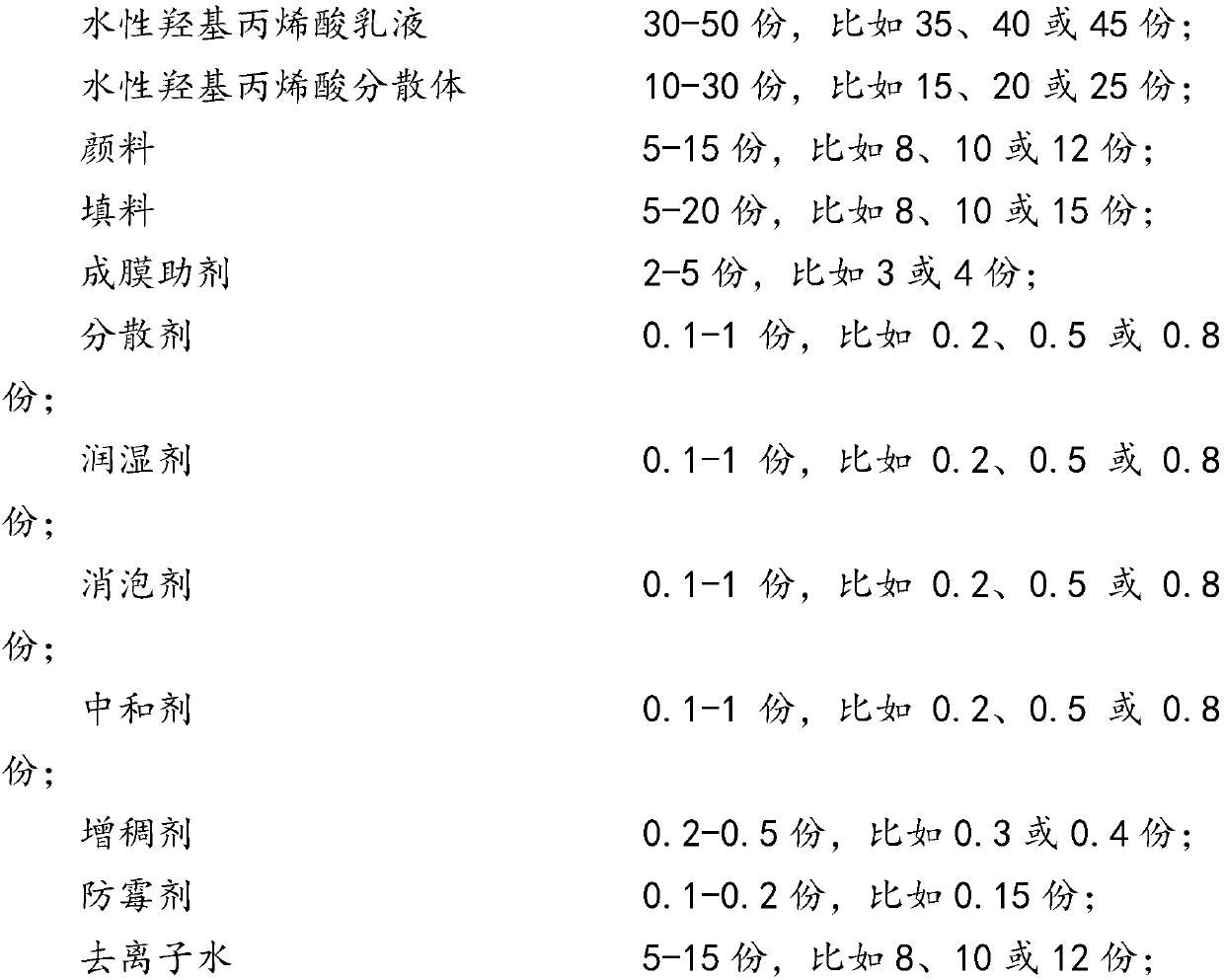

Method used

Image

Examples

preparation example Construction

[0041] Preparation of the base material to be coated: sandblasting and derusting the surface of the base material, and the derusting level reaches the Sa2.5 level specified in GB / T8923.

[0042] On the substrate to be coated, a double-coat system is prepared by high-pressure airless spraying construction technology, water-based epoxy zinc-rich primer (zinc powder content ≥ 80wt%, derived from Megaborne 116), the dry film thickness of the paint film is 30 μm, and it is self-drying 3~5min, then baked at 70-80℃ for 20-30min to obtain; the topcoat layer, evenly sprayed on the primer layer, the dry film thickness of the paint film is 40-50μm, dry for 5~10min, then baked at 70-80℃ 20-30min to get.

[0043] Unless otherwise specified, the reagents used in the present invention are analytically pure.

[0044] The embodiment selects the hydroxyacrylic acid emulsion to be Wanhua chemical 0676 and Luhydran S 938T; Hydroxy acrylic dispersions are from Wanhua Chemical 2033 and Bayer's...

Embodiment 1

[0051] A component, comprising the following components by weight: hydroxyacrylic acid emulsion ( 0676) 45 parts, hydroxyacrylic acid dispersion ( 2033) 15 parts, 3 parts of film-forming aid lauryl alcohol ester, 2 parts of titanium dioxide (Dragon Mang R-996), 3 parts of phthalocyanine blue (Shenzhen Mingyuan Chemical Pigment Co., Ltd.) talcum powder (800 mesh Guangxi Osmanthus brand ) 8 parts, barium sulfate (1250 mesh Qingdao Linke Chemical) 10 parts, dispersant BYK-190 1 part, wetting agent BYK-346 0.5 part, defoamer Tego 1488 0.3 part, neutralizer AMP-95 0.1 part , thickener U604 0.3 parts, antifungal agent KF-88 0.1 parts, deionized water 11.7 parts.

[0052] Preparation method:

[0053] (a) Add 90% of the formula amount of water into the condensed water dispersing tank, and then add water-based hydroxyacrylic acid dispersion, neutralizer, dispersant, wetting agent, and 50% formula amount of defoamer at a rate of 1000r / min pre-dispersion 15min.

[0054] (b) Add pi...

Embodiment 2

[0063] A component, comprising the following components by weight: hydroxyacrylic acid emulsion ( 0676) 30 parts, hydroxyacrylic acid dispersion ( 2033) 30 parts, 3 parts of film-forming aid dipropylene glycol butyl ether, iron oxide red (Bayferrox 4130) 5 parts, talcum powder (800 mesh Guangxi osmanthus brand) 8 parts, mica powder (800 mesh Chuzhou Sericite Factory) 2 5 parts of heavy calcium carbonate (800 mesh Changzhou Calcium Carbonate Co., Ltd.), 1 part of dispersant BYK-190, 0.5 part of wetting agent Tego wet270, 0.2 part of defoamer Tego 1488, 0.1 part of neutralizing agent AMP-95 , thickener U605 0.2 parts, antifungal agent KF-88 0.1 parts, deionized water 14.9 parts.

[0064] B component, comprising the following components by weight: water-based isocyanate curing agent ( 268) 70 parts, 30 parts of propylene glycol methyl ether acetate.

[0065] Prepare with embodiment 1.

[0066] Mix component A and component B according to the ratio of A:B=9:1 to obtain a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com