Niobium and manganese modified tin oxide-coated lithium nickel cobalt manganate positive electrode material and preparation method thereof

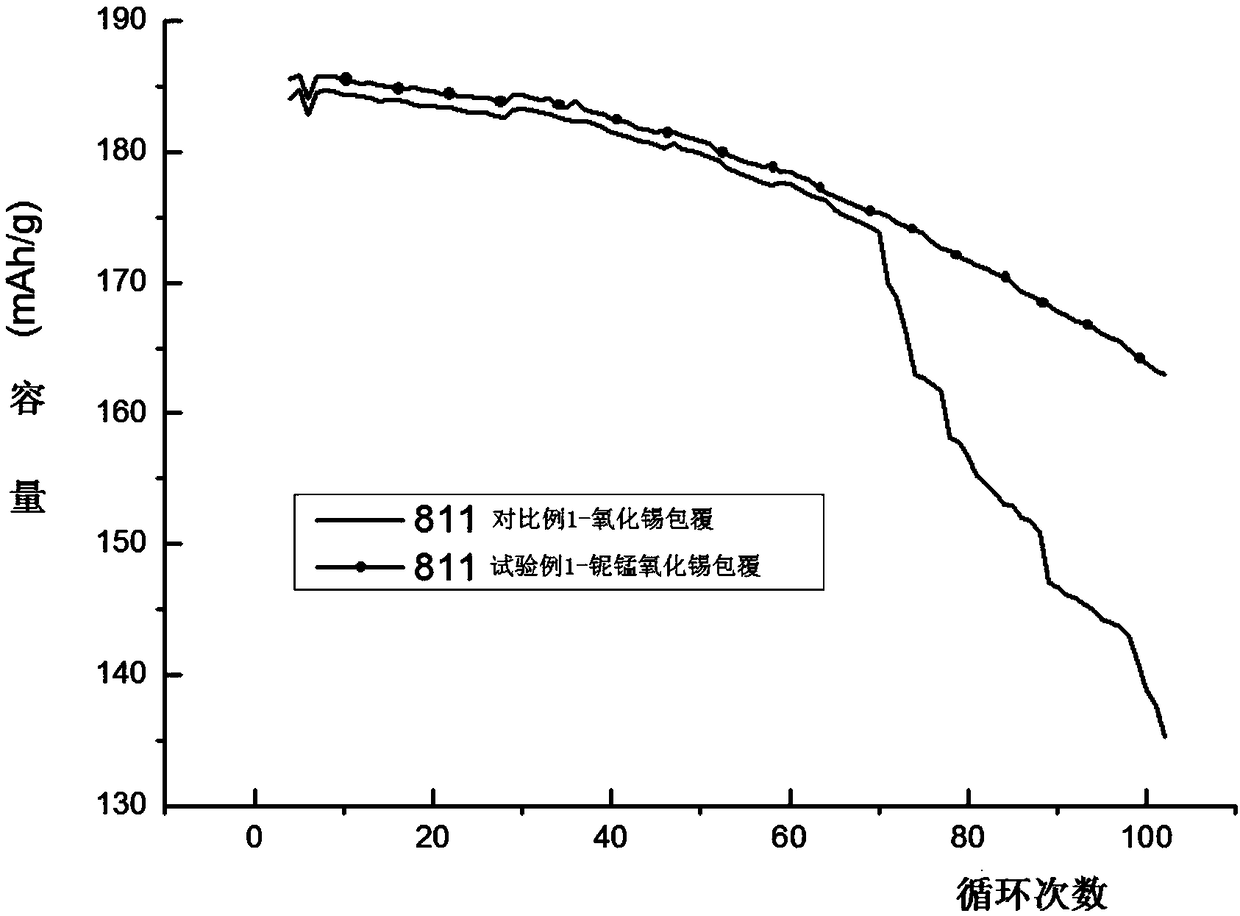

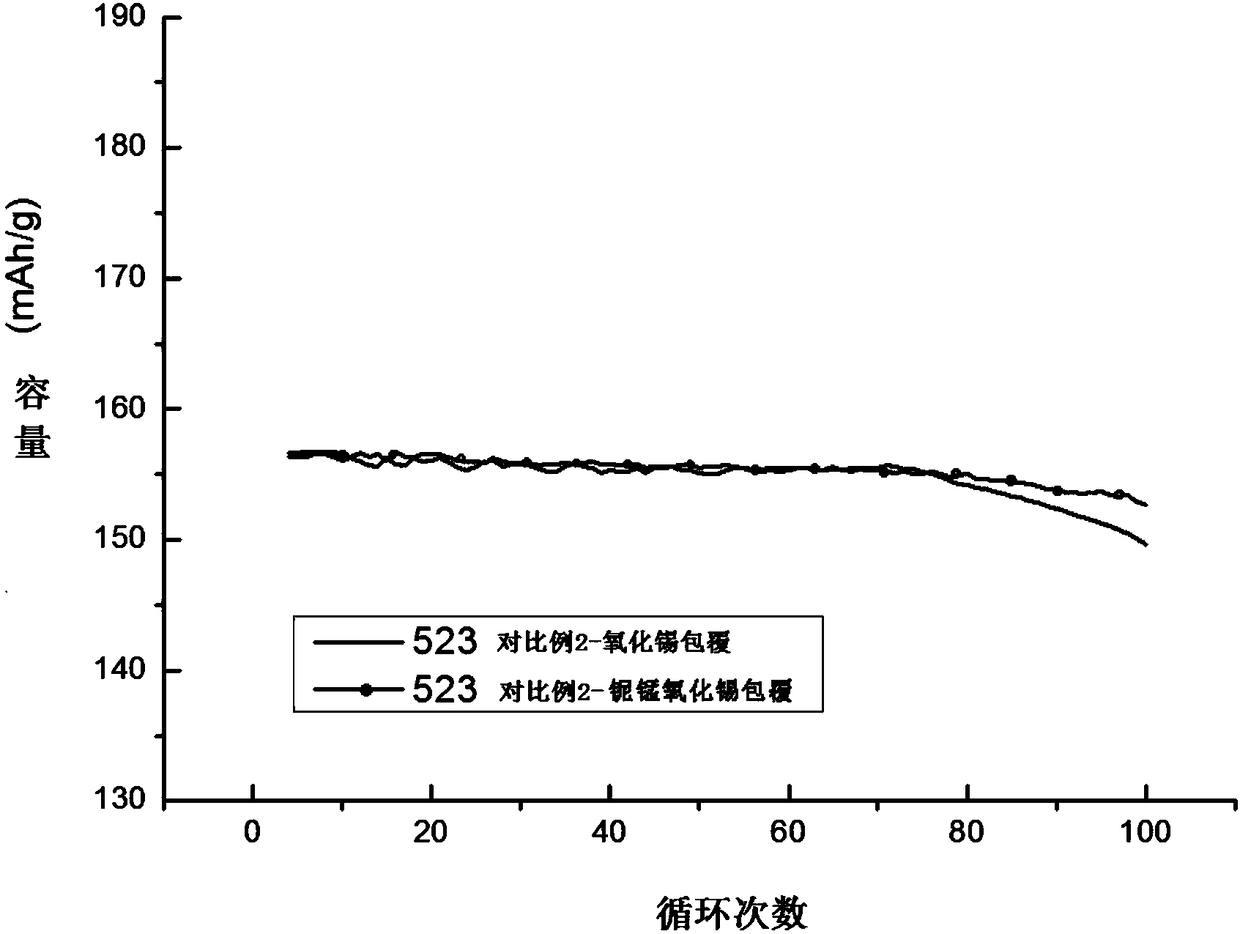

A technology of nickel-cobalt lithium manganate and cathode material, which is applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of poor cycle performance of nickel-cobalt lithium manganate batteries, and reduce electron residues and internal resistance. , the effect of slowing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the nickel cobalt lithium manganese oxide cathode material coated with niobium manganese modified tin oxide provided by the invention comprises the following steps:

[0018] Step S1, weighing tin oxide and niobium manganese oxide, mixing them and treating them at low temperature to obtain a niobium manganese tin oxide mixture.

[0019] Among the oxides of tin oxide and niobium manganese weighed in this step, the molar ratio of tin niobium manganese Sn:Nb:Mn=1:(0.1~0.3):(0.2~0.5), the range of low temperature treatment is 200-500°C . The tin oxide is tin monoxide or tin dioxide. The niobium-manganese oxide is a general term for various valence state oxides of niobium and manganese elements, and there are many choices, such as niobium oxide, niobium dioxide, niobium trioxide, and niobium pentoxide etc. Manganese oxide may be manganese monoxide, manganese dioxide, or the like.

[0020] Step S2, weighing the nickel-cobalt-manganese ternary mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com