Processing method of gap filling and manufacturing method of shallow trench isolation groove

A processing method and gap filling technology, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced film performance, poor uniformity, and increased etching rate, so as to improve performance and avoid performance. The effect of reducing and improving film properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

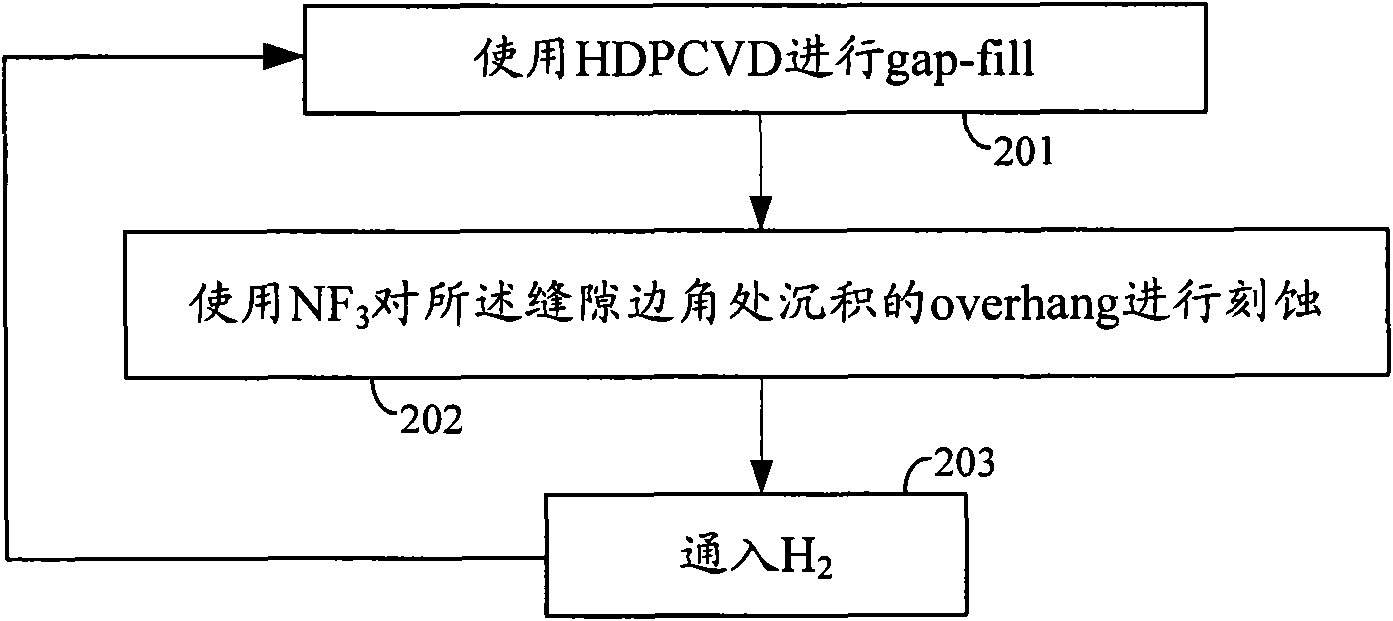

[0039] An embodiment of the present invention provides a gap filling processing method, which is used to form a thin film on a semiconductor substrate with a gap and completely fill the gap. The process is as follows image 3 shown, including:

[0040] Step 301: use HDPCVD to perform gap-fill;

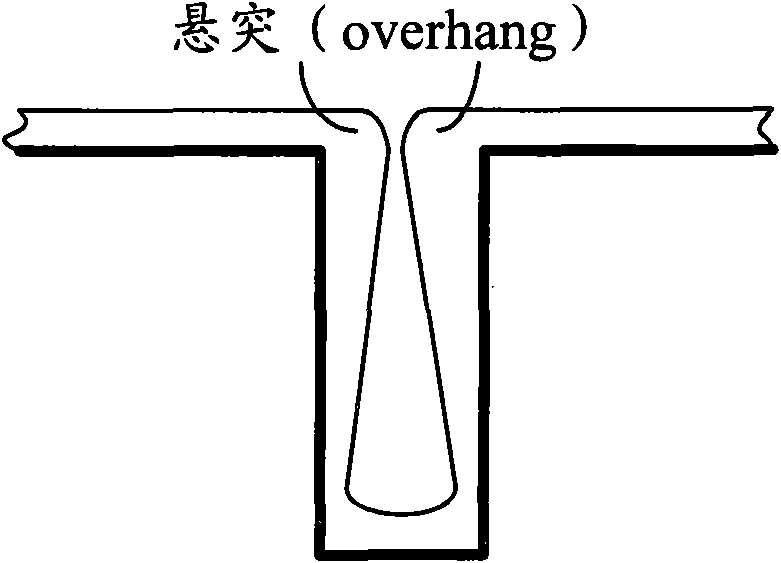

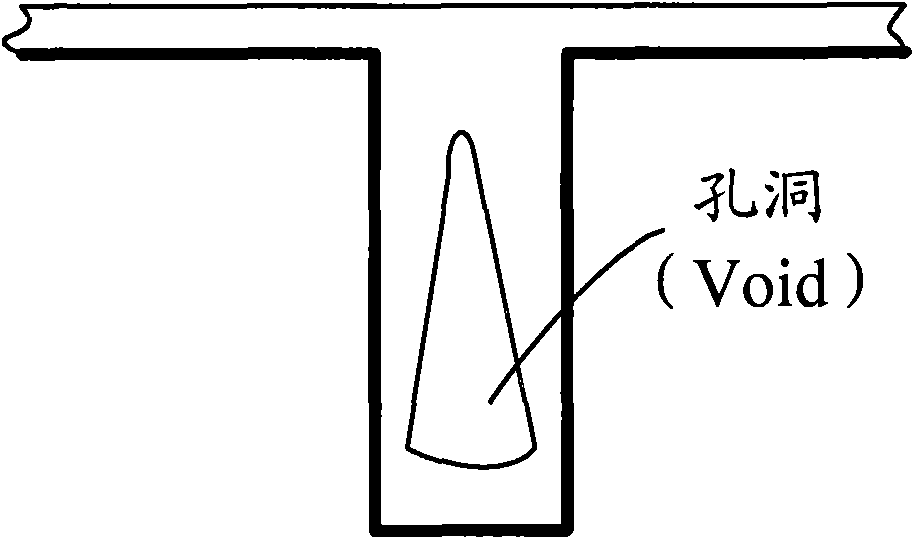

[0041] Step 302: use NF 3 Etching (etch) the overhang deposited at the corners of the slit to prevent it from sealing the opening of the slit;

[0042] Step 303: After the first etching is completed, inject H 2 carry out hydrogen passivation treatment;

[0043] Step 304: Introduce oxygen to react with the residual hydrogen gas after the hydrogen passivation treatment, and discharge the remaining gas out of the reaction chamber, and return to step 301 until t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com