Patents

Literature

128 results about "Hydrogen passivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen passivation refers to the stabilization of silicon material surfaces from chemical reactions through the creation of hydrogen silicon bonds.

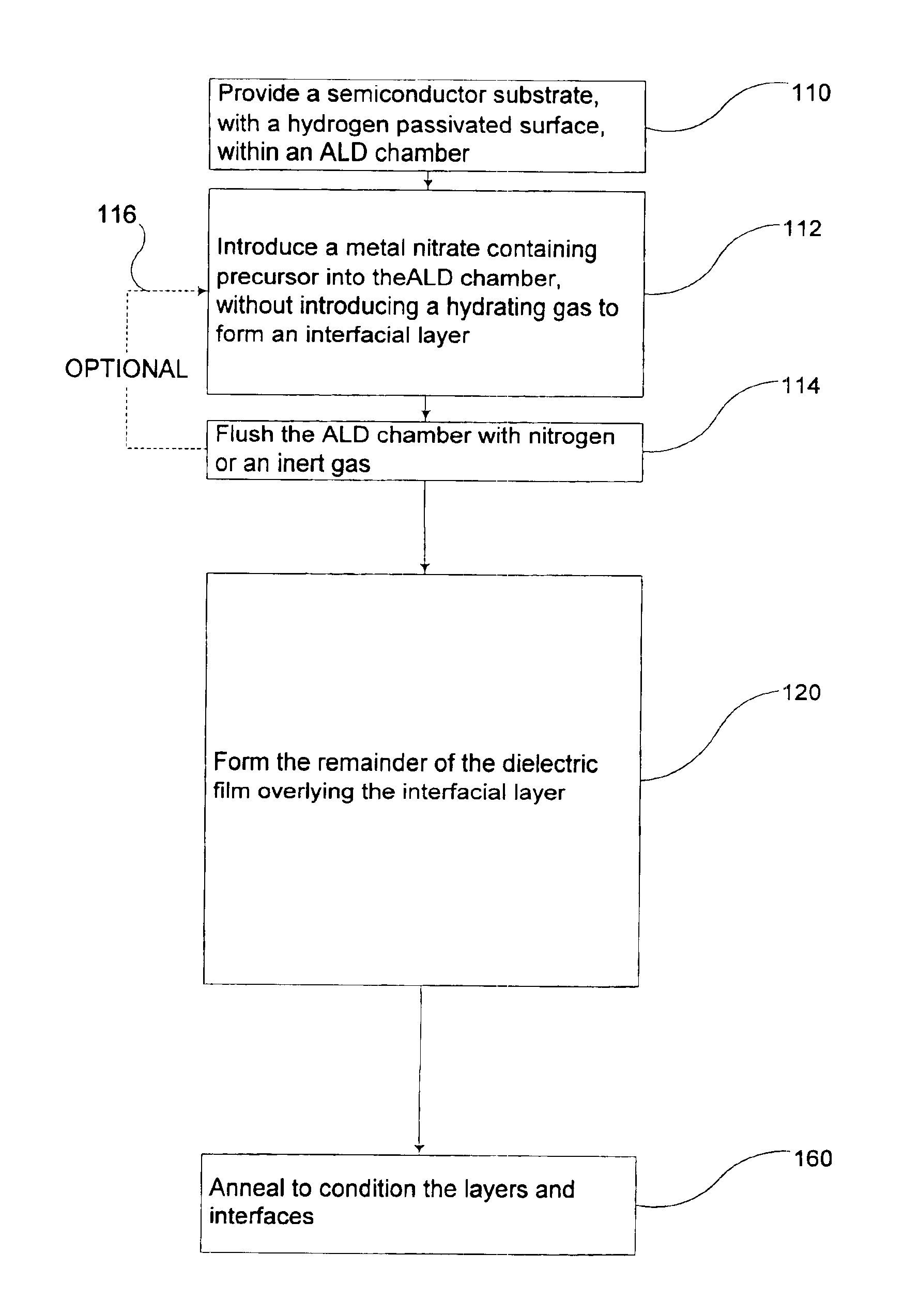

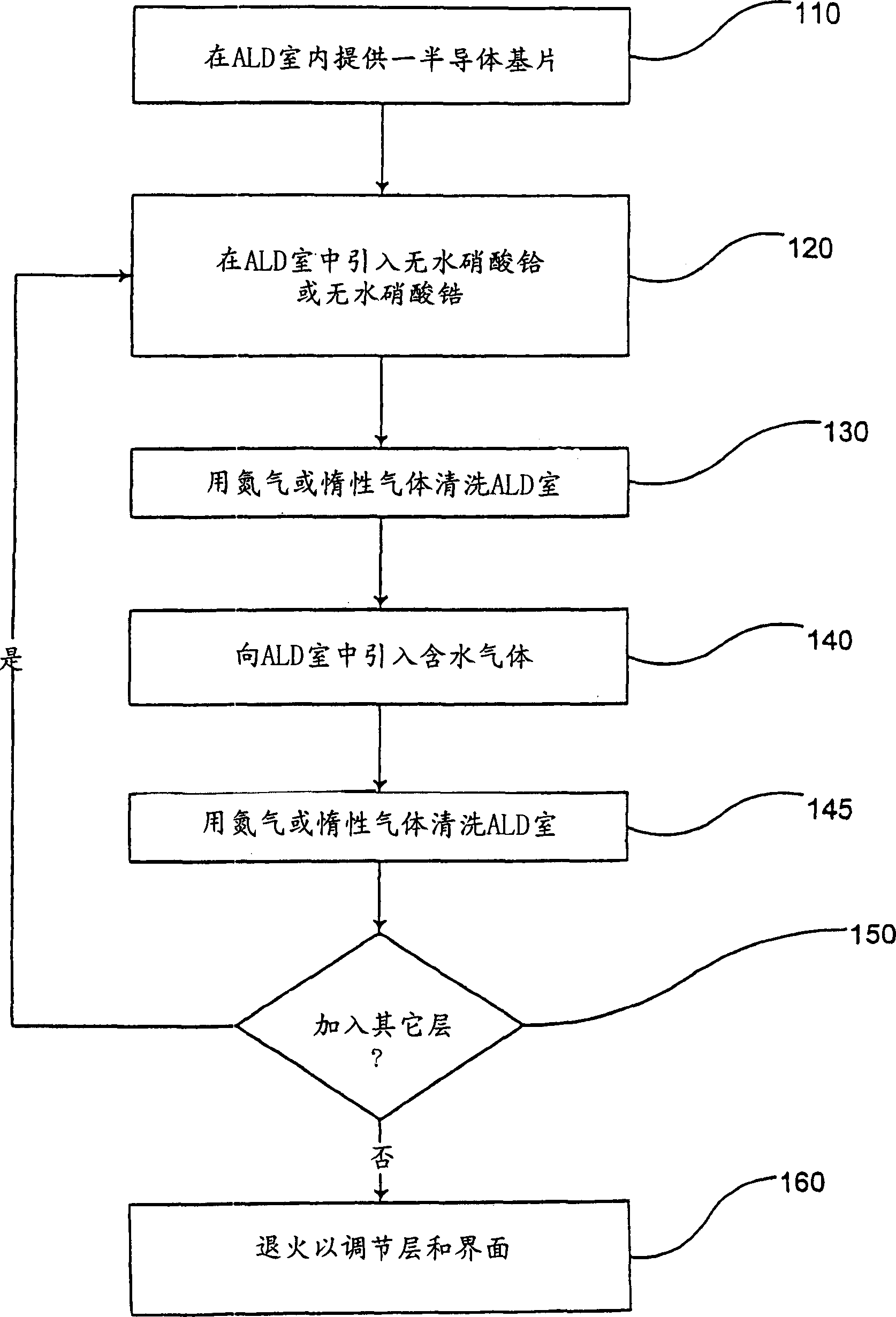

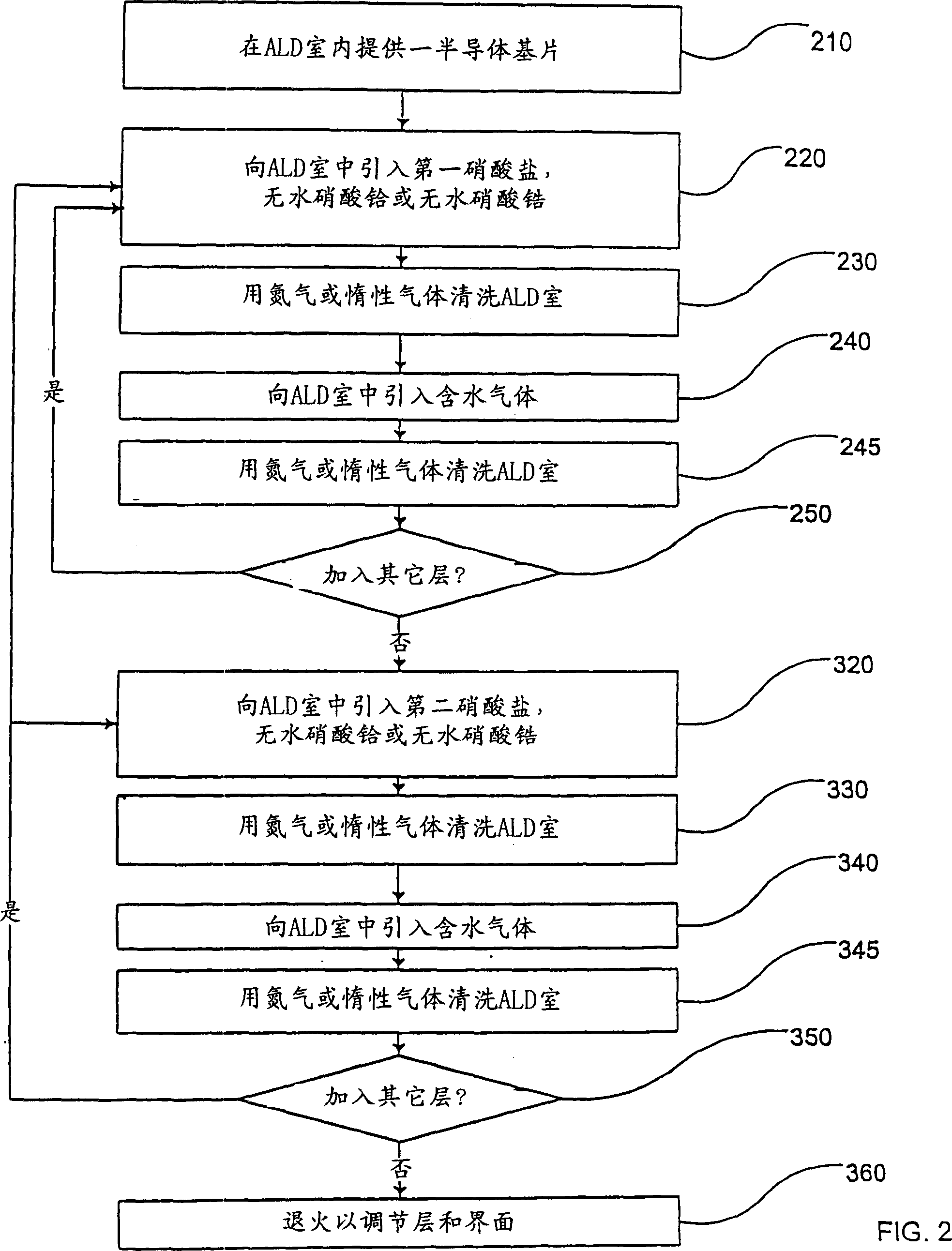

Method to control the interfacial layer for deposition of high dielectric constant films

Methods of forming an interfacial layer on a hydrogen-passivated substrate are provided. These methods utilize atomic layer deposition techniques incorporating metal nitrate-based precursors, such as hafnium nitrate or zirconium nitrate, without introducing a hydrating agent, or oxidizing agent, such as water, during the formation of the interfacial layer. Also provided are methods of forming high-k films, by first forming an interfacial layer on the surface of a hydrogen-passivated substrate, and then depositing one, or more, high-k dielectric films.

Owner:SHARP LAB OF AMERICA INC

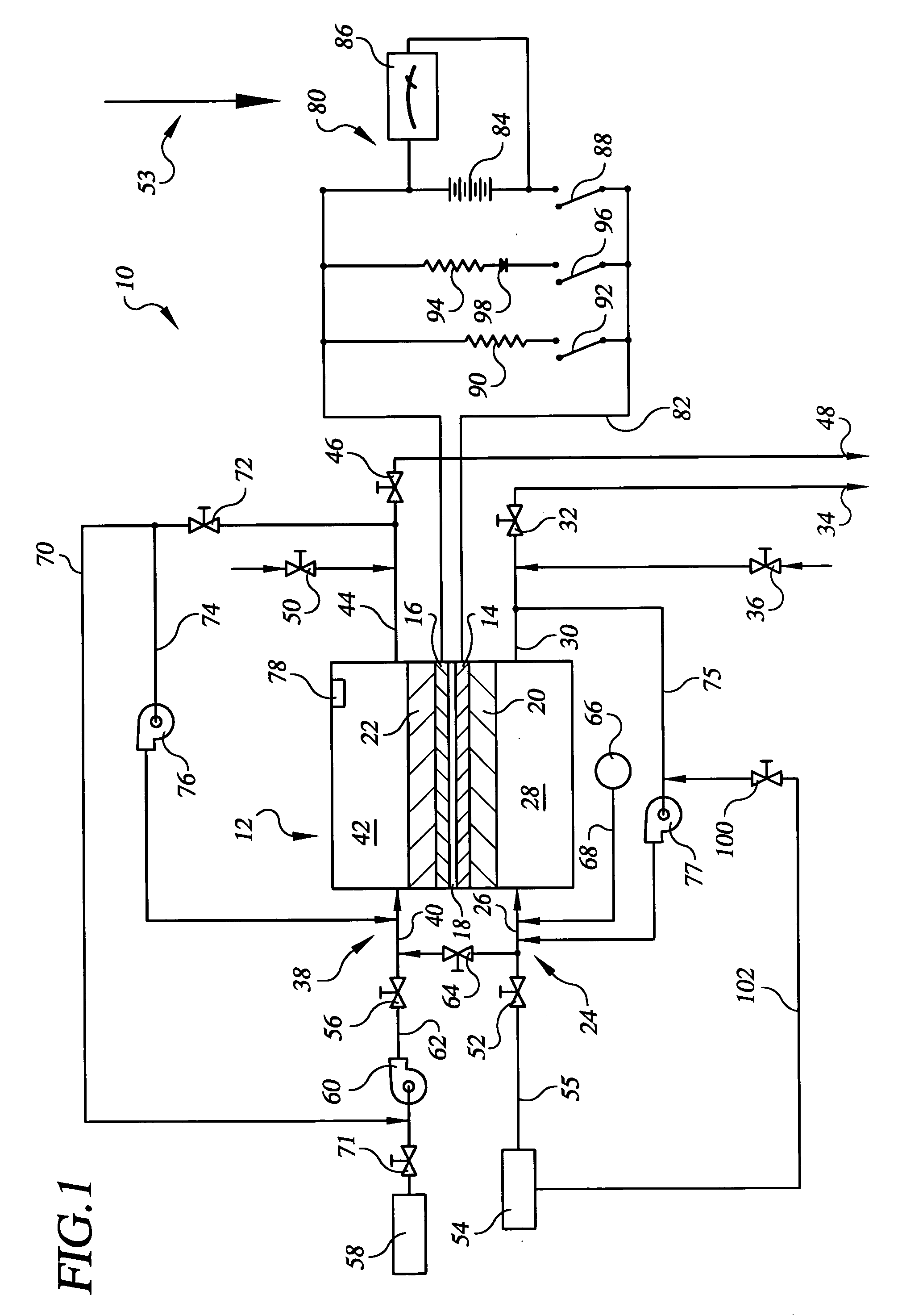

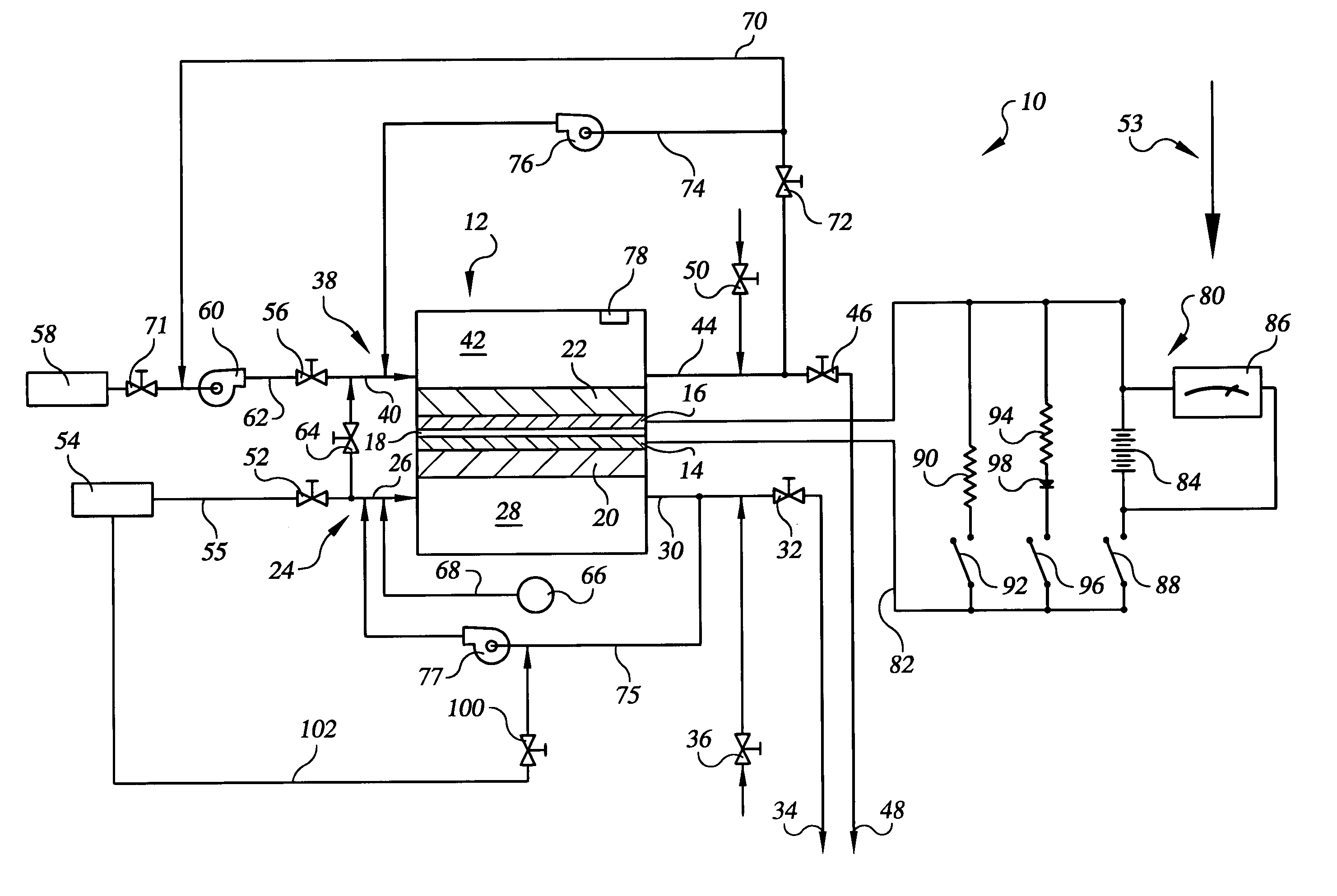

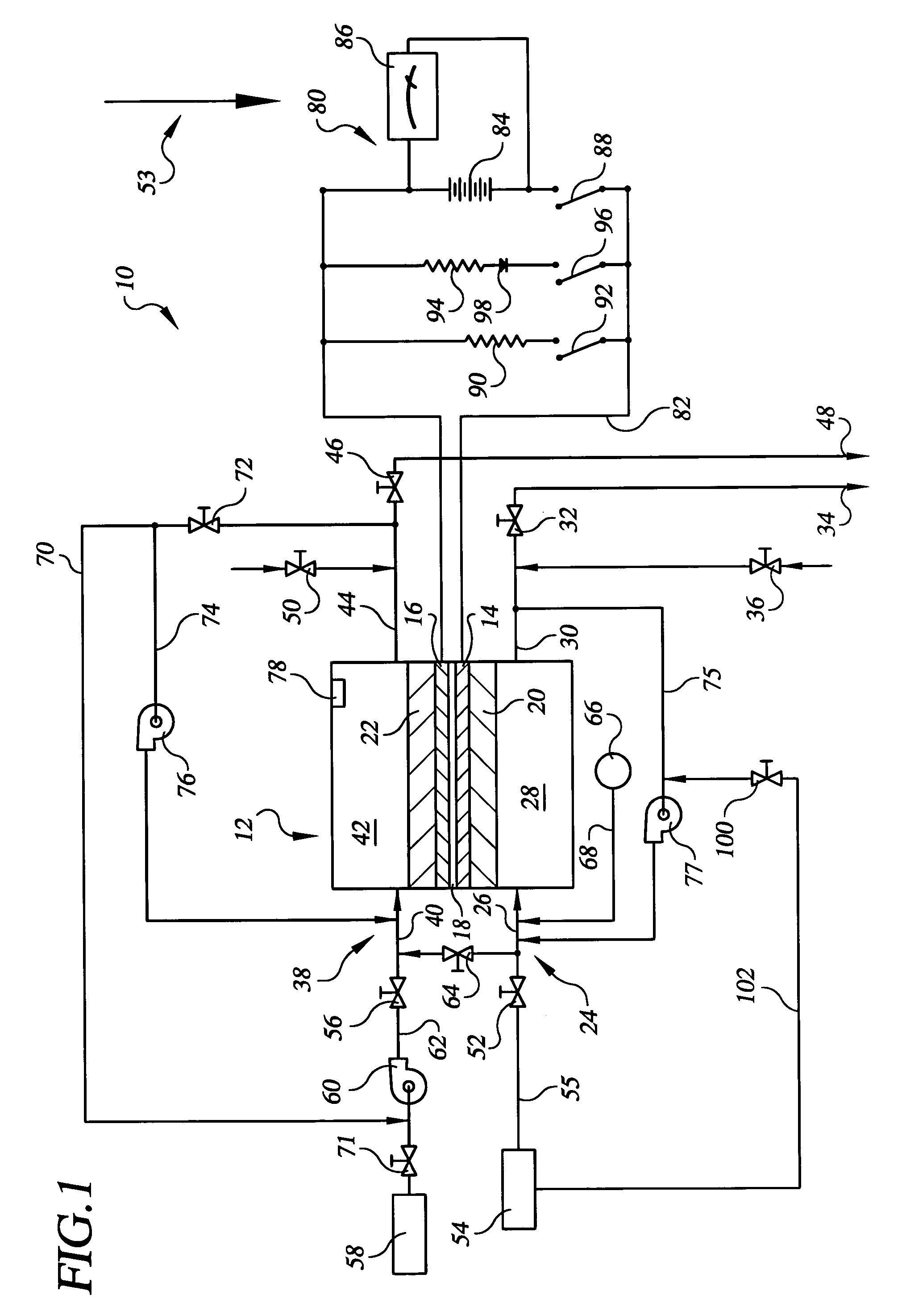

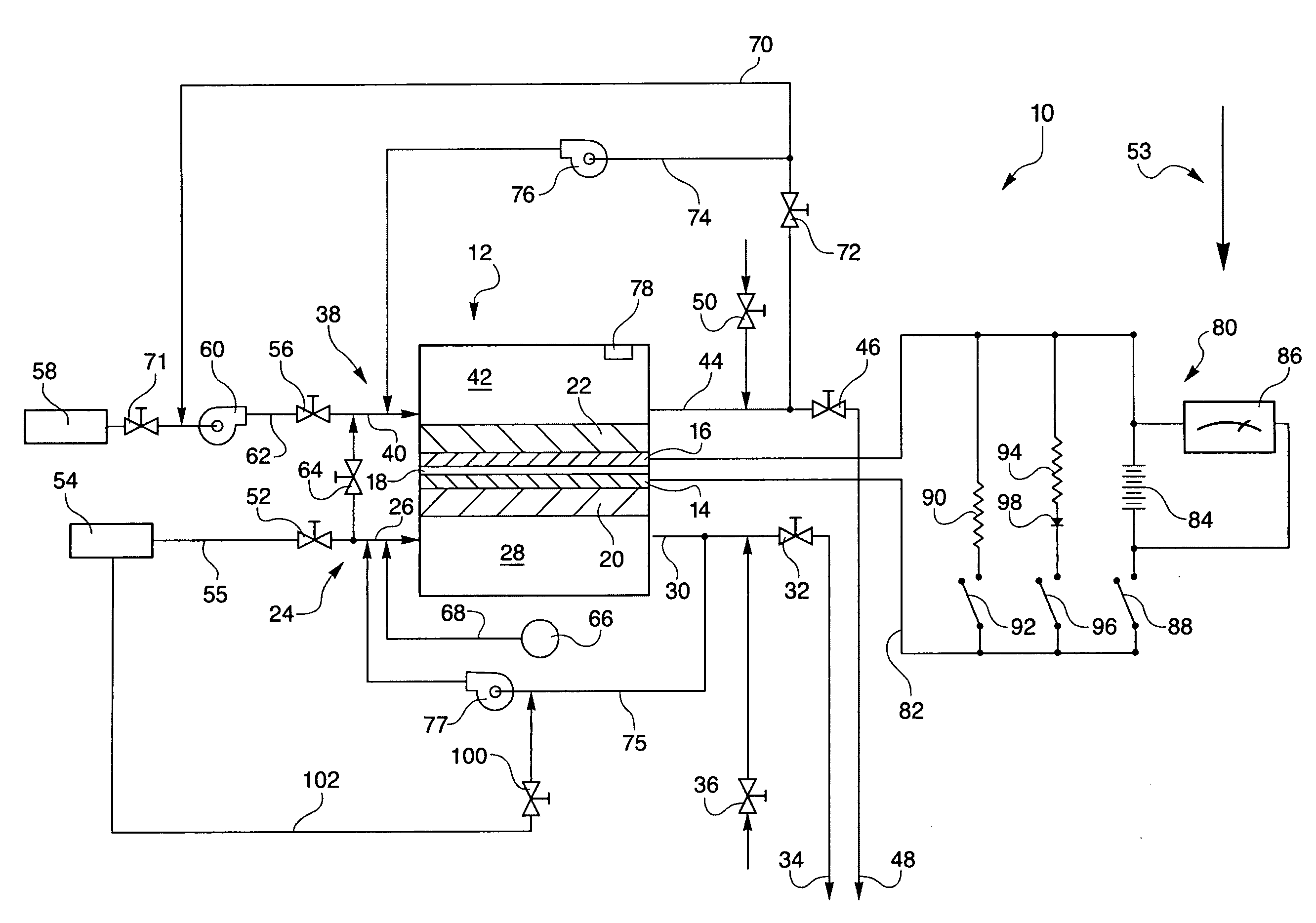

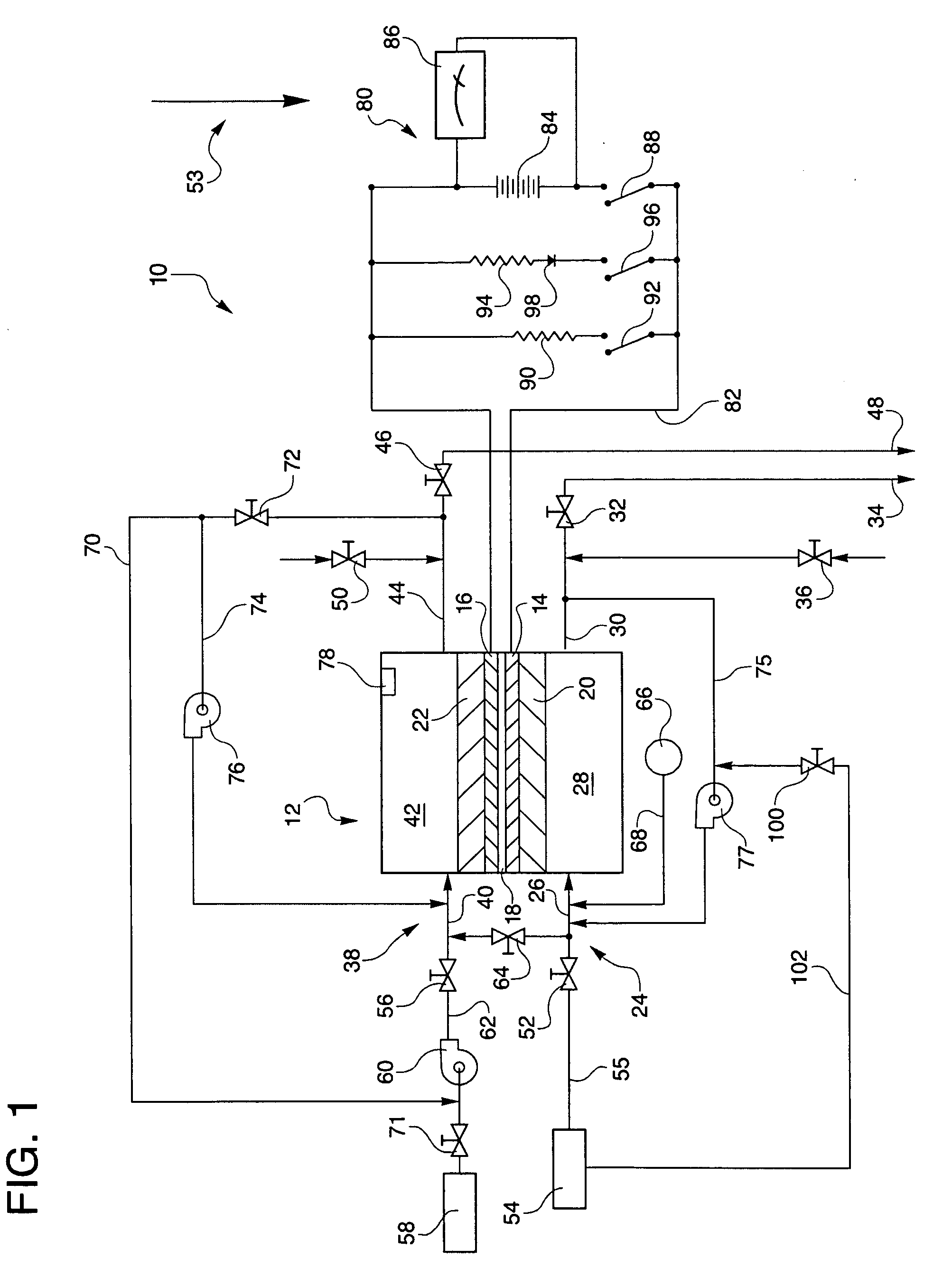

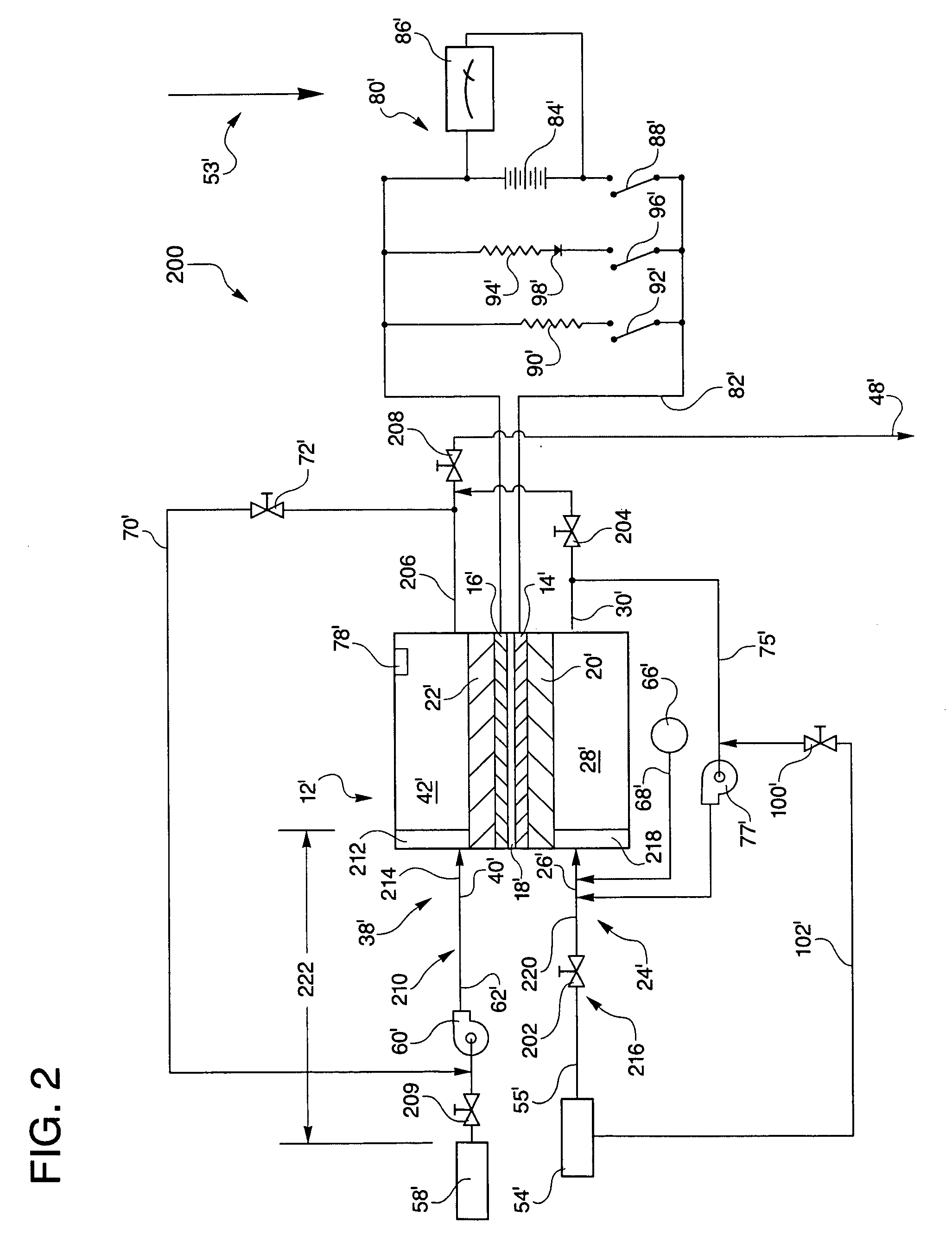

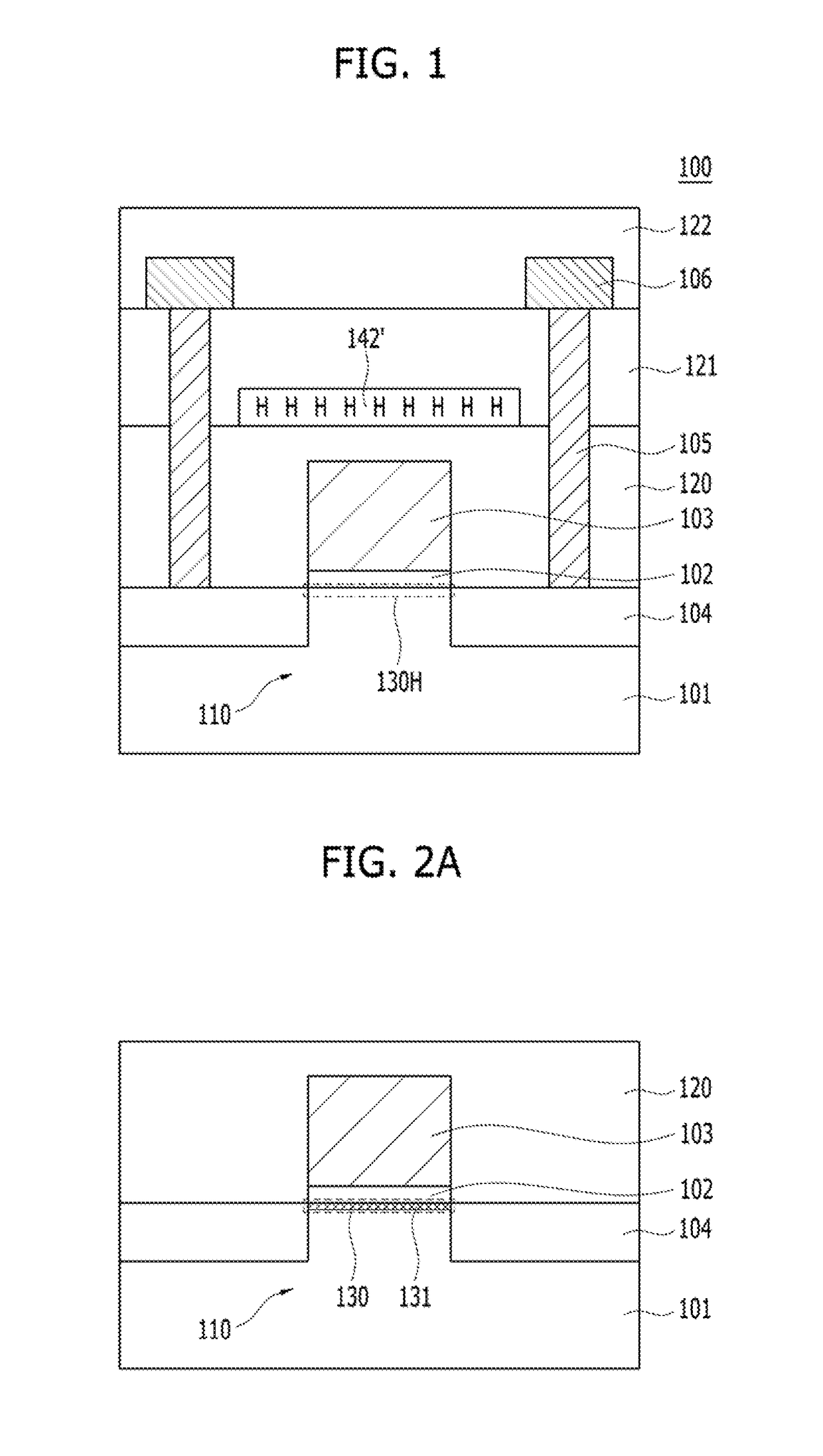

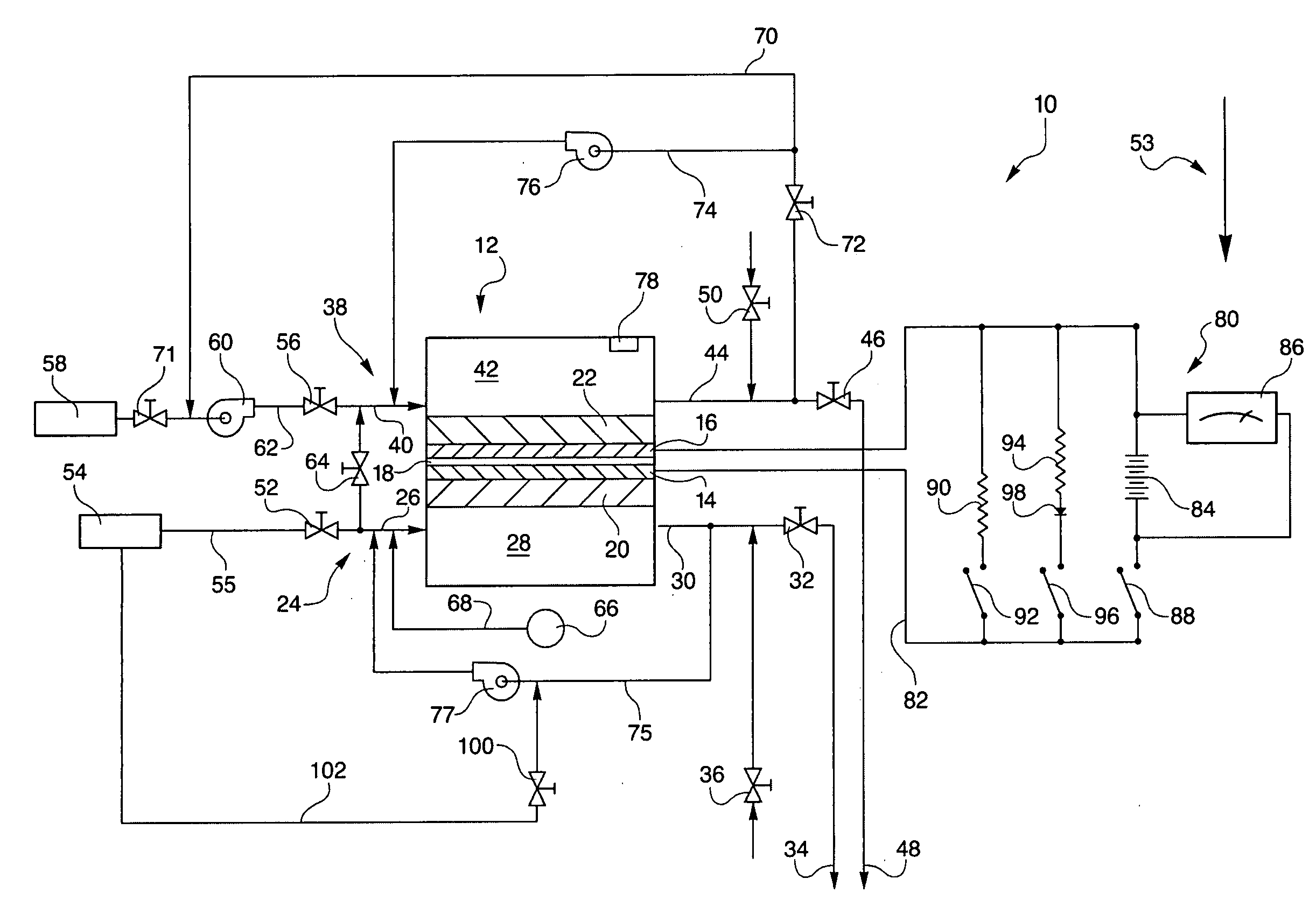

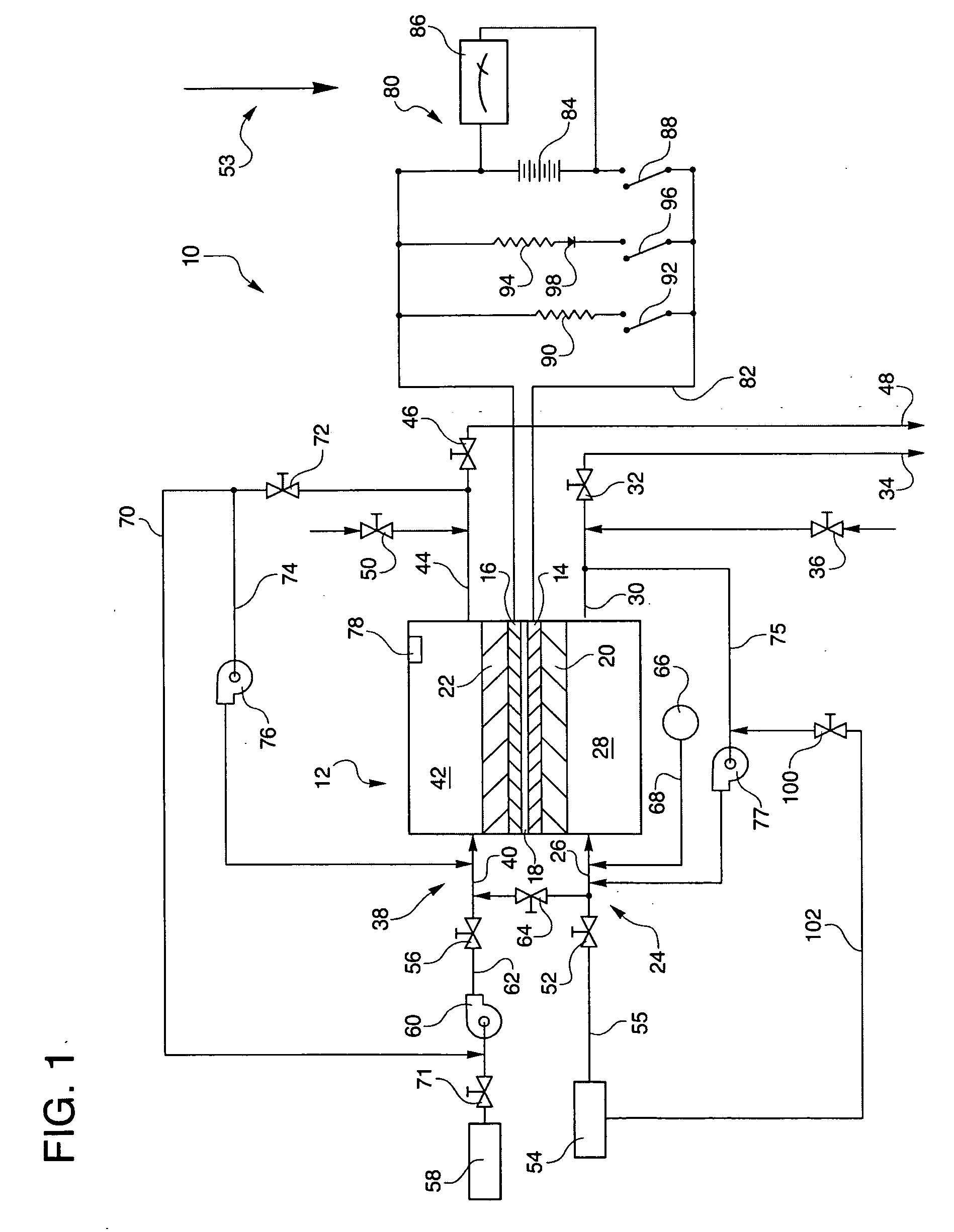

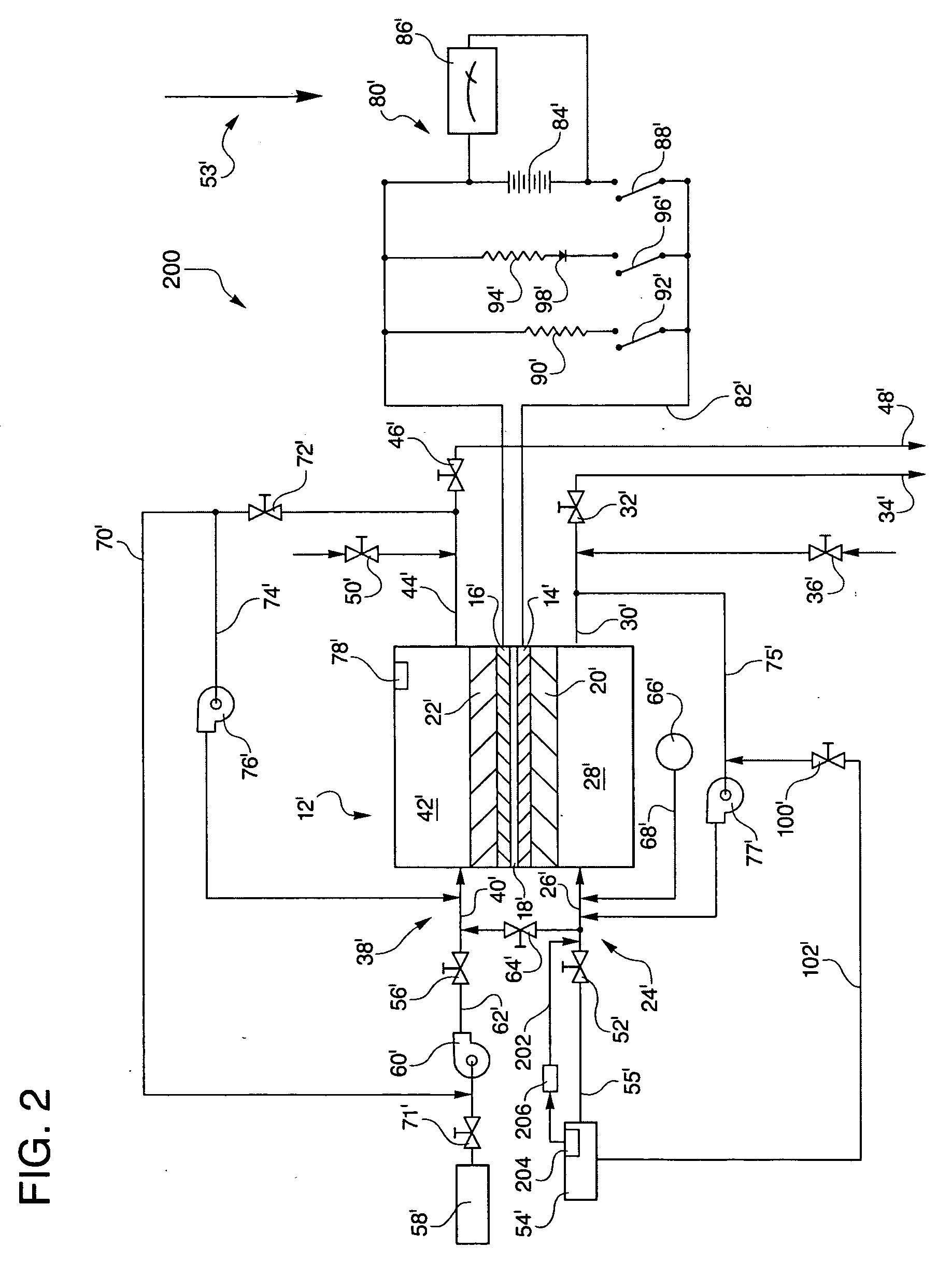

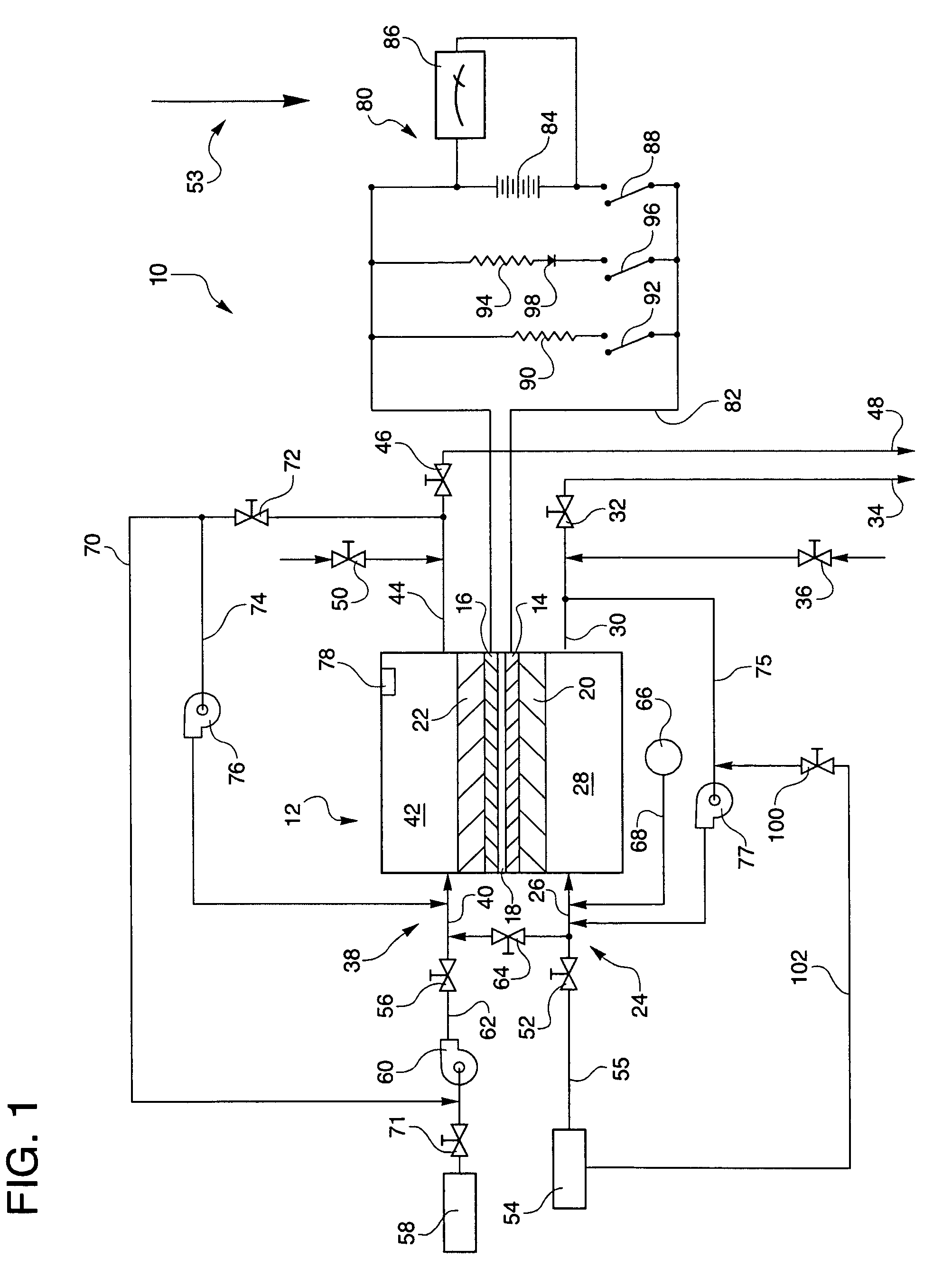

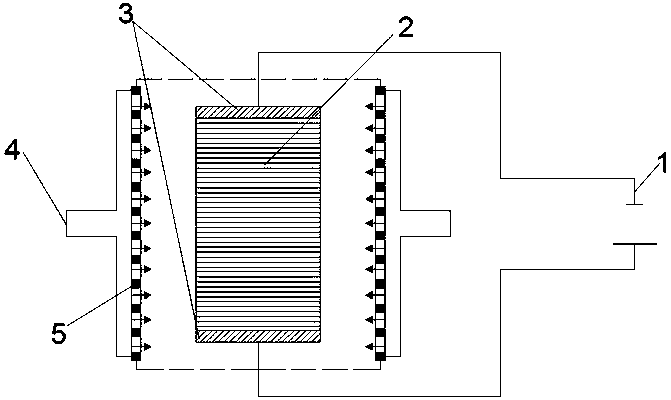

Hydrogen passivation shut down system for a fuel cell power plant

ActiveUS20050031917A1Move quicklyMinimize oxidation corrosionReactant parameters controlFuel cells groupingPower stationEngineering

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10). An anode flow path (24) is in fluid communication with an anode catalyst (14) for directing hydrogen fuel to flow adjacent to the anode catalyst (14), and a cathode flow path (38) is in fluid communication with a cathode catalyst (16) for directing an oxidant to flow adjacent to the cathode catalyst (16) of a fuel cell (12). Hydrogen fuel is permitted to transfer between the anode flow path (24) and the cathode flow path (38). A hydrogen reservoir (66) is secured in fluid communication with the anode flow path (24) for receiving and storing hydrogen during fuel cell (12) operation, and for releasing the hydrogen into fuel cell (12) whenever the fuel cell (12) is shut down.

Owner:AUDI AG

Hydrogen passivation shut down system for a fuel cell power plant

InactiveUS6984464B2Minimize oxidation corrosionRapid fuelReactant parameters controlFuel cells groupingPower stationEngineering

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10). An anode flow path (24) is in fluid communication with an anode catalyst (14) for directing hydrogen fuel to flow adjacent to the anode catalyst (14), and a cathode flow path (38) is in fluid communication with a cathode catalyst (16) for directing an oxidant to flow adjacent to the cathode catalyst (16) of a fuel cell (12). Hydrogen fuel is permitted to transfer between the anode flow path (24) and the cathode flow path (38). A hydrogen reservoir (66) is secured in fluid communication with the anode flow path (24) for receiving and storing hydrogen during fuel cell (12) operation, and for releasing the hydrogen into fuel cell (12) whenever the fuel cell (12) is shut down.

Owner:AUDI AG

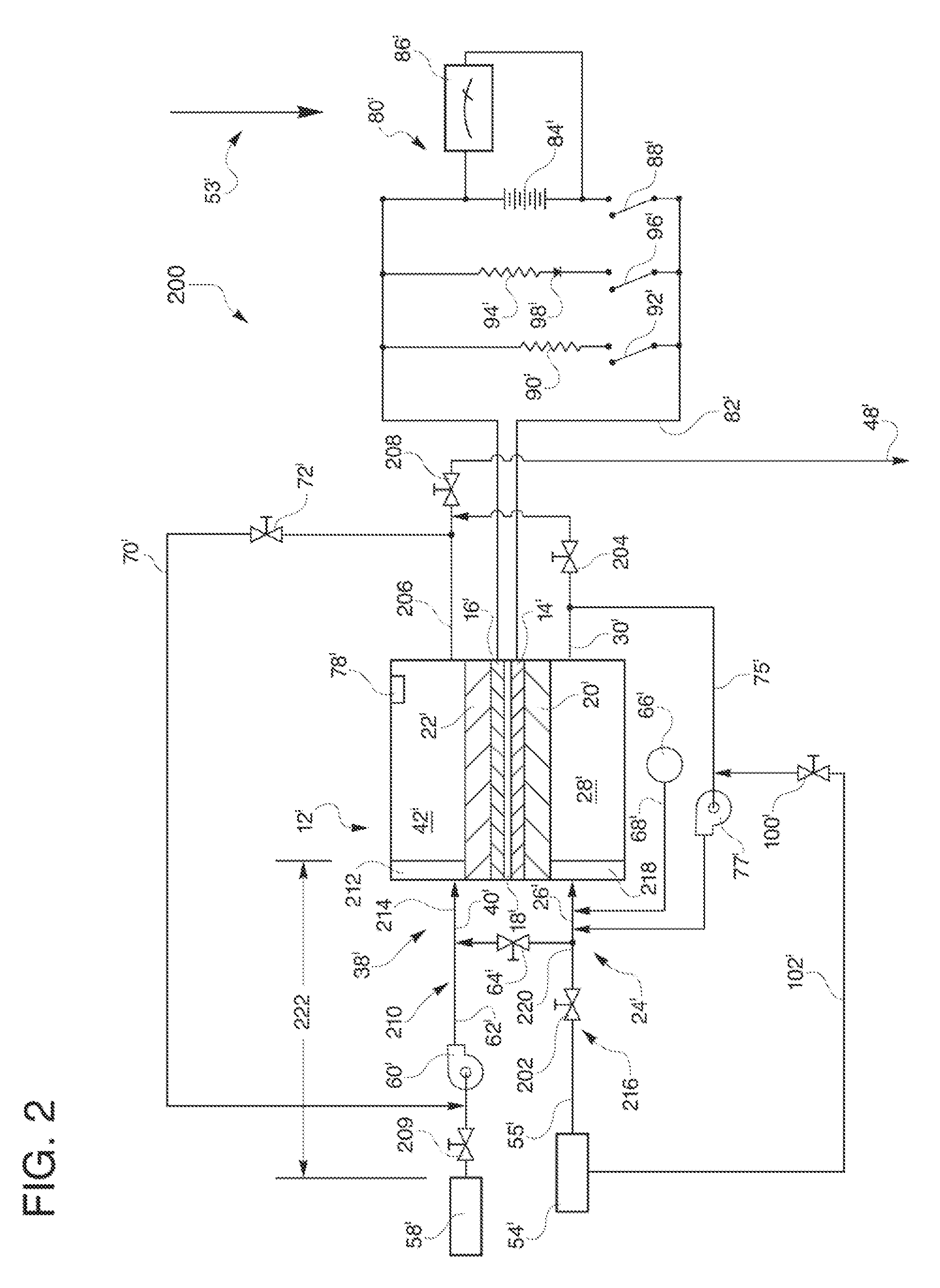

Hydrogen passivation shut down system for a fuel cell power plant

ActiveUS20090220832A1Move quicklyIncrease entryReactant parameters controlFuel cells groupingExhaust valvePower station

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10, 200). During shut down of the plant (10, 200), hydrogen fuel is permitted to transfer between an anode flow path (24, 24′) and a cathode flow path (38, 38′). A controlled-oxidant flow device (209) near an oxygen source (58′) permits a minimal amount of atmospheric oxygen to enter the power plant (200) during shut down to equalize pressure between ambient atmosphere and the flow paths (24′, 28′) and to keep limited atmospheric oxygen entering the power plant (200) through the device (209) as far as possible from fuel cell flow fields (28′, 42′). A non-leaking hydrogen inlet valve (202), a non-leaking cathode exhaust valve (208), and a combined oxidant and fuel exhaust line (206) also minimize penetration of oxygen into the shut down power plant (200).

Owner:UNITED TECH CORP +1

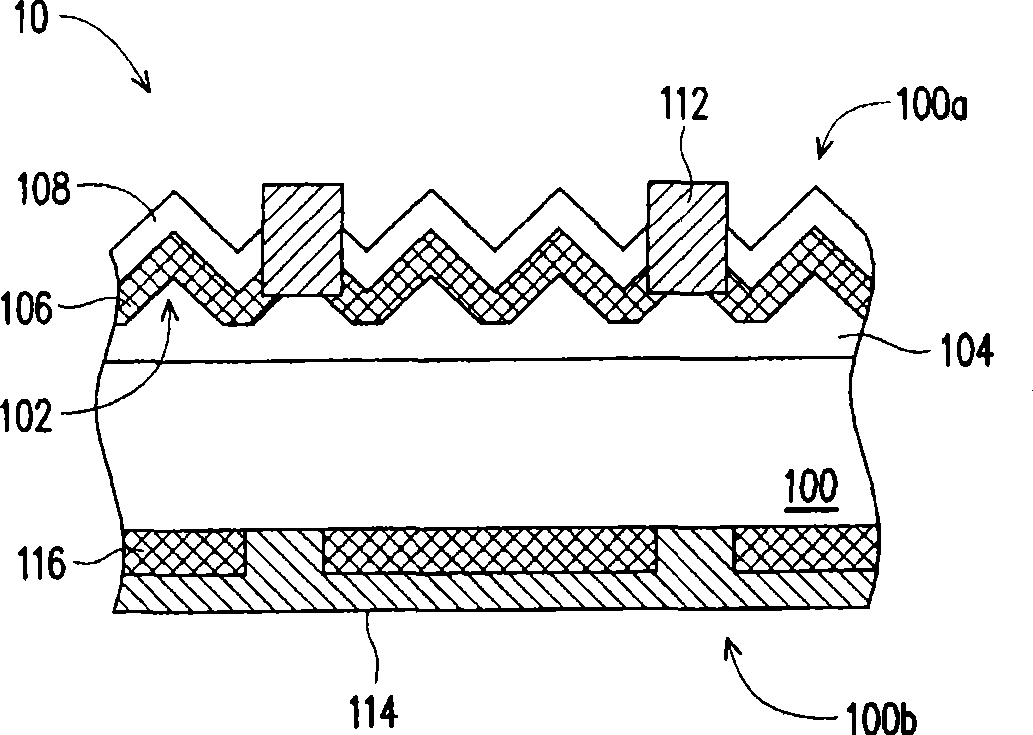

Selective Emitter and Texture Processes for Back Contact Solar Cells

InactiveUS20090126786A1Improve sheet resistanceEnhanced Vapor DepositionFinal product manufactureEnergy based chemical/physical/physico-chemical processesHigh resistanceDiffusion

Methods for manufacturing textured selective emitter back contact solar cells, and solar cells made in accordance therewith. A separate antireflective coating is preferably deposited, which also preferably provides simultaneous hydrogen passivation. The high sheet resistance and low sheet resistance selective emitter diffusions may be performed in either order.

Owner:APPLIED MATERIALS INC

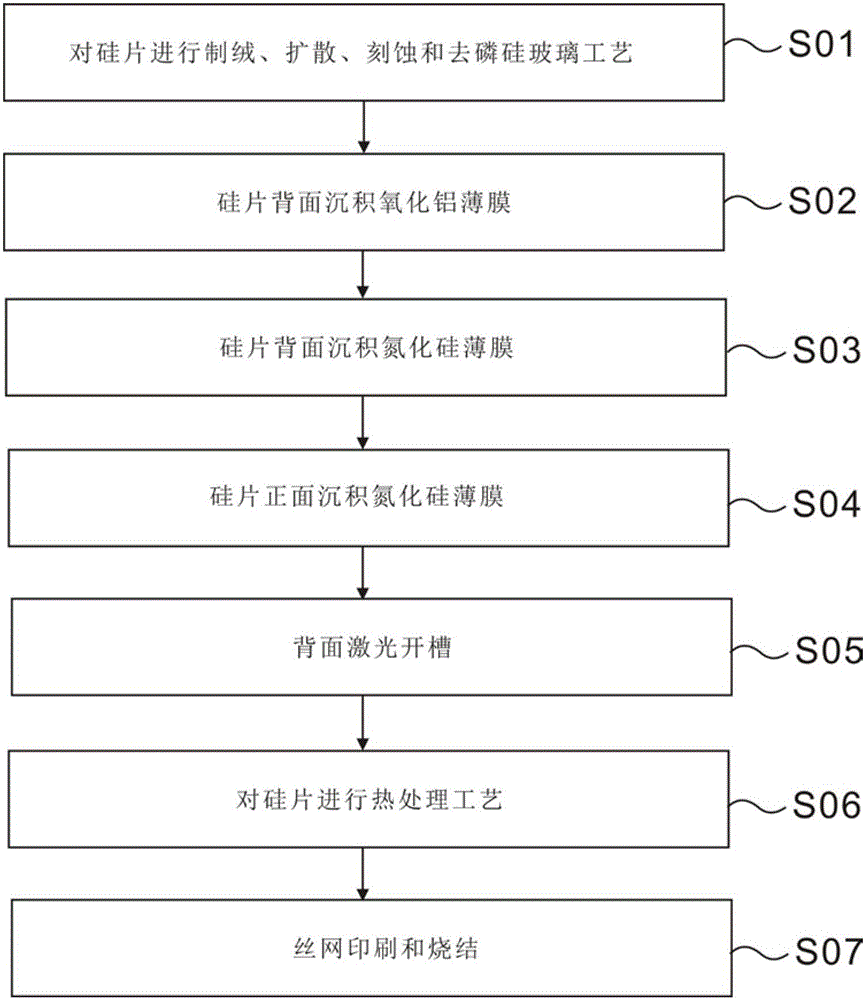

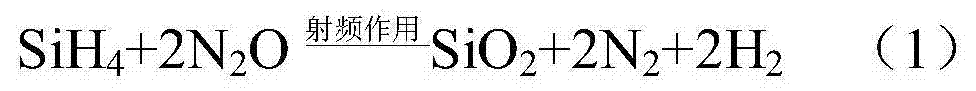

Process for preparing crystalline silicon solar cell by secondary texturing method

InactiveCN102185035AImprove conversion efficiencyWon't hurtFinal product manufactureSemiconductor devicesReactive-ion etchingIon

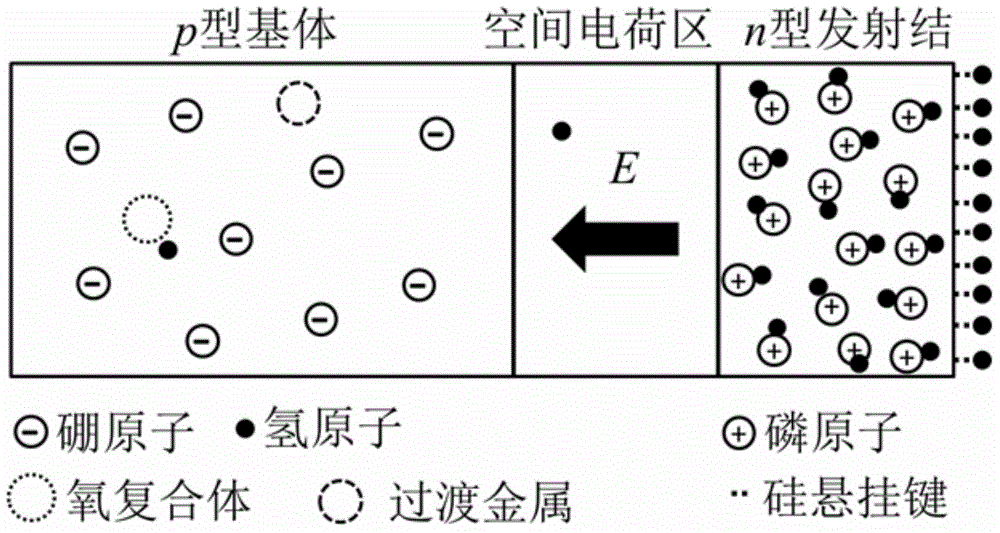

The invention relates to a method for preparing a crystalline silicon solar cell. The method specifically comprises the following steps of: 1) performing wet texturing, and performing reactive ion etching, passivation and deionization for secondary texturing; and 2) diffusing a silicon chip obtained by the step 1), and sequentially performing edge etching, removal of phosphorosilicate glass, hydrogen passivation, deposition of a silicon nitride film, silk screening of cathode, anode and back aluminum, and sintering. In the method for preparing the crystalline silicon solar cell, the method for prolonging the optical distance of light in crystalline silicon and reducing light reflection loss is mainly provided; and the crystalline silicon chip prepared by the method provided by the invention has relatively lower surface reflectivity, and the hydrogen passivation performed before the deposition of the silicon nitride film can reduce silicon dangling bonds, form Si-H, reduce surface states, increase short-circuit current and fulfill the aim of improving the conversion efficiency.

Owner:山东力诺太阳能电力股份有限公司

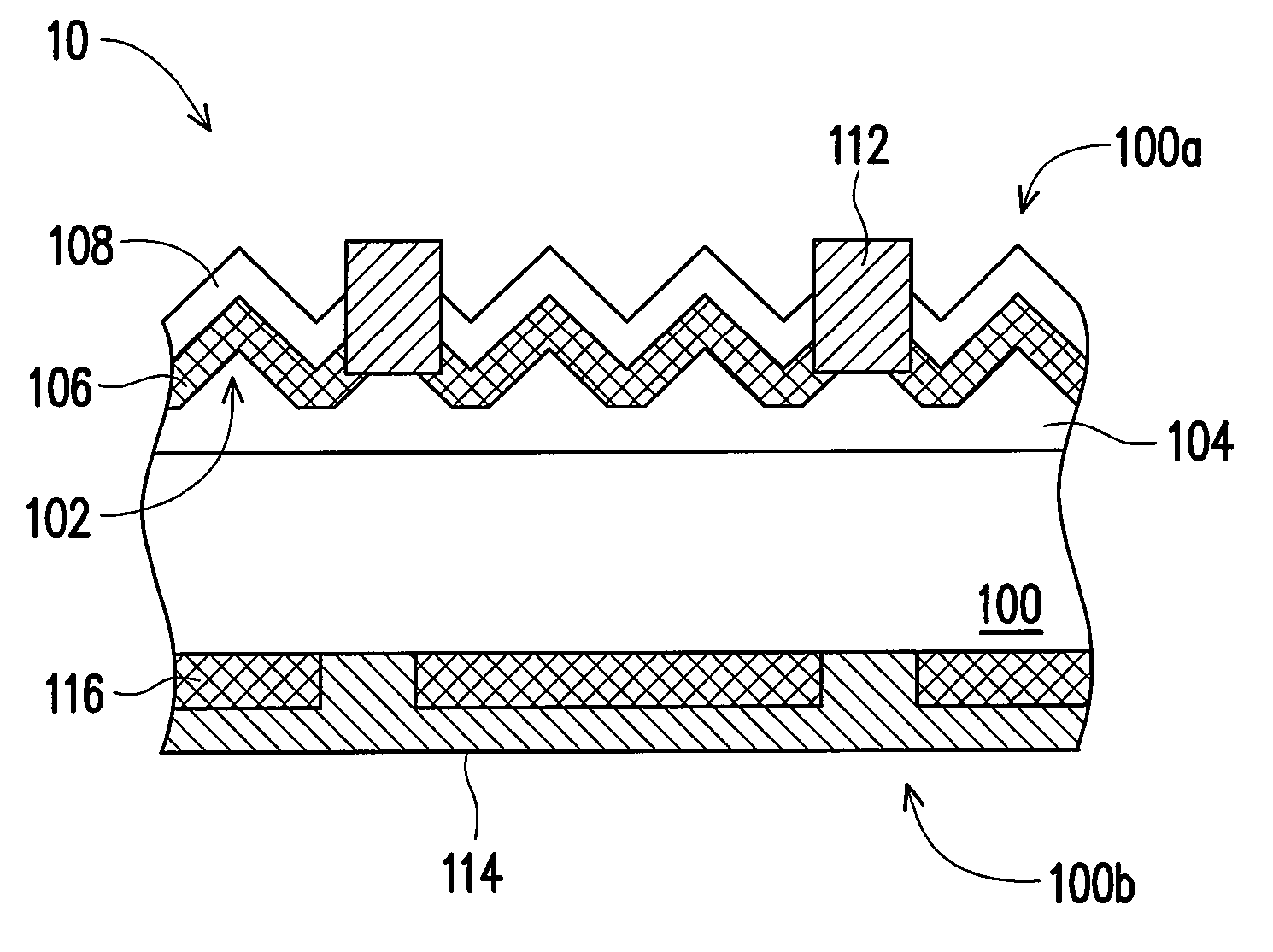

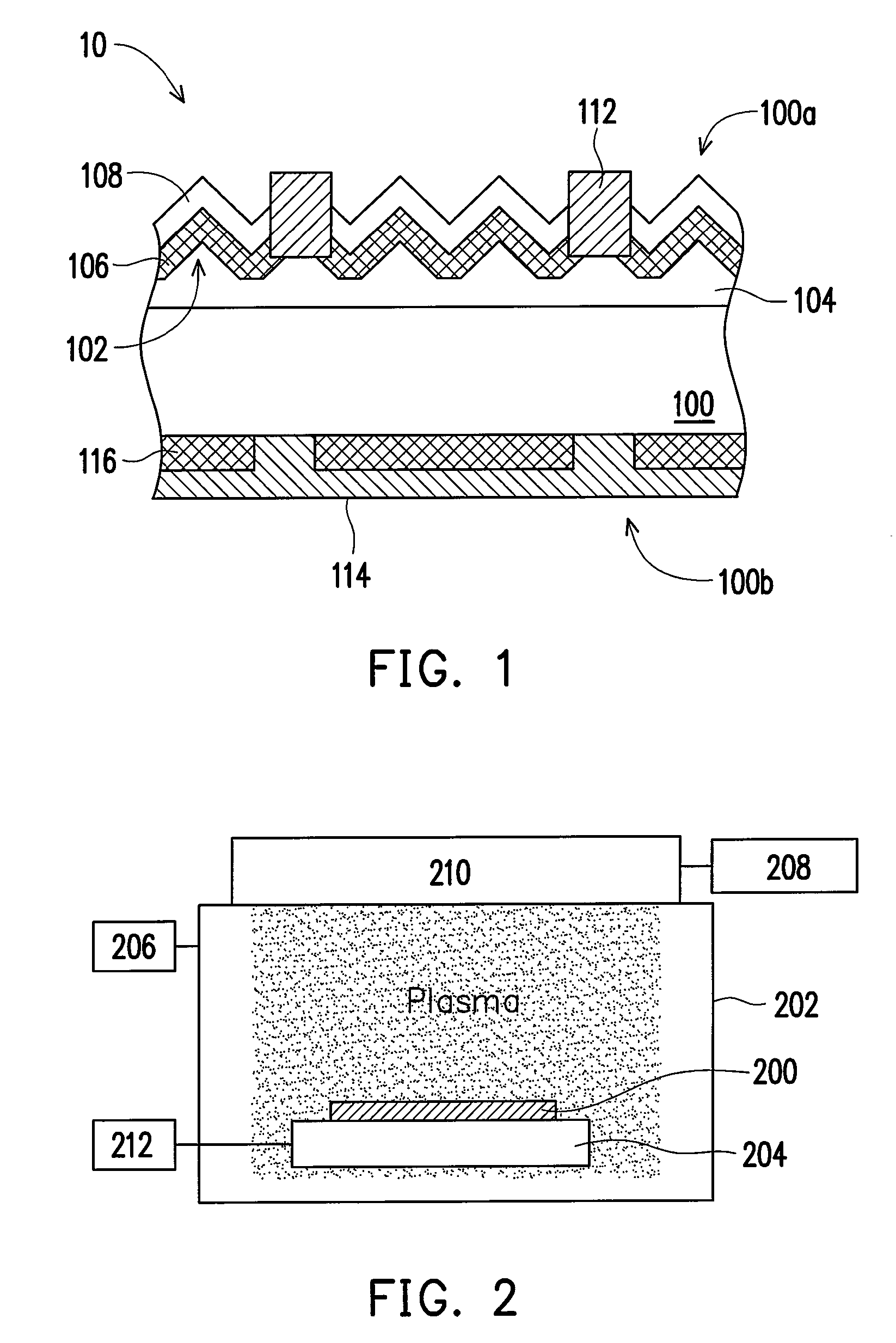

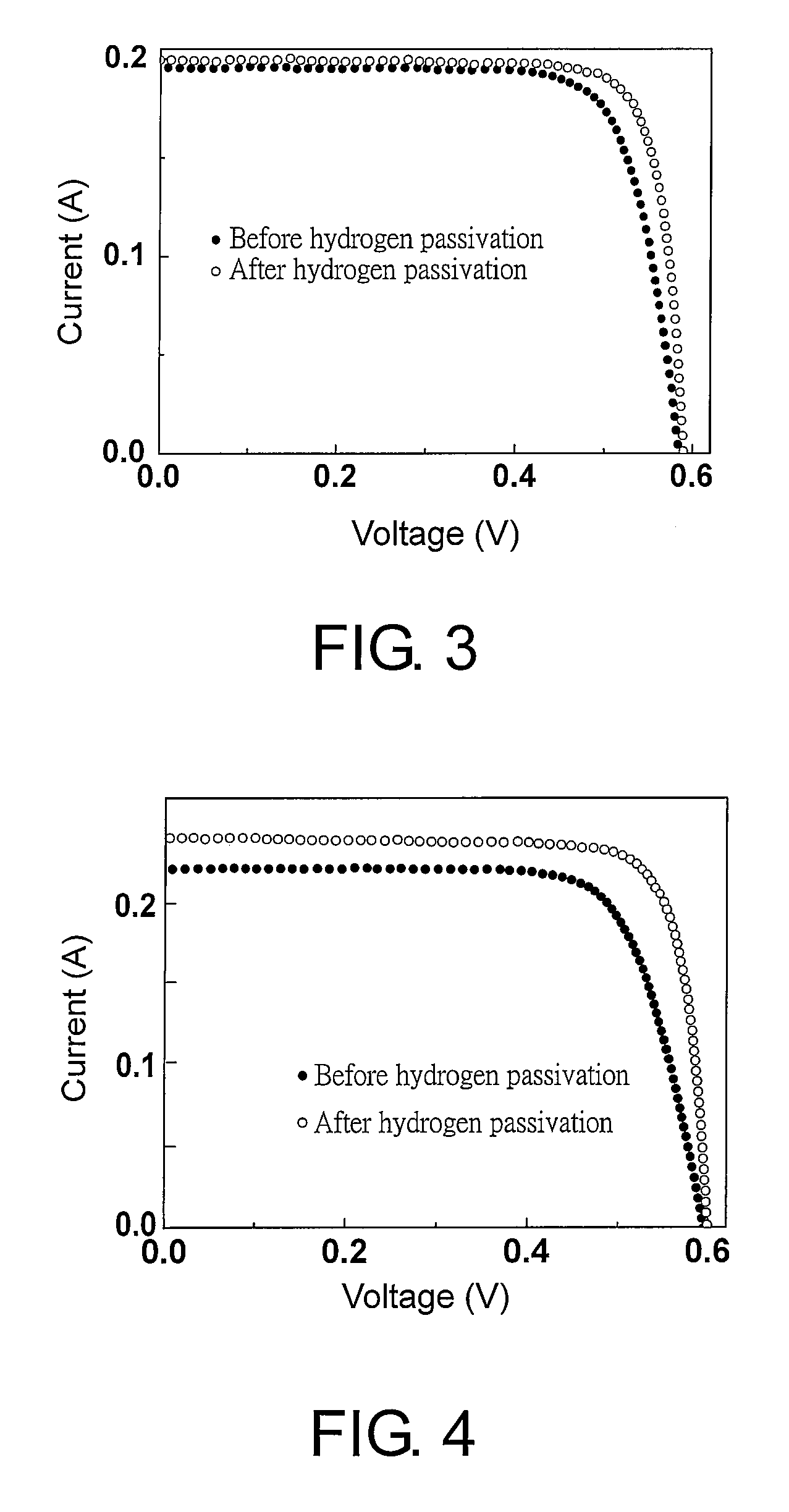

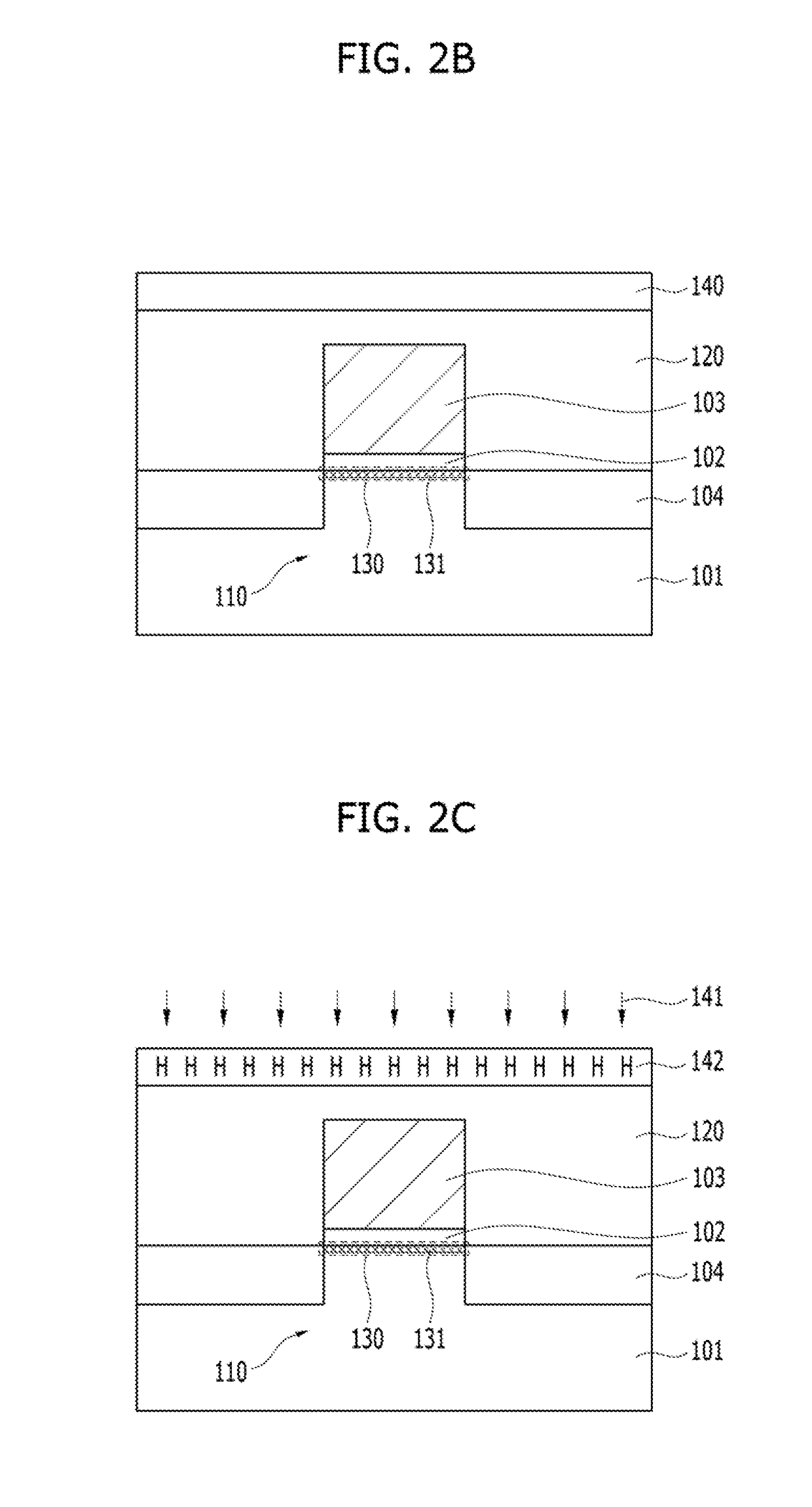

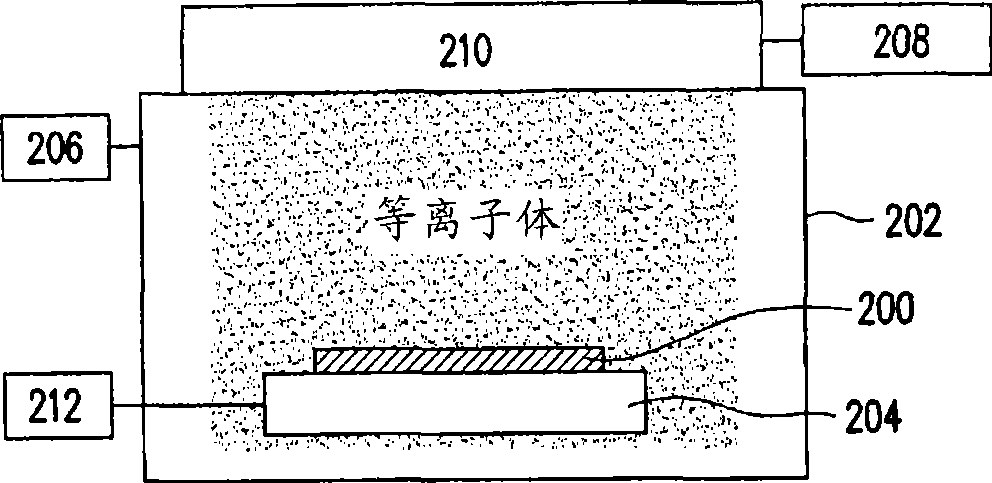

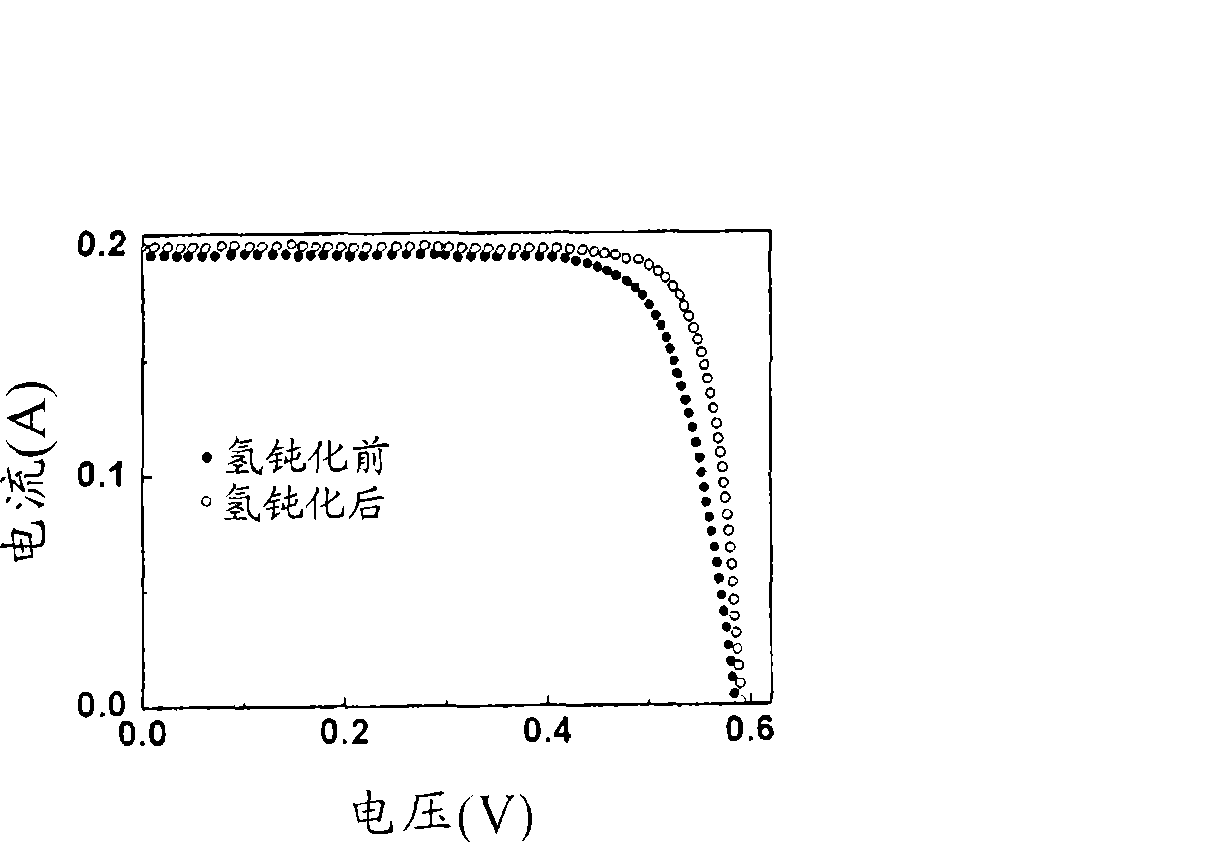

Method of fast hydrogen passivation to solar cells made of crystalline silicon

InactiveUS20090101202A1Improve performanceFast passivationFinal product manufacturePhotovoltaic energy generationCrystallographic defectHydrogen ion

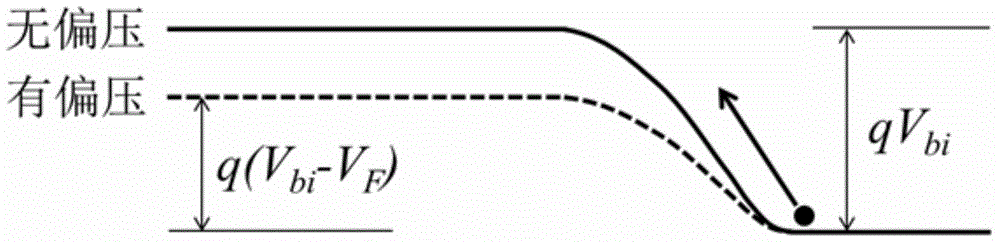

A method of improving efficiency of solar cells made of crystalline silicon, including monocrystalline silicon, multicrystalline silicon and polycrystalline silicon is provided. In the method, a negative bias pulse is applied to solar cells at a predetermined voltage, a predetermined frequency, and a predetermined pulse width while immersing the solar cells in a hydrogen plasma. Hydrogen ions are attracted and quickly implanted into the solar cells. Thus, the passivation of crystal defects in the solar cells can be realized in a short period. Meanwhile, the properties of an antireflection layer cannot be damaged as proper operating parameters are used. Consequently, the serious resistance of the solar cells can be significantly reduced and the filling factor increases as a result. Further, the short-circuit current and the open-circuit voltage can be increased. Therefore, the efficiency can be enhanced.

Owner:IND TECH RES INST +1

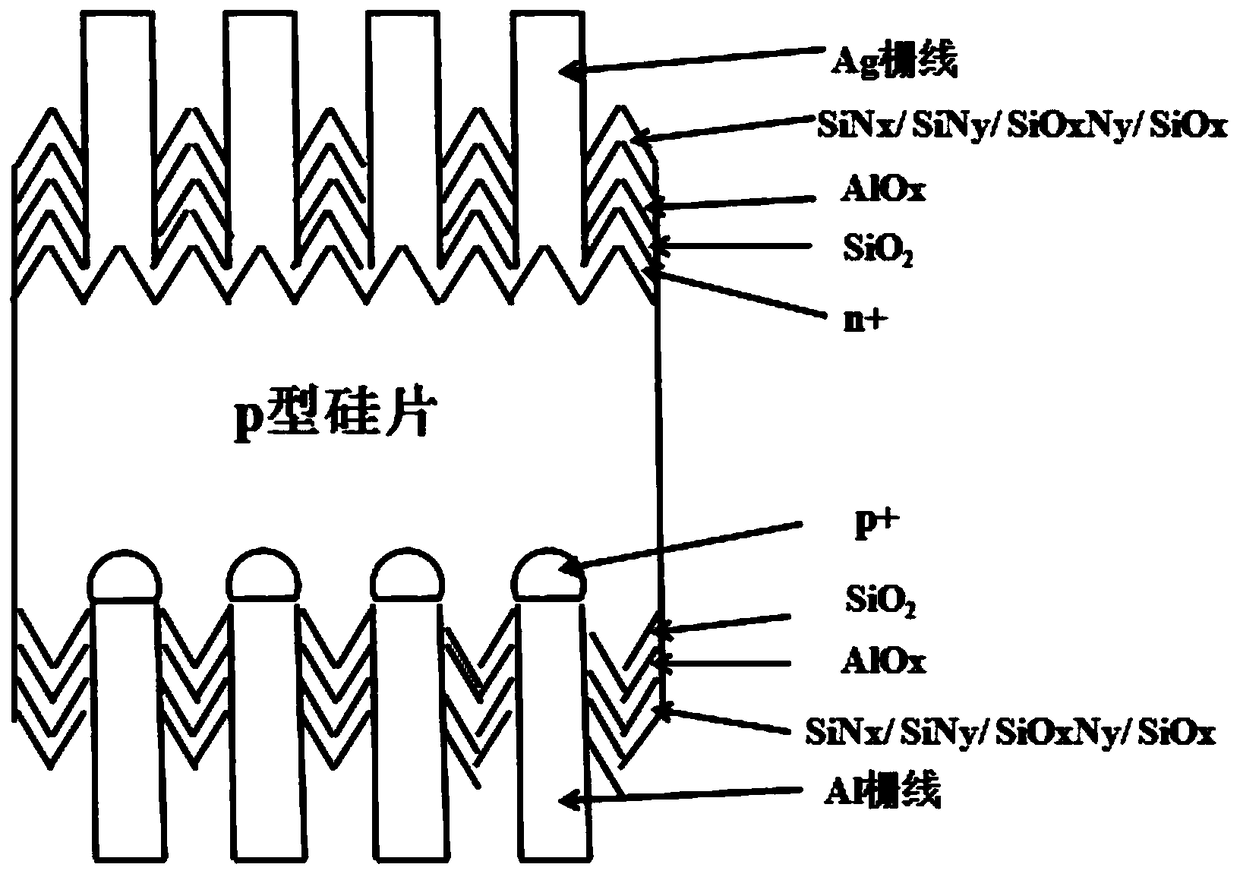

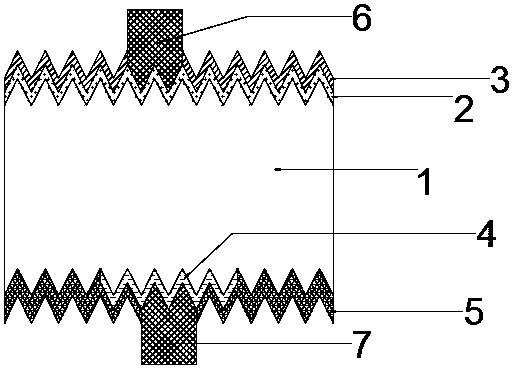

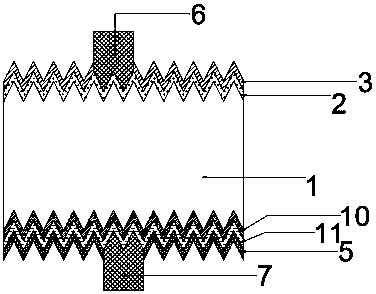

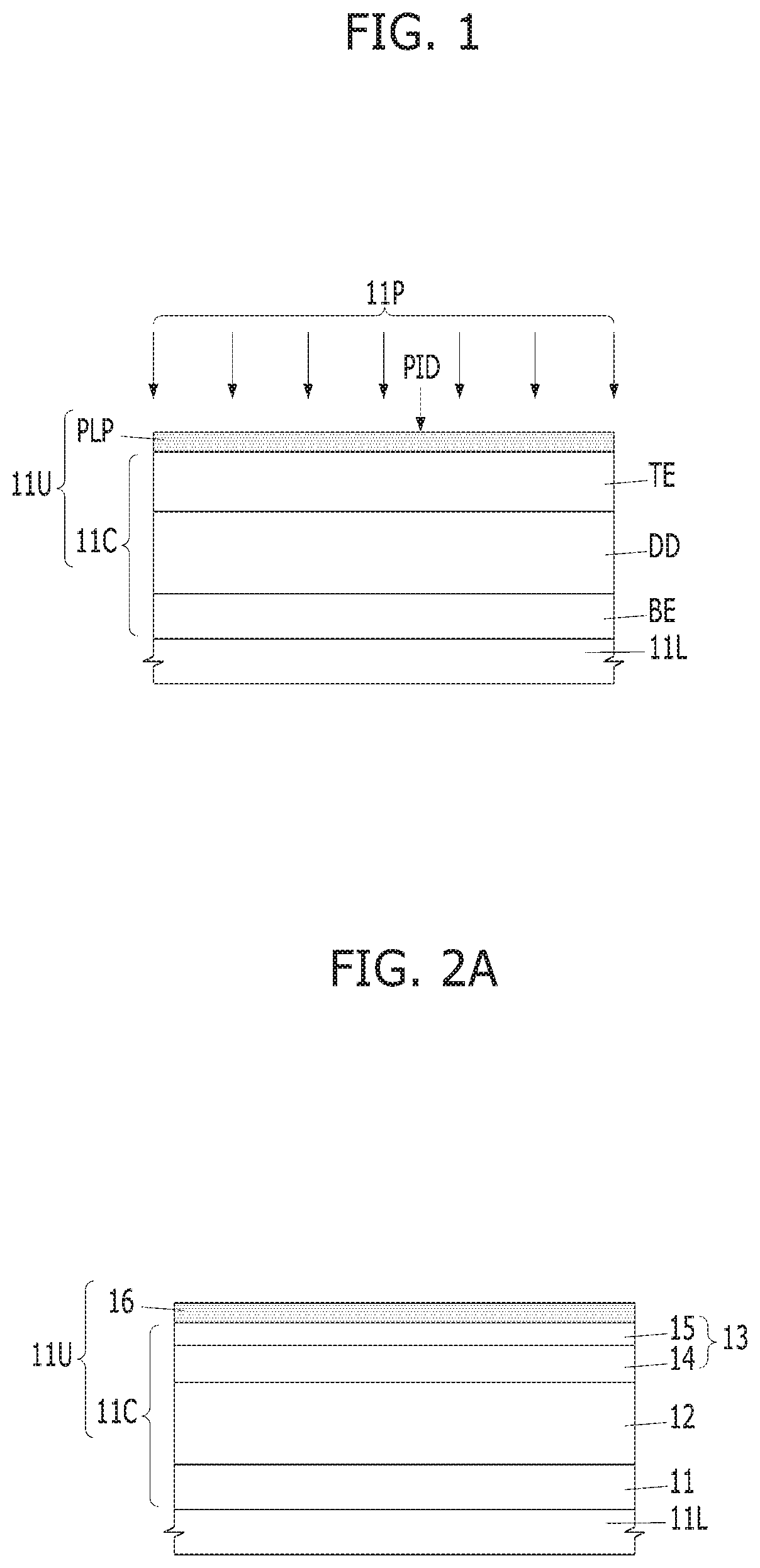

Crystalline silicon solar cell resisting to PID effect and manufacturing method thereof

InactiveCN103413840AImprove performanceImprove passivation effectFinal product manufactureSemiconductor devicesScreen printingEtching

The invention discloses a crystalline silicon solar cell resisting to a PID effect. The crystalline silicon solar cell comprises a silicon substrate and a passive film arranged on the silicon substrate. The passive film comprises a compact layer SiO2, a loose layer SiO2, a compact layer Si3N4 and a loose layer Si3N4 all of which sequentially deposit on the front surface of the silicon substrate in a laminated mode. In addition, the invention relates to a manufacturing method of the crystalline silicon solar cell. The manufacturing method comprises the steps of texture making, diffusion, etching, oxidation, PECVD, silk-screen printing and sintering test. Double SiO2 / Si3N4 films composed of an SiO2 passive film growing under the low temperature and an Si3N4 film are adopted so as to obviously improve the performance of the solar cell and enhance the passivation effect of the surface of the solar cell, wherein the Si3N4 film is formed in the PECVD mode and has the hydrogen passivation function and good antireflection effect.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

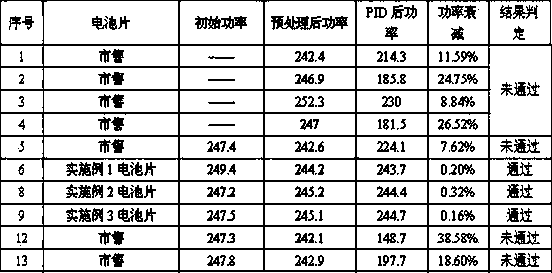

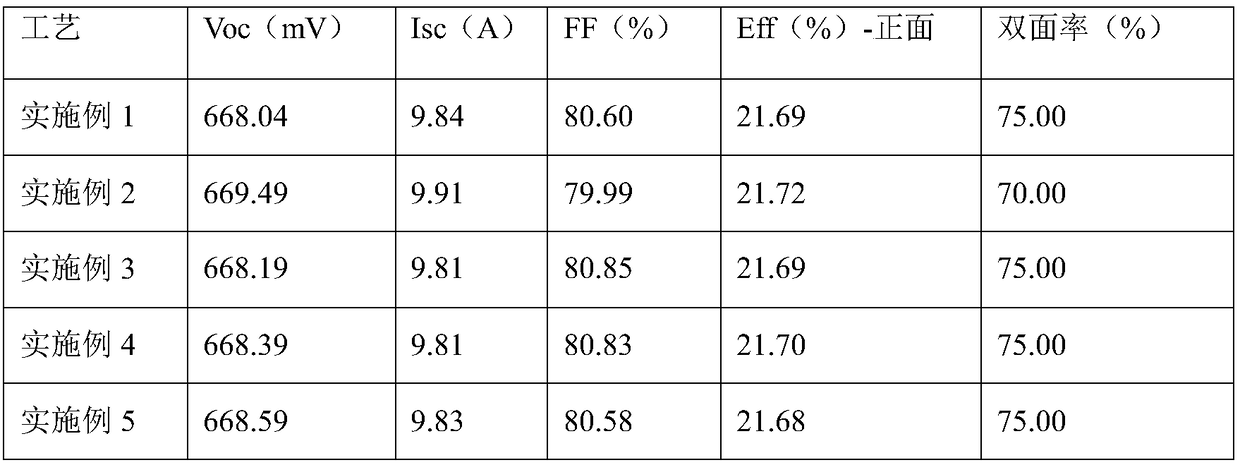

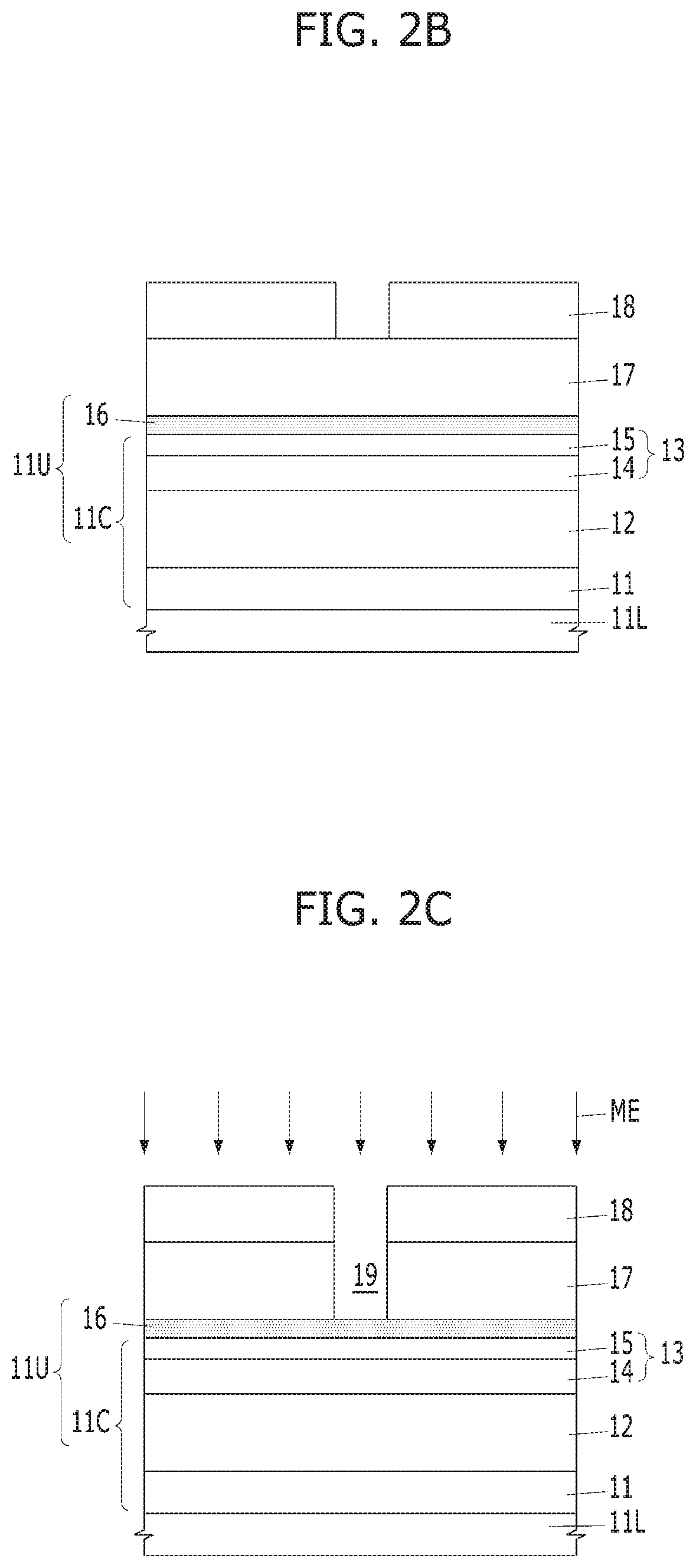

A double-sided PERC solar cell structure and a preparation process thereof

ActiveCN109087956AReduce warpageGuaranteed anti-PID performanceFinal product manufacturePhotovoltaic energy generationEngineeringDeposition process

The invention provides a novel double-sided PERC battery structure and a preparation process thereof. The front and back passivation layers of the battery are symmetrical, which greatly reduces the warpage of the double-sided battery and improves the mechanical load strength of the module. On the basis of ensuring the anti-PID performance of the battery, the laminated passivation structure adoptsa unique surface passivation layer deposition process to optimize the optical (anti-reflection effect) and electrical (hydrogen passivation effect) performance of the front and back surfaces, and to achieve the improvement and enhancement of the front conversion efficiency, double-sided ratio and anti-LID effect of the battery. The double-sided PERC battery process adopted by the invention The SiO2 and AlOx layers on the front and back sides are formed simultaneously by thermal oxidation and ALD respectively, and the SiNx / SiNy / SiOxNy / SiOx layers on the front and back sides are formed by PECVDdeposition respectively. The deposition order of the front and back sides can be adjusted.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

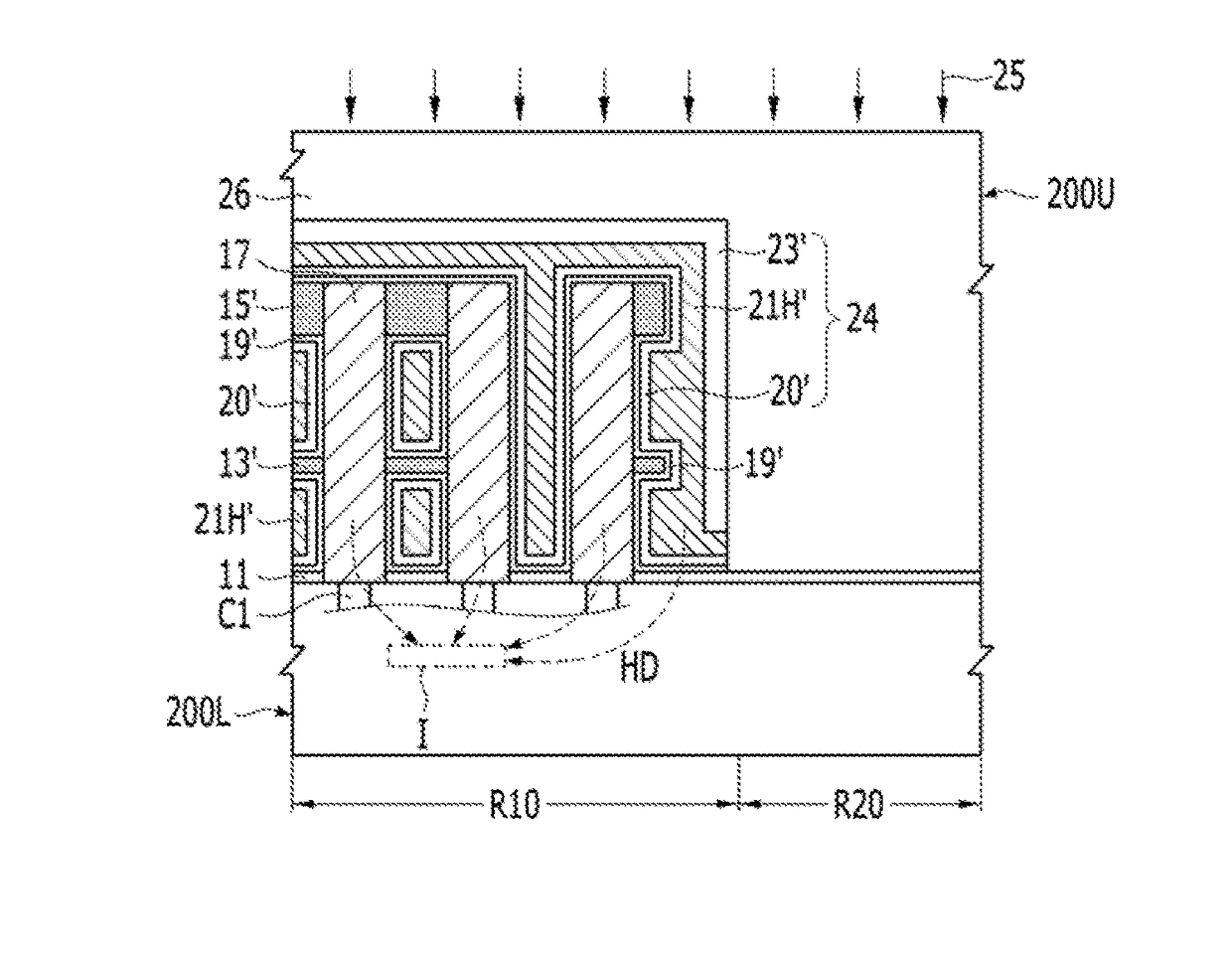

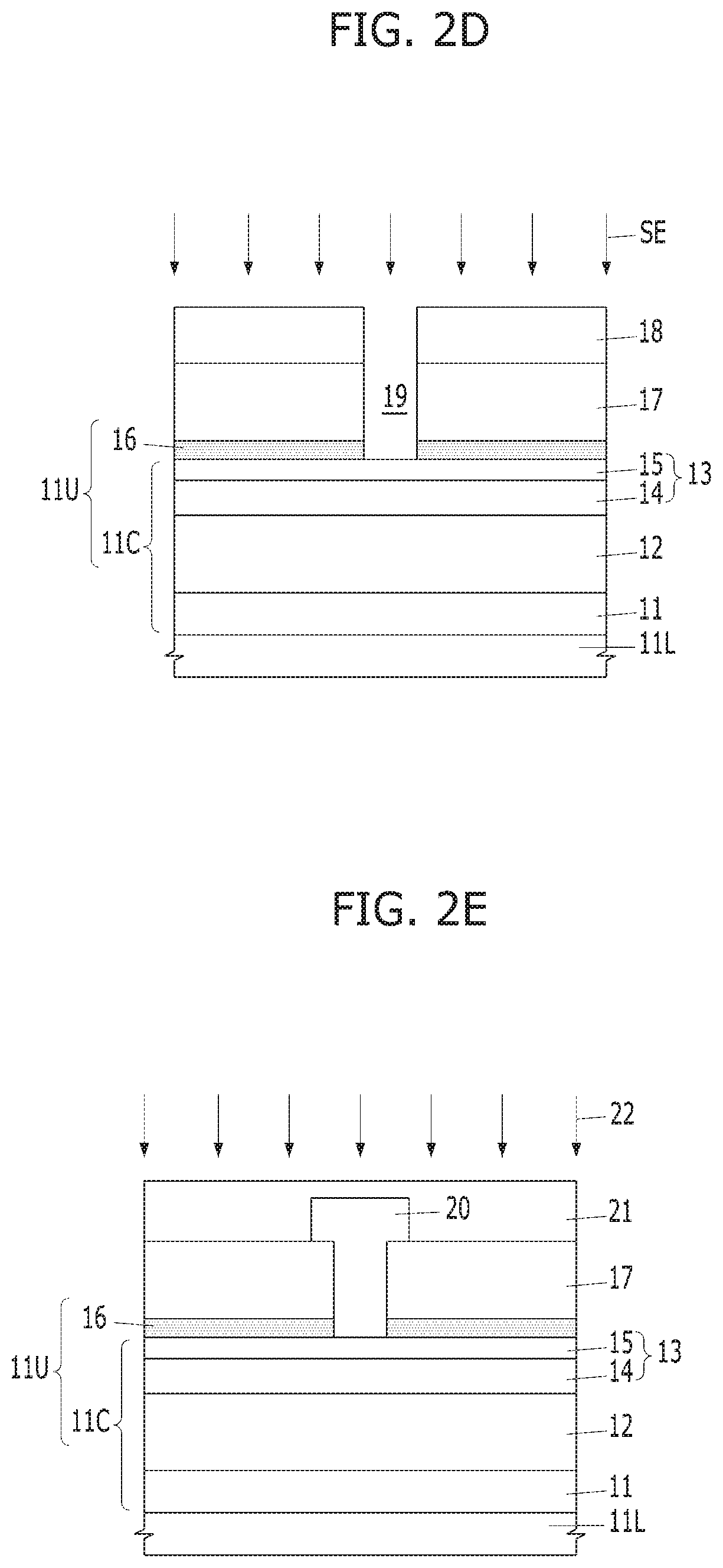

Semiconductor device and method for fabricating the same

ActiveUS20180175042A1Without deteriorationTransistorSolid-state devicesPower semiconductor deviceSemiconductor

A method for fabricating a semiconductor device includes: forming a transistor in a semiconductor substrate; forming a capacitor including a hydrogen-containing top electrode over the transistor; and performing an annealing process for hydrogen passivation after the capacitor is formed.

Owner:SK HYNIX INC

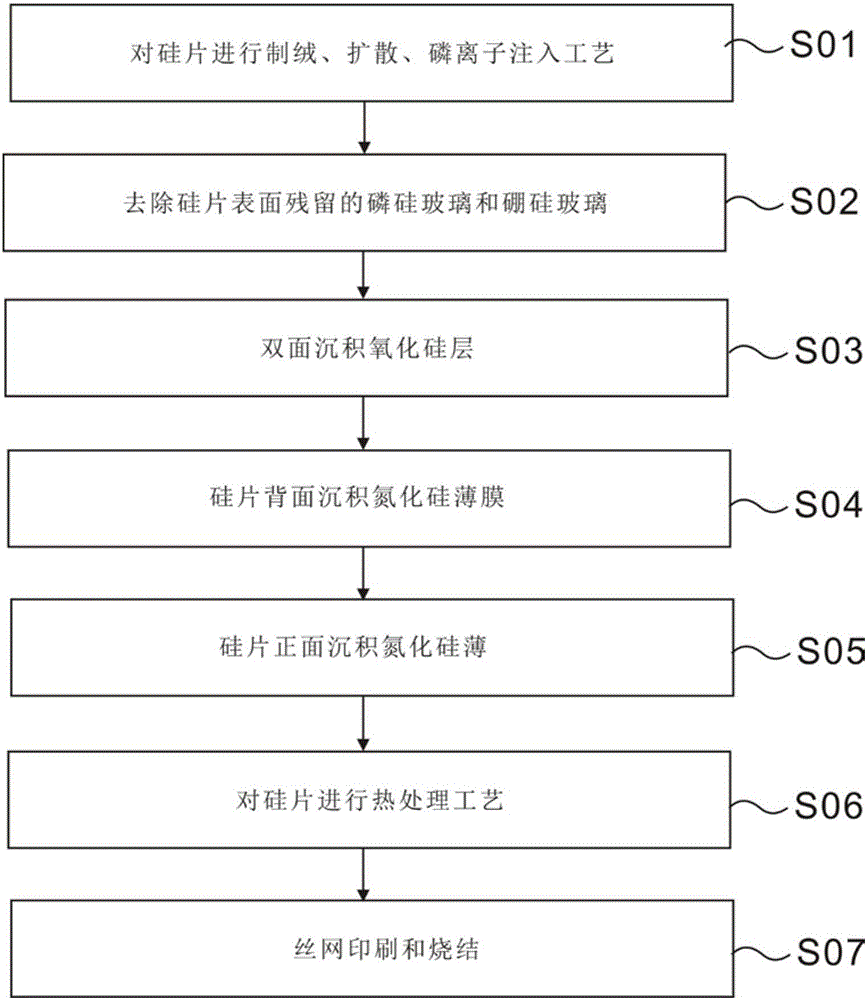

Preparation method of passivated emitter and rear side cell (PERC) and passivated emitter and rear total diffused (PERT) solar cells

InactiveCN105097961AIncrease the open circuit voltageIncrease the open circuit voltage by 10-15mV, the battery efficiencyPhotovoltaic energy generationSemiconductor devicesProduction lineCharge carrier

The invention discloses a preparation method of passivated emitter and rear side cell (PERC) and passivated emitter and rear total diffused (PERT) solar cells, and belongs to the technical field of silicon solar cells. A heat treatment technology is added on the basis of an existing technology, so that the hydrogen passivation effect of a silicon nitride film is further improved; carrier recombination is lowered; the electrical properties of the solar cells are improved; the open-circuit voltage of the cells is improved by 10-15mV; and the efficiency of the cells is improved by 0.3%-0.5%. In addition, sintering furnace equipment on an existing enterprise production line is fully utilized by a fast heat treatment technology; the equipment investment is fully reduced; the manufacturing cost of the cells is not increased; and the method disclosed by the invention is simple and feasible, easy to realize, relatively low in cost, and suitable for popularization and application.

Owner:北京飞行博达电子有限公司

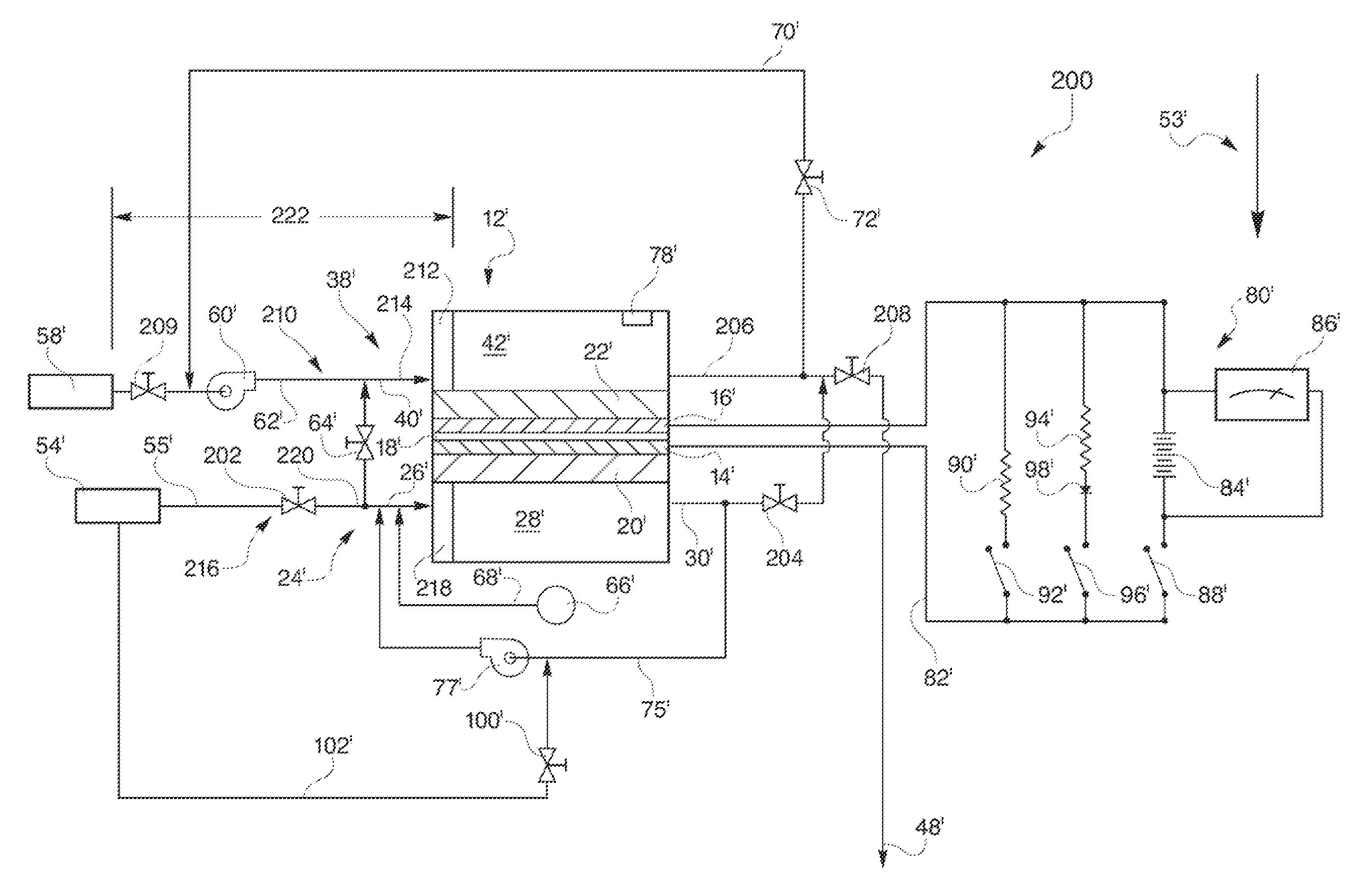

Hydrogen passivation shut down system for a fuel cell power plant

ActiveUS20090214906A1Move quicklyAvoiding inefficient loss of hydrogenReactant parameters controlCell component detailsPower stationNuclear engineering

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10, 200). During shut down of the plant (10, 200), hydrogen fuel is permitted to transfer between an anode flow path (24, 24′) and a cathode flow path (38, 38′). A passive hydrogen bleed line (202) permits passage of a smallest amount of hydrogen into the fuel cell (12′) necessary to maintain the fuel cell (12′) in a passive state. A diffusion media (204) may be secured in fluid communication with the bleed line (202) to maintain a constant, slow rate of diffusion of the hydrogen into the fuel cell (12′) despite varying pressure differentials between the shutdown fuel cell (12′) and ambient atmosphere adjacent the cell (12′).

Owner:INT FUEL CELLS +1

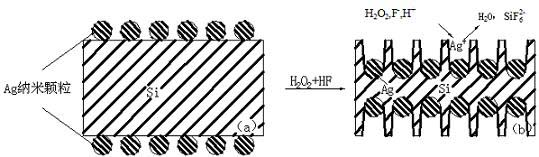

Method for preparing two-sided silicon nano-wire array

InactiveCN102556953AImprove efficiencyEasy to operateDecorative surface effectsChemical vapor deposition coatingChemical platingSilicon nanowires

The invention relates to a silicon nano-wire, in particular to a method for preparing a two-sided silicon nano-wire array. According to the method, a silicon surface is etched by combining the corrosivity of a solution and the catalysis of metal ions at low temperature to form the silicon nano-wire array. The method comprises the following steps of: cleaning the silicon surface; passivating the surface of a silicon wafer by using hydrogen; covering a uniform layer of silver nanoparticle network on each of two surfaces of the silicon wafer by using a chemical plating method; preparing the two-sided silicon nano-wire array; and removing excessive silver nanoparticles. The method has the advantages that: expensive equipment and high-temperature environment are avoided in the preparation process, and the method is easy to operate and control, low in cost and high in efficiency, and can be applied to large-scale industrial production.

Owner:JIANGSU UNIV

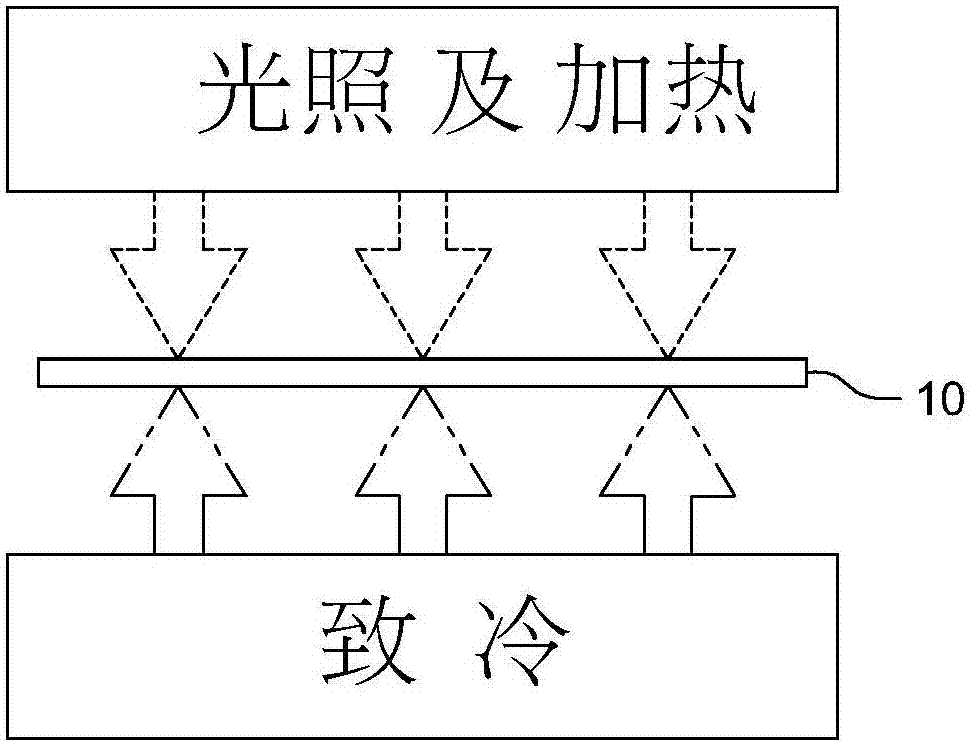

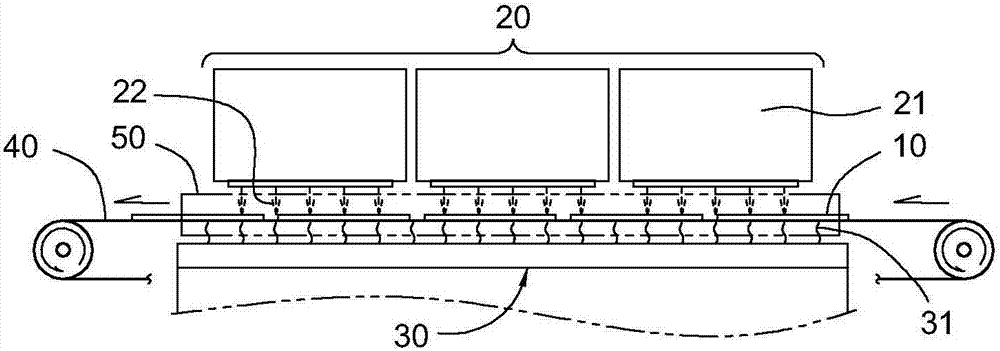

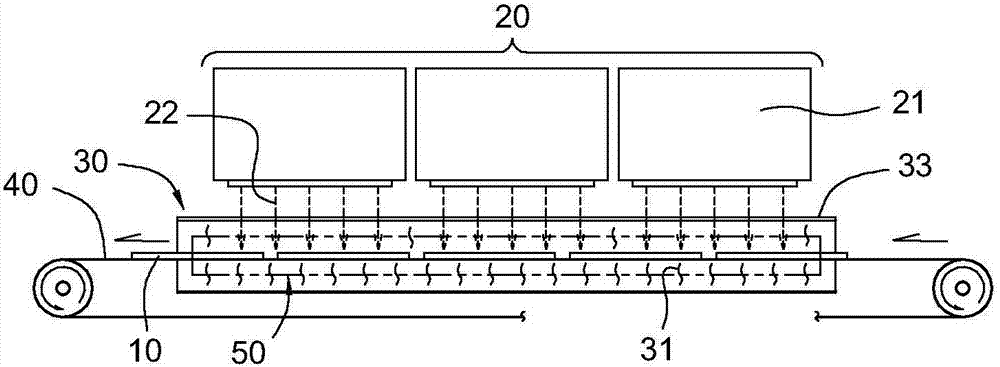

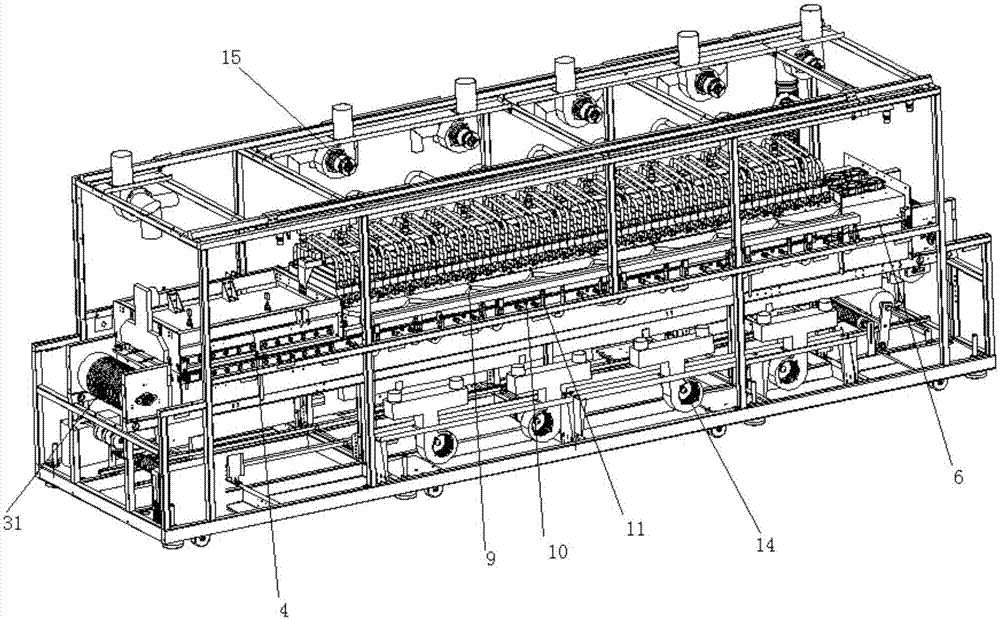

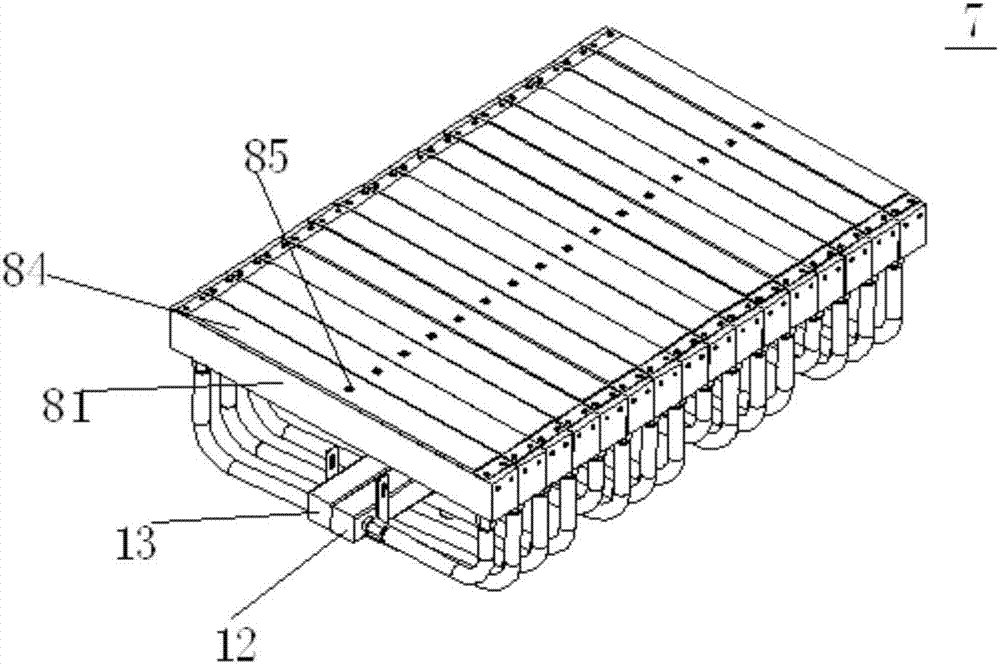

Hydrogen passivation processing method and device for solar cell

ActiveCN107546296AAvoid harmReduce the chance of light decayFinal product manufactureSemiconductor devicesSolar cellCooling medium

The invention discloses a hydrogen passivation processing method for a solar cell, which comprises the steps of setting the illumination intensity of a light source, and irradiating the solar cell ina suspended manner by using the light source; heating the solar cell by radiation heat generated by the light source; and cooling the solar cell by using a cooling medium, and enabling the solar cellto be maintained at a constant temperature, wherein irradiation, heating and cooling are performed on the solar cell simultaneously, so that the appropriateness rate of the solar cell in the hydrogenpassivation processing process is improved. Accordingly, the invention further provides a hydrogen passivation processing device for implementing the method.

Owner:ASIA NEO TECH IND

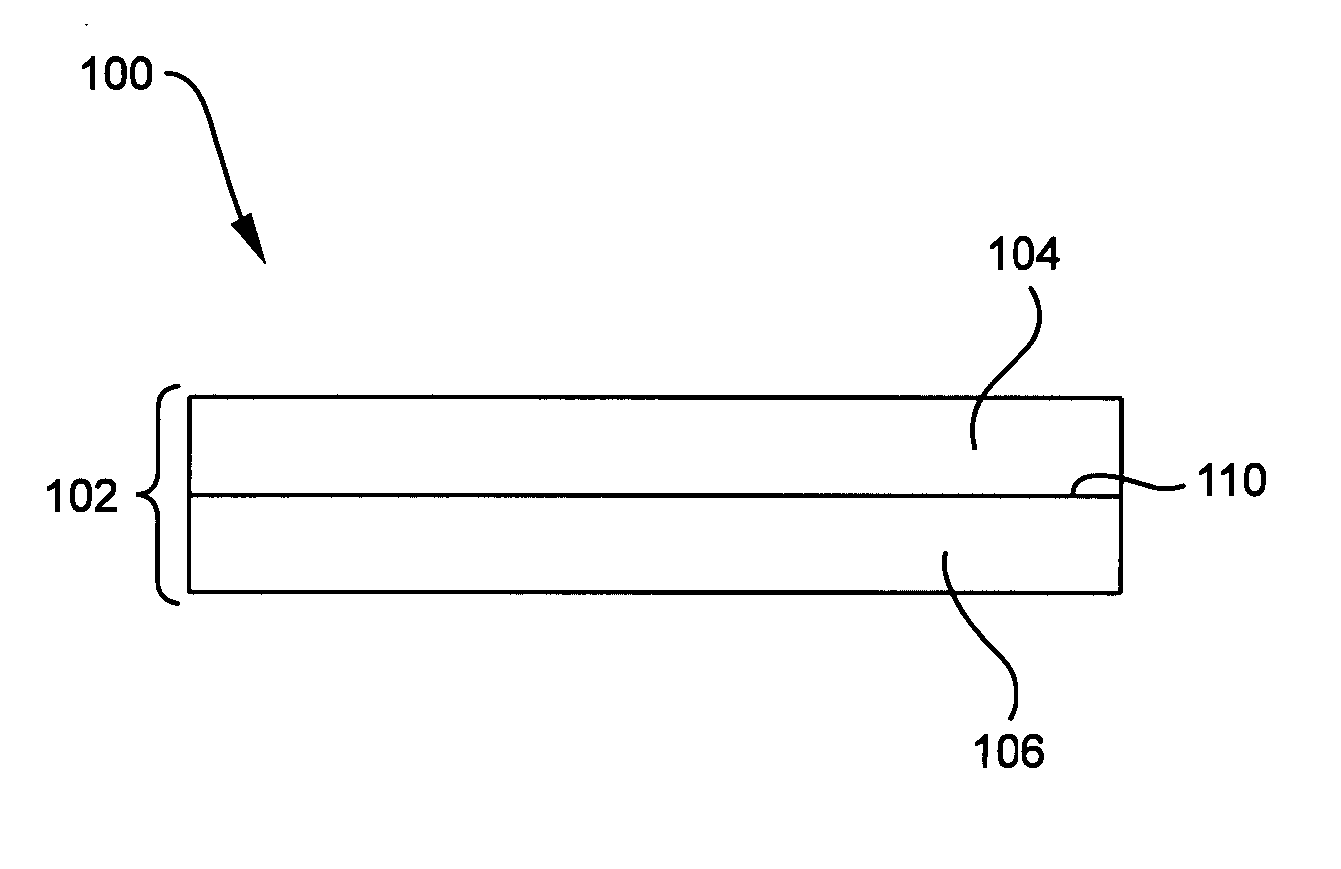

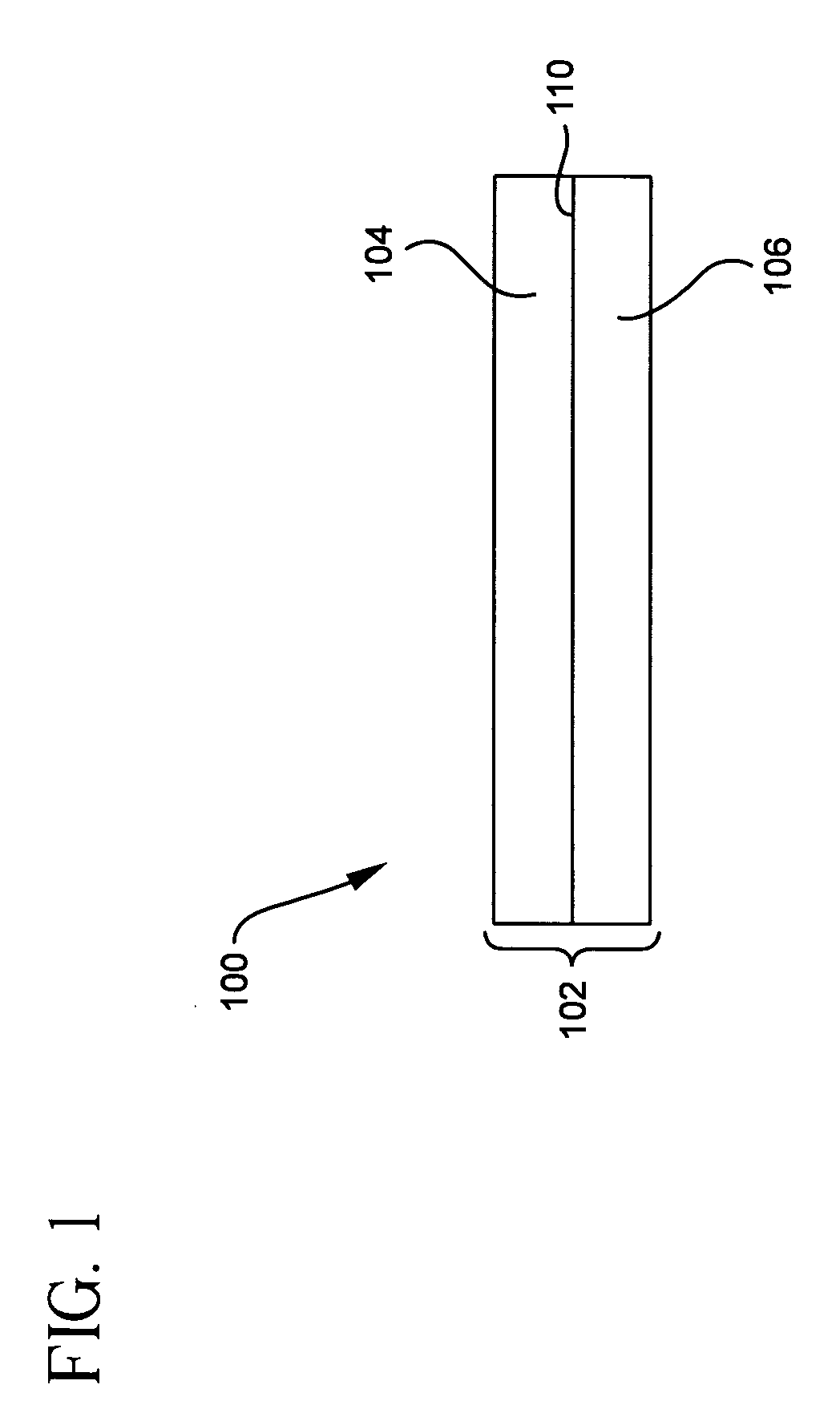

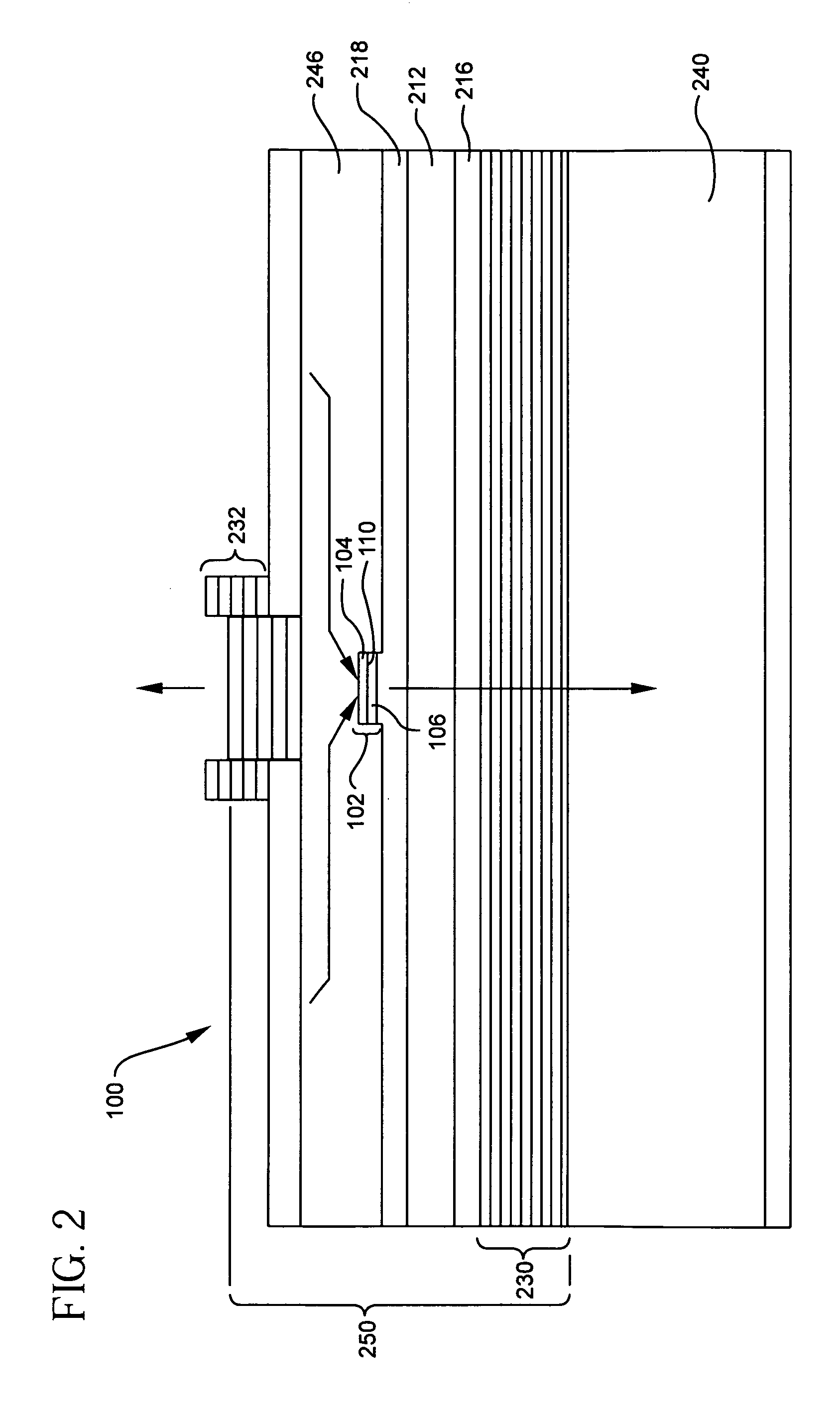

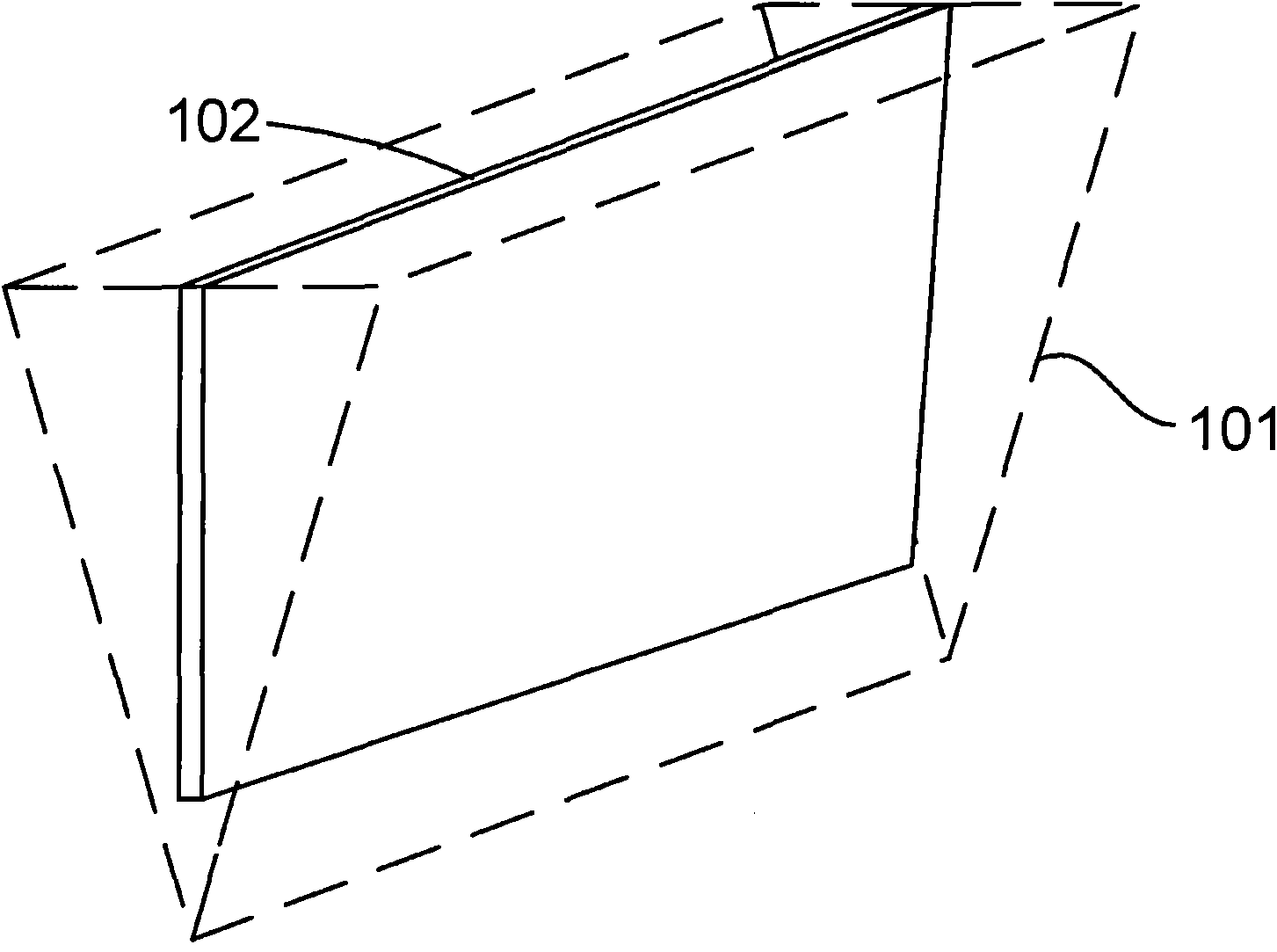

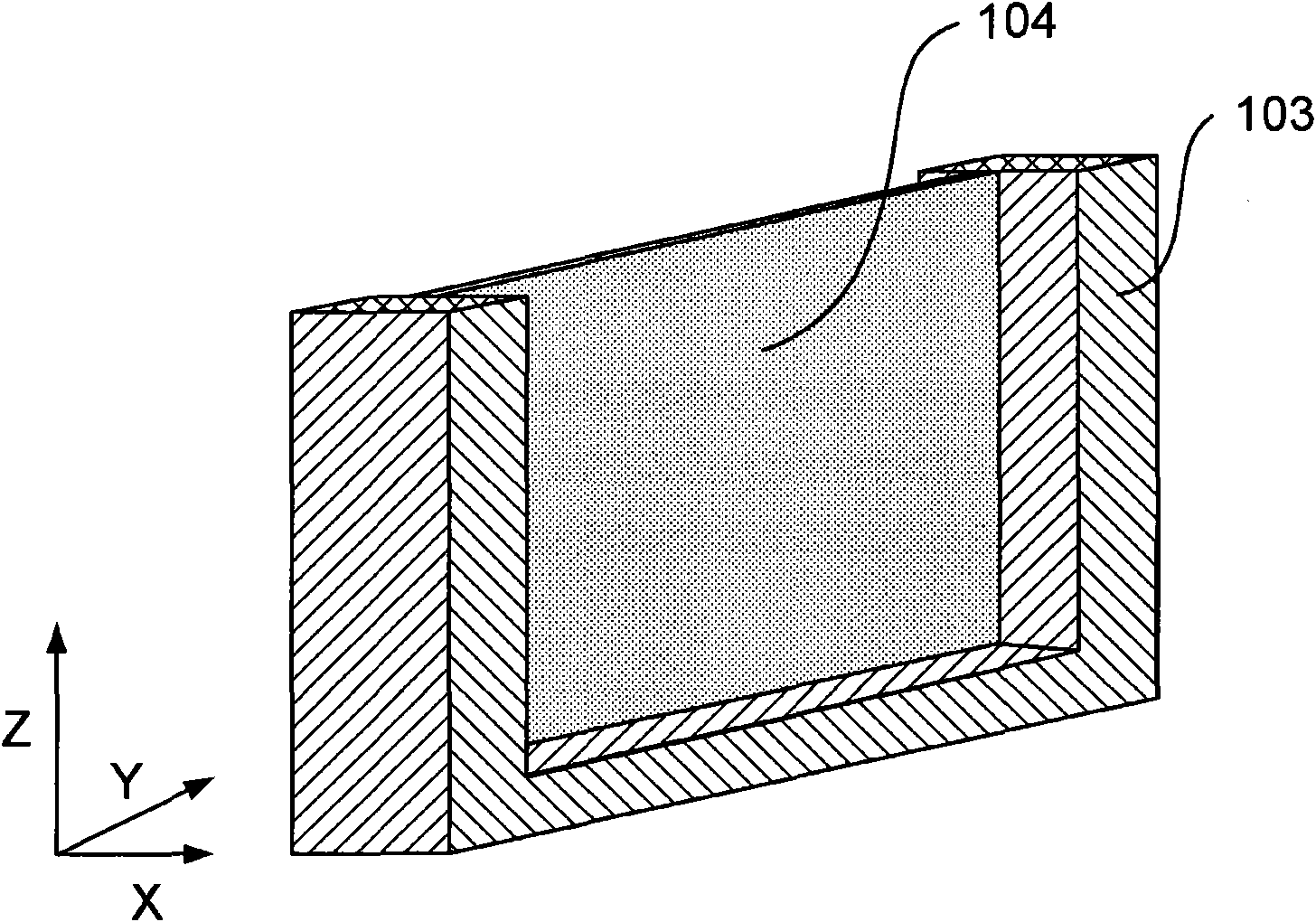

Tunnel junctions for long-wavelength vcsels

ActiveUS20050253164A1Good junctionDeleterious effectLaser detailsLaser active region structureIndiumSemiconductor materials

A tunnel junction device (102) with minimal hydrogen passivation of acceptors includes a p-type tunnel junction layer (106) of a first semiconductor material doped with carbon. The first semiconductor material includes aluminum, gallium, arsenic and antimony. An n-type tunnel junction layer (104) of a second semiconductor material includes indium, gallium, arsenic and one of aluminum and phosphorous. The junction between the p-type and an-type tunnel junction layers forms a tunnel junction (110).

Owner:THORLABS QUANTUM ELECTRONICS

Fabrication method of n-type solar cell

InactiveCN107863417ABroaden the sintering process windowReduce contact resistanceFinal product manufacturePhotovoltaic energy generationElectrical resistance and conductanceBack surface field

The invention provides a fabrication method of an n-type solar cell. The fabrication method comprises the steps of performing surface texturing and cleaning on an n-type silicon substrate; fabricatingan emitter on a front surface of the silicon substrate; performing insulation processing; fabricating a back-surface field and a back-surface passivation layer; fabricating a front-surface passivation and anti-reflection film; patterning the front surface and a back surface to form an electrode paste layer containing a conductive constituent; performing first thermal treatment process; performingsecond thermal treatment process; and comparing the second thermal treatment process with the first thermal treatment process. By the thermal treatment process for twice, the contact resistance and the series resistance of a battery electrode can be reduced, the sintering temperature can be reduced, the influence of high-temperature sintering on the emitter of the battery and passivation performance of a surface field is reduced, and the battery sintering process window can be expanded; and by thermal treatment for twice, the hydrogen passivation performance of a passivation film can be improved, the integral electrical performance conversion efficiency is improved, so that optimal passivation performance and optimal contact performance are simultaneously achieved.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

Method of fast hydrogen passivation to solar cells made of crystalline silicon

ActiveCN101414648AInhibit deteriorationReduce processing timeFinal product manufacturePhotovoltaic energy generationSilicon solar cellHydrogen ion

A method of improving efficiency of solar cells made of crystalline silicon, including monocrystalline silicon, multicrystalline silicon and polycrystalline silicon is provided. In the method, a negative bias pulse is applied to solar cells at a predetermined voltage, a predetermined frequency, and a predetermined pulse width while immersing the solar cells in a hydrogen plasma. Hydrogen ions are attracted and quickly implanted into the solar cells. Thus, the passivation of crystal defects in the solar cells can be realized in a short period. Meanwhile, the properties of an antireflection layer cannot be damaged as proper operating parameters are used. Consequently, the serious resistance of the solar cells can be significantly reduced and the filling factor increases as a result. Further, the short-circuit current and the open-circuit voltage can be increased. Therefore, the efficiency can be enhanced.

Owner:IND TECH RES INST

Heterojunction battery layered hydrogen passivation method, hydrogen passivation device, battery, battery module and solar power station

InactiveCN110459651AReduce surface recombination ratePromote passivationFinal product manufacturePhotovoltaic energy generationHeterojunctionHigh concentration

The invention discloses a heterojunction battery layered hydrogen passivation method, a hydrogen passivation device, a battery, a battery module and a solar power station. According to the hydrogen passivation method, at least one time of hydrogen passivation treatment is carried out on the semi-finished product of the heterojunction battery during the heterojunction battery preparation process, and in the case of hydrogen passivation treatment, the semi-finished product of the heterojunction battery is heated and irradiated by a light source. The heterojunction battery layered hydrogen passivation method adopts the hydrogen passivation process during the heterojunction battery preparation process, high-concentration hydrogen atoms can be diffused to the interface of a silicon crystal, a silicon dangling bond on the interface can be better passivated, and the surface recombination rate of the silicon crystal is significantly reduced.

Owner:SUZHOU MAIZHENG TECH CO LTD

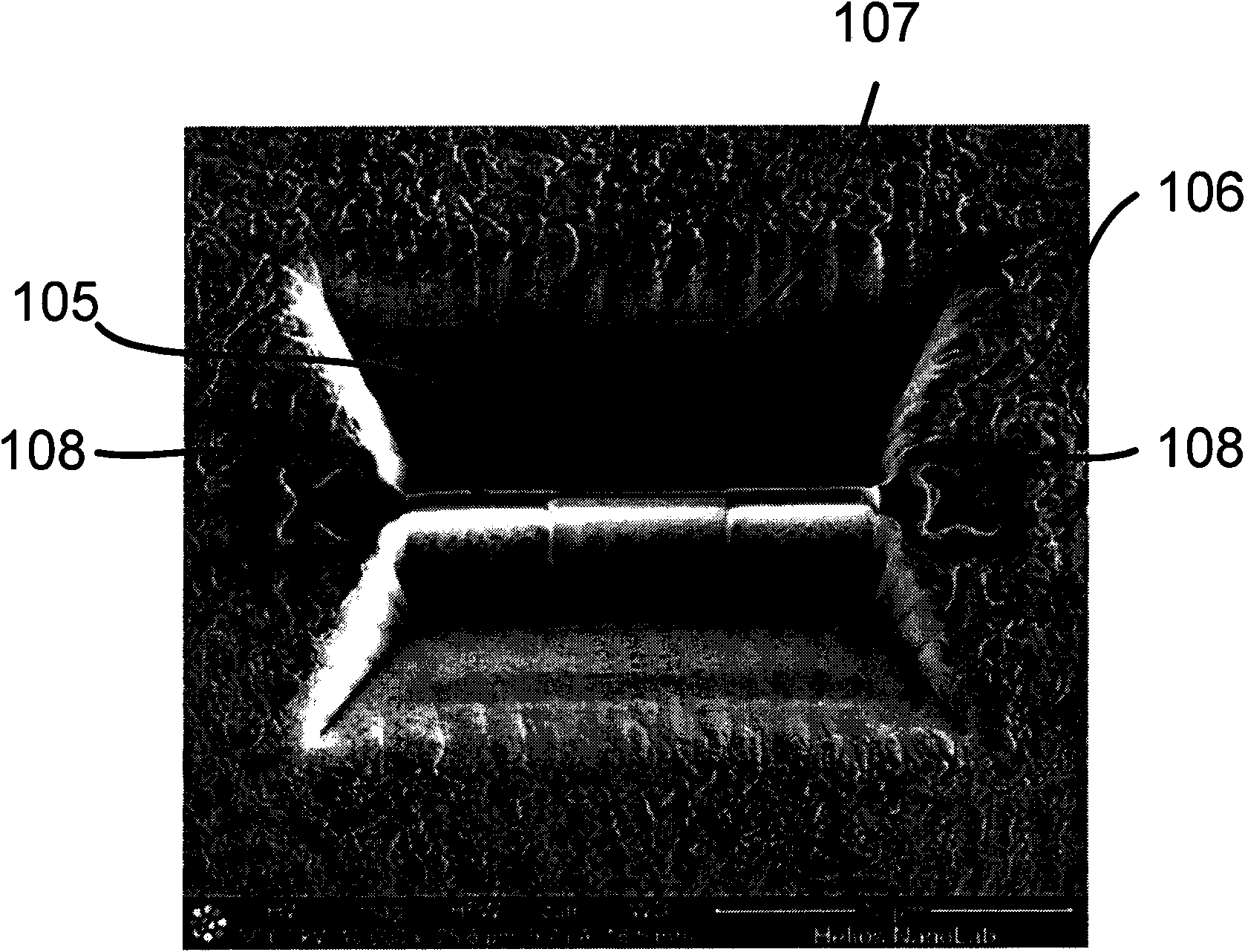

Method of machining a work piece with a focused particle beam

InactiveCN101644644AElectric discharge tubesPreparing sample for investigationParticle beamAtomic physics

The invention relates to a method of machining a work piece with a focused particle beam. The invention relates to a method for producing high-quality samples for e.g. TEM inspection. When thinning samples with e.g. a Focused Ion Beam apparatus (FIB), the sample often oxidizes when taken from the FIB due to the exposure to air. This results in low-quality samples, that may be unfit for further analysis. By forming a passivation layer, preferably a hydrogen passivation layer, on the sample in situ , that is: before taking the sample from the FIB, high quality samples are obtained.

Owner:FEI CO

Hydrogen passivation shut down system for a fuel cell power plant

ActiveUS8142950B2Increase entryRisk minimizationReactant parameters controlFuel cells groupingExhaust valvePower station

The invention is a hydrogen passivation shut down system for a fuel cell power plant (10, 200). During shut down of the plant (10, 200), hydrogen fuel is permitted to transfer between an anode flow path (24, 24′) and a cathode flow path (38, 38′). A controlled-oxidant flow device (209) near an oxygen source (58′) permits a minimal amount of atmospheric oxygen to enter the power plant (200) during shut down to equalize pressure between ambient atmosphere and the flow paths (24′, 28′) and to keep limited atmospheric oxygen entering the power plant (200) through the device (209) as far as possible from fuel cell flow fields (28′, 42′). A non-leaking hydrogen inlet valve (202), a non-leaking cathode exhaust valve (208), and a combined oxidant and fuel exhaust line (206) also minimize penetration of oxygen into the shut down power plant (200).

Owner:UNITED TECH CORP +1

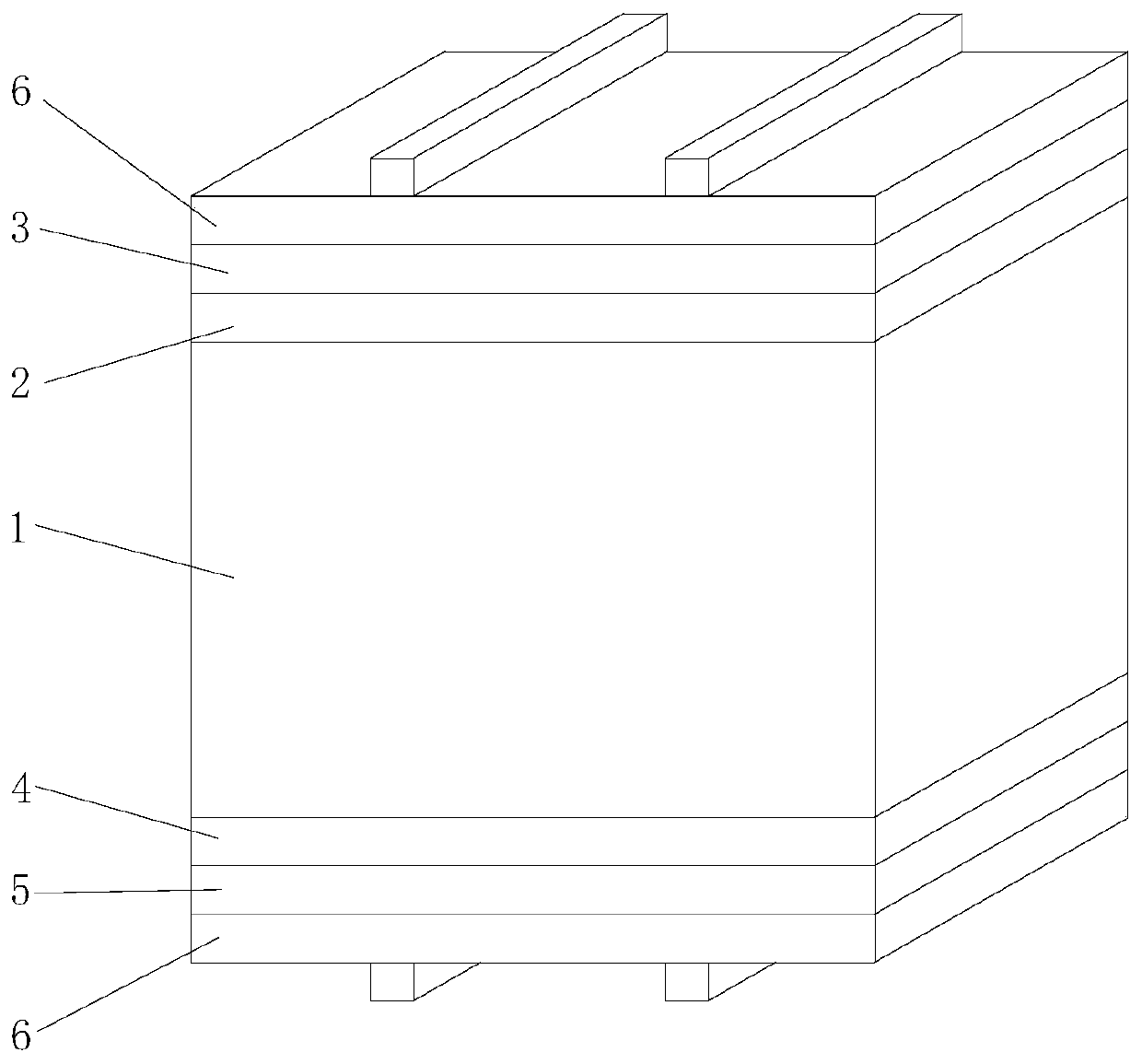

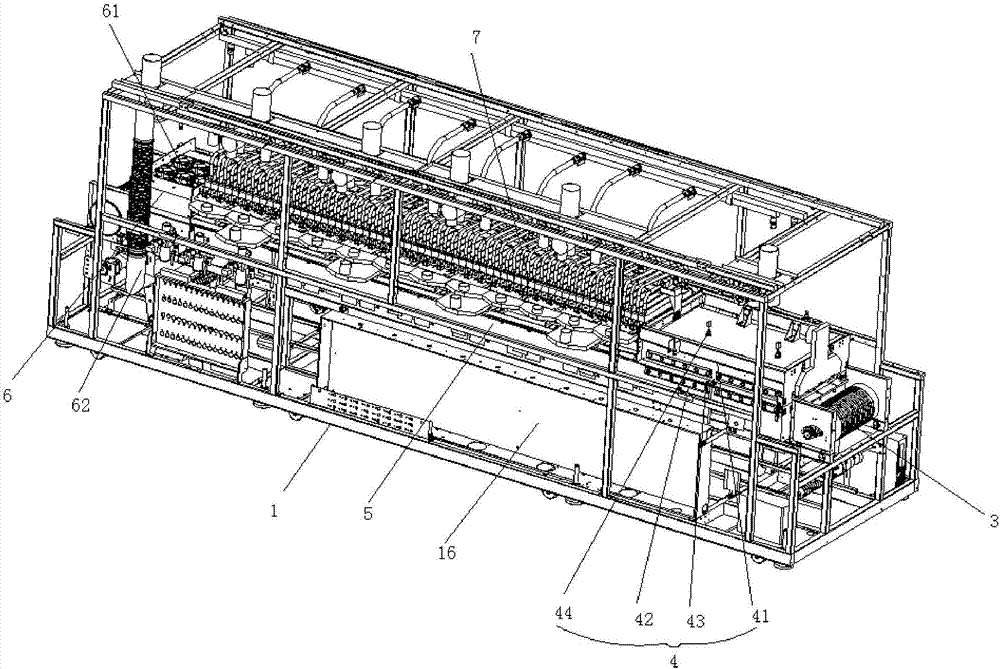

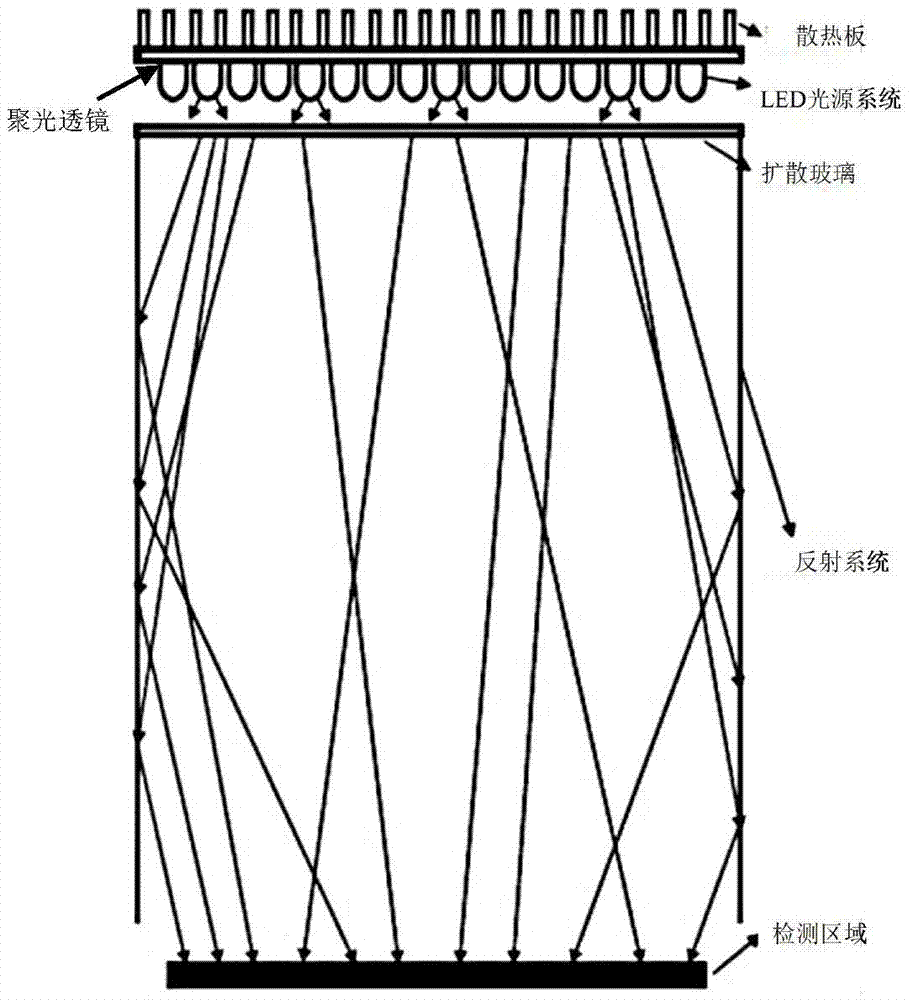

Luminous decay resistant furnace

ActiveCN107046081AAvoid light decayFinal product manufactureSemiconductor devicesLuminous intensityEngineering

The invention discloses a luminous decay resistant furnace, which comprises a furnace bracket and a plurality of constant-current sources, wherein a conveying device for conveying wafers circularly is arranged on the furnace bracket, the furnace bracket is sequentially provided with a preheating region, a luminous region and a cooling region along a direction from a charging end to a discharging end of the conveying device, a plurality of groups of LED lamp luminous modules which are arranged side by side are positioned just above the luminous region, each group of LED lamp luminous modules is composed of a plurality of LED lamp strips having a water cooling function, and each LED lamp strip is controlled by one of the constant-current sources independently. According to the luminous decay resistant furnace, one constant-current source controls one LED lamp strip independently, so that the LED lamp strip has ultra-high luminous intensity, the heating temperature thereof can be controlled, and the LED lamp strip operates at constant temperature. In the process that the wafers enter the luminous decay resistant furnace, the wafers are subjected to strong light exposure by means of the plurality of groups of LED lamp luminous modules, and the hydrogen passivation effect of the wafers is obvious.

Owner:FOLUNGWIN AUTOMATIC EQUIP CO LTD

Semiconductor device and method for fabricating the same

ActiveUS20200212169A1Improve reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A method for fabricating a semiconductor device includes forming an upper structure in which a bottom electrode, a dielectric layer, a top electrode and a plasma protection layer are sequentially stacked on a lower structure, exposing the upper structure to a plasma treatment, and exposing the plasma-treated upper structure and the lower structure to a hydrogen passivation process.

Owner:SK HYNIX INC

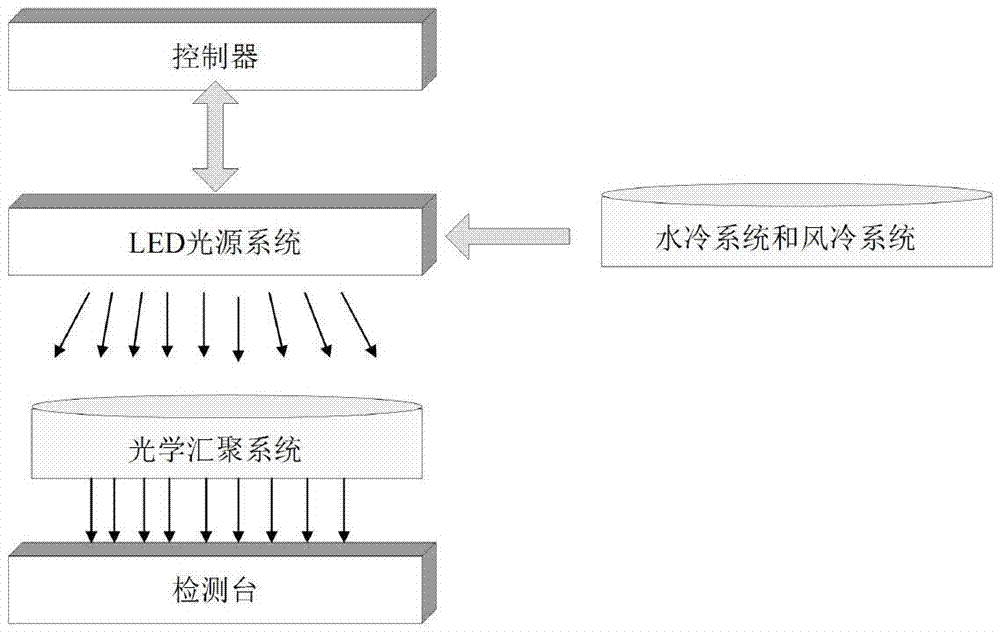

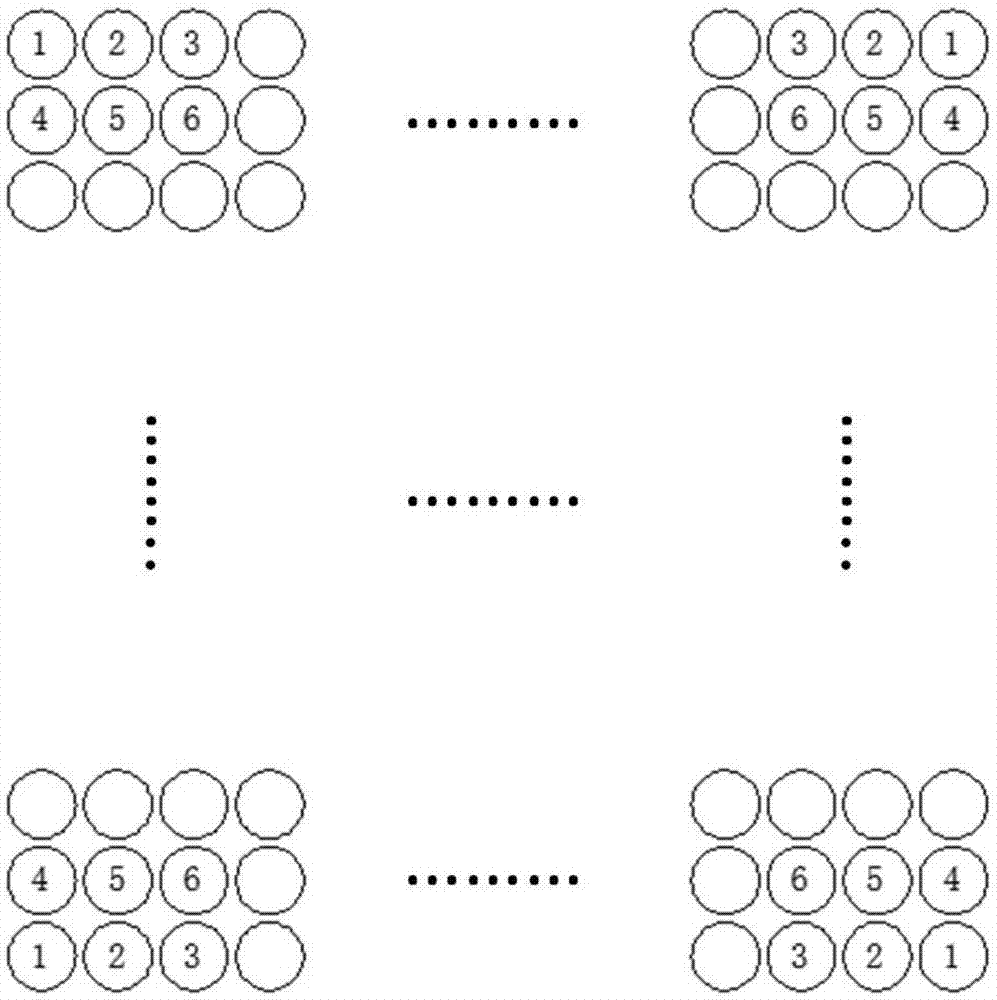

Photo-induced hydrogen passivation and defect repair device for LED (Light Emitting Diode) silicon solar cell

ActiveCN105449044AReduce compoundingImprove performanceFinal product manufacturePhotovoltaic energy generationLattice defectsDefect repair

The invention discloses a photo-induced hydrogen passivation and defect repair device for an LED (Light Emitting Diode) silicon solar cell. The device comprises a test bed for placing the silicon solar cell and keeping the temperature constant, and further comprises an LED light source system, an optical convergence system and a controller, wherein the LED light source system comprises an LED array for emitting light; the optical convergence system is arranged on a light emitting path of the LED array, and is used for converging the light emitted by the LED array to a detection area of the test bed; and the controller is used for modifying the parameters of the light emitted by the LED array as well as analyzing and calculating the passivation and defect parameters of the silicon solar cell. The device improves the conversion efficiency of the solar cell by passivating impurity defects in crystalline silicon, passivating a silicon material and repairing lattice defects such as dislocation in a polycrystalline silicon material.

Owner:JIANGNAN UNIV

Amorphous silicon passivation N-type back contact battery and manufacturing method thereof

InactiveCN102738288AIncrease short circuit currentIncrease productivityPhotovoltaic energy generationSemiconductor devicesAmorphous siliconP type doping

The invention relates to an amorphous silicon passivation N-type back contact battery and a manufacturing method thereof. The battery comprises an N-type silicon wafer substrate, a P-type doping layer and an N-type amorphous silicon layer are arranged on the back of the N-type silicon wafer substrate, and electrodes are arranged on the P-type doping layer and the N-type amorphous silicon layer. The manufacturing method of the battery comprises steps of forming the P-type doping layer on the back of the N-type silicon wafer substrate in a diffusion manner through a mask mode; forming a groove in the back of a diffused silicon wafer; and depositing the N-type amorphous silicon layer in the groove through a mask mode. The P-type doping layer and the N-type amorphous silicon layer form a P-type emitting electrode and an N-type back field on the back of the back contact battery, and the electrodes are arranged on the P-type emitting electrode and the N-type back field. The N-type amorphous silicon layer is formed by the silicon wafer, an electric field in the back contact battery is formed by utilizing a good hydrogen passivation effect and a good field passivation effect of the N-type amorphous silicon layer, a passivation effect is improved, the efficiency of the battery is improved obviously, a process is simple, and production efficiency is improved.

Owner:TRINA SOLAR CO LTD

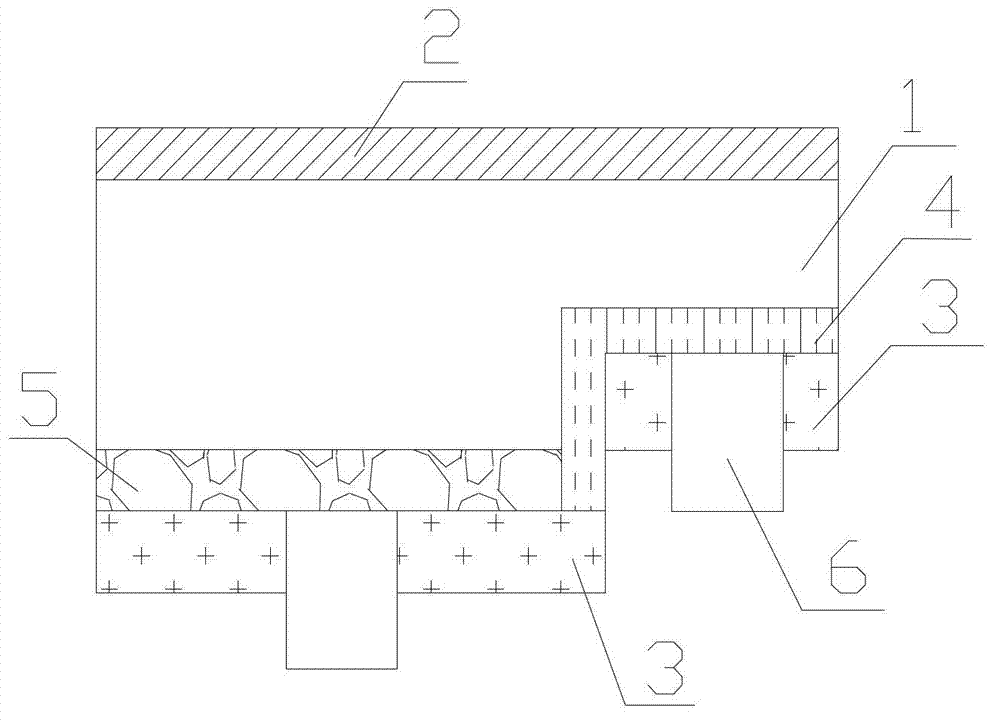

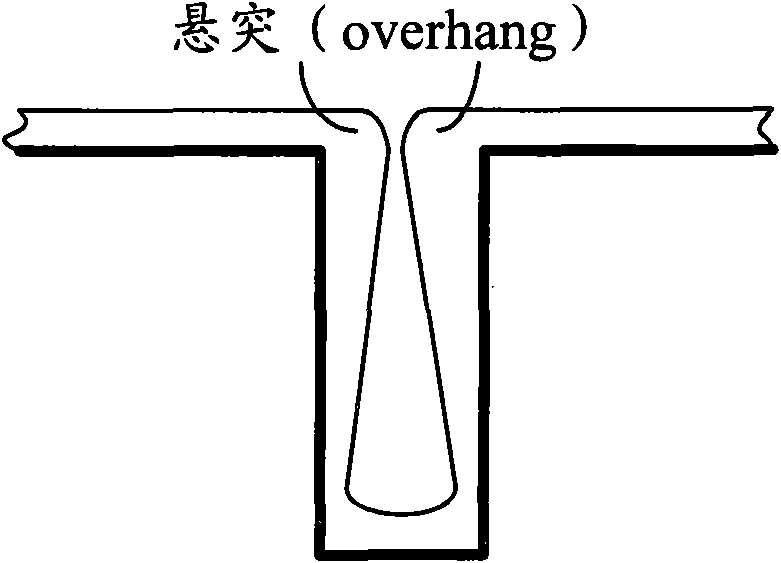

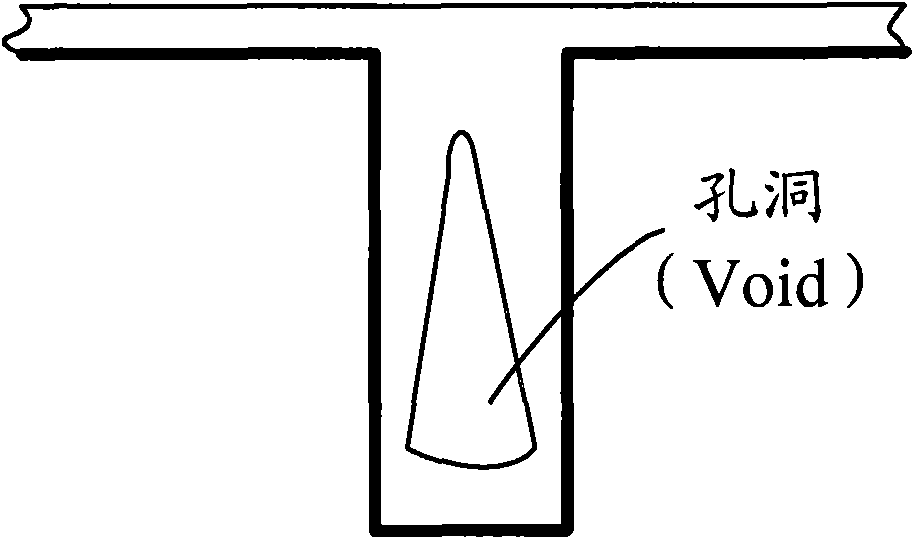

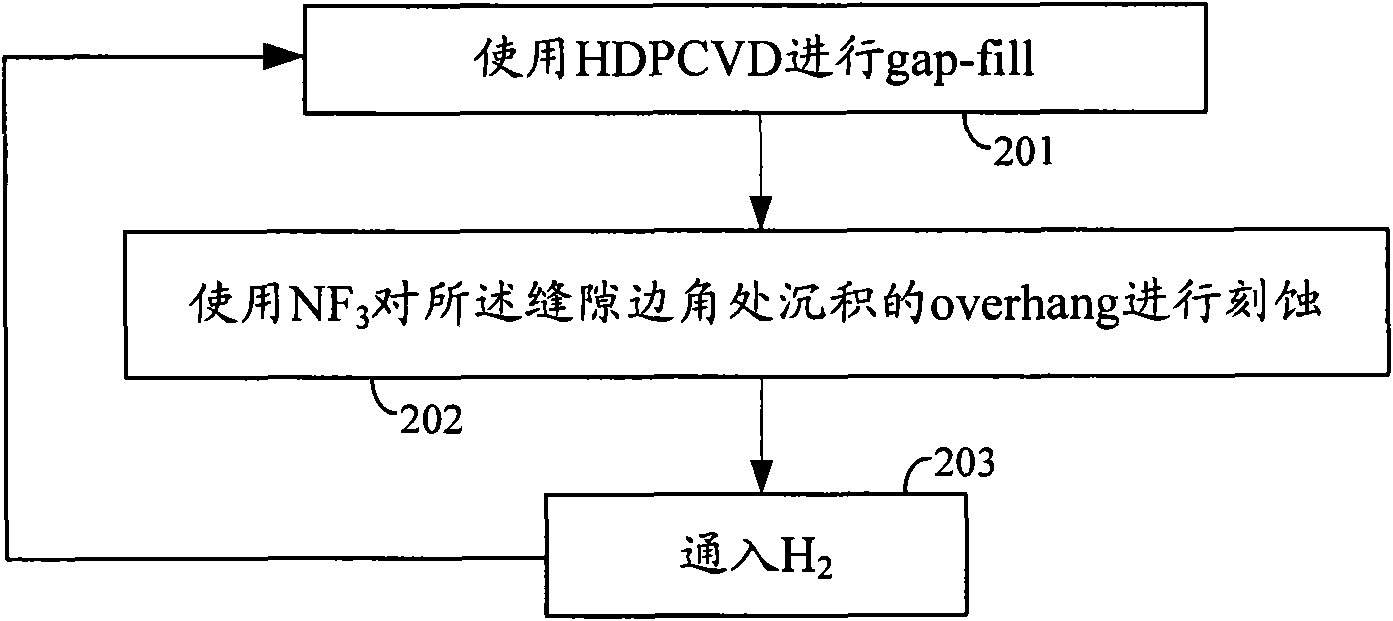

Processing method of gap filling and manufacturing method of shallow trench isolation groove

InactiveCN101673660AAvoid introducingReduce performanceSemiconductor/solid-state device manufacturingHigh densityChemical vapor deposition

The invention discloses a processing method of gap filling, which is used for forming a thin film on a semiconductor substrate with a gap and completely filling the gap. The processing method comprises the following steps: using a method of high-density plasma chemical vapor deposition (PCVD) to fill the gap; using nitrogen trifluoride to etch the overhang deposited in the corner of the gap; afterintroducing hydrogen gas for hydrogen passivating treatment, introducing oxygen gas to react with the residual hydrogen gas after hydrogen passivating treatment, and discharging all the gases in thereaction chamber; and then, returning to carry out the gap filling operation until the filling of the gap is completed. The embodiment of the processing method of gap filling can remove the residual hydrogen gas in the reaction chamber by introducing the oxygen gas after the hydrogen passivating treatment so as to prevent the hydrogen gas from being introduced into the generated thin film, avoid various kinds of performance reduction caused by the generation of H2 and improve the performance of the thin film. The invention also discloses a manufacturing method of a shallow trench isolation groove, which can improve the performance of an isolation groove thin film.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

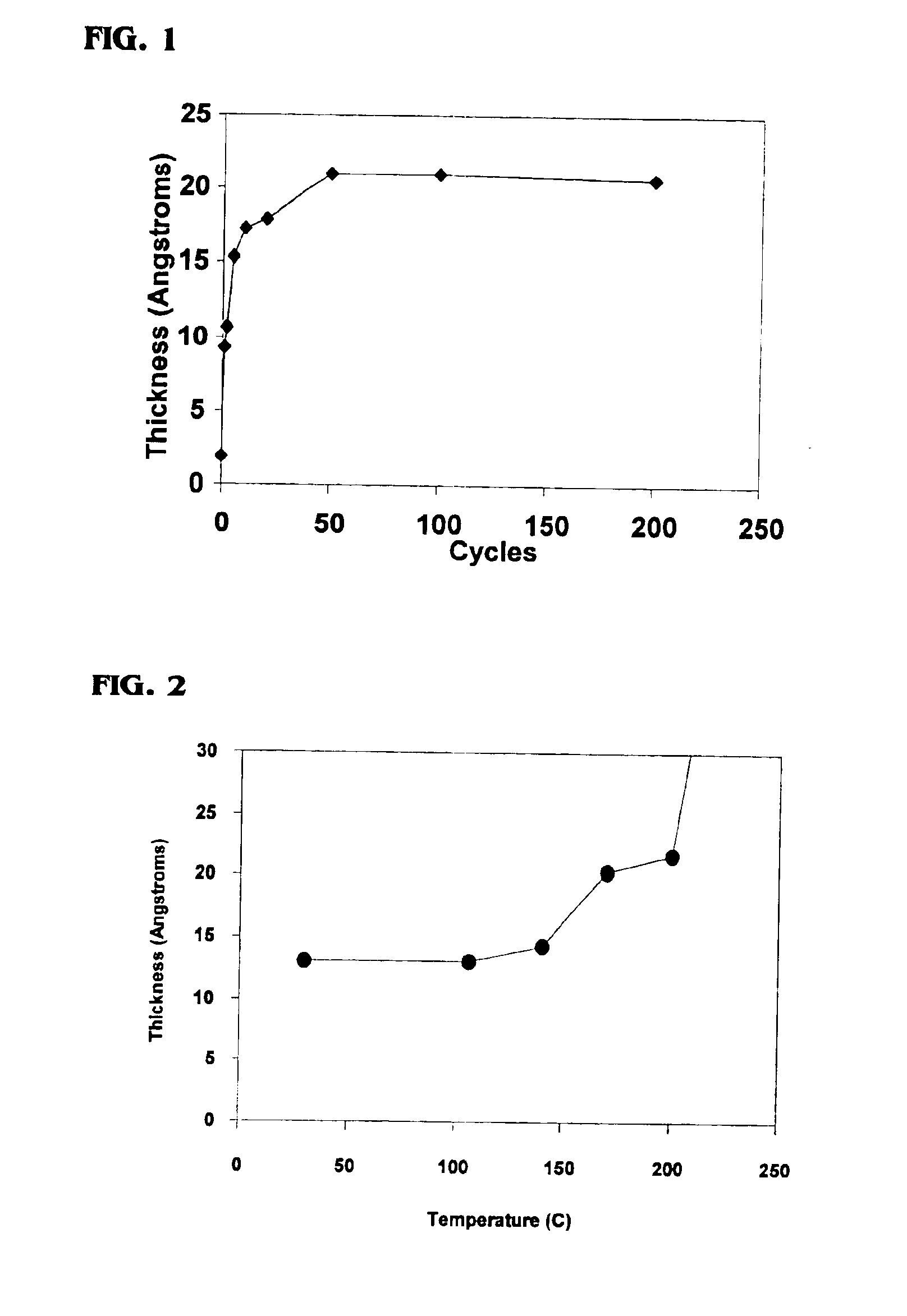

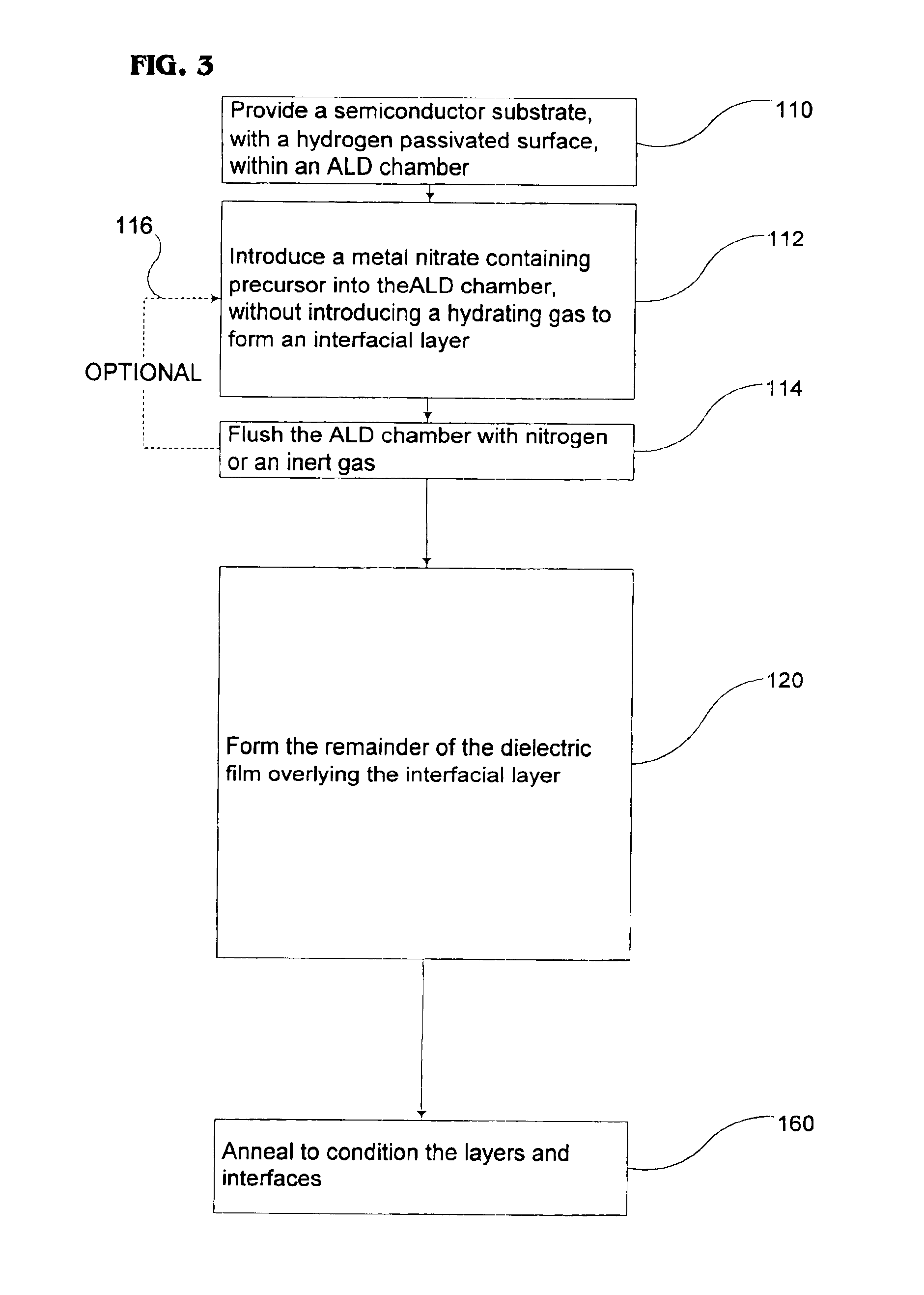

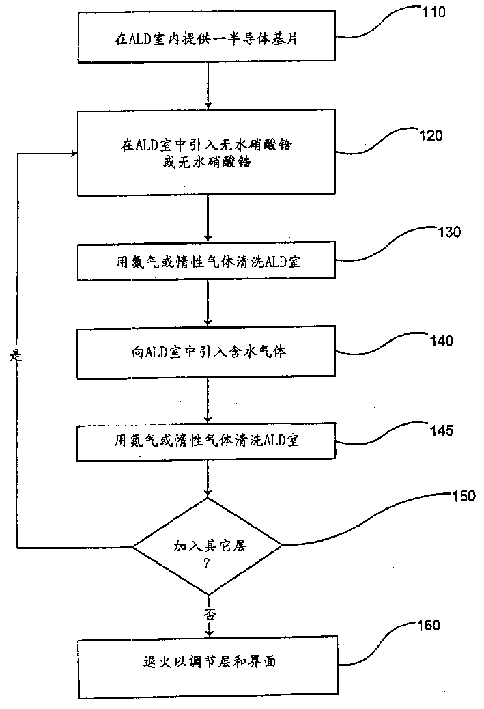

Method for dipositing high-dielectric constant material on chip using atomic layer diposition method

InactiveCN1396638ASemiconductor/solid-state device manufacturingNanotechnologyHafniumAtomic layer deposition

Methods of forming hafnium oxide, zirconium oxide and nanolaminates of hafnium oxide and zirconium oxide are provided. These methods utilize atomic layer deposition techniques incorporating nitrate-based precursors, such as hafnium nitrate and zirconium nitrate. The use of these nitrate based precursors is well suited to forming high dielectric constant materials on hydrogen passivated silicon surfaces.

Owner:SHARP KK

Hydrogen passivation technology for improving light failure problem of mono-crystalline solar cell

ActiveCN108630772AIncrease power generation capacityImprove the long-term stable power generation capacity of photovoltaic cellsFinal product manufacturePhotovoltaic energy generationFailure rateStable state

The invention discloses a hydrogen passivation technology for improving a light failure problem of a mono-crystalline solar cell. The technology comprises the following steps: regulating the conversion quantity, between the high compound state and the low compound state, of B-O defect in a silicon substrate by using the H in the SiN:H film on the solar cell surface and controlling the current andtemperature and like elements exerted on a cell, and regulating the passivation quantity on the B-O defect by the H by using the current, thereby achieving a new stable state, wherein this state cannot return to the high compound state to influence the cell efficiency due to the illumination, so that the failure rate is reduced to within 1.5% under the standard light failure testing condition whenthe efficiency reduction degree of the mono-crystalline solar cell is within 0.07%. The technology disclosed by the invention is not limited to the mono-crystalline solar cell, and further comprisesmono-crystalline-like and polycrystalline solar cells, and the photoelectric conversion efficiency of the cell cannot be reduced by the light failure improved obtained on the polycrystalline solar cell. The technology temperature, the current and the time selected by the invention are easy to achieve and control; the technology is simple in method, obvious in effect, and capable of being compatible with the industrial production, and has high practical value.

Owner:上饶捷泰新能源科技有限公司

Hydrogen passivation method for solar cell

ActiveCN104638063AImprove conversion efficiencyGood passivation effectFinal product manufacturePhotovoltaic energy generationHigh concentrationSemiconductor materials

The invention relates to a hydrogen passivation method for a solar cell, which comprises the following steps: (1) keeping the solar cell in a temperature range of 100 DEG C to 400 DEG C; (2) simultaneously applying a forward voltage to a pn junction of the solar cell to reduce a built-in potential. The method disclosed by the invention has the beneficial effects of solving the difficult problem how to introduce high-concentration hydrogen atom into a solar cell matrix, having an obvious passivation effect on impurities and defects in a semiconductor material matrix and reducing recombination activity of the semiconductor material matrix used as an electronic-hole composite center; the method is beneficial for improving conversion efficiency of the solar cell. Meanwhile, the method can be well compatible to the manufacturing process of an existing solar cell piece, is easy for industrialization implementation and has high practical value.

Owner:杭州晶宝新能源科技有限公司

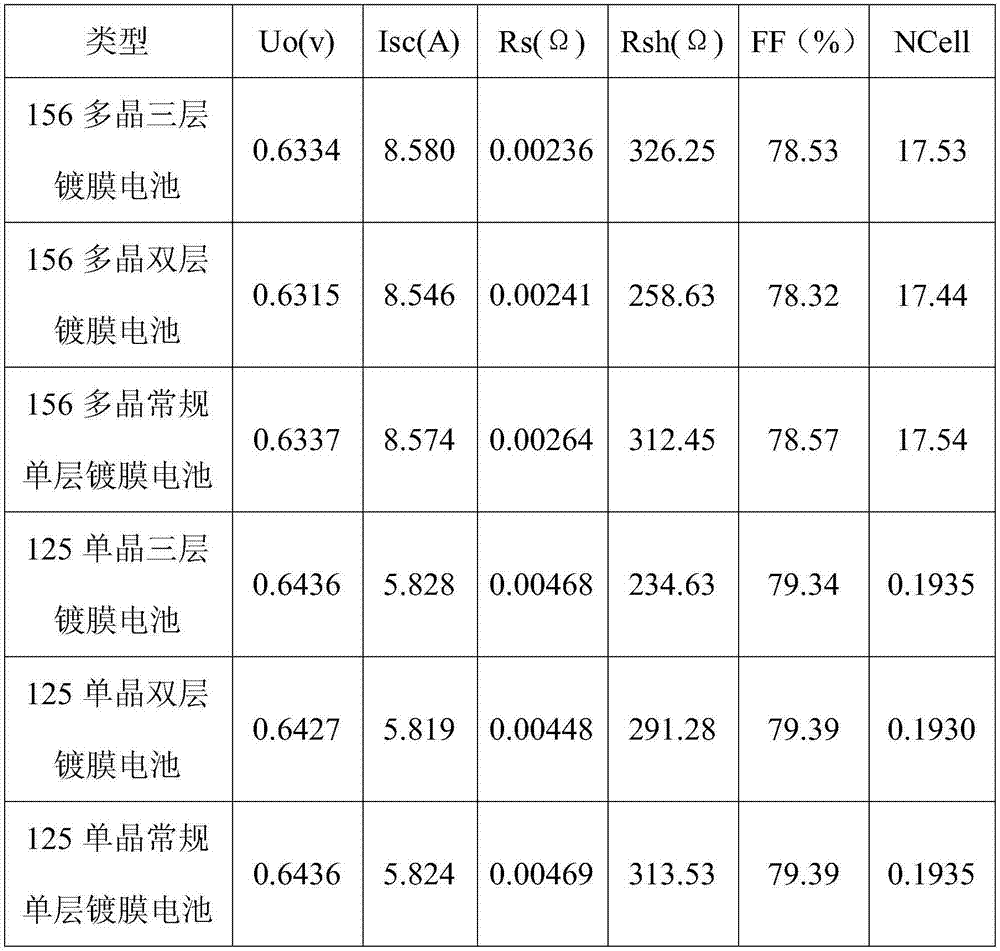

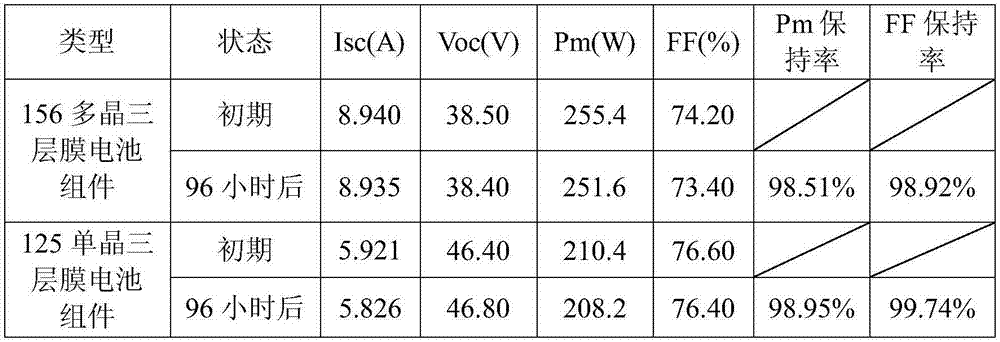

PECVD coating technology used for preparing assembly crystal silicon solar energy battery

ActiveCN104498908AHas anti-PID effectConversion efficiency does not decreaseFinal product manufactureChemical vapor deposition coatingElectrical batterySilicon solar cell

The invention discloses a PECVD coating technology used for preparing an assembly anti-PID crystal silicon solar energy battery, and an anti-PID solar energy battery assembly can be prepared under prerequisite that the transition efficiency of battery piece is not decreased. The method is characterized in that a silicon nitride- silicon dioxide-silicon nitride lamination antireflection film is deposited on a silicon chip surface, the lamination antireflection film has the characteristics that the internal layer silicon nitride membrane has good hydrogen passivation effect, transition efficiency of battery piece is not decreased, a silica membrane has Na4 ions obstruction characteristic, so that the assembly has anti-PID effect. The technology has the beneficial effect that the PECVD coating technology is adjusted, no equipment is added, battery process operation is not increased, the anti-PID effect can be realized under prerequisite that transition efficiency of battery piece is not decreased; The scheme is simple and feasible, cost is low, the technology can be used for large industrial production; the technology is suitable for all the tubular type PECVD coating equipment for monocrystalline or polycrystalline crystal silicon solar energy battery.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

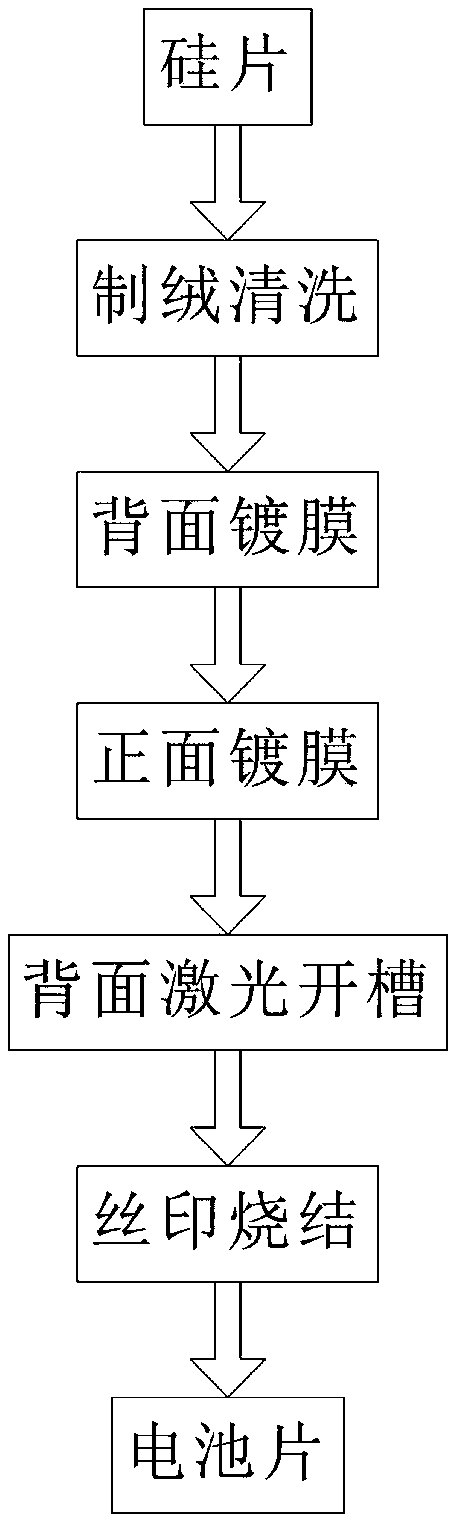

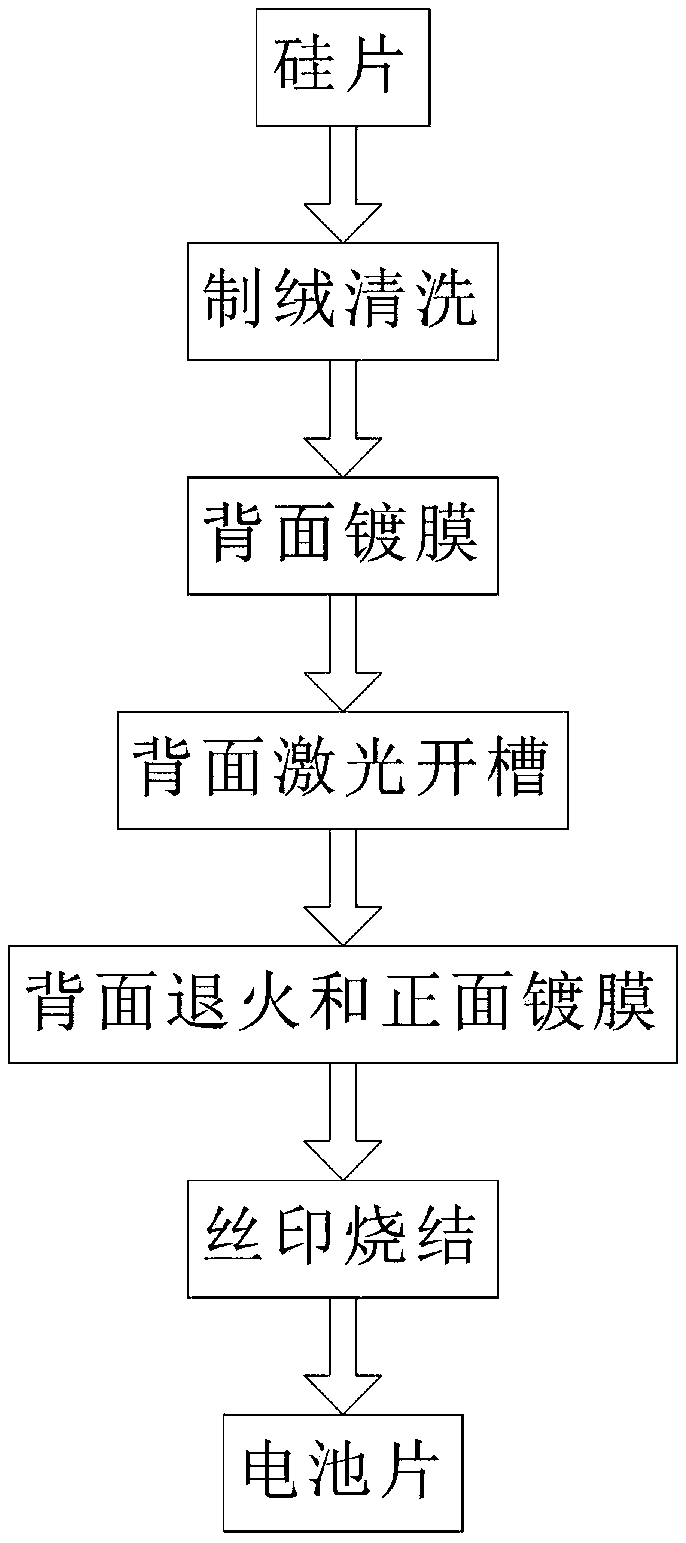

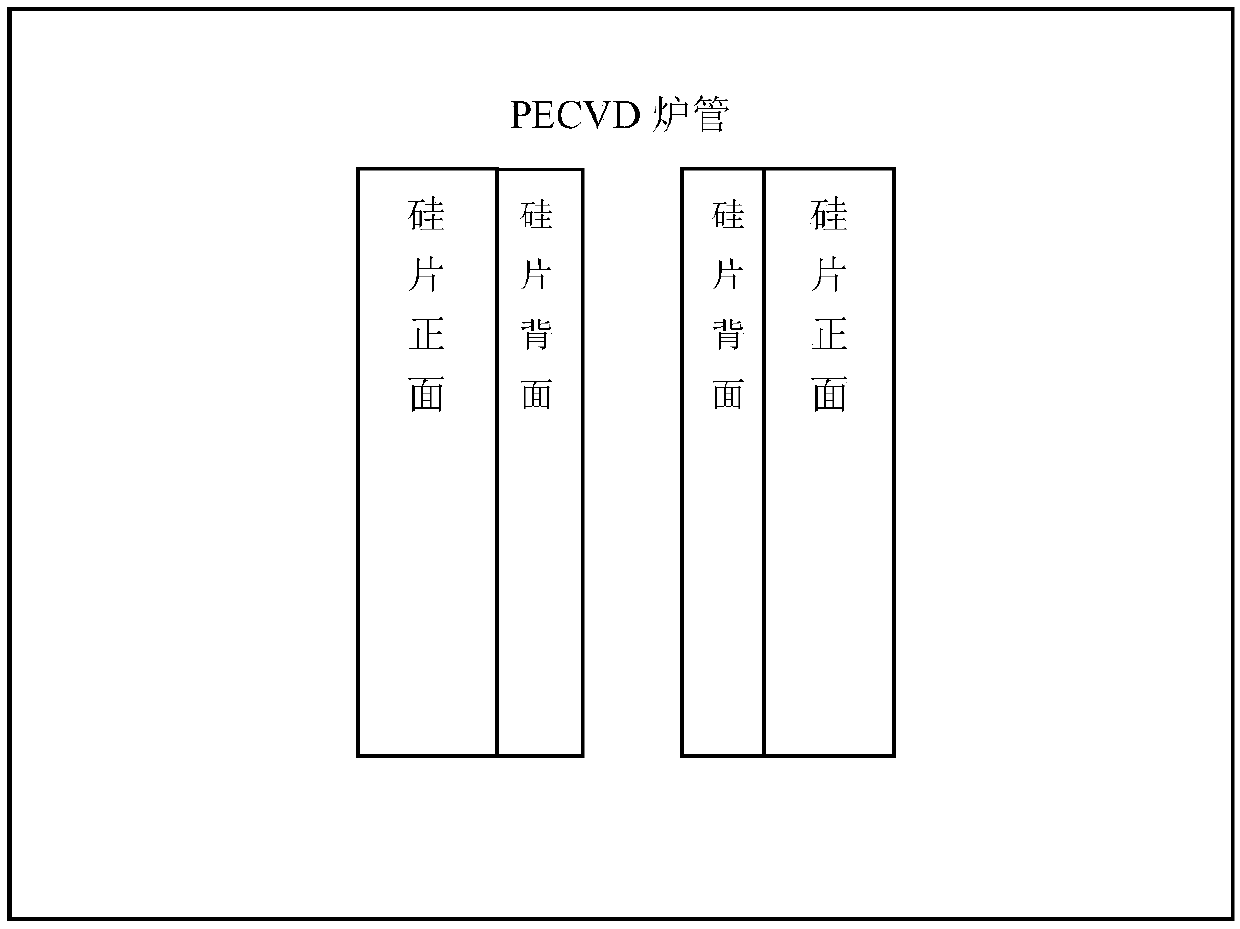

Silicon wafer back-surface annealing and front-side coating integrated method and preparation method of battery piece

InactiveCN109616556AReduce compound rateImprove life expectancyFinal product manufactureSemiconductor devicesLattice defectsOxygen

The invention discloses a silicon wafer back-surface annealing and front-side coating integrated method, which comprises the following steps of carrying out laser grooving on the back surface of a silicon wafer by utilizing laser equipment, placing the silicon wafer subjected to laser grooving into a deposition device, introducing reaction gas SiH4 and NH3 and N2 into the deposition cavity of thedeposition device for deposition so as to coat the front surface of the silicon wafer. According to the silicon wafer back surface annealing and front surface coating integrated method, the laser grooving is carried out before the front surface coating process, and the back annealing is carried out by utilizing the medium-high-temperature oxygen-free environment in the PECVD process, and meanwhile, the front-surface film coating can be synchronously completed, no extra annealing process is added; the thermal shock, thermal damage and crystal lattice defects caused by the high-energy laser grooving on the back surface can be recovered and restored; and the composite rate of the damaged surface of the silicon wafer after laser is further reduced, and the method also can be used for carryingout hydrogen passivation on the position of the back grooving (window opening), so that the minority carrier lifetime of the silicon wafer damaged by the laser is prolonged, and the efficiency of thesolar cell is further improved.

Owner:HANWHA SOLARONE QIDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com