Silicon wafer back-surface annealing and front-side coating integrated method and preparation method of battery piece

A battery chip and silicon chip technology, applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of laser thermal shock on the back of the silicon chip, damage to the silicon matrix lattice structure, stress concentration, and loss of battery efficiency, etc., to improve solar energy. Effects of battery efficiency, reduction of cell fragmentation rate, and improvement of minority carrier life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

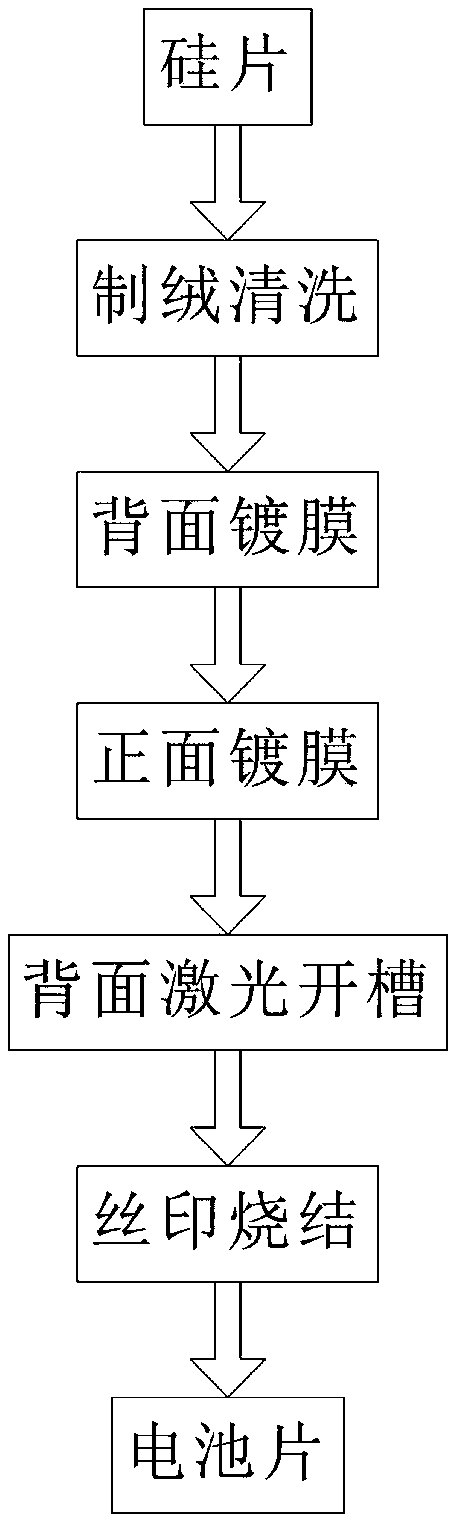

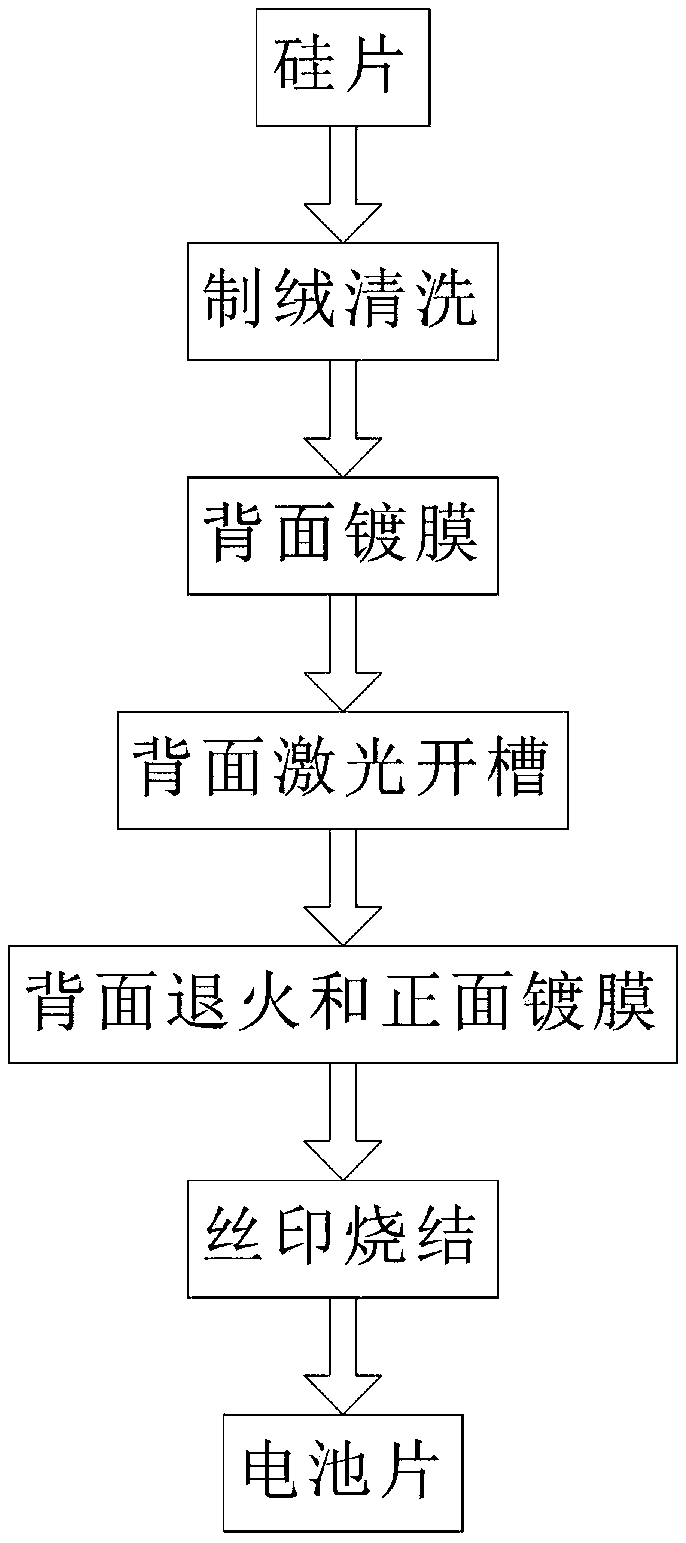

[0026] refer to Figures 2 to 3 , a method for preparing a battery sheet of the present embodiment, comprising the following steps:

[0027] Step S1: Prepare materials

[0028] Prepare single-polycrystalline silicon wafers with suitable resistivity, and perform texturing cleaning, back coating, etc. according to the battery process.

[0029] Step S2: Laser groove on the back

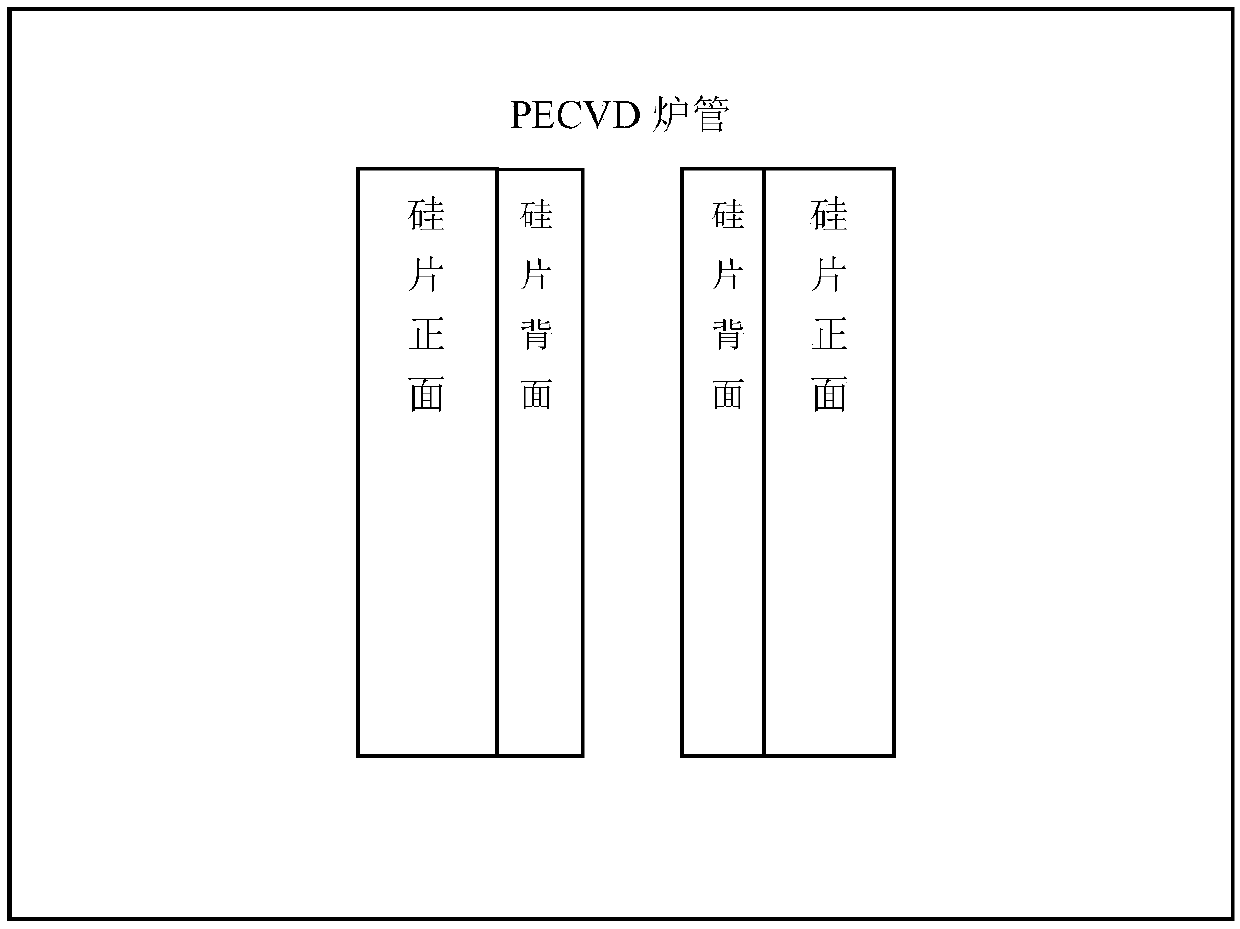

[0030] Put the silicon wafer that has undergone processes such as texture cleaning and back coating in step S1 into the laser equipment, set the laser percentage to 100% in the laser parameters, the laser frequency to 800kHz, and the laser pattern to be a regular hexagonal symmetrical pattern with a separation point of 500um , The size of the laser dot pattern is 155*155mm. After setting the appropriate laser parameters, the high-energy laser beam is used to bombard the film on the back of the silicon wafer to form the back groove (window) effect of removing the film and the molten silicon surface.

...

Embodiment 2

[0043] Embodiment 2 result and discussion

[0044] The detection of the battery sheet produced by using Example 1 and the battery sheet produced by the traditional process of Comparative Example 1, wherein Eta is the conversion efficiency, Uoc is the open circuit voltage, Isc is the short circuit current, FF is the fill factor, and Rs is Series resistance, Rsh is parallel resistance, IRev2 is reverse current, Breakage is screen fragmentation rate, the results are as follows:

[0045] Table 1 Test results

[0046]

[0047] In Example 1, the back annealing and the front coating are integrated, and the lattice defects and thermal stress damage are repaired by annealing, so as to improve battery efficiency and reduce hidden crack fragments. From the electrical performance test results in Table 1, it can be concluded that the gain in photoelectric conversion efficiency of the battery in Example 1 comes from the improvement of Uoc, the main reason is that after laser damage anneal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com