Method of machining a work piece with a focused particle beam

A technology for processing workpieces, particle beams, used in material analysis using wave/particle radiation, preparation of samples for testing, electrical components, etc., which can solve problems such as expensive modifications, inability to reliably produce high-quality samples, and complex instrumentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

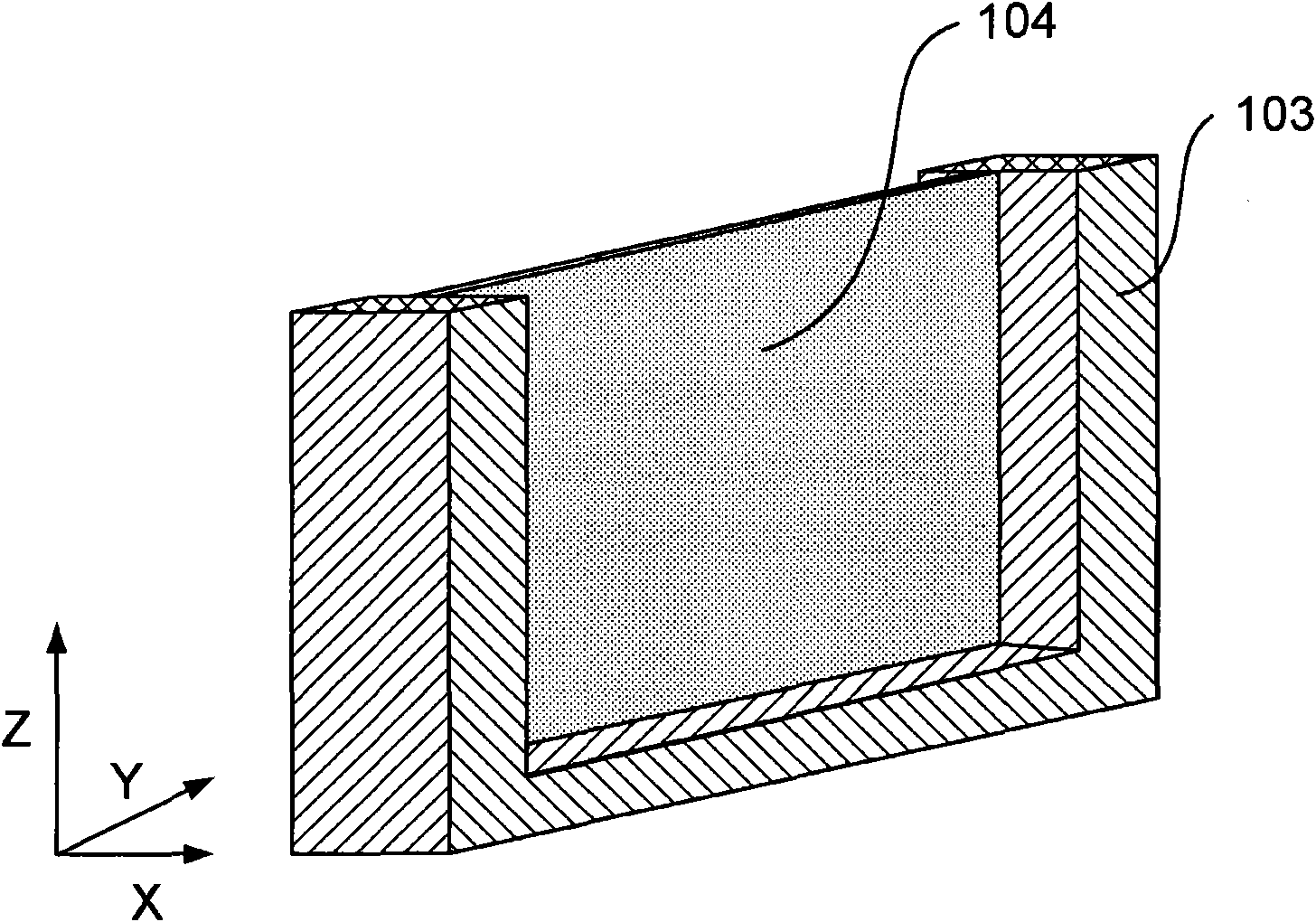

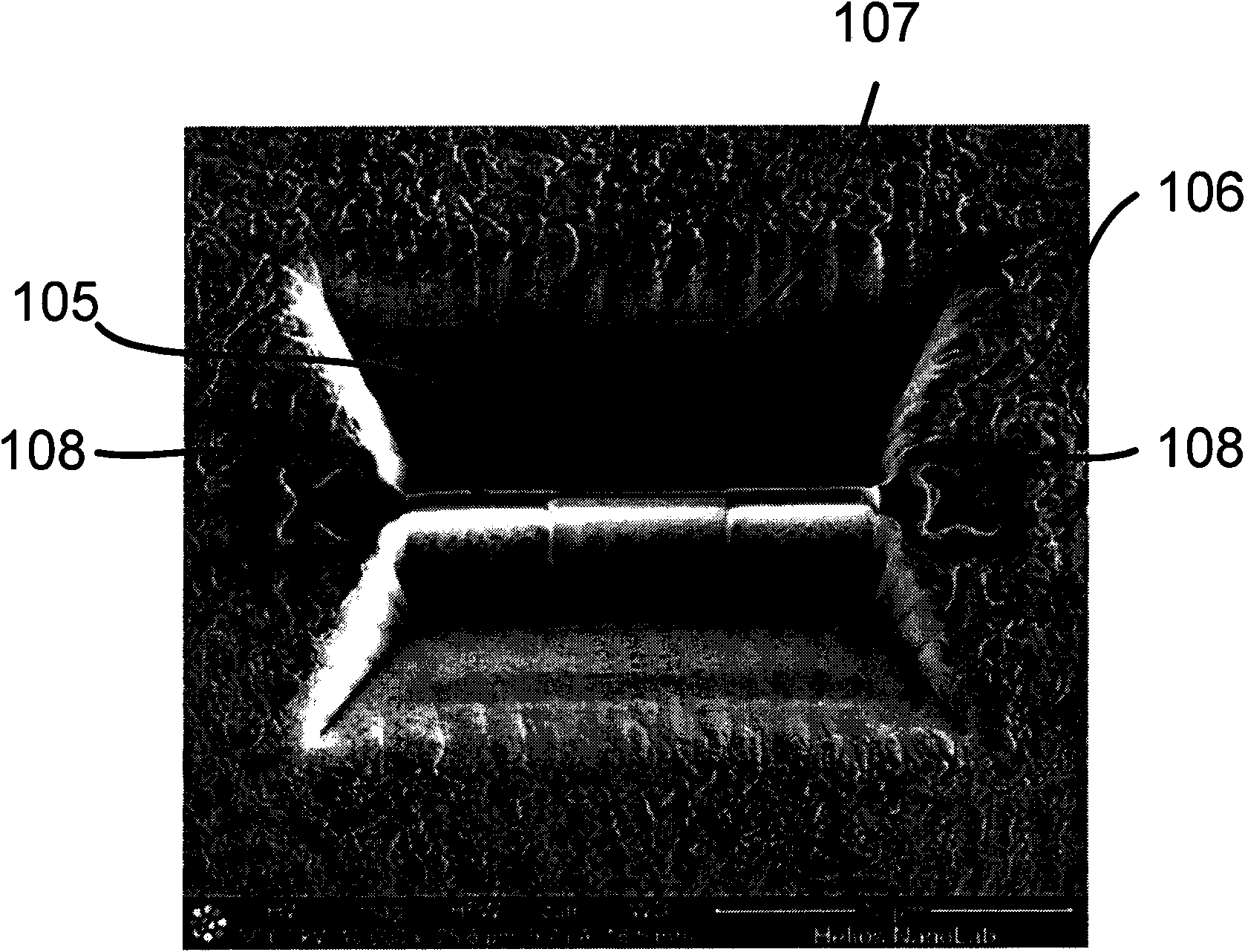

[0038] Figure 1a , 1b and 1c schematically show the formation of thinned flakes for inspection in TEM.

[0039] Figure 1a Wedges and lamellas taken from workpieces are schematically shown. A wedge 101 of, for example, semiconductor material breaks away from a workpiece (eg, a wafer). The wedge is then thinned into a thin sheet 102 . Usually the flakes are still too thick to be used as TEM samples.

[0040] It should be noted that the wedge may take the form of a thick sheet.

[0041] Figure 1b A thick lamella 102 detached earlier is schematically shown to be locally thinned to form a sample with relatively strong edges 103 and thin film 104 . Film 104 typically has a final thickness of less than 50 nm, although films having a thickness of, for example, 100 nm or greater may be used for some applications.

[0042] Grinding is preferably accomplished with an ion beam scanned across the surface of the lamella at an oblique angle, ie in a direction parallel to or close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com