Dielectric ceramic composition and monolithic ceramic capacitor

A dielectric and composition technology, applied in the field of laminated ceramic capacitors, can solve the problems of low relative permittivity and inappropriateness, and achieve the effect of increasing the resistivity and increasing the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

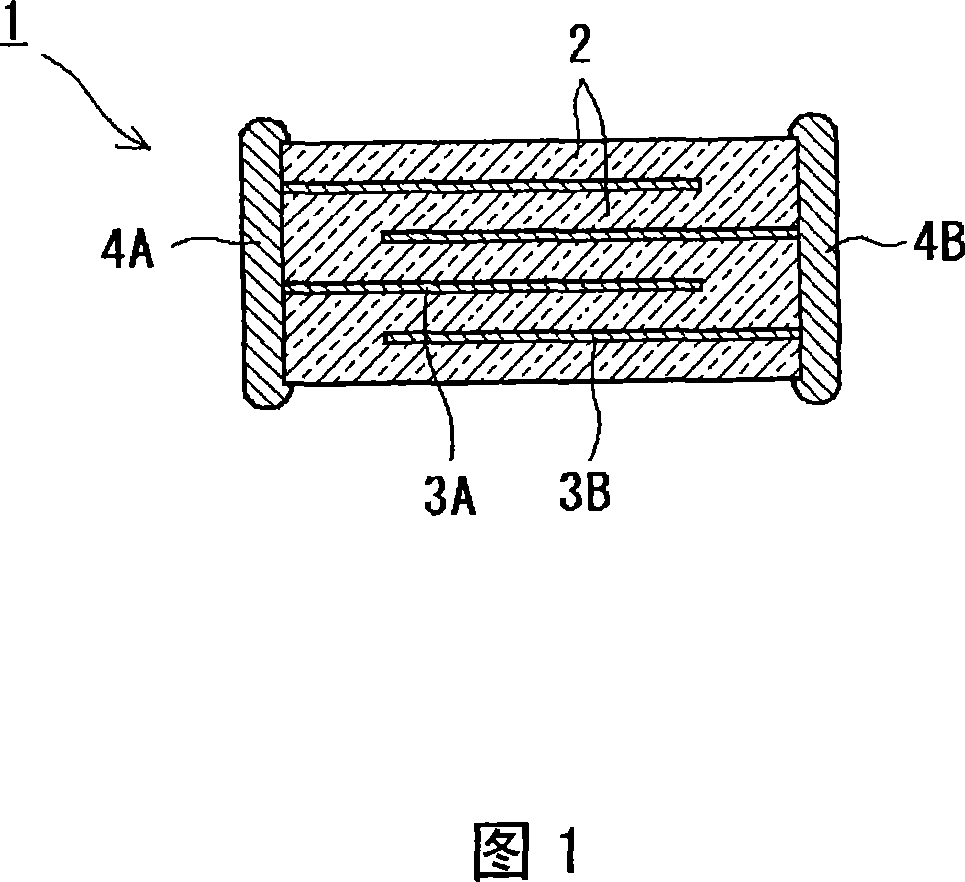

Image

Examples

Embodiment 1

[0031] In this example, relative to the main component KSr 2 Nb 5 o 15 Mn was added, and the influence of the Mn content was investigated. That is, the dielectric ceramic compositions shown in Table 1 were prepared according to the following procedures (1) and (2), and multilayer ceramic capacitors of Sample Nos. 1 to 23 were fabricated using these dielectric ceramic compositions according to the following procedures. Next, the electrical characteristics of these multilayer ceramic capacitors were evaluated, and Table 1 shows the evaluation results. In addition, in Table 1, the samples marked with * are substances outside the scope of the present invention.

[0032] (1) Modulation of dielectric ceramic raw materials

[0033] Preparation of pre-synthesized tungsten bronze type composite oxide KSr as the main component 2 Nb 5 o 15 Powder, in addition, prepared MnCO as the raw material of the subcomponent added to the main component 3 、Cr 2 o 3 、CoCO 3 , Fe 2 o 3 , N...

Embodiment 2

[0045] In this embodiment, the basic composition of the main component is KSr 2 Nb 5 o 15 The dielectric ceramic composition KSr whose Nb site is replaced by subcomponent A such as Mn shown in Table 2 2 (Nb 5-x A x )O 15 , in the same manner as in Example 1, a multilayer ceramic capacitor was produced, and the same evaluation as in Example 1 was performed to investigate the influence of the substitution amount x of the subcomponent A in the main component of Example 1. In addition, in Table 2, the samples marked with * are substances outside the scope of the present invention.

[0046] (1) Modulation of dielectric ceramic raw materials

[0047] In this example, the basic composition KSr as the main component 2 Nb 5 o 15 raw material, prepared K 2 CO 3 , Nb 2 o 5 , SrCO 3 For each powder, MnCO, which is the raw material of subcomponent A for substituting a part of Nb in the basic composition, was prepared separately. 3 、Cr 2 o 3 、CoCO 3 , Fe 2 o 3 , NiO, ZnO...

Embodiment 3

[0059] In the present embodiment, adopt the basic composition of main component as shown in table 3 to be KSr 2 Nb 5 o 15 Dielectric ceramic composition (K 1-y Na y )Sr 2 (Nb 5-x A x )O 15 , A laminated ceramic capacitor was produced in the same manner as in Example 2, and the same evaluation as in Example 2 was performed to investigate the influence of the substitution amount y of Na at the K site in the main component of Example 2. In addition, in Table 3, the samples marked with * are substances outside the scope of the present invention.

[0060] (1) Modulation of dielectric ceramic raw materials

[0061] In this example, the basic composition KSr as the main component 2 Nb 5 o 15 The original raw materials were prepared separately for K 2 CO 3 , Nb 2 o 5 , SrCO 3 Each of the powders, Na as the raw material of the subcomponent Na for substituting a part of K of the basic composition 2 CO 3 powder, and MnCO as the raw material of subcomponent Mn for substi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com