Flame-retardance formaldehyde-free industrial hemp straw fiberboard and manufacturing method thereof

A technology of industrial hemp and straw fiber, which is applied in the manufacture of tools, flat products, and other household appliances. It can solve the problems of inability to change the material density and flame-retardant grade, and cannot achieve bonding, so as to facilitate mechanized large-scale production and facilitate operation, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

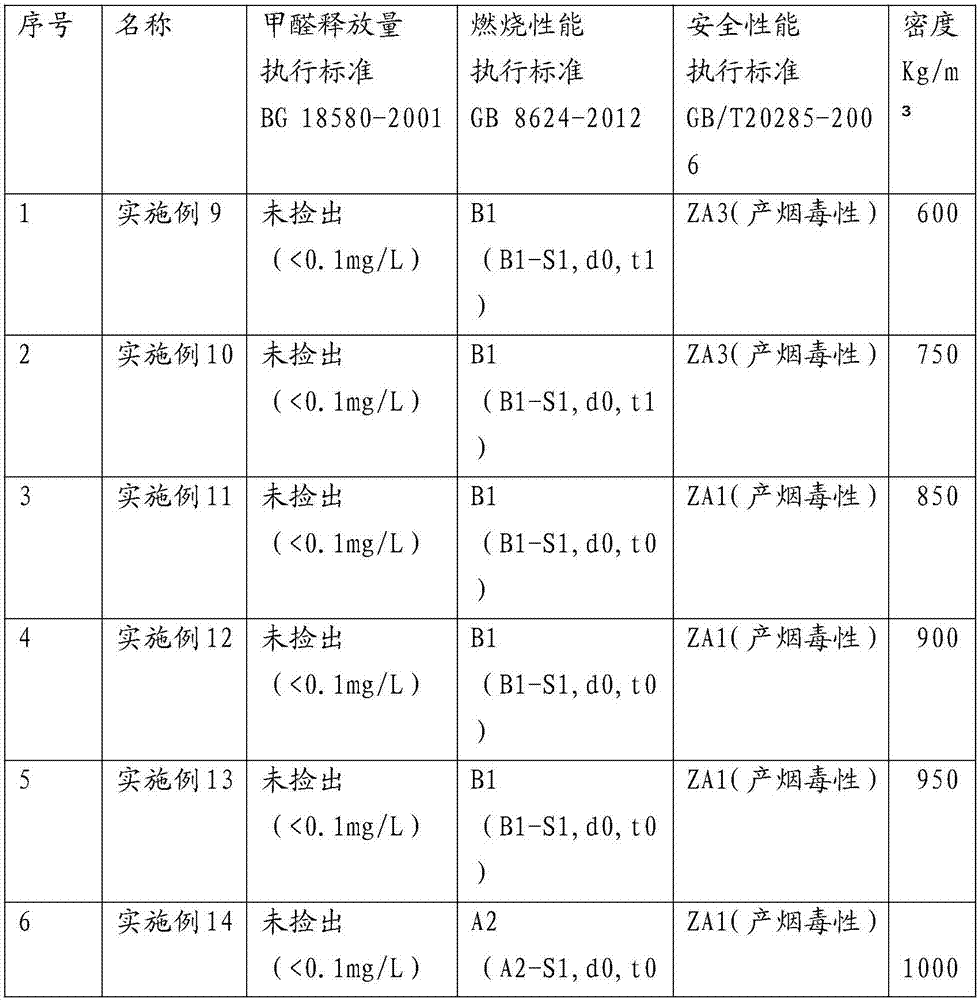

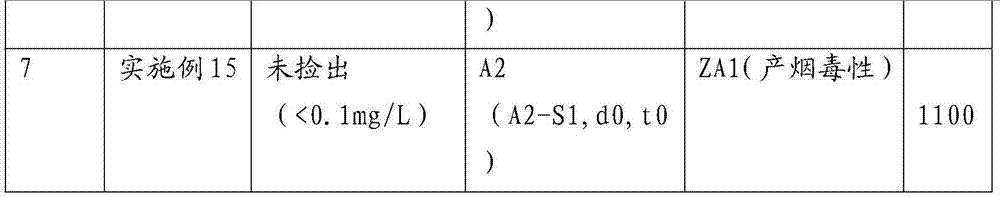

Examples

Embodiment 1

[0047] A flame-retardant formaldehyde-free industrial hemp straw fiberboard, raw materials include industrial hemp straw whole stalk core scraps and a flame-retardant adhesive accounting for 18% by weight of the scraps; the flame-retardant adhesive consists of A component, B component Composition with C component, each component raw material comprises by weight:

[0048] Component A: 16 parts of magnesium chloride, 3.4 parts of polyvinyl alcohol and 100 parts of water;

[0049] Component B: 20 parts of magnesium chloride, 80 parts of magnesium sulfate, 100 parts of water;

[0050] Component C: 7 parts of magnesium oxide.

Embodiment 2

[0052] A flame-retardant formaldehyde-free industrial hemp straw fiberboard, raw materials include industrial hemp straw whole stalk core scraps and a flame-retardant adhesive accounting for 48% by weight of the scraps; the flame-retardant adhesive consists of A component, B component Composition with C component, each component raw material comprises by weight:

[0053] Component A: 14 parts of magnesium chloride, 2.4 parts of polyvinyl alcohol and 100 parts of water;

[0054] Component B: 12 parts of magnesium chloride, 50 parts of magnesium sulfate, 100 parts of water;

[0055] Component C: 5 parts of magnesium oxide.

[0056] The whole stalk core scrap of industrial hemp straw is divided into granular material and fibrous scrap. The industrial hemp straw fiber board has a three-layer structure, which is sequentially a granular material layer, a fibrous scrap layer and a granular material layer.

Embodiment 3

[0058] A flame-retardant formaldehyde-free industrial hemp straw fiberboard, raw materials include industrial hemp straw whole stalk core scraps and a flame-retardant adhesive accounting for 20% by weight of the scraps; the flame-retardant adhesive consists of A component, B component Composition with C component, each component raw material comprises by weight:

[0059] Component A: 15 parts of magnesium chloride, 3 parts of polyvinyl alcohol and 100 parts of water;

[0060] Component B: 15 parts of magnesium chloride, 60 parts of magnesium sulfate, 100 parts of water;

[0061] Component C: 6 parts of magnesium oxide.

[0062] The whole stalk core scrap of industrial hemp straw is divided into granular material and fibrous scrap. The industrial hemp straw fiber board has a three-layer structure, which is sequentially a granular material layer, a fibrous scrap layer and a granular material layer.

[0063] The granular material accounts for 30% of the weight ratio of the crus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com