Method for dipositing high-dielectric constant material on chip using atomic layer diposition method

A kind of atomic layer deposition and substrate technology, applied in metal material coating process, coating, circuit, etc., can solve the problems of occupying space, hindering single layer deposition, low dielectric constant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

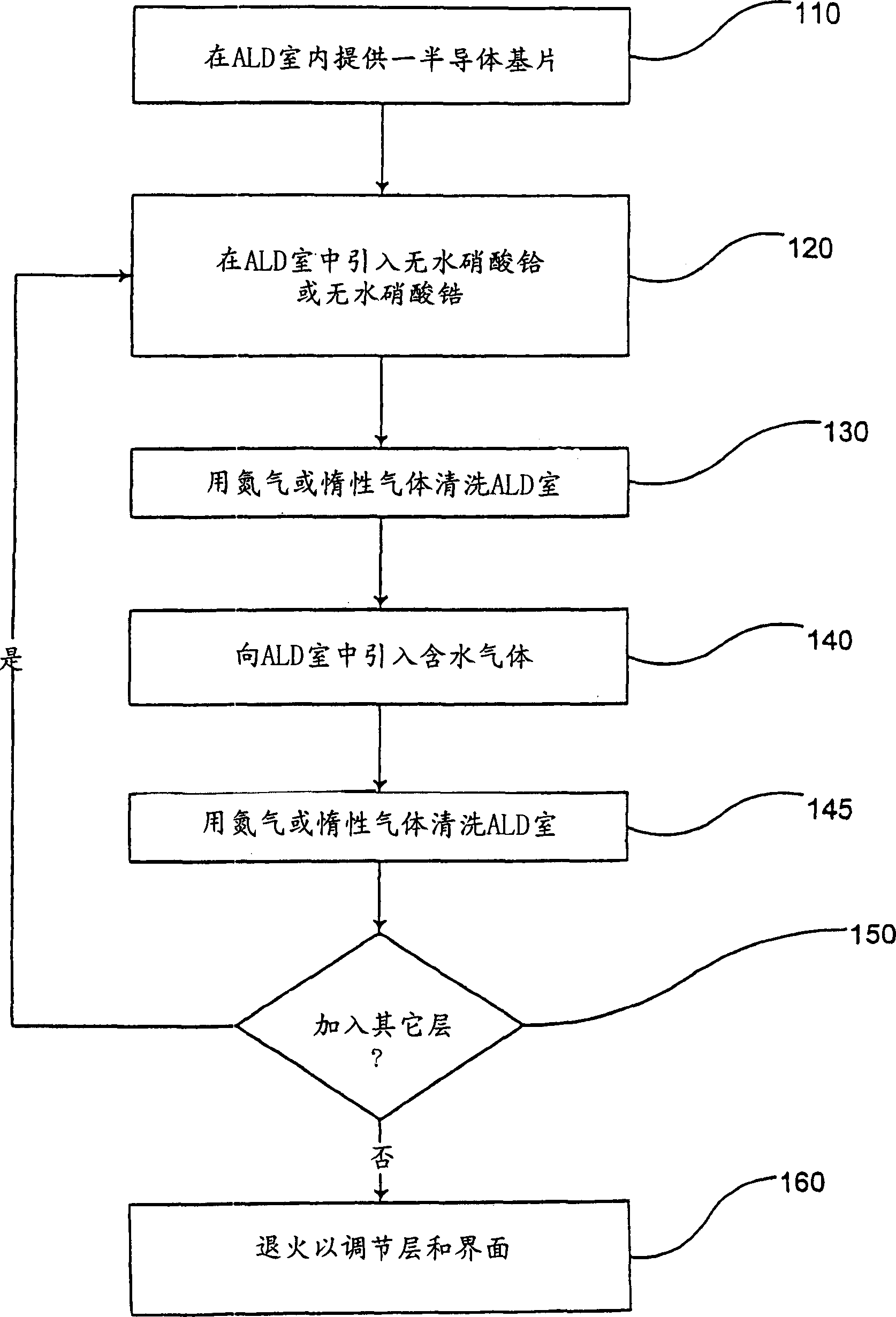

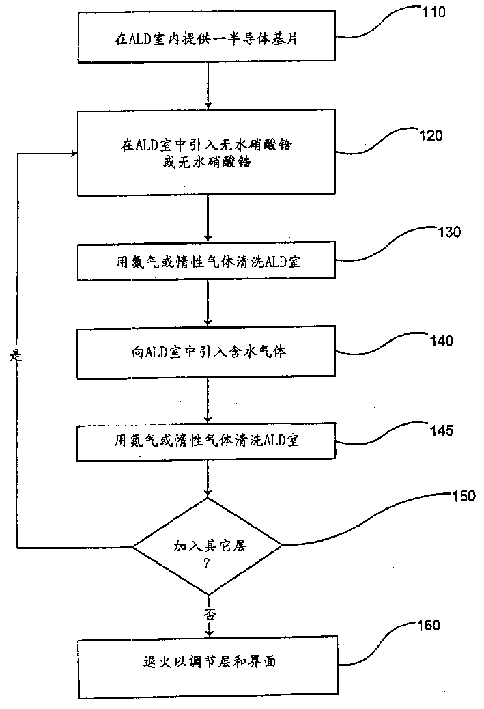

[0013] figure 1 is to illustrate the deposition of HfO 2 or ZrO 2 Flowchart of the thin film method steps. Step 110 provides a semiconductor substrate within an ALD chamber. Commercial ALD tools are currently available. An ALD tool, type F120, manufactured by Microchemistry Ltd. of Finland (now a division of ASM), can be used in the methods described herein. In a preferred embodiment, the semiconductor substrate has a hydrogen-terminated silicon surface. Although the method described here is particularly suitable for addressing the deposition of HfO on hydrogen-terminated silicon surfaces 2 or ZrO 2 problem, but it is also perfectly possible to use this method on other surfaces, including silicon dioxide, silicon oxynitride, SiGe surfaces and surfaces such as ZrSiO 4 and HfSiO 4 Depositing HfO on such a silicate 2 or ZrO 2 .

[0014] The semiconductor substrate is heated to a certain temperature to form the atomic layer deposition range. For example, when using anh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com