High-concentration carbon hole solution for PCB and preparation method thereof

A PCB board, high-concentration technology, applied in the direction of electrical connection formation of printed components, etc., can solve problems such as pollution, resource waste environment, troublesome use process, etc., and achieve the effects of avoiding settlement, strong conductivity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

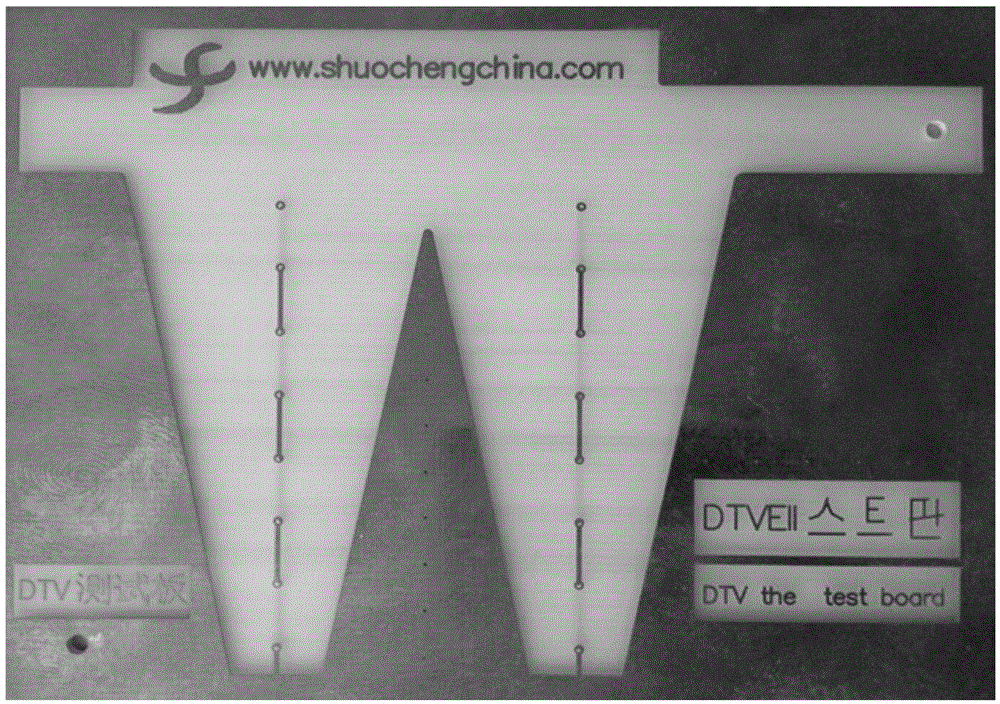

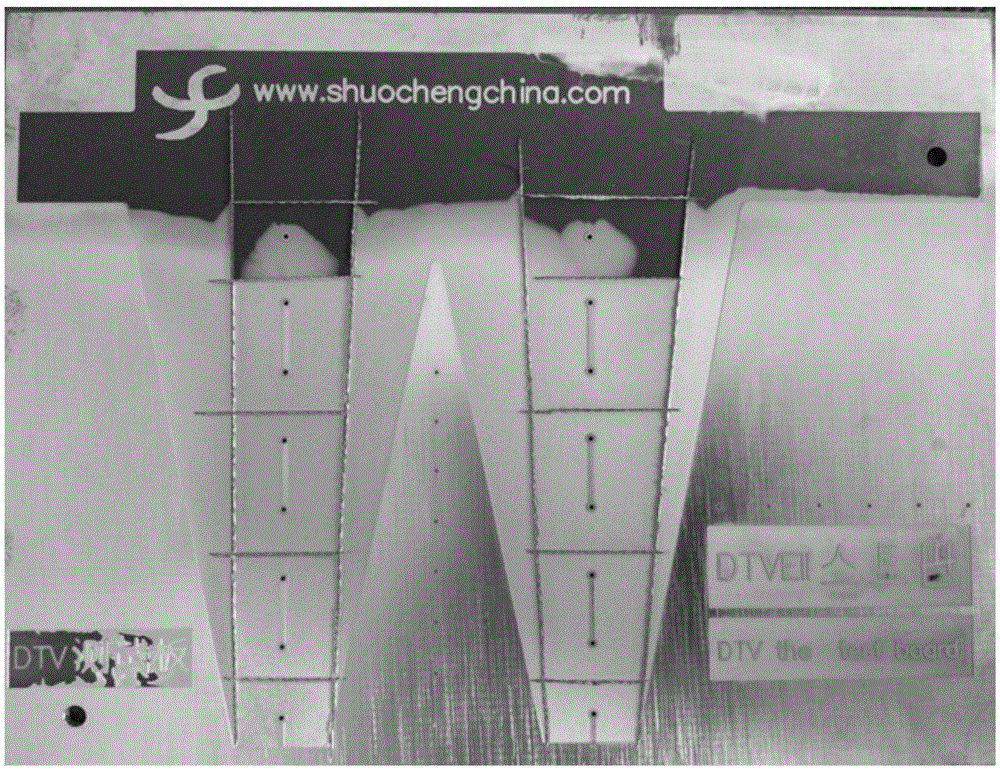

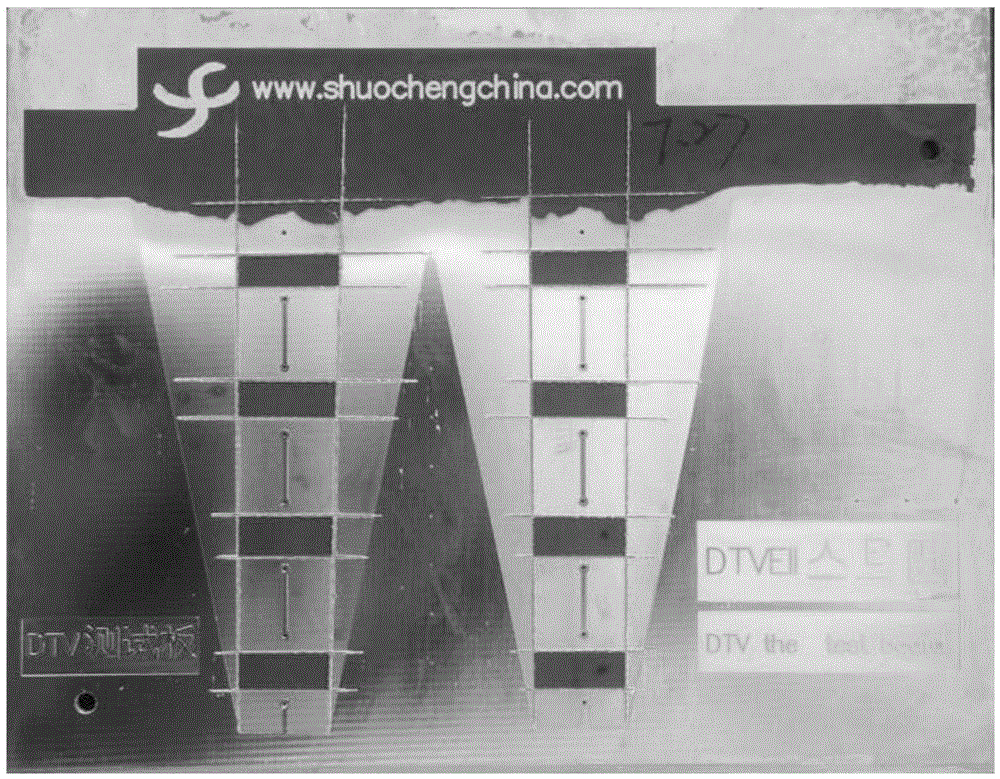

Image

Examples

Embodiment 1

[0028] The high-concentration carbon pore liquid used in the PCB board of the present embodiment 1 is calculated based on the weight percentage of the high-concentration carbon pore liquid used in the final PCB board, and its proportioning ratio is:

[0029] Conductive carbon material: CabotXC-72 is 9%;

[0030] Surfactant: alkyl polyoxyethylene ether sulfate is 4%;

[0031] Organic dispersant: sodium cellulose sulfonate is 6%;

[0032] Wetting agent: PEG600 is 1.6%;

[0033] pH regulator: sodium carbonate-sodium bicarbonate;

[0034] water balance.

[0035] The steps of the high-concentration carbon pore liquid preparation method for the PCB board of Preparation Example 1 are as follows:

[0036] 1) Prepare material A and material B,

[0037] Preparation of material A: disperse the amount of conductive carbon material in the amount of wetting agent solution, and soak for 12 hours to obtain the material A;

[0038] Preparation of material B: adding a pH regulator to the ...

Embodiment 2

[0044] The high-concentration carbon pore liquid used in the PCB board of the present embodiment 2 is calculated based on the weight percentage of the high-concentration carbon pore liquid used in the final PCB board, and its proportioning is:

[0045] Conductive carbon material: F900A superconductive carbon black is 7%;

[0046] Surfactant: sodium alkyl polyoxyethylene ether sulfate is 8%;

[0047] Organic dispersant: sodium succinate sulfonate is 4%;

[0048] Wetting agent: polyether is 2%;

[0049] pH regulator: sodium carbonate-sodium bicarbonate;

[0050] water balance.

[0051] The steps of the high-concentration carbon pore liquid preparation method for the PCB board of preparation embodiment two are as follows:

[0052] 1) Prepare material A and material B,

[0053] Preparation of material A: disperse the amount of conductive carbon material in the amount of wetting agent solution, and soak for 12 hours to obtain the material A;

[0054] Preparation of material B...

Embodiment 3

[0060] The high-concentration carbon pore liquid used in the PCB board of the present embodiment 3 is calculated based on the weight percentage of the high-concentration carbon pore liquid used in the final PCB board, and its proportioning ratio is:

[0061] Conductive carbon material: F900A superconductive carbon black is 8%;

[0062] Surfactant: potassium alkyl polyoxyethylene ether sulfate is 7%;

[0063] Organic dispersant: sodium branched alkylbenzene sulfonate is 8%;

[0064] Wetting agent: JFC is 5%;

[0065] pH regulator: sodium carbonate-sodium bicarbonate;

[0066] water balance.

[0067] The steps of the high-concentration carbon pore liquid preparation method for the PCB board of preparation embodiment three are as follows:

[0068] 1) Prepare material A and material B,

[0069] Preparation of material A: disperse the amount of conductive carbon material in the amount of wetting agent solution, and soak for 12 hours to obtain the material A;

[0070] Preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com