Gear oil composition and preparation method thereof

A technology of composition and gear oil, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of general extreme pressure and anti-wear performance, accelerated oil product failure, shortened life and other problems, achieve good anti-oxidation ability, improve The effect of oil change interval and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

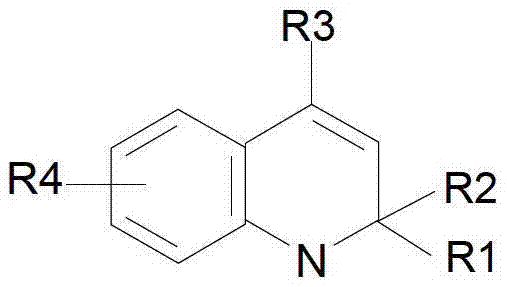

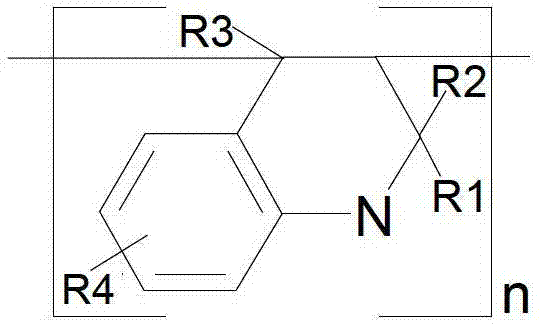

[0056] Add 100 parts of water-insoluble polyether base oil Emkarox VG222 (Croda Company, Inc, the same below) into a stainless steel mixing kettle with agitator, keep the temperature of the kettle at 40°C, and then add 0.6 parts of Naugalube TMQ (2,2 , 4-trimethyl-1,2-dihydroquinoline antioxidant, Uniroyal Chemical Company, Inc. the same below), 0.08 parts of metal deactivator benzotriazole derivative T551 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 1 part of antiwear agent nonyl phosphate amine salt mixture Irgalube349 (Ciba Specialty Chemicals Inc), 0.5 part of extreme pressure agent aminothioester T323 (Jinzhou Tianbu Lubricating Oil Additive Co., Ltd.), 0.002 part T901 methyl silicone oil (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 0.003 parts of demulsifier propylene oxide / ethylene oxide block copolymer 5957 (Lubrizol Petroleum Chemical Company, the same below) was added into the blending kettle, started to stir until t...

Embodiment 2

[0062] Add 100 parts of water-insoluble polyether base oil Emkarox VG222 (Croda Company, Inc, the same below) into a stainless steel blending kettle with a stirrer, keep the temperature of the kettle at 40°C, and then add 0.8 parts of Naugalube TMQ, 0.1 parts of Metal deactivator T551, 1 part of antiwear agent tricresyl phosphate, 0.4 part of extreme pressure agent vanlube972 (2,5-dimercapto-1,3,4-thiadiazole dimer and butoxy triethylene glycol Compound, R.T.Vanderbilt Holding Company, Inc), 0.003 parts of T901, 0.005 parts of demulsifier Add 5957 into the blending kettle, start stirring until the mixture is completely dissolved, uniform and transparent, and the finished gear oil D is obtained.

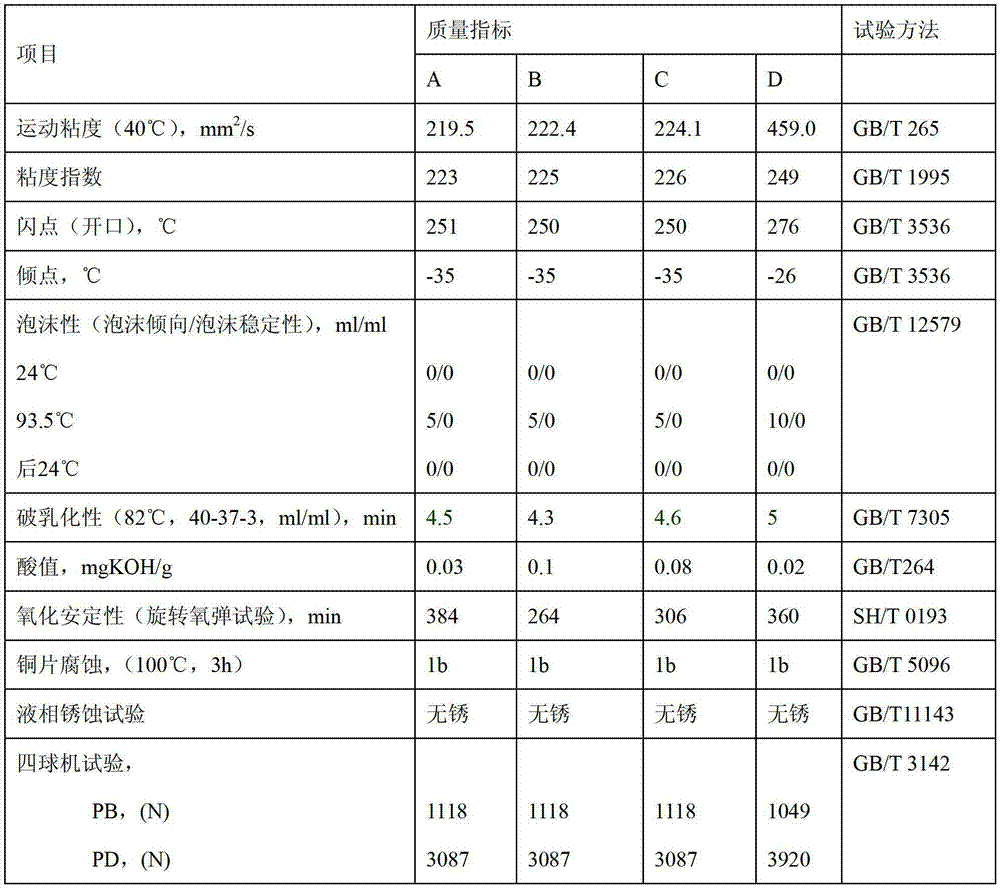

[0063] The obtained gear oil compositions A, B, C and D are verified in Table 1 by test results.

[0064] Table 1

[0065]

[0066] The results of the data in Table 1 show that 2,2,4-trialkyl-1,2-dihydroquinoline antioxidants and metal deactivators have a certain antioxidant syn...

Embodiment 3

[0068]Except that the extreme pressure agent was changed to sulfurized isobutylene, the rest were the same as in Example 2 to obtain the finished gear oil E. The anti-oxidation performance of the oil is evaluated by differential scanning calorimetry (DSC) test, test conditions: the test sample weighs 2.00 mg, the oxygen flow rate is 100 ml / min, and in the dynamic test, the heating rate is 5 °C / min. In the static oxidation test, the temperature was 200°C. The test results of the oxidation test are shown in Table 2.

[0069] Table 2

[0070]

[0071] It can be concluded from the table that the gear oil composition of the present invention has outstanding high temperature oxidation resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com