Hydrogen passivation technology for improving light failure problem of mono-crystalline solar cell

A solar cell and hydrogen passivation technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of restricting the development of photovoltaic industry, unfavorable power generation, and crystalline silicon solar cell efficiency attenuation, etc., to improve local overheating and uneven heat dissipation. , The effect of current and time is easy and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a

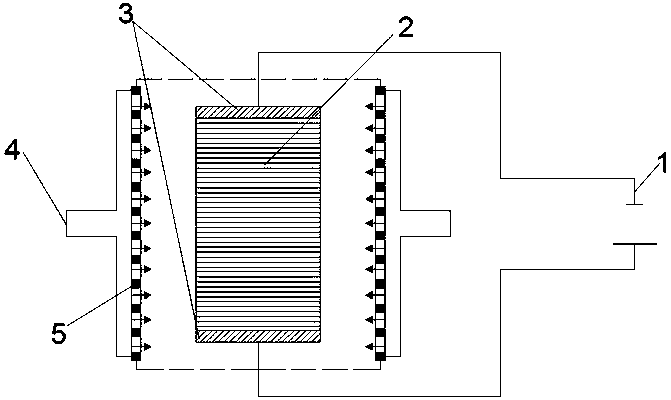

[0030] Such as figure 1 As shown, a hydrogen passivation process for improving the light decay problem of single crystal solar cells includes a DC power supply 1, a single crystal battery 2, a conductive separator 3, a vent hole 4, and an aluminum plate 5; It is electrically connected with the conductive separator 3 on the positive and negative poles of the single crystal battery 2; an external temperature control system is installed on the outside of the single crystal battery 2; the external temperature control system is composed of a vent hole 4 and an aluminum plate 5; Aluminum plates 5 with through holes are installed on both sides of the monocrystalline battery 2; a vent hole 4 is installed on one side of the above-mentioned aluminum plate 5, and the through holes of the above-mentioned aluminum plates 5 are all communicated with the vent hole 4, which is through the gas The flow meter is used to adjust the blowing air flow to cool down or maintain the temperature of the...

Embodiment 1

[0034] A hydrogen passivation process for improving the light decay problem of single crystal solar cells, including a DC power supply 1, a single crystal battery 2, a conductive separator 3, a vent hole 4, and a ventilation plate 5; it is characterized in that: the DC power supply 1 is connected to the The conductive separator 3 on the positive and negative poles of the monocrystalline battery 2 is electrically connected; an external temperature control system is installed on the exterior of the monocrystalline battery 2; the external temperature control system is composed of a vent hole 4 and a ventilation plate 5; Ventilation plates 5 with air holes are installed on both sides of the single crystal battery 2; a vent hole 4 is installed on one side of the above-mentioned ventilation plate 5, and the air holes of the above-mentioned aluminum plate 5 are all communicated with the vent hole 4, which is through the air. The flow meter is used to adjust the blowing air flow to coo...

Embodiment 2

[0048] All the other are the same as embodiment 1

[0049] The conductive separator 3 and ventilation plate 5 are copper plates.

[0050] The thickness of the conductive separator 3 and the ventilation plate 5 is 7 mm.

[0051] A hydrogen passivation process for improving the light decay problem of single crystal solar cells, which is completed through the following steps:

[0052] The first stage: stacking monocrystalline cells in series, the single crystal cells of the same specification are stacked in series in the same direction, the number of cells is 270; add a copper plate on the top and bottom of the cells, the advantage is to protect the cells at both ends from being scratched by the electrodes hurt;

[0053] The second stage: connect the positive pole of the DC power supply to the positive pole of the monocrystalline battery (P-type terminal), and the negative pole to the negative pole of the battery (N-type terminal), apply a positive current to the battery and ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com