Method of forming oxide film, method of manufacturing semiconductor device, and film forming apparatus configured to form oxide film

A film-forming method and oxide film technology, which are applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, and from chemically reactive gases, etc., can solve the problem of low crystallinity of oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

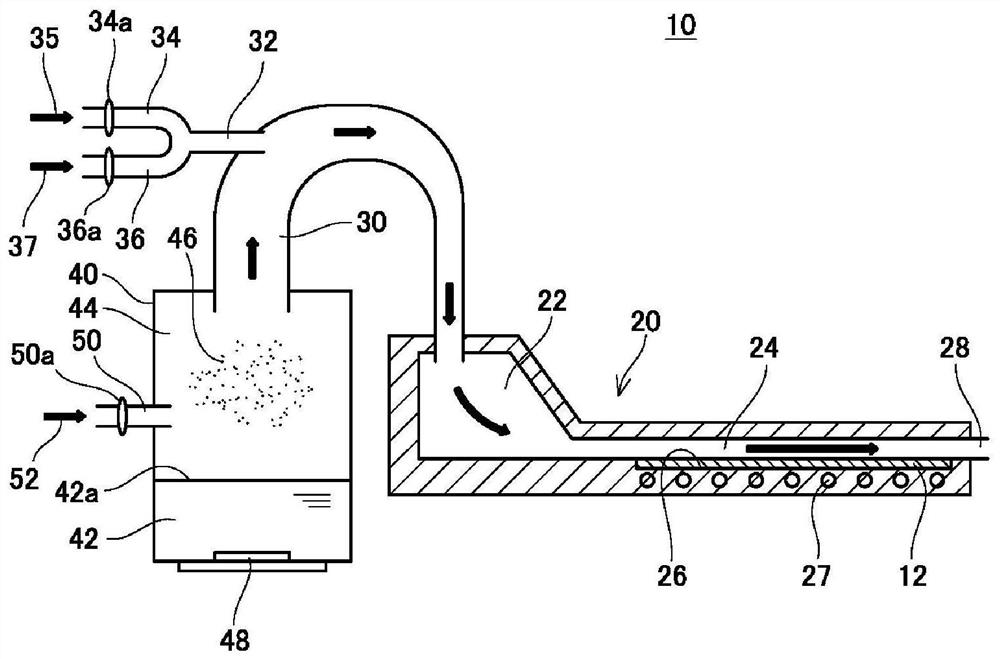

[0012] figure 1 The shown film forming apparatus 10 is an apparatus for epitaxially growing a gallium oxide film on the surface of a substrate 12 . The gallium oxide film is a semiconductor film. The film forming apparatus 10 is used to manufacture a semiconductor device having a gallium oxide film. The film forming apparatus 10 has a heating furnace 20 and a storage tank 40 .

[0013] The storage tank 40 is an airtight container. Storage tank 40 is stored with the raw material of gallium oxide film dissolved in water (H 2 O) the solution 42 formed. A space 44 is provided between the water surface 42 a of the solution 42 and the upper surface of the storage tank 40 . An ultrasonic vibrator 48 is provided on the bottom surface of the storage tank 40 . The ultrasonic vibrator 48 applies ultrasonic waves to the solution 42 stored in the storage tank 40 . When ultrasonic waves are applied to the solution 42, the water surface 42a of the solution 42 vibrates, and a spray of ...

Embodiment 2

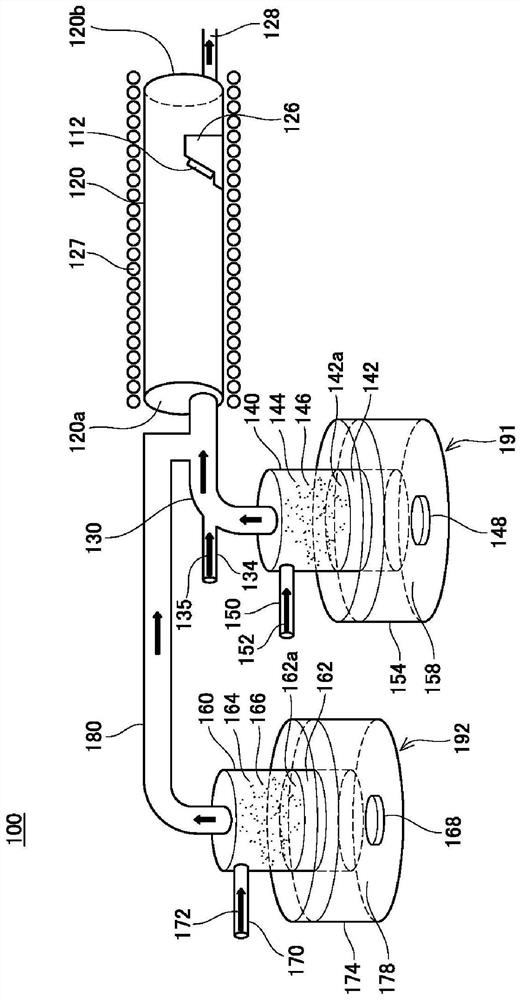

[0026] figure 2 The film formation apparatus 100 of Example 2 shown is an apparatus for epitaxially growing a gallium oxide film on the surface of a substrate 112 . The film forming apparatus 100 is used to manufacture a semiconductor device having a gallium oxide film. The film forming apparatus 100 has a first spray supply device 191 , a second spray supply device 192 , and a heating furnace 120 .

[0027] The furnace 120 is a tubular furnace extending from an upstream end 120a to a downstream end 120b. The downstream end of the solution spray supply path 130 is connected to the upstream end 120 a of the heating furnace 120 . The discharge pipe 128 is connected to the downstream end 120 b of the heating furnace 120 . A substrate mounting table 126 for supporting the substrate 112 is provided in the heating furnace 120 . The substrate mounting table 126 is configured such that the substrate 112 is inclined with respect to the longitudinal direction of the heating furnace...

Embodiment 3

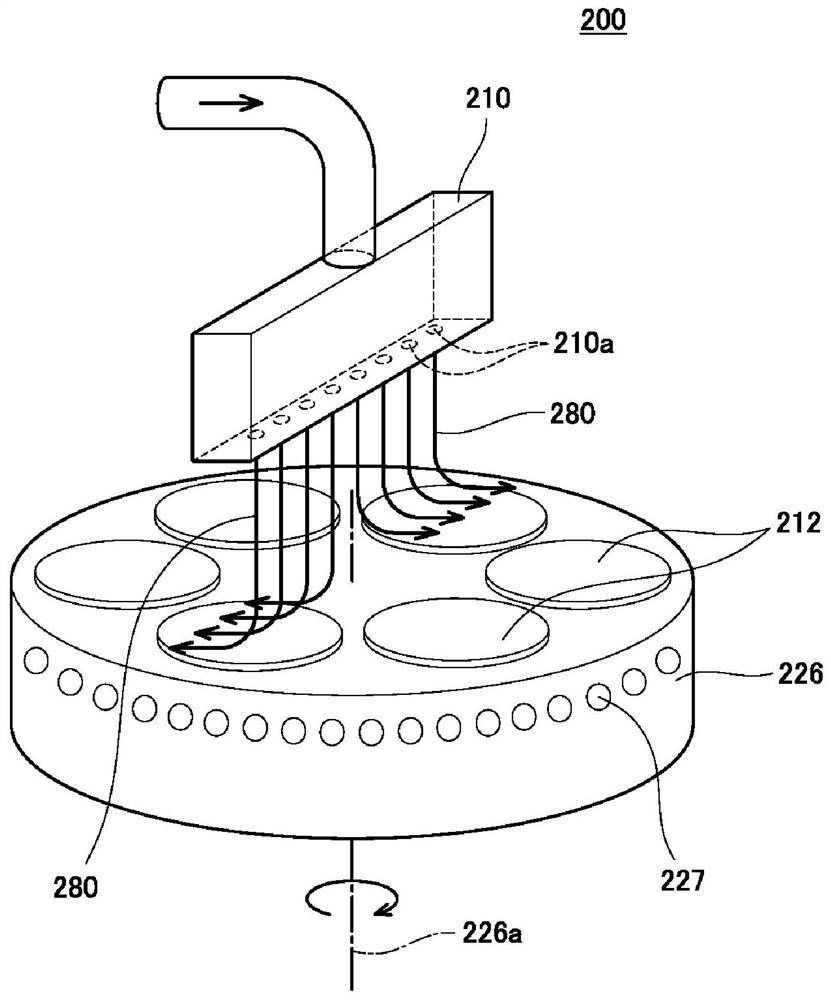

[0044] image 3 The film formation apparatus 200 of Example 3 is shown. In the film forming apparatus of Example 3, spray and gas are ejected from nozzles 210 to a plurality of substrates 212 . In addition, in Example 3, descriptions of spray and gas supply devices (for example, storage tanks and gas supply sources) are omitted.

[0045] The film forming apparatus of Example 3 has a substrate mounting table 226 capable of mounting a plurality of substrates 212 . A heater 227 for heating the substrate 212 is provided inside the substrate mounting table 226 . A plurality of substrates 212 are arranged around a central axis 226 a of the substrate mounting table 226 . The substrate stage 226 rotates around the central axis 226a. The nozzle 210 is arranged on the substrate mounting table 226 . The nozzle 210 and the substrate mounting table 226 are installed in the heating furnace. The nozzle 210 has a rectangular parallelepiped shape that is long in one direction. On the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com