High performance leadless piezoelectric ceramics and preparation technology

A lead-free piezoelectric, high-performance technology, applied in the field of piezoelectric ceramics, can solve problems such as lead toxicity and side effects, and achieve high-performance stability, high-voltage electrical performance, and high-dielectric effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing,

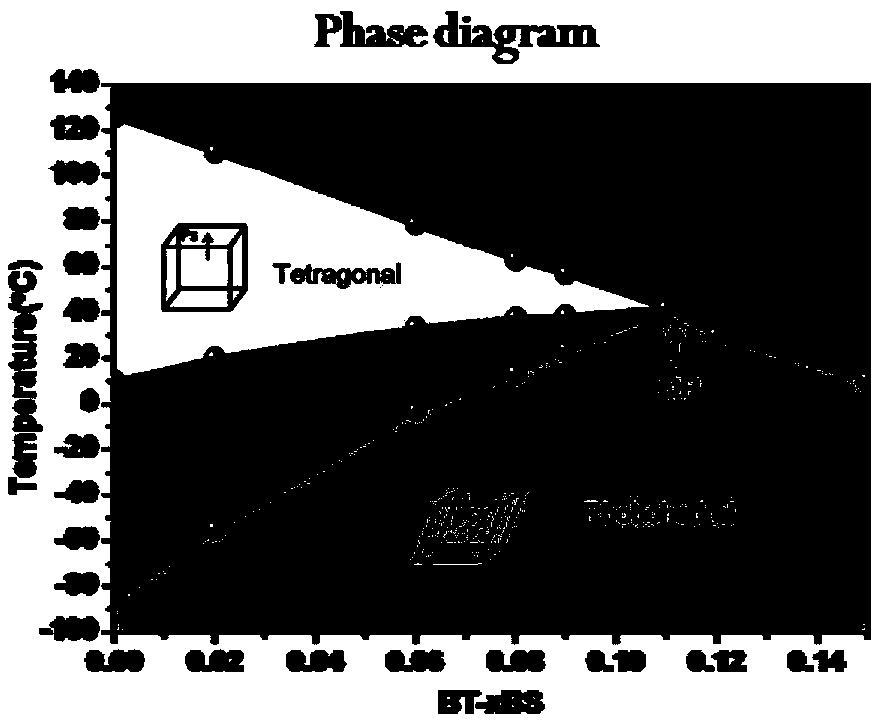

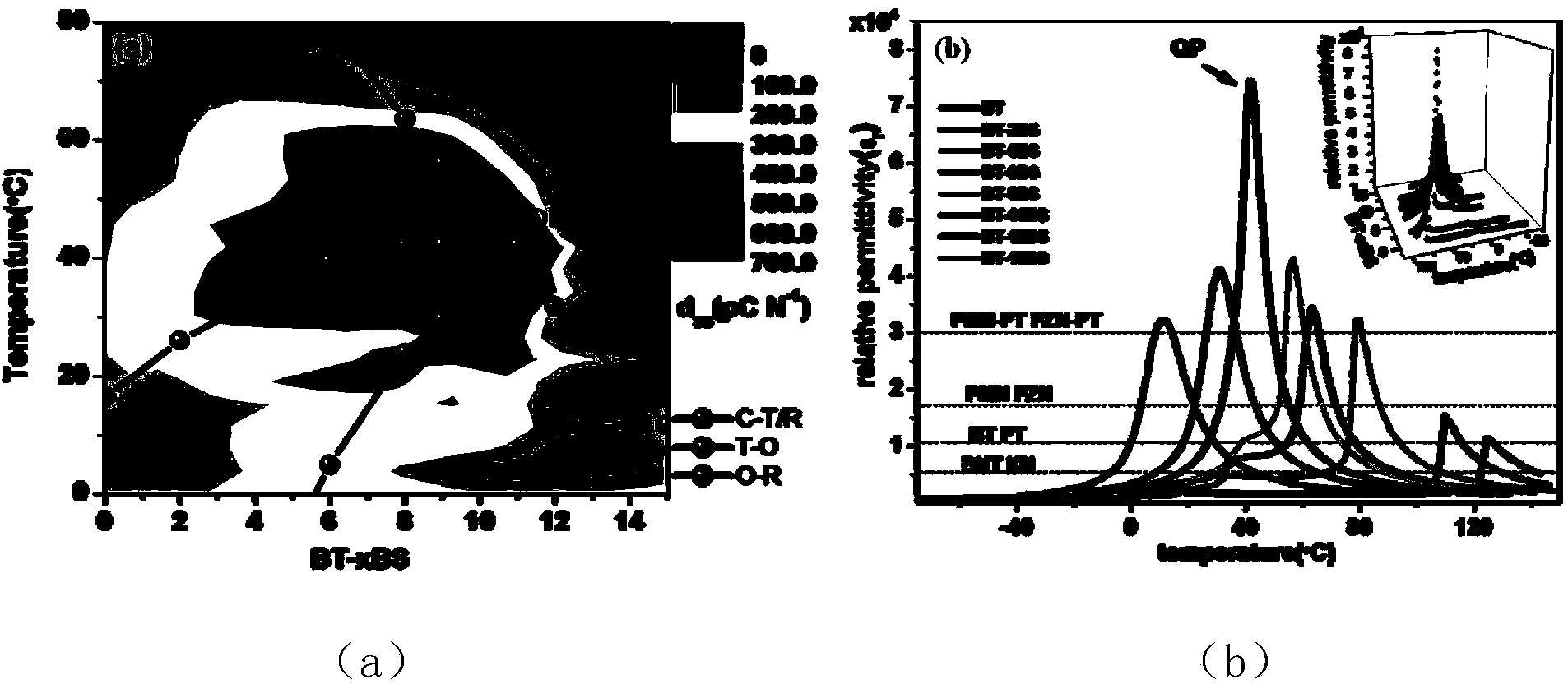

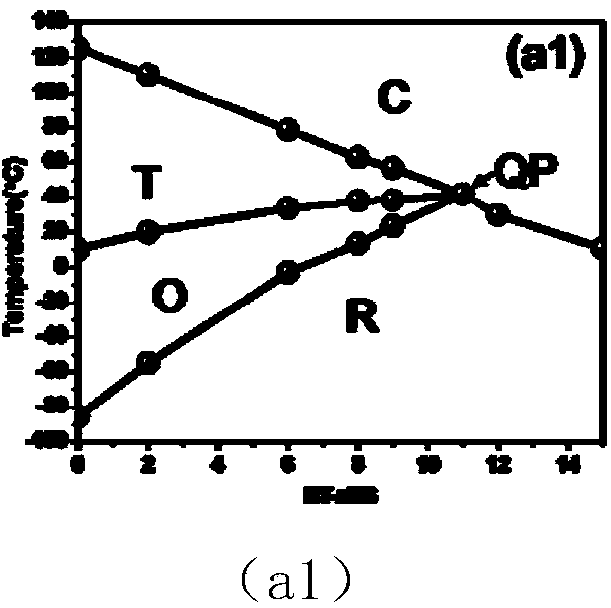

[0029] The present invention is a high-performance lead-free piezoelectric ceramic, barium titanate (0.89BaTiO) doped with barium stannate 3 -0.11BaSnO 3 ), and its raw material components are stoichiometrically:

[0030] Titanium dioxide: barium carbonate: tin dioxide=0.89:1:0.11

[0031] A preparation process of high-performance lead-free piezoelectric ceramics, comprising the following steps:

[0032] (1) Ingredients

[0033] The raw materials titanium dioxide, barium carbonate and tin dioxide are mixed according to the stoichiometric ratio (molar ratio) of 0.89:1:0.11;

[0034] (2) Ball milling

[0035] Put the raw materials weighed in step (1) into a ball milling tank. The ball milling medium is distilled water and zirconia balls. The mass ratio of raw materials, distilled water, and zirconia balls is 1:2:2. Ball mill for 4 hours, and then ball mill The mixture is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com