A double-sided PERC solar cell structure and a preparation process thereof

A solar cell and preparation technology, applied in the direction of sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of increasing the risk of LID and PID of cells and modules, affecting the front conversion efficiency of cells, etc., to achieve bifaciality and Improved anti-LID effect, improved double-sided ratio and anti-LID effect, improved mechanical load strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

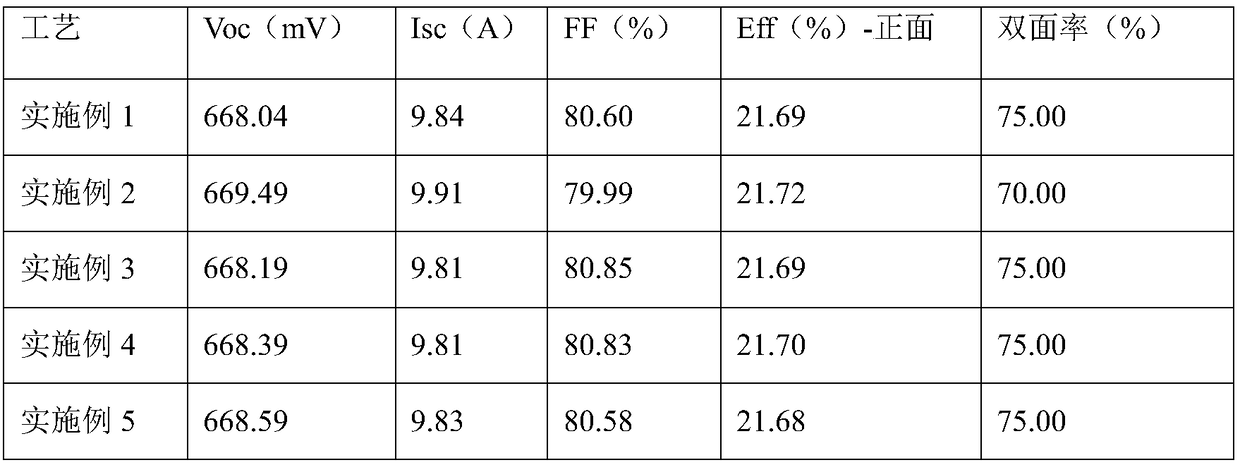

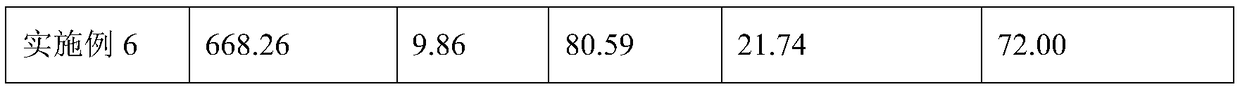

Embodiment 1

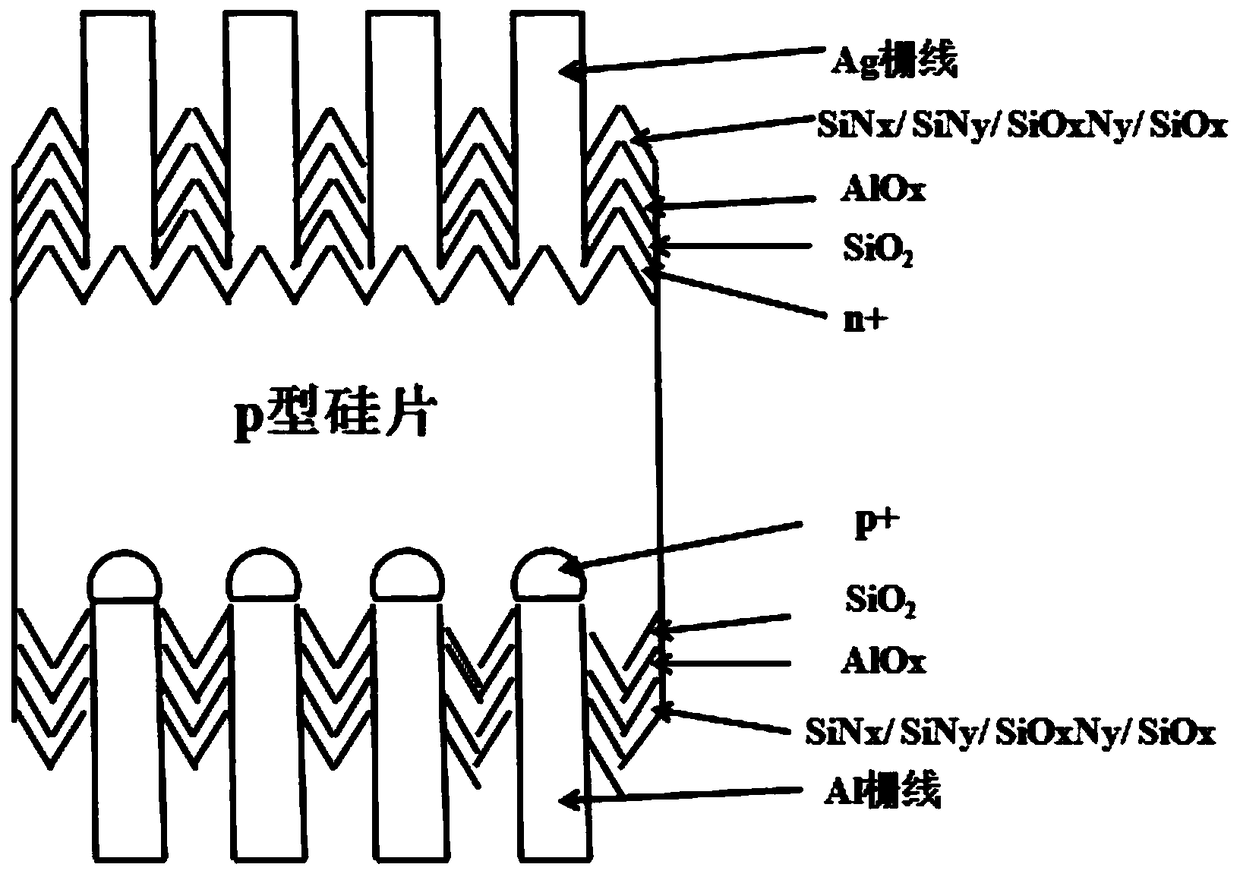

[0028] refer to figure 1 , a bifacial PERC solar cell structure with SiO on the front and back of the cell 2 / AlOx / SiNx / SiNy / SiOxNy / SiOx stacked structure, where the front and back SiO 2 layer is simultaneously formed by thermal oxidation or ozone oxidation, SiO 2 Layer thickness 5-20nm; front and back AlOx(Al 2 o 3 ) layer is formed by simultaneous deposition of atomic layer deposition (ALD), the AlOx layer thickness is 3-30nm, and the refractive index is 1.60-1.65; or a combination of two or more) are formed by PECVD deposition respectively, the thickness of the front SiNx / SiNy / SiOxNy / SiOx stack is 5-20nm, 20-40nm, 30-50nm and 40-60nm respectively, and the total thickness of the stack is 80-90nm , the refractive indices are 2.0-2.3, 1.8-2.0, 1.6-1.9 and 1.4-1.6 respectively; the backside SiNx / SiNy / SiOxNy / SiOx stack thicknesses are 15-30nm, 30-60nm, 40-70nm and 60-90nm respectively, The total thickness of the stack is 80-160nm, and the refractive indices are 2.0-2.3, 1.8...

Embodiment 2

[0040] In the third step of embodiment 1, the belt speed of back chain etching is 1.5m / min, the etching depth is 5um, and the reflectivity of the back surface is 40%; other processes are the same as in embodiment 1.

Embodiment 3

[0042] In the 5th step in embodiment 1, ALD deposits, deposits Al simultaneously on both sides 2 o 3 , the deposition temperature is 250° C., the pressure is 100 mTor, and the time is 400 s; other processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com