Novel tire shoulder separation-preventing agent and preparation method and application thereof

A kind of anti-shoulder anti-air agent, a new technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of high cost, affecting the mechanical properties of composite materials, limited rare earth sources, etc., to achieve low production cost, excellent Thermal conductivity, effect of improving tear resistance and flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

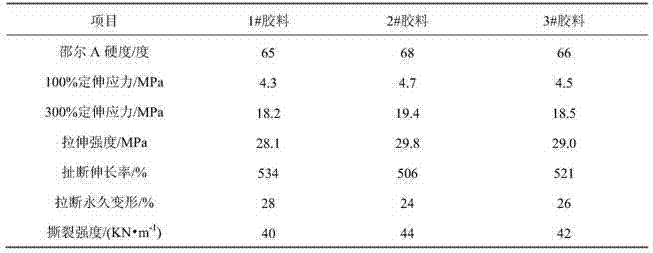

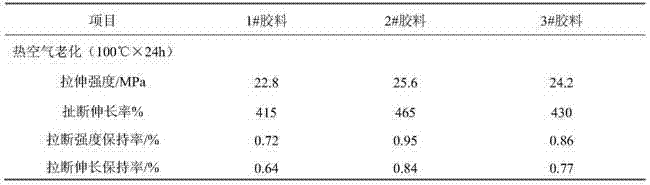

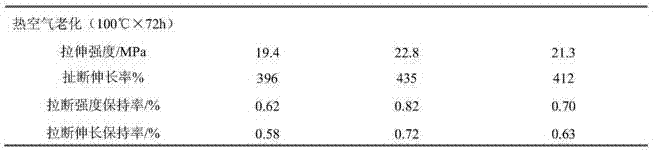

Examples

Embodiment 1

[0059] Take raw material by weighing as follows, prepare 100 grams of anti-shoulder anti-shoulder agent of the present invention

[0060] 2-Mercaptobenzimidazole Zinc 30g

[0061] Terpene phenolic resin 15g

[0062] Nano Highly Active Alumina 55g

[0063] The preparation steps are as follows:

[0064] Mix 2-mercaptobenzimidazole zinc, terpene phenolic resin and nanometer highly active alumina in a twin-screw belt mixer, and then send them to a twin-screw extrusion granulator for extrusion granulation to obtain tires Use new anti-shoulder air agent products.

Embodiment 2

[0066] Take raw material by weighing as follows, prepare 100 grams of anti-shoulder anti-shoulder agent of the present invention

[0067] 2-Mercaptobenzimidazole Zinc 35g

[0068] Terpene phenolic resin 15g

[0069] Nano Highly Active Alumina 50g

[0070] The preparation method is the same as in Example 1.

Embodiment 3

[0072] Take raw material by weighing as follows, prepare 100 grams of anti-shoulder anti-shoulder agent of the present invention

[0073] 2-Mercaptobenzimidazole Zinc 30g

[0074] Terpene phenolic resin 20g

[0075] Nano Highly Active Alumina 50g

[0076] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com