Method for preparing and spaying anticorrosion coating for western wind farm tower

A technology for anti-corrosion coatings and wind farms, applied in anti-corrosion coatings, epoxy resin coatings, devices for coating liquid on the surface, etc., can solve the problem of no anti-corrosion coatings and related materials for towers in western wind farms, and achieve good interlayer Effects of adhesion, reduction of wind power generation cost, reduction of corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

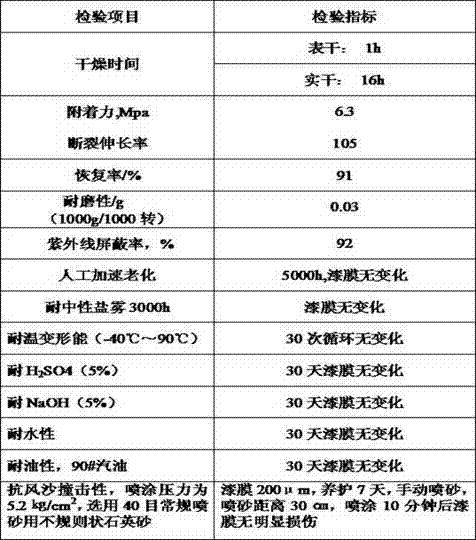

Embodiment 1

[0075] Weigh 35.0g of GF-630A elastic epoxy resin, 18g of mixed solvent (xylene: n-butanol: cyclohexanone = 1:1:1), 0.08g of BYK-4510, 0.4g of BYK-306 and mix Together and disperse and stir evenly, then add 23g of zinc powder and 0.5g of BYK-A530 for re-dispersion and stirring, after dispersing and stirring evenly, put them together in a sand mill for grinding until the fineness reaches 80μm, when the viscosity reaches 80 ~ After 110 seconds, the primer group A was prepared for use. Before spraying, 0.7 parts by weight of GF-630B was put into 10.0 parts by weight of the primer group A and fully dispersed and stirred evenly to obtain the primer, that is, the Primer A group: said primer B group=10g:0.7g.

[0076]Weigh 30g of PUASTOMER-2804 ultra-linear elastic resin, 30.0g of shielding impermeability material (the ratio of mica iron oxide: glass flakes: mica powder in the 30.0g parts by weight = 2:1:1), 15g of Mix the solvent (xylene: butyl acetate: PMA=1:1:1) and disperse and ...

Embodiment 2

[0080] Weigh 30.0g of GF-630A elastic epoxy resin, 15g of mixed solvent (xylene: n-butanol: cyclohexanone = 1:1:1), 0.05g of BYK-4511, 0.3g of BYK-306 and mix Together, disperse and stir evenly, then add 20g of zinc powder and 0.3g of EFKA-2035 for re-dispersion and stirring, after dispersing and stirring evenly, put them together in a sand mill for grinding until the fineness reaches 80μm, when the viscosity reaches 80 ~ After 110 seconds, the primer group A was prepared for use. Before spraying, 0.82 parts by weight of GF-630B was put into the primer group A of 10.0 parts by weight and fully dispersed and stirred to obtain the primer, that is, the Primer A group: said primer B group=10g:0.82g.

[0081] Weigh 35g of PUASTOMER-2804 ultra-linear elastic resin, 33.0g of shielding and anti-seepage material (the ratio of mica iron oxide: glass flakes: mica powder in the 33.0g parts by weight = 2:1:1), 18g of Mix the solvent (xylene: butyl acetate: PMA=1:1:1) and disperse and stir...

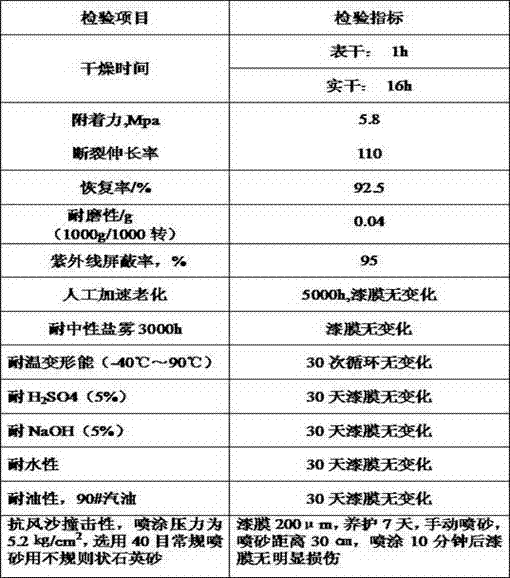

Embodiment 3

[0086] Weigh 40.0g of GF-630A elastic epoxy resin, 20g of mixed solvent (xylene: n-butanol: cyclohexanone = 1:1:1), 0.1g of BYK-4511, 0.5g of BYK-306 and mix Together, disperse and stir evenly, then add 25g of zinc powder and 0.7g of EFKA-2035 for re-dispersion and stirring, after dispersing and stirring evenly, put them together in a sand mill for grinding until the fineness reaches 80μm, when the viscosity reaches 80 ~ After 110 seconds, the primer group A was prepared for use. Before spraying, 0.81 parts by weight of GF-630B was put into 10.0 parts by weight of the primer group A and fully dispersed and stirred evenly to obtain the primer, that is, the Primer A group: said primer B group=10g:0.81g.

[0087] Weigh 40g of PUASTOMER-2804 ultra-linear elastic resin, 35.0g of shielding and anti-seepage material (the ratio of mica iron oxide: glass flakes: mica powder in the 35.0g parts by weight = 2:1:1), 20g of The mixed solvent (xylene: butyl acetate: PMA=1:1:1) is mixed toge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com