GdSrMnCo codoped bismuth ferrite multiferroic film and making method thereof

A multi-ferrous thin film, bismuth ferrite technology, applied in the coating and other directions, to achieve the effect of suppressing valence fluctuations, good dielectric and ferroelectric properties, and suppressing the volatilization of Bi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Clean the FTO / glass substrate with detergent, acetone, and absolute ethanol respectively and seal it in absolute ethanol for later use;

[0031] Step 2: Taking bismuth nitrate, gadolinium nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.99:0.03:0.03:0.94:0.04:0.02 (x=0.03 ) is dissolved in ethylene glycol methyl ether, stirs 30min, then adds acetic anhydride, stirs 90min, obtains the stable precursor solution that the total concentration of metal ions is 0.2mol / L; Wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3.2:1;

[0032] Step 3: Wash the FTO / glass substrate with deionized water and use N 2 Blow dry, and then irradiate the clean FTO / glass substrate with an ultraviolet light irradiation instrument for 40 minutes, so that the surface of the FTO / glass substrate reaches atomic cleanliness, and then spin-coat the precursor solution o...

Embodiment 2

[0035] Step 1: Clean the FTO / glass substrate with detergent, acetone, and absolute ethanol respectively and seal it in absolute ethanol for later use;

[0036] Step 2: Taking bismuth nitrate, gadolinium nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.96:0.06:0.03:0.94:0.04:0.02 (x=0.06 ) is dissolved in ethylene glycol methyl ether, stirs 30min, then adds acetic anhydride, stirs 90min, obtains the stable precursor solution that metal ion total concentration is 0.25mol / L; Wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3.5:1;

[0037] Step 3: Wash the FTO / glass substrate with deionized water and use N 2 Blow dry, and then irradiate the clean FTO / glass substrate with an ultraviolet light irradiation instrument for 40 minutes, so that the surface of the FTO / glass substrate reaches atomic cleanliness, and then spin-coat the precursor solution on the...

Embodiment 3

[0040] Step 1: Clean the FTO / glass substrate with detergent, acetone, and absolute ethanol respectively and seal it in absolute ethanol for later use;

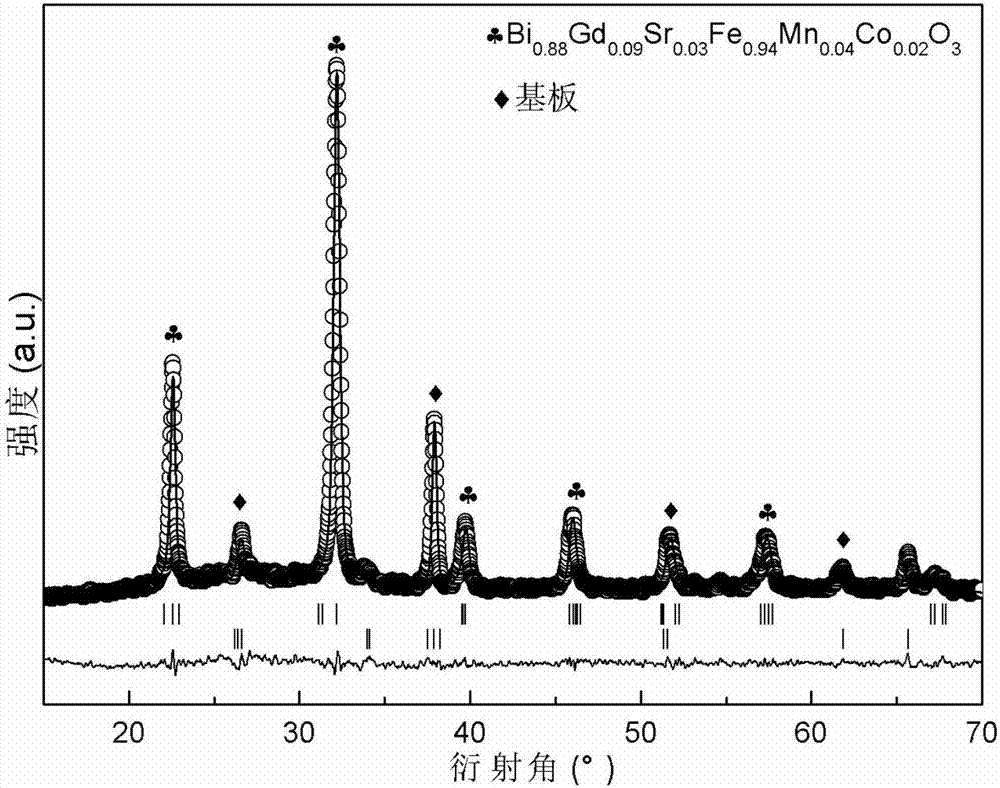

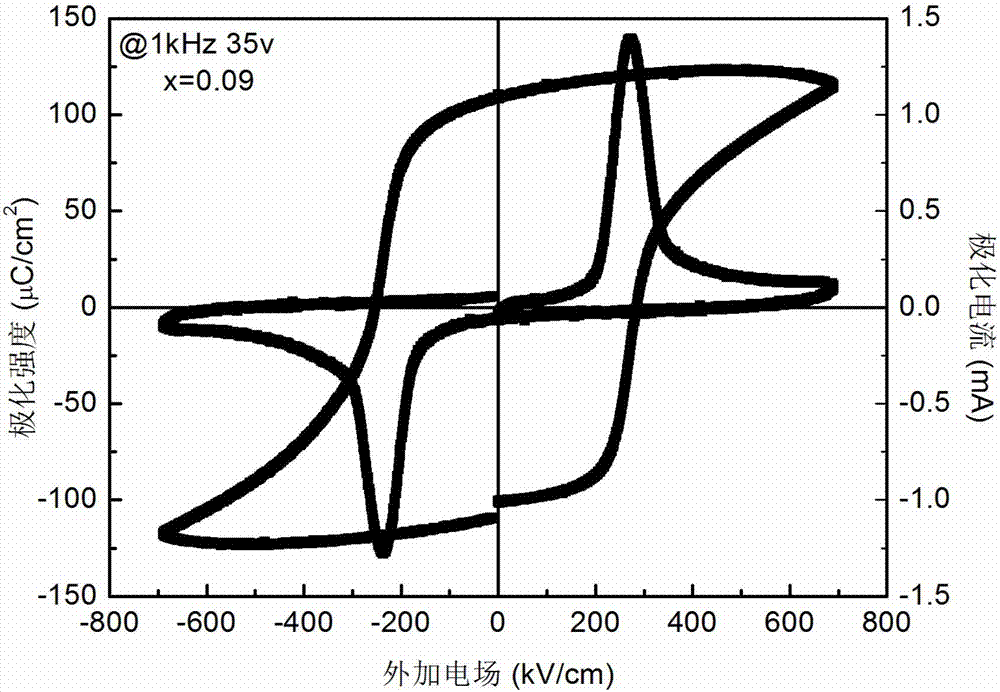

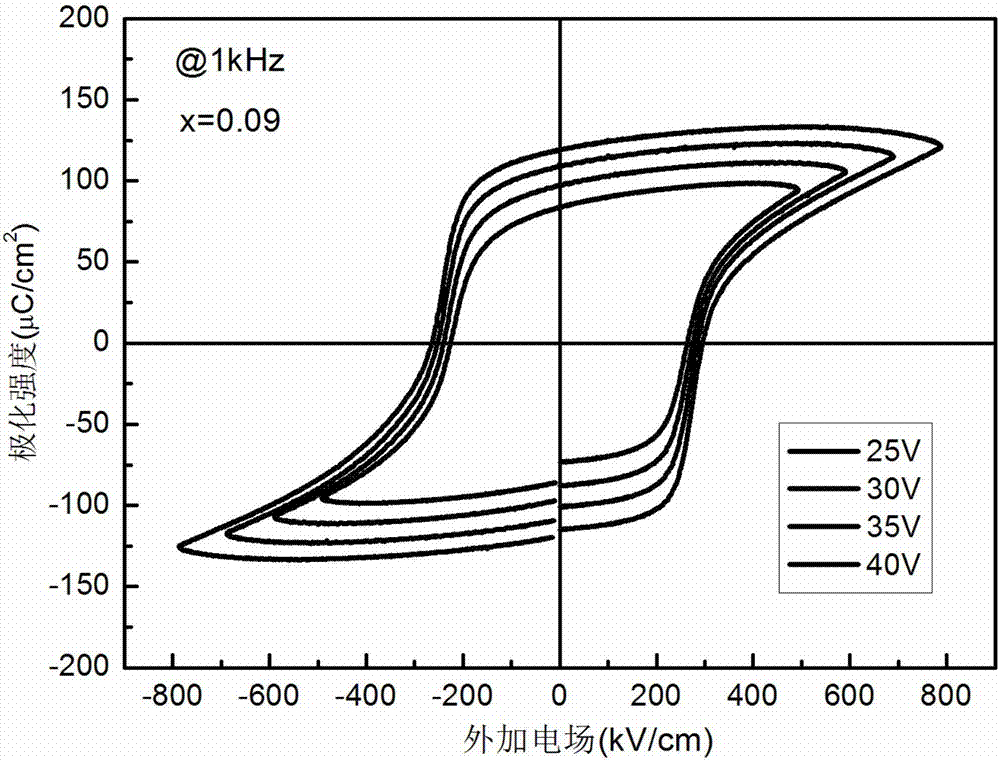

[0041] Step 2: Take bismuth nitrate, gadolinium nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate as raw materials (5% excess bismuth nitrate), the molar ratio is 0.93:0.09:0.03:0.94:0.04:0.02 (x=0.09 ) is dissolved in ethylene glycol methyl ether, stirs 30min, then adds acetic anhydride, stirs 90min, obtains the stable precursor solution that metal ion total concentration is 0.3mol / L; Wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0042] Step 3: Wash the FTO / glass substrate with deionized water and use N 2 Blow dry, and then irradiate the clean FTO / glass substrate with a UV irradiator for 40 minutes, so that the surface of the FTO / glass substrate reaches atomic cleanliness, and then spin-coat the precursor solution on the FTO / glass substrate, and the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com