Polynary composite water treatment agent

A water treatment agent, multi-component compound technology, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc., can solve the problem of low dosage, no chemical synergy, and no effective comprehensive Scale and corrosion inhibition and stability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

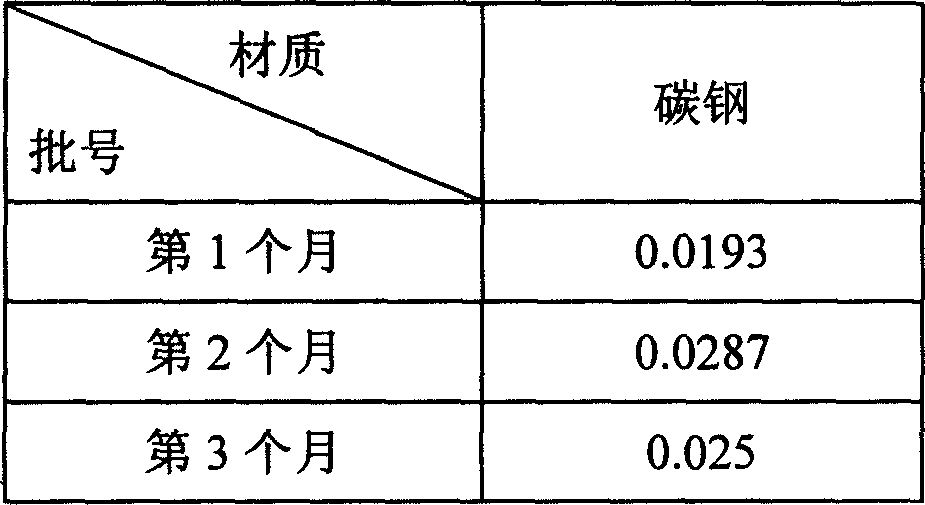

[0009] The types and amounts of the terpolymer containing sulfonic acid groups, organic phosphoric acid, zinc salt, and metal corrosion inhibitor were changed to carry out Examples 1-7, and the raw material ratio and test results are shown in Table 2.

[0010] Table 2 Raw material ratio and test results

[0011] serial number

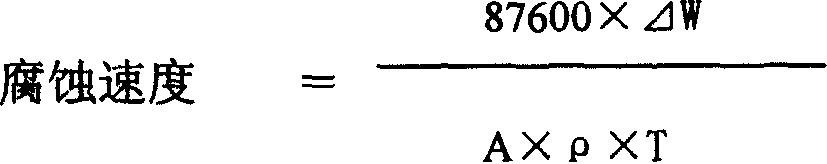

corrosion rate

mm / a

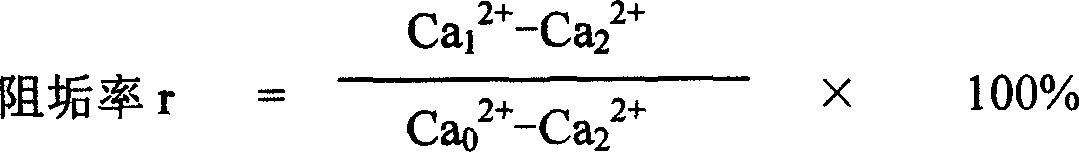

Scale inhibition rate

%

Pharmacy ratio

Example 1

0.040

80.6

AA / AMPS / HPA:HEDP:Zn 2+ =20:6:1

Example 2

0.019

87.20

AA / AMPS / HPA:HEDP:Zn 2+ =30:5:1

Example 3

0.040

81.60

AA / AMPS / HPA:PBTCA:Zn 2+ =20:10:1

Example 4

0.040

80.36

AA / AMPS / AM:HEDP:Zn 2+ =20:8:1

Example 5

0.037

80.23

AA / AMPS / AMPP:HEDP:Zn 2+ =20:5:1

Example 6

0.023

91.80

AA / AMPS / HPA:HEDP:BTA:Zn 2+ =30:5:1:1

Example 7

0.030

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com