Method for preparing two-sided silicon nano-wire array

A silicon nanowire array, double-sided technology, applied in the field of preparation of double-sided silicon nanowire arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

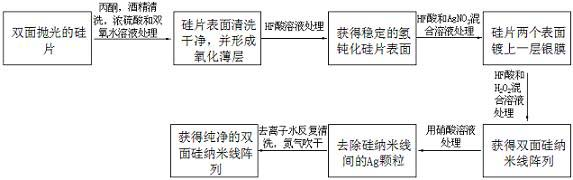

[0024] 1. Silicon wafer cleaning:

[0025] Wash with acetone and alcohol ultrasonic vibration respectively, room temperature for 10 min;

[0026] into concentrated H 2 SO 4 :H 2 o 2 =3:1 (V:V) solution boiled for 30 min;

[0027] Rinse the glass surface with deionized water;

[0028] Blow dry with high-purity nitrogen.

[0029] 2. Put the cleaned silicon wafer into 5% HF acid solution and corrode for 3 min at room temperature.

[0030] 3. Put the silicon wafer into HF acid and AgNO quickly at room temperature 3 The mixed solution, which contains 3mol of HF acid per liter of mixed solution, contains AgNO per liter of mixed solution 3 0.01 mol, and stirred slowly for 40 s, and then the surface of the silicon wafer was washed repeatedly with deionized water.

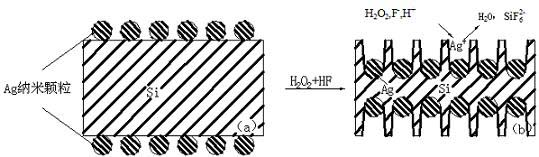

[0031] 4. Pad and fix the silicon wafer, put it into HF acid and H 2 o 2 The mixed solution of the composition was treated for 40min, wherein every liter of mixed solution contained 2.8 mol of HF acid, and every ...

Embodiment 2

[0034] 1, step 1 is the same as embodiment 1.

[0035] 2, step 2 is the same as embodiment 2.

[0036] 3. HF acid and AgNO in step 3 3 The mixed solution, wherein every liter of mixed solution contains HF acid is 4.8mol, and every liter of mixed solution contains AgNO 3 0.05 mol and stirred slowly for 30 s.

[0037] 4. Put HF acid and H in step 4 2 o 2 The mixed solution of the composition was treated for 30min, wherein every liter of mixed solution contained 4.8 mol of HF acid, and every liter of mixed solution contained H 2 o 2 The solution is 0.15mol.

[0038] 5. Step 5 is the same as Step 5 in Example 1.

Embodiment 3

[0040] 1, step 1 is the same as embodiment 1.

[0041] 2, step 2 is the same as embodiment 2.

[0042] 3. HF acid and AgNO in step 3 3 The mixed solution, which contains 3.6mol of HF acid per liter of mixed solution, contains AgNO per liter of mixed solution 3 0.03 mol and stirred slowly for 90 s.

[0043] 4. Put HF acid and H in step 4 2 o 2 The mixed solution of the composition was treated for 60 minutes, wherein each liter of mixed solution contained 3.2 mol of HF acid, and each liter of mixed solution contained H 2 o 2 The solution is 0.4mol.

[0044] 5. Step 5 is the same as Step 5 in Example 1.

[0045] The silicon nanowires prepared by the present invention have a length of 2 to 3 microns and a diameter of 50 to 100 nanometers; the density of the silicon nanowires on the silicon chip surface reaches 10 4 ~10 5 roots per square centimeter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com