Thin-film transistor, array substrate, preparation method thereof, and display device

A technology of thin film transistors and array substrates, applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of TFT devices that are difficult to turn off, high free carrier concentration, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the embodiment of the present invention has the characteristics of being able to control the concentration of oxygen vacancies and free carriers of the metal oxide, good stability, simple preparation process, and low cost.

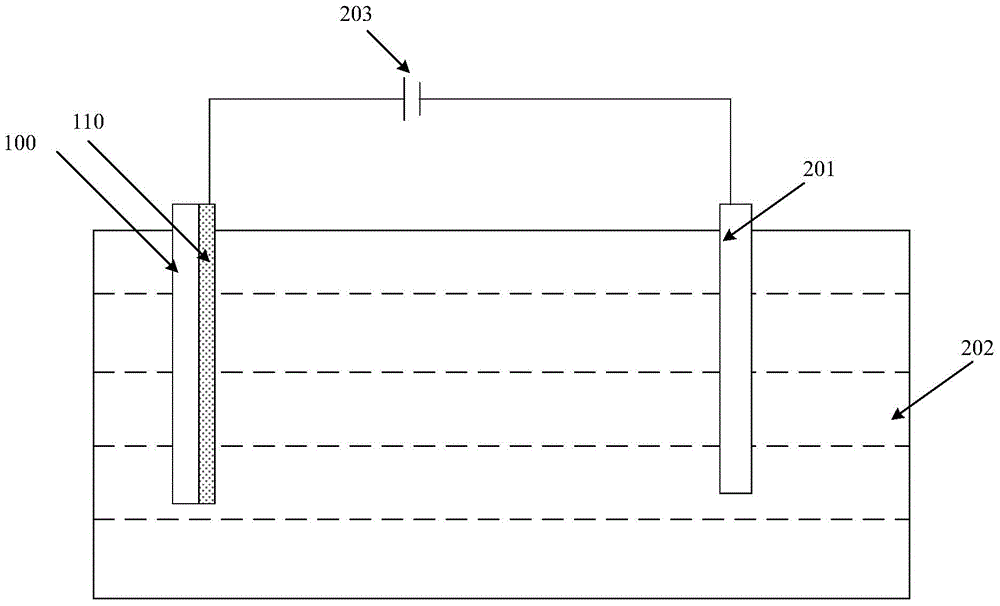

[0044] For example, in this method, as figure 2 As shown, the electrochemical oxidation treatment of the metal oxide film includes the following steps.

[0045] With the metal oxide film 110 as the anode, the cathode 201 and the substrate 100 formed with the metal oxide film 110 are placed in the electrolytic solution (electrolyte) 202, the metal oxide film 110 and the cathode 201 are respectively connected to the positive pole and the negative pole of the power supply 203 Connected, energized for electrochemical oxidation treatment.

[0046] During the electrochemical oxidation process, the cations of the oxygen vacancies in the metal oxide film will combine with the electrolyzed oxygen, thereby reducing the oxygen vacan...

Embodiment 1

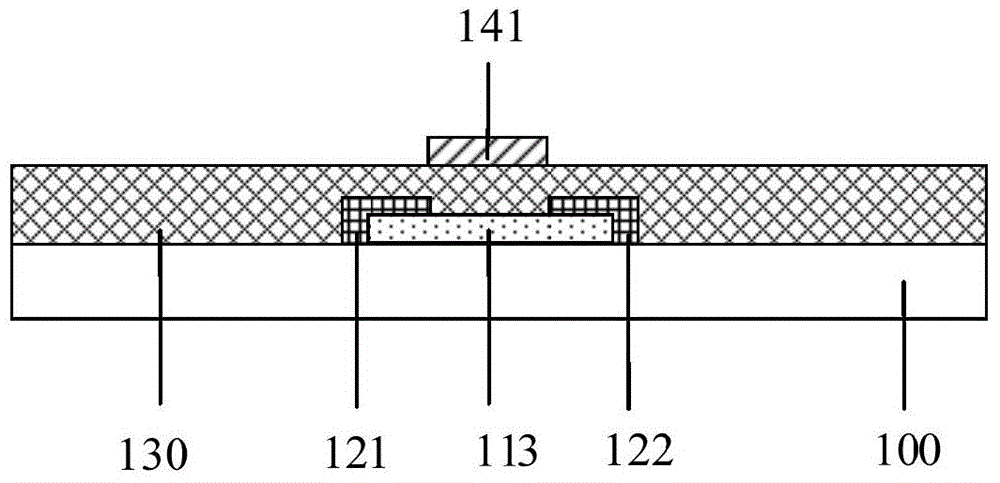

[0061] A kind of metal oxide thin film transistor, its structure is as image 3 As shown, it includes a substrate 100 , an active layer 113 , a source 121 , a drain 122 , a gate insulating layer 130 and a gate 141 . The metal oxide thin film transistor has a top-gate structure. The material of the active layer 113 can be, for example, indium zinc oxide.

[0062] Such as figure 2 As shown in FIG. 4 , the manufacturing method of the metal oxide thin film transistor includes the following steps.

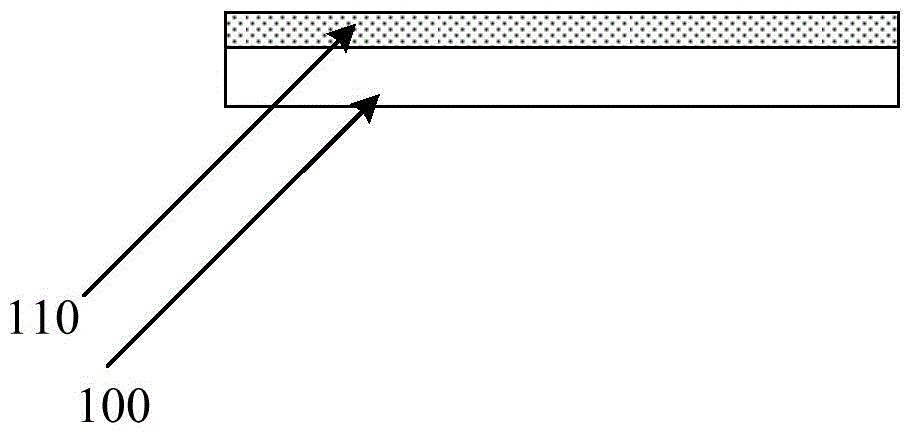

[0063] (1) Form a metal oxide thin film 110 on the substrate 100, such as Figure 4a shown. The metal oxide is, for example, indium zinc oxide.

[0064] (2) Performing electrochemical oxidation treatment on the metal oxide thin film 110 , for example, includes the following steps.

[0065] With the metal oxide film 110 as the anode, the cathode 201 and the substrate 100 formed with the metal oxide film 110 are placed in the electrolyte solution 202, the metal oxide film and the c...

Embodiment 2

[0083] A kind of metal oxide thin film transistor, its structure is as Image 6 As shown, it includes a substrate 100 , an active layer 113 , a source 121 , a drain 122 , a gate insulating layer 130 and a gate 141 . The metal oxide thin film transistor has a bottom gate structure. The material of the active layer 113 is, for example, indium zinc oxide.

[0084] Such as figure 2 As shown in FIG. 7 , the manufacturing method of the metal oxide thin film transistor includes the following steps.

[0085] (1) Form a conductive film 140 on the substrate 100, such as Figure 7a shown, and pattern it to form a gate 141, such as Figure 7b shown.

[0086] For example, a Mo / Al / Mo laminated metal layer can be formed by sputtering, for example, with a thickness of 25nm / 100nm / 25nm respectively, and the gate 141 can be patterned by photolithography.

[0087] (2) forming an insulating film as the gate insulating layer 130, such as Figure 7c shown.

[0088] For example, SiNx and SiO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com