A kind of method for graphene sponge barrier layer to enhance anti-reduction performance of brazed joint

A graphene sponge and brazing joint technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as restoration failure, and achieve the effect of prolonging service life, simple and effective operation, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

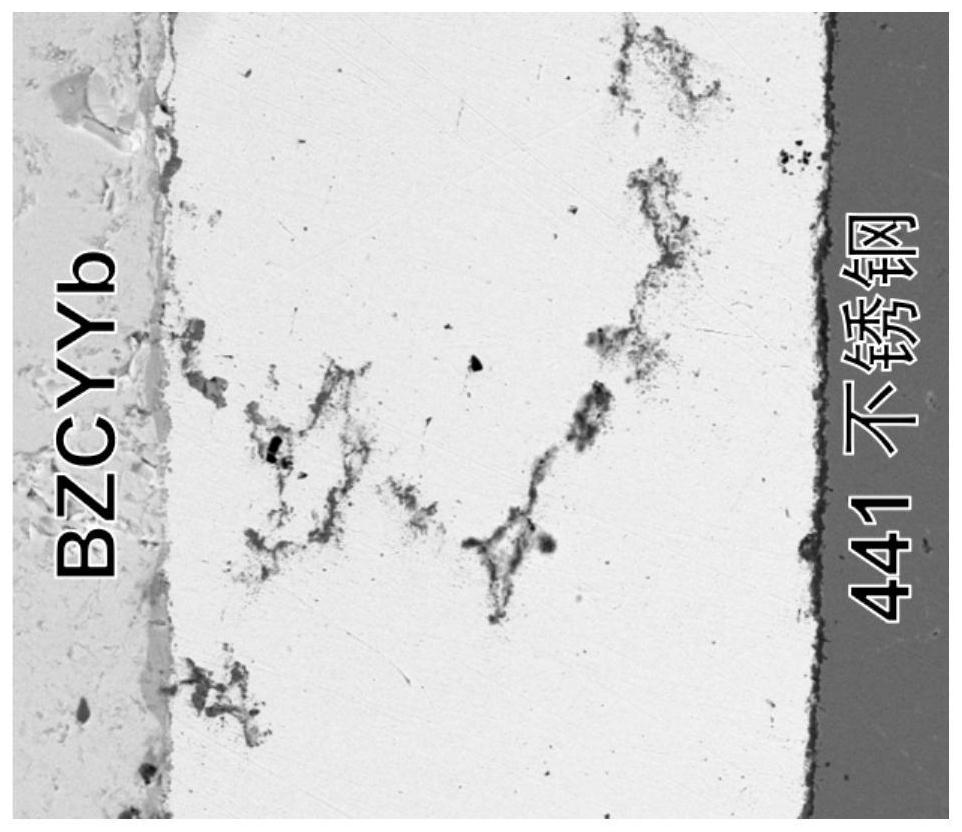

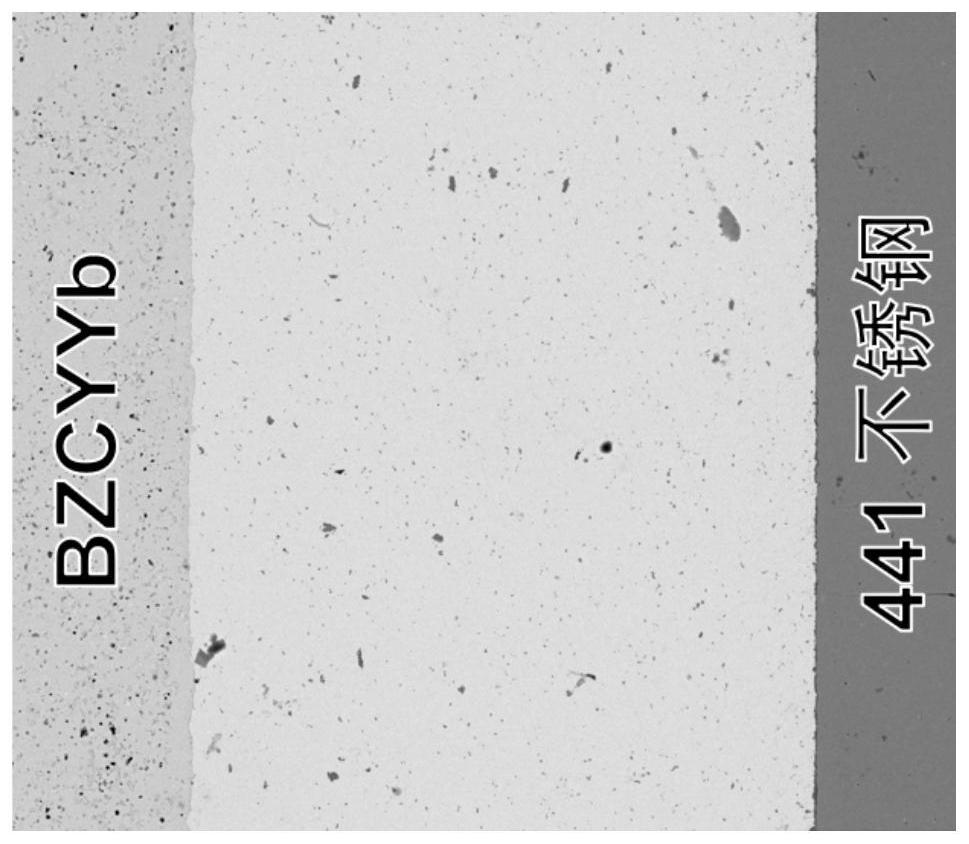

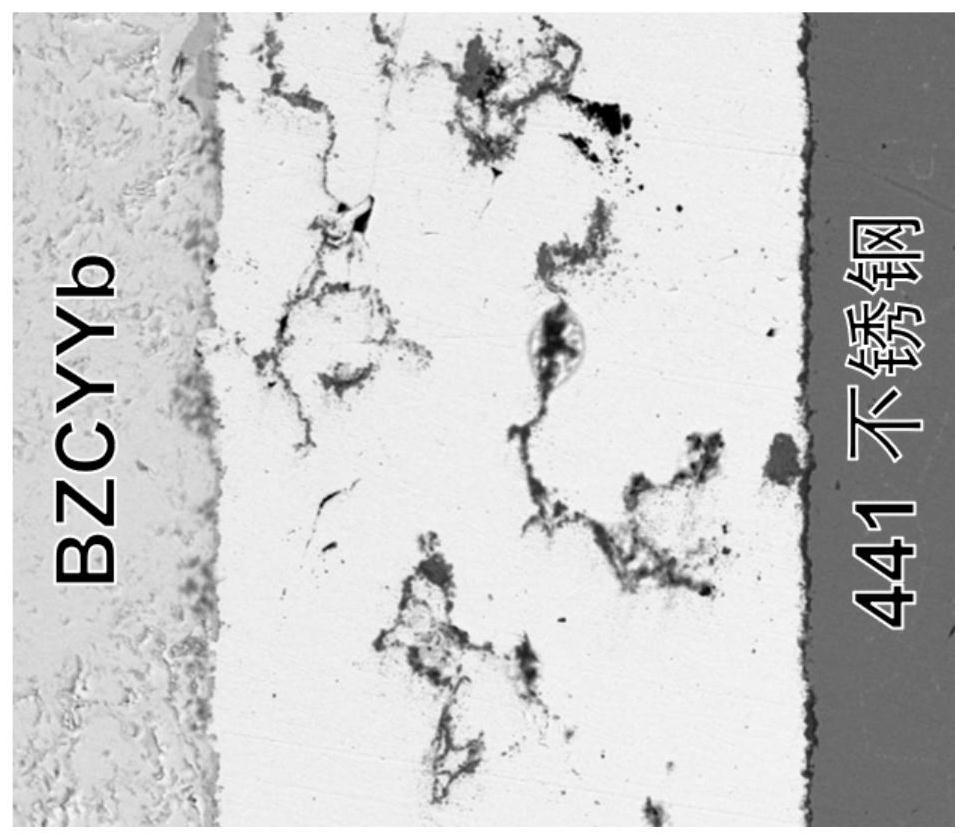

Image

Examples

specific Embodiment approach 1

[0018] Embodiment 1: The method for enhancing the anti-reduction performance of the brazed joint by the graphene sponge barrier layer of the present embodiment is specifically implemented according to the following steps:

[0019] 1. Cut the graphene sponge into thin slices along the direction parallel to the cross section to obtain the graphene sponge barrier layer;

[0020] 2. Configure the noble metal-oxide solder with an oxide mole fraction of 0.1-20 mol.%, and then press the solder into a solder sheet;

[0021] 3. Grind the to-be-welded surfaces of the metals to be welded and the ceramics to be welded respectively, and then put the metals to be welded and the ceramics to be welded into anhydrous ethanol for ultrasonic cleaning to obtain the cleaned ceramics to be welded and the metals to be welded;

[0022] Fourth, stack the cleaned metal to be welded, the first brazing filler metal sheet, the graphene sponge barrier layer, the second brazing filler metal sheet and the cl...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thickness of the graphene sponge barrier layer described in Step 1 is 0.2-8 mm.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the precious metal-oxide solder described in step 2 is Ag-CuO system solder, Ag-V 2 O 5 System solder, Ag-Nb 2 O 5 System solder, Ag-SiO 2 System solder, Ag-TeO 2 System solder, Pt-CuO system solder or Pt-Nb 2 O 5 System solder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com