Smoke producing agent capable of being massively applied and preparing and igniting method

A smoke generator, a large-scale technology, applied in the direction of combustion methods, smoke/mist generation, manufacturing tools, etc., can solve the problems of high hazards, low ignition efficiency, and failure to light smoke pots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] When natural vibration is adopted, and the layout, position, quantity and size of the openings on the smoke pot are the same, when the fuse is used to ignite, the average ignition time is shown in Table 2.

[0018]

[0019] At room temperature, the average ignition time of each group has no significant change, and the misfire rate of the ignition index is 5-10%, but as the temperature drops, the misfire rate increases significantly, especially in winter when the ignition effect is lost at -20°C.

Embodiment 2

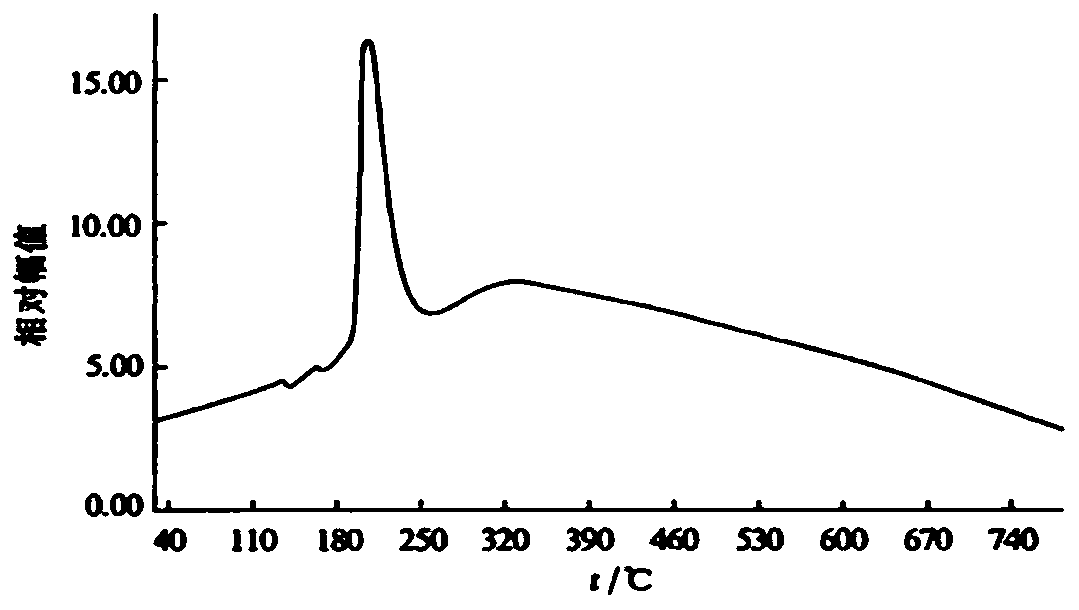

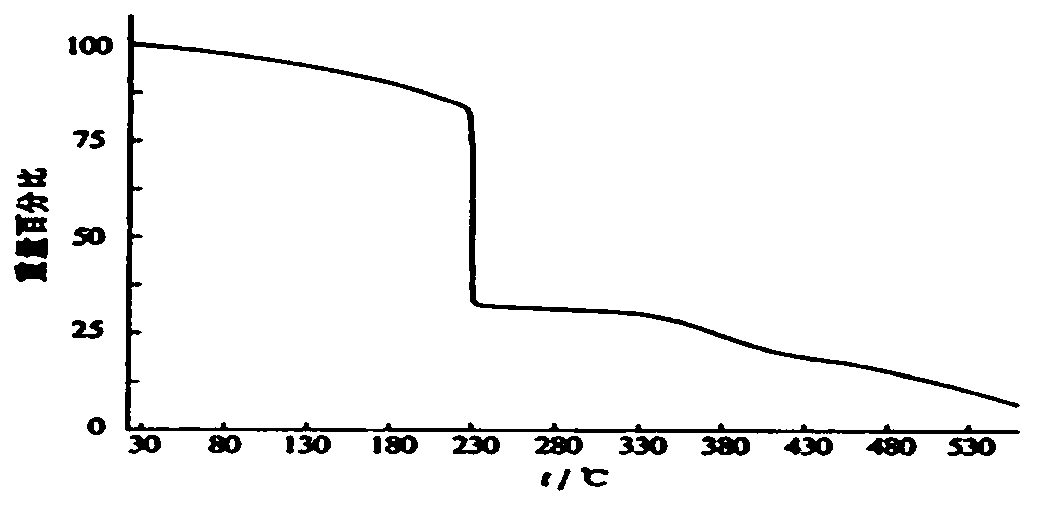

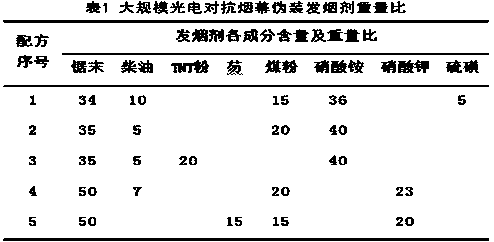

[0021] Under the same temperature conditions, the ignition conditions of each group of formulations were comparable. Consider that the formulations of each group differ only in substances with higher flash points. The ignition point of the fuming agent mainly depends on flammable substances such as sawdust with a lower ignition point. Therefore, the theoretical analysis is the same as the actual observation. Therefore, a formula is randomly selected for differential thermal test and thermogravimetric test. see attached results figure 1 , attached figure 2 .

[0022] The results of physical and chemical testing instrument analysis are consistent. It shows that the ignition point of each formulation is stable at a value, and the smoking agent is basically kept in the same temperature range during the smoking process. This provides a basis for the study of new electric igniters. In addition, the maximum smoke rate can be judged from the heat loss diagram of the smoker V'...

Embodiment 3

[0024] The invention also provides an electric igniter used for the long-distance and large-scale rapid smoking of the smoking pot. Because it involves flammable and explosive dangerous goods and pyrotechnics, the invention finally succeeded after going through hardships and a lot of experiments and explorations. Its preparation method is to coat a layer of acrylic glue on the ignition rod produced by Heilongjiang Jianhua Machinery Factory, and then connect it with an electric ignition head through a plastic pipe. The electric igniter is characterized by rain and water resistance, high ignition capacity and long time, short ignition time and stable and reliable effect. The actual test results are shown in Table 3.

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com