Patents

Literature

62 results about "Partial solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The partial solutions are associated with the nodes of the branching tree that are not leaves (as Samuel reminded me, except for the nodes that became leaves by pruning, these are partial solutions too). For example, if you're optimizing a function over a subset of R^4, an example of a partial solution would be (1,x2,2,x4),...

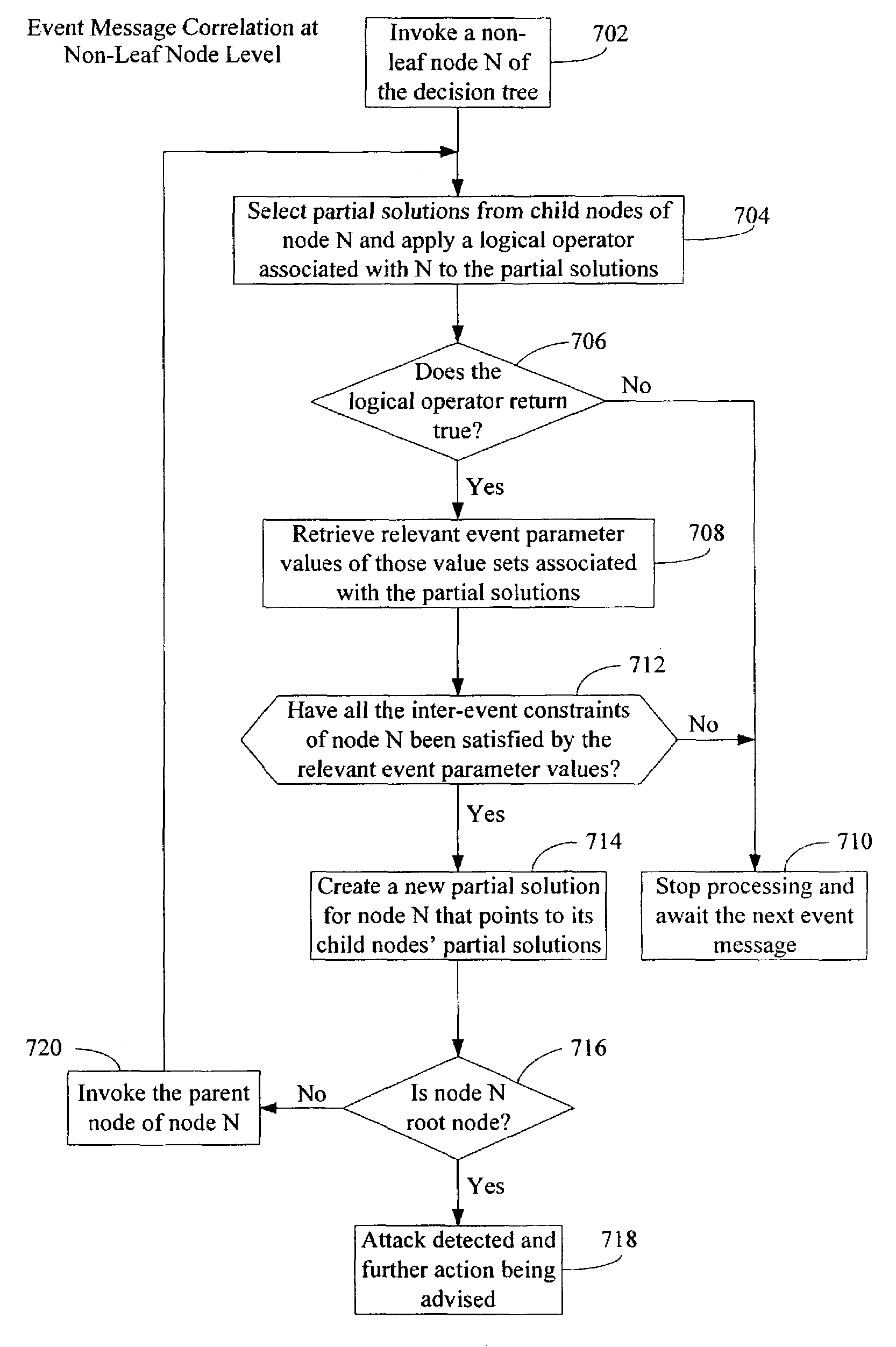

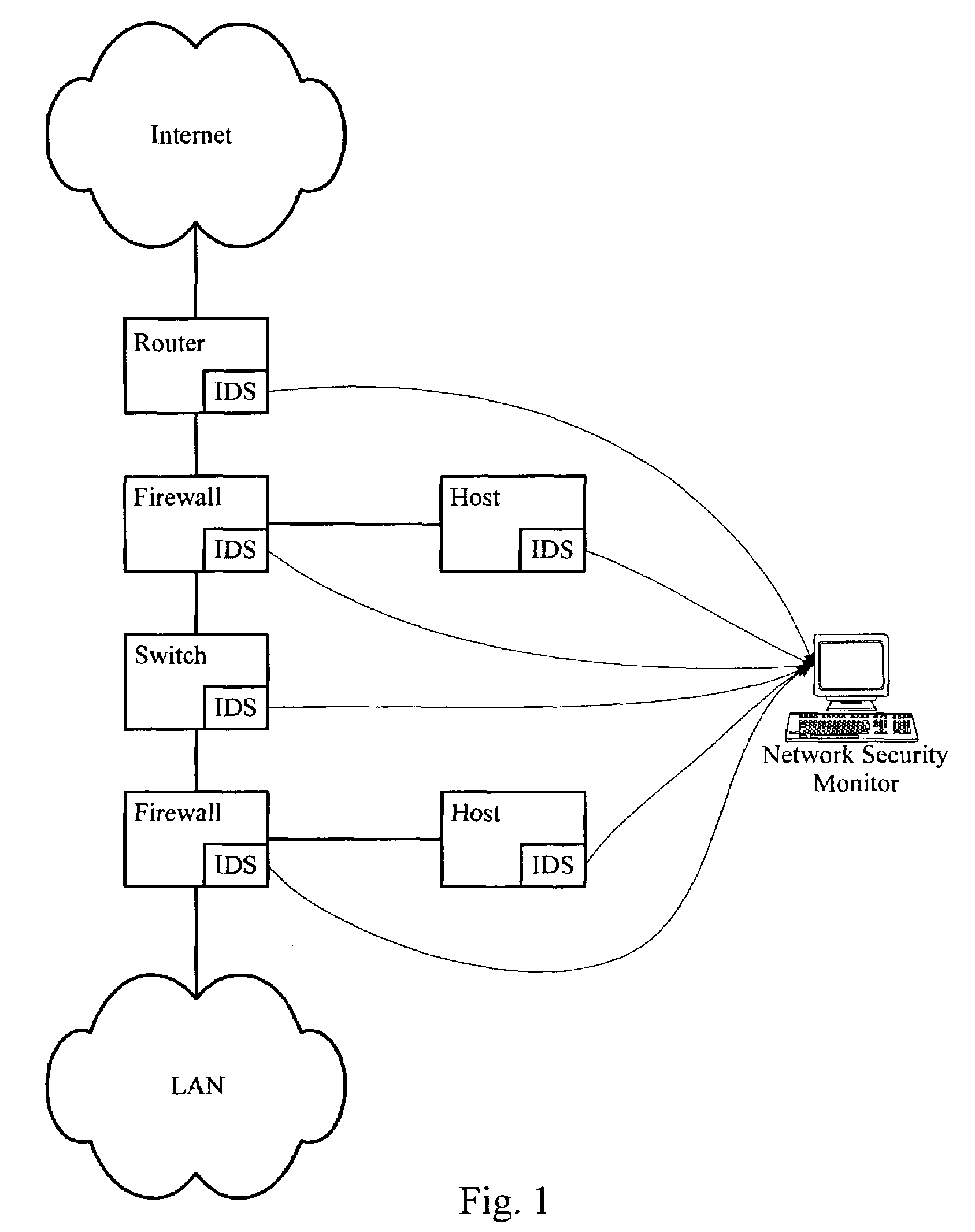

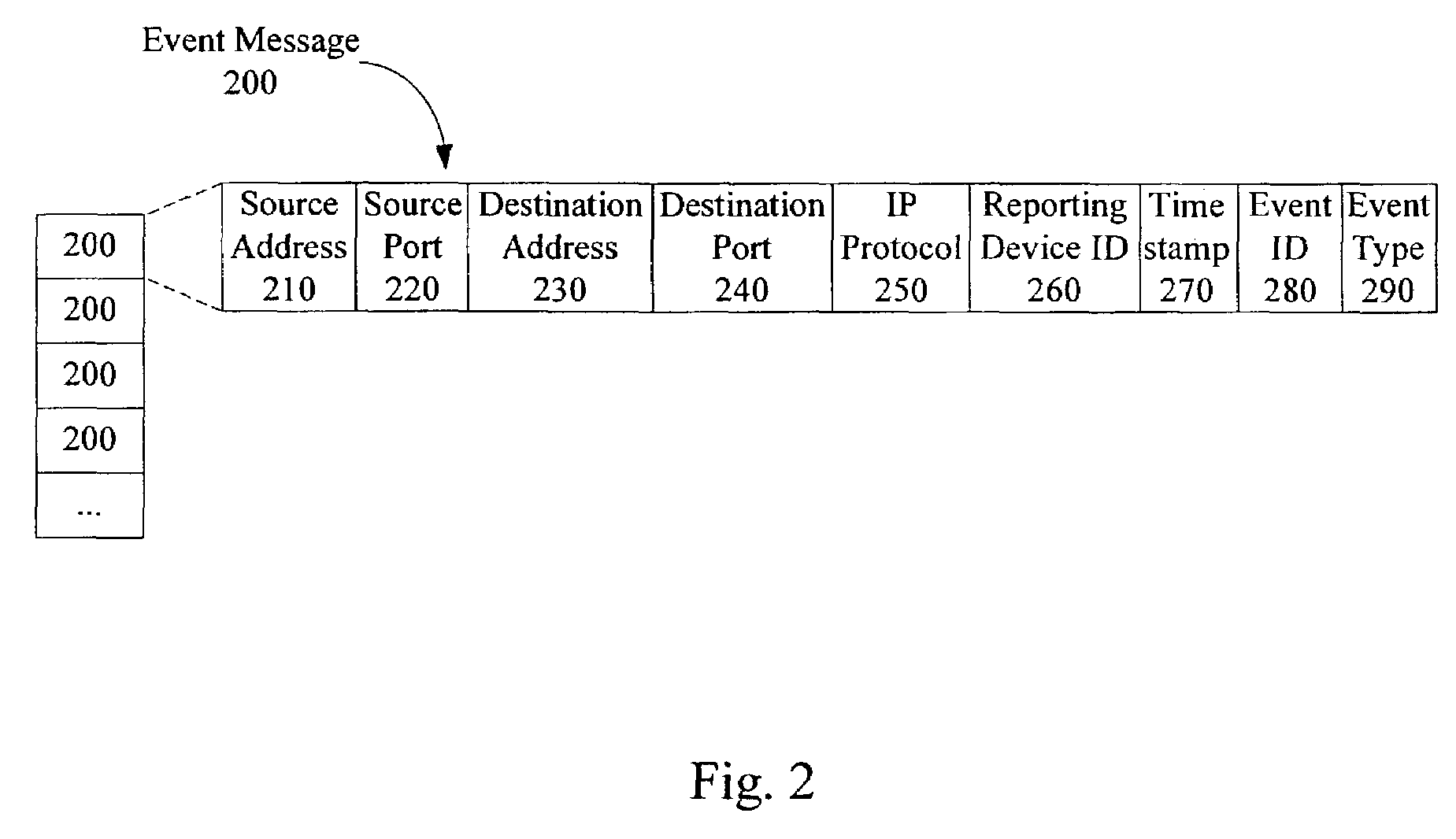

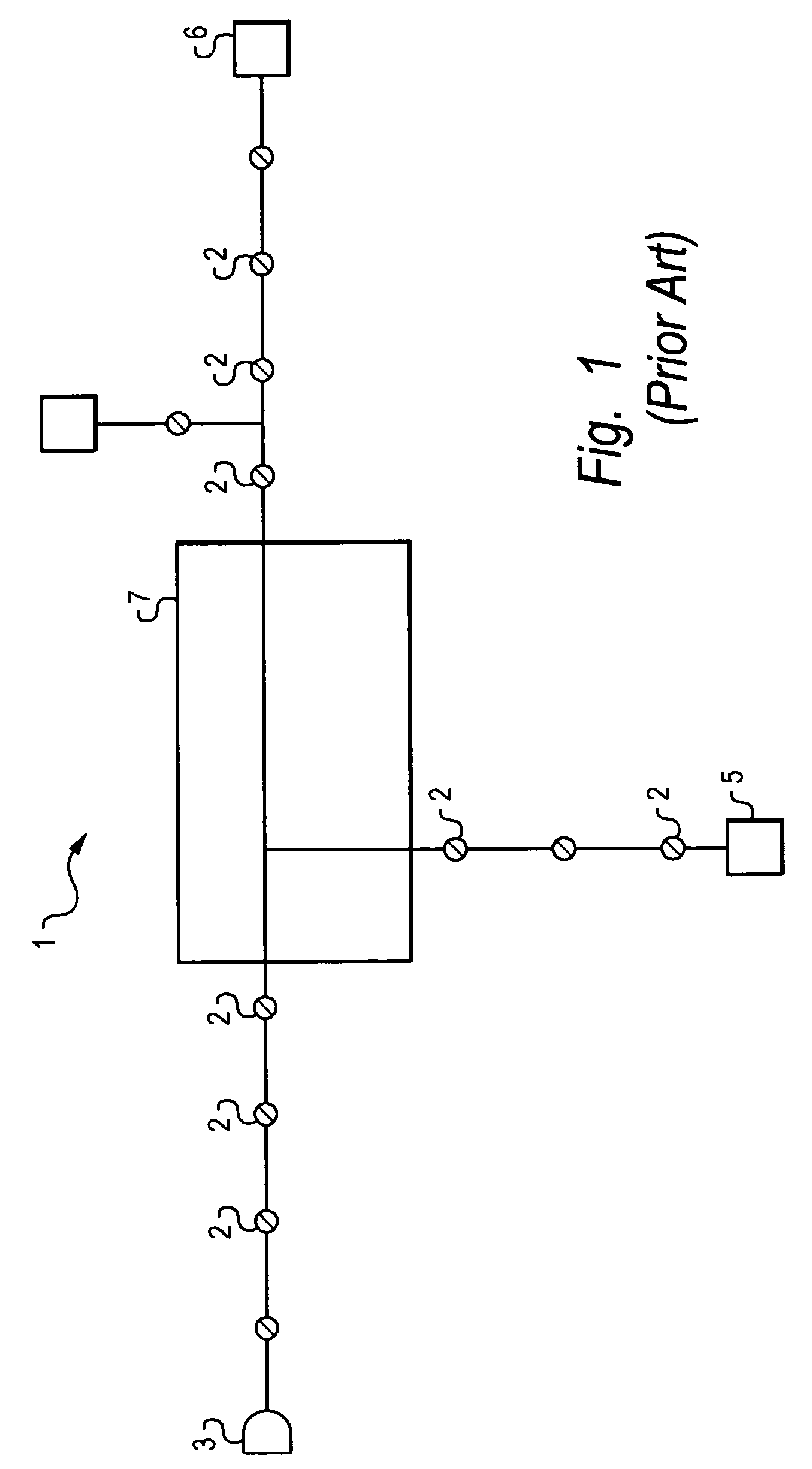

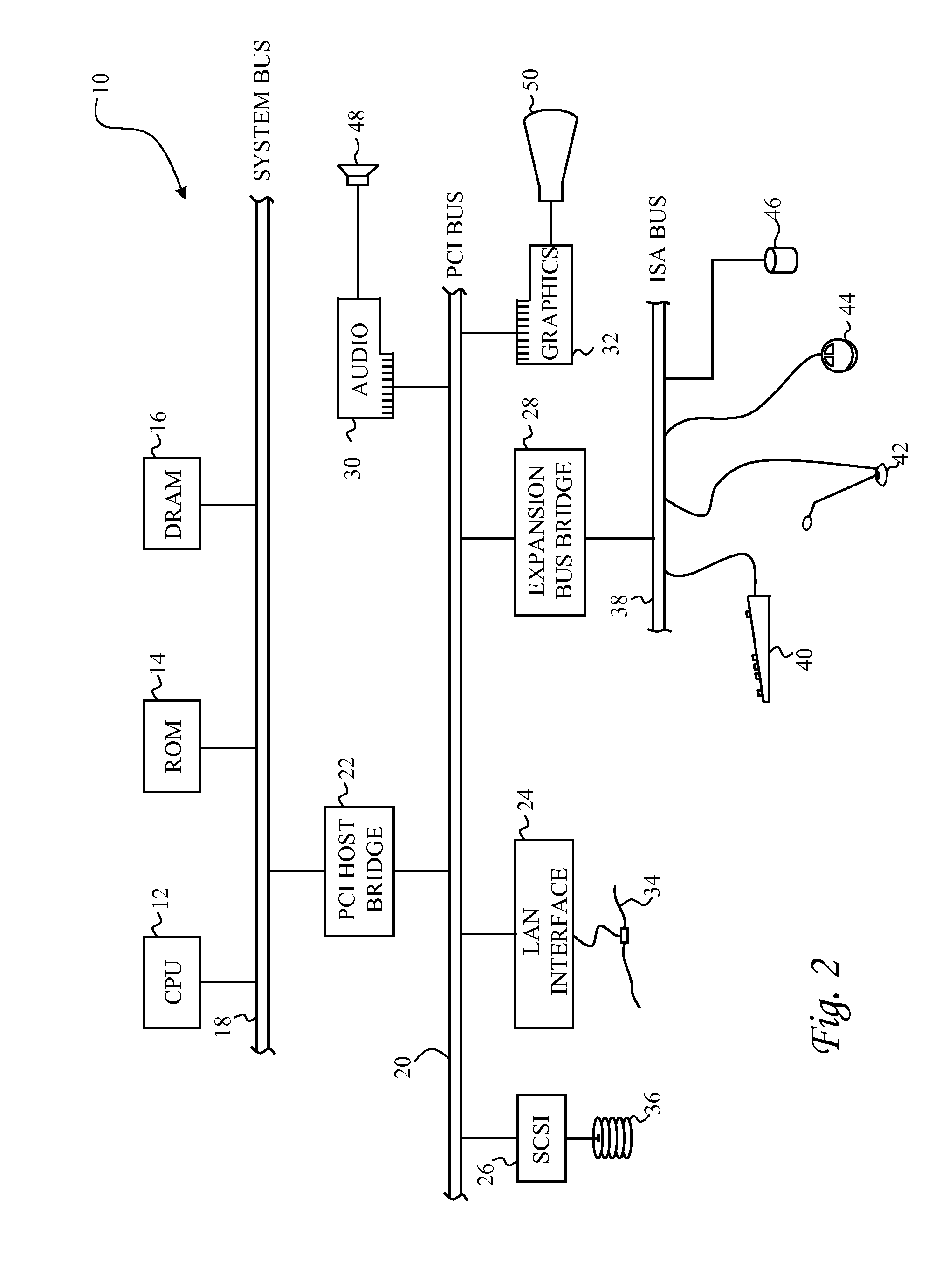

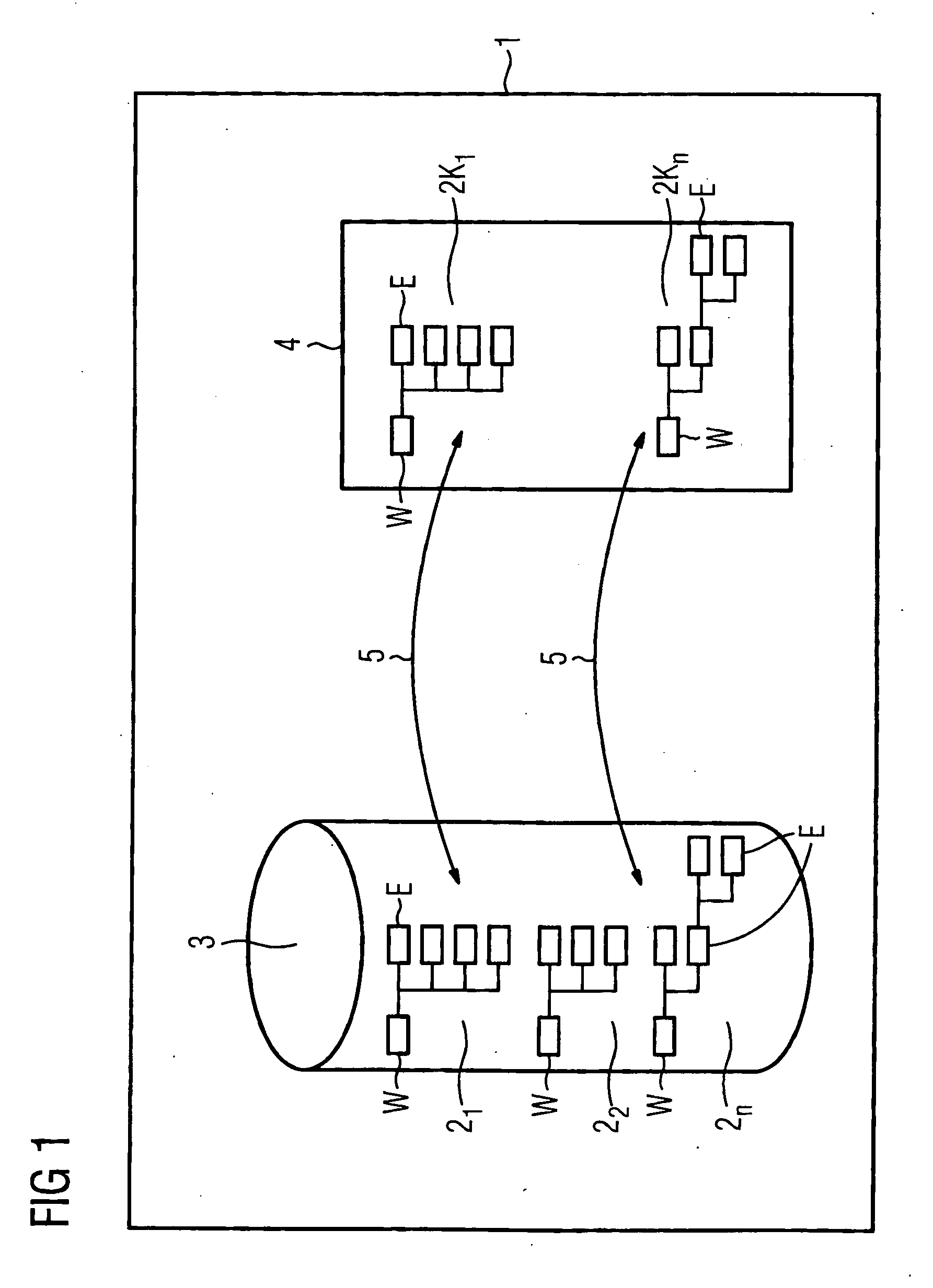

Network security monitoring system

InactiveUS7483972B2Memory loss protectionError detection/correctionMonitoring systemPartial solution

A security monitoring system processes event messages related to computer network security in real time, evaluating inter-event constraints so as to identify combinations of events that are partial solutions to a predefined event correlation rule, and furthermore evaluating combinations of the partial solutions do determine if they together satisfy the predefined event correlation rule. A decision tree is formed based on the rule. Event messages are categorized into groups at leaf nodes of the tree in accordance with a plurality of intra-event constraints, and then the messages are correlated in accordance with a plurality of inter-event constraints at non-leaf nodes of the tree. When the inter-event constraint at a root node of the tree has been satisfied, a network attack alert is issued and protective actions may be taken.

Owner:CISCO TECH INC

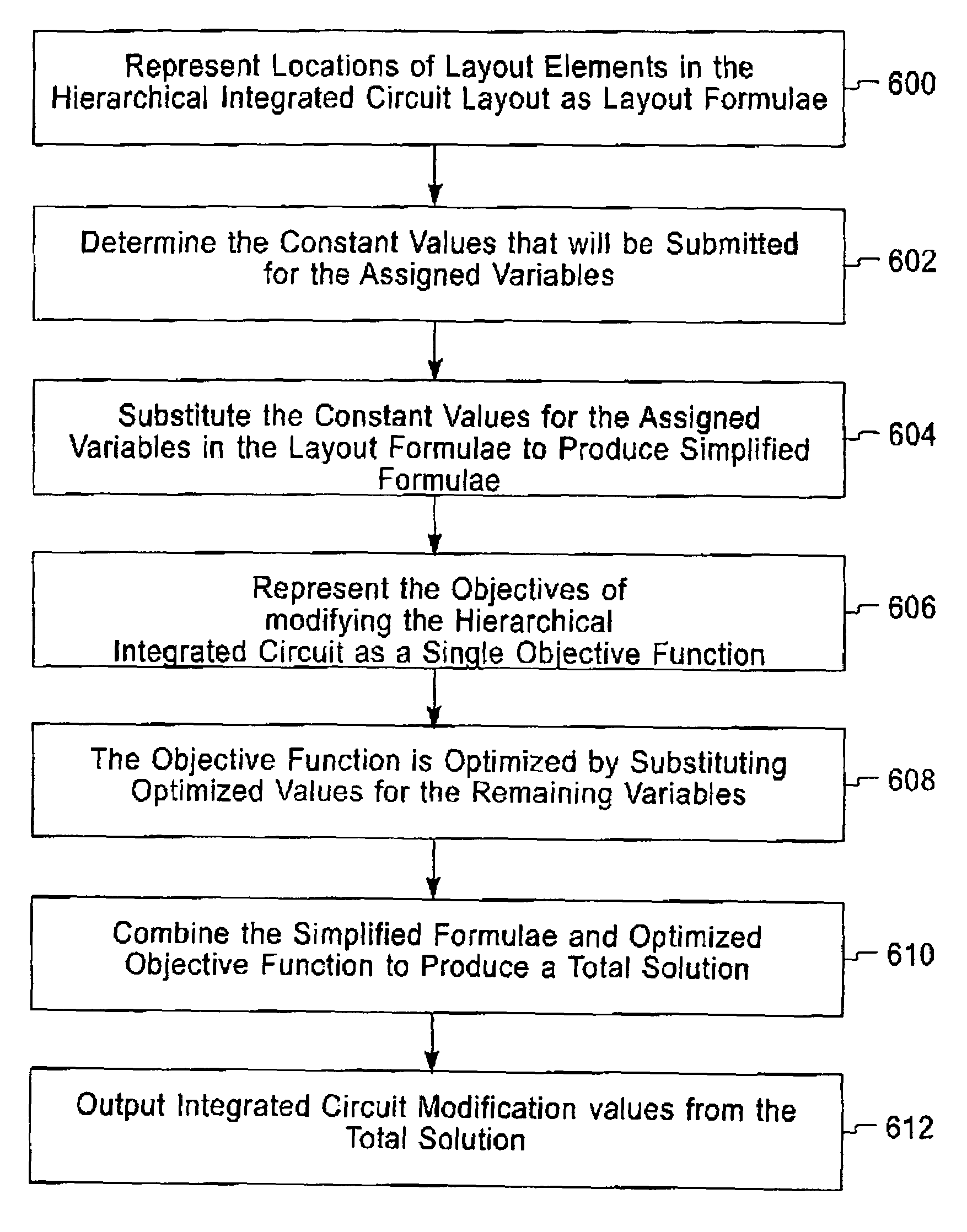

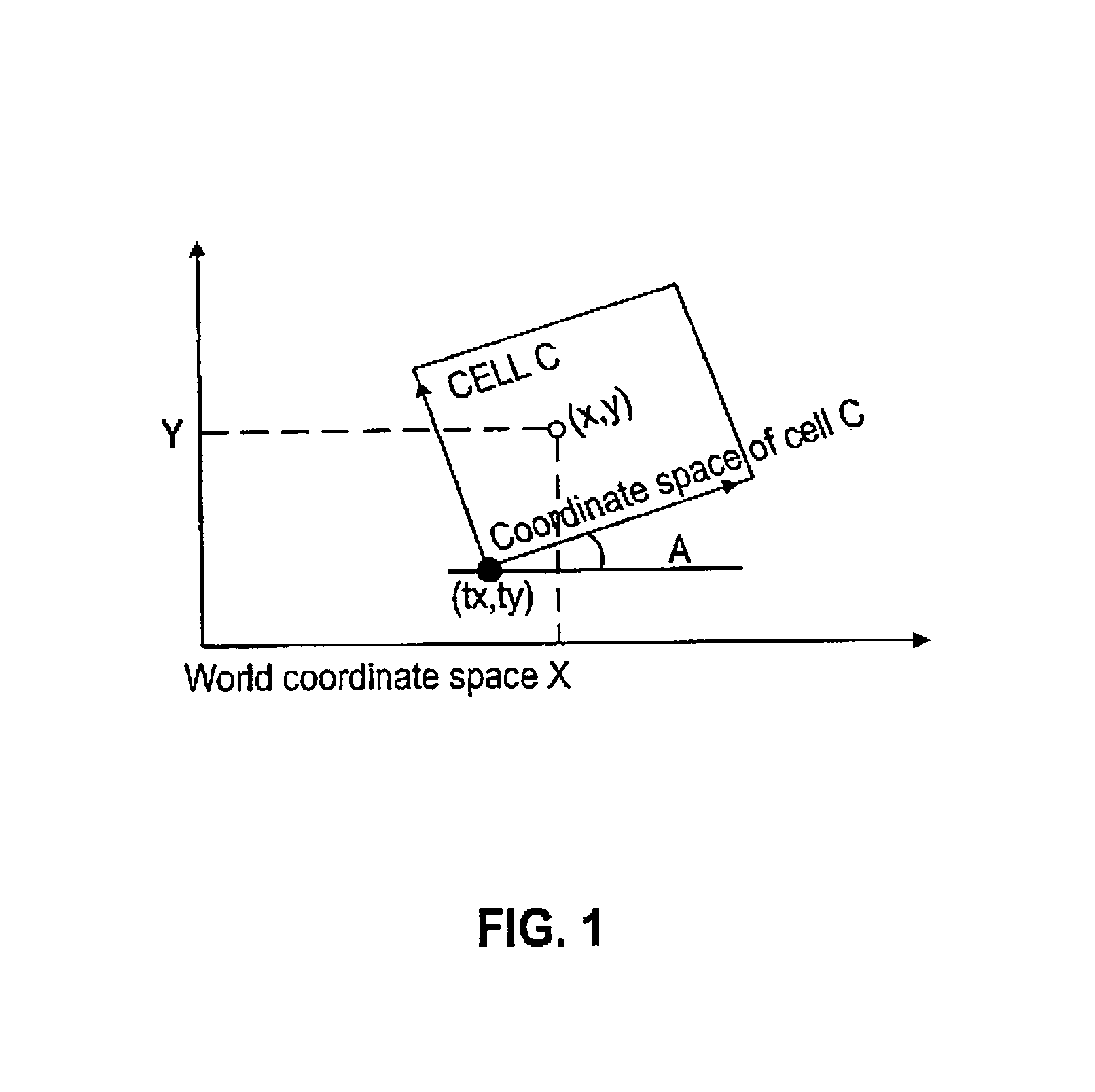

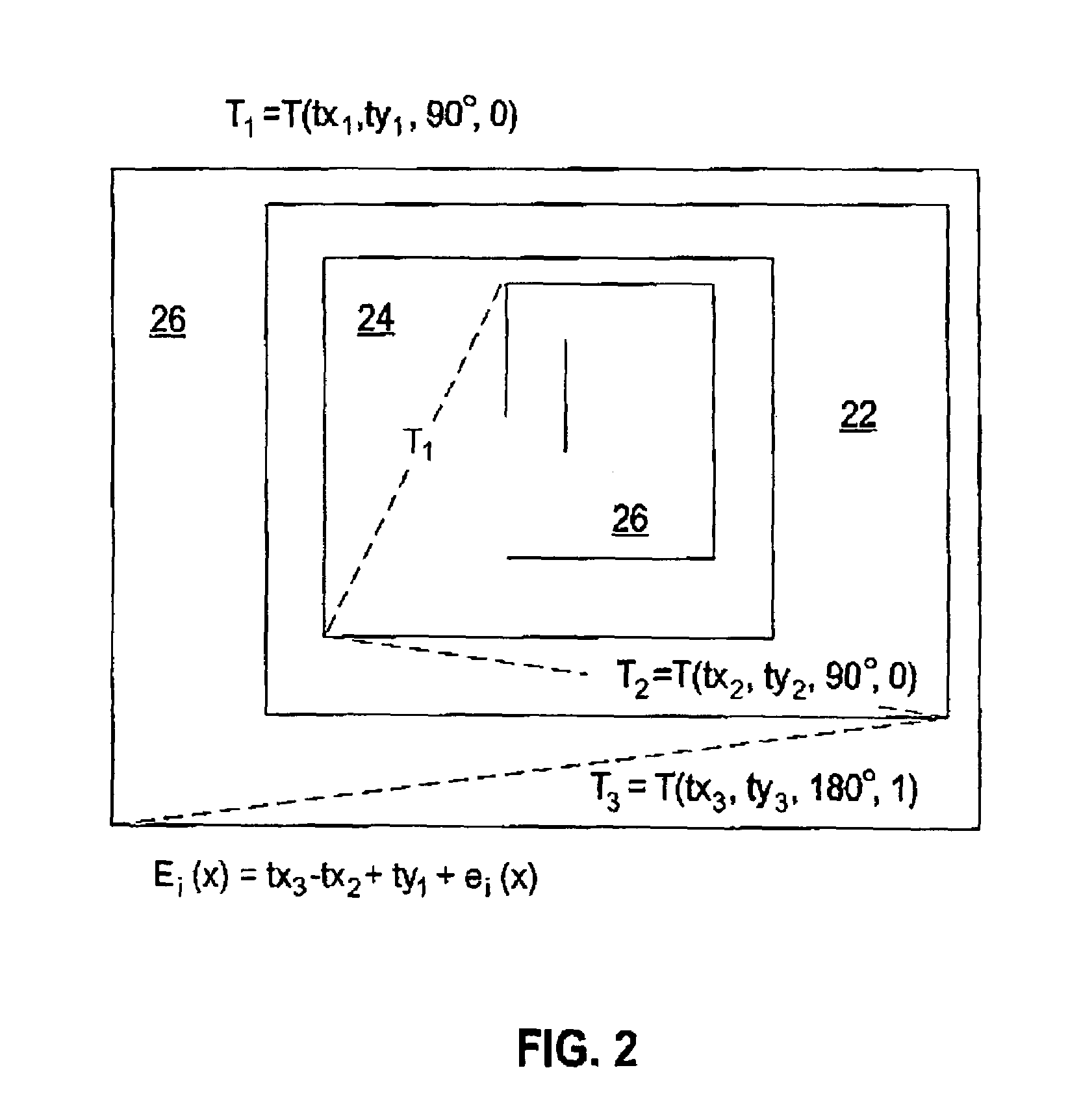

Practical method for hierarchical-preserving layout optimization of integrated circuit layout

InactiveUS6986109B2High yieldReduce coupling noiseCAD circuit designSoftware simulation/interpretation/emulationComputer architecturePartial solution

Owner:INT BUSINESS MASCH CORP

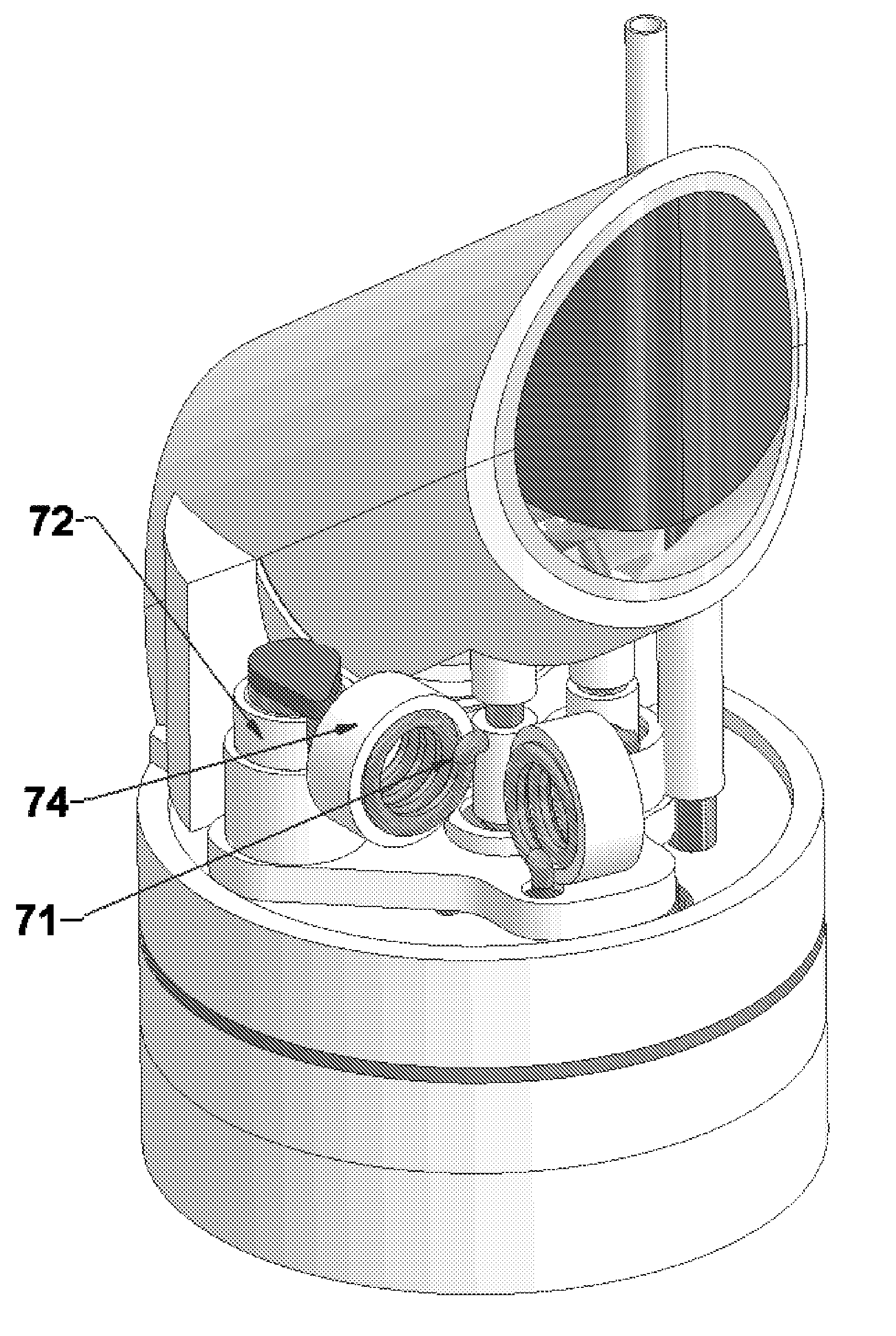

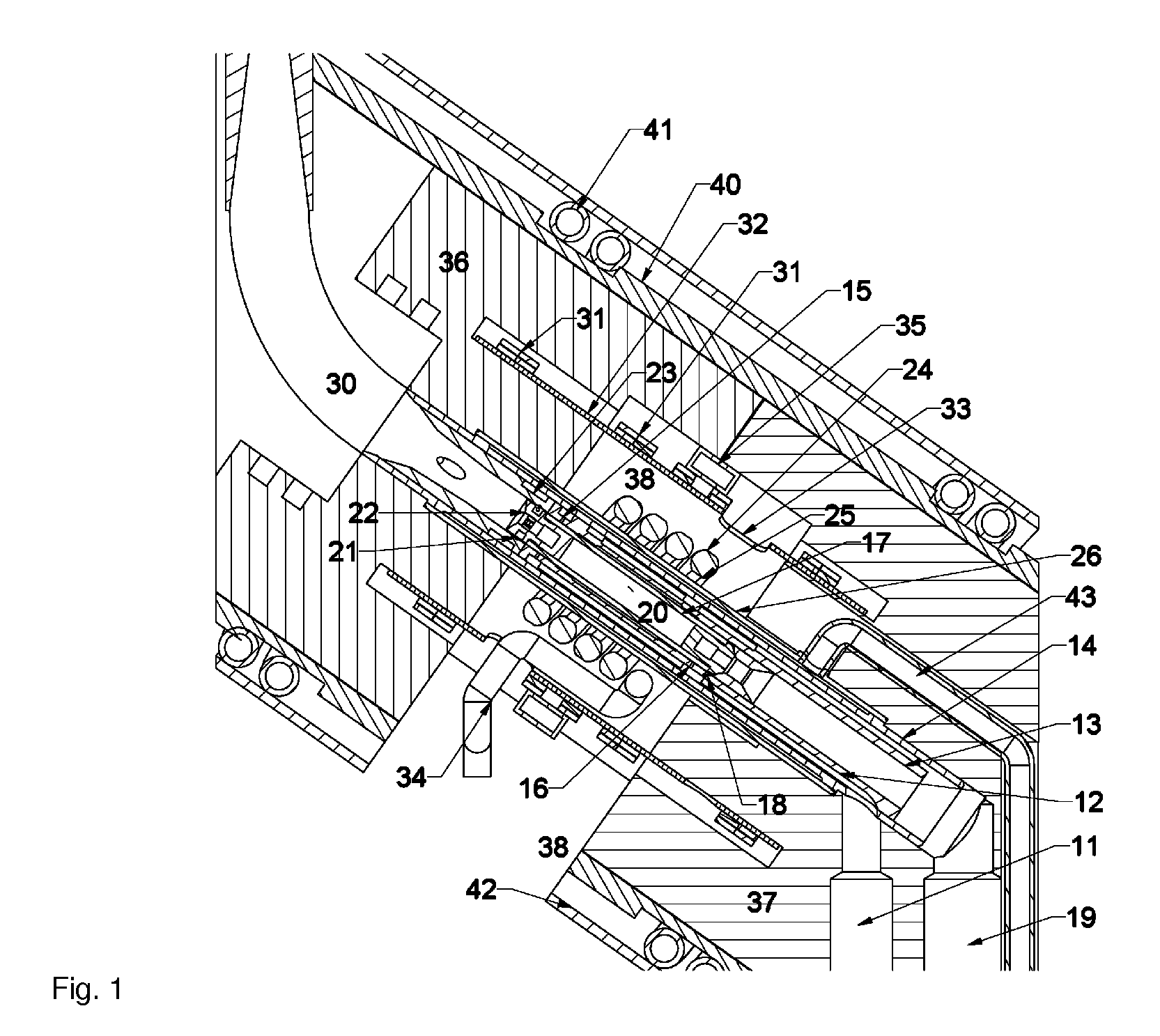

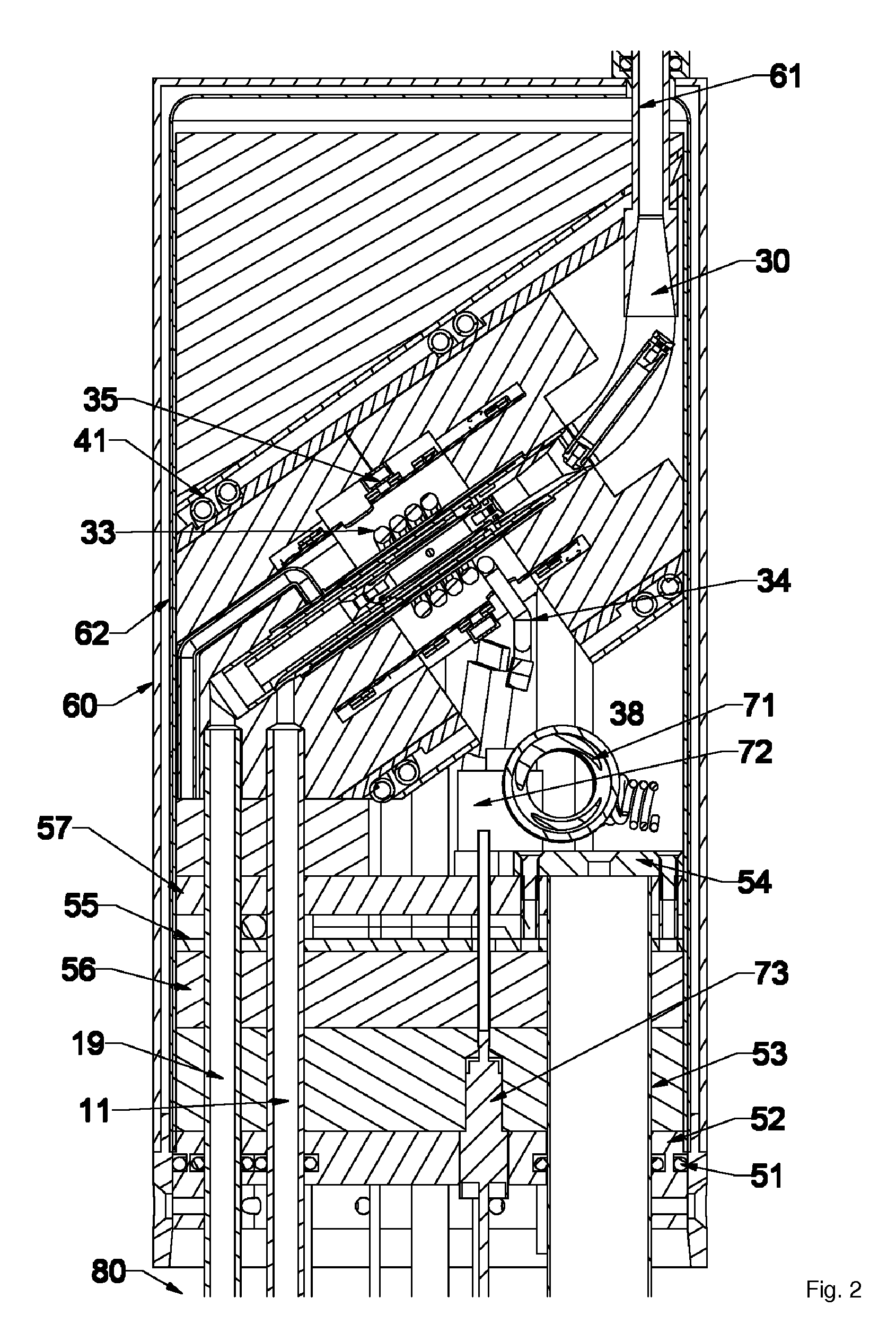

NMR CryoMAS Probe for High-field Wide-bore Magnets

InactiveUS20060176056A1Reduce riskImprovement factorElectric/magnetic detectionMeasurements using magnetic resonancePartial solutionNitrogen gas

An MAS probe is disclosed for obtaining a substantial improvement in signal to noise (S / N) in triple-resonance high-resolution (HR) magic-angle-spinning (MAS) NMR of samples near room temperature (RT) in high-field magnets where the magnet's RT shim bore is greater than 60 mm. All critical circuit components, including the sample coils, are located along with the spinner assembly in a thermally insulated cold zone pressurized with helium gas. The spinner assembly attaches to a sealed, curved, rotor-loading tube to permit automatic sample change, and it is surrounded by a partially insulated jacket cooled with a cryogenic fluid, generally nitrogen gas. The MAS probe is also compatible with magic angle gradients, variable temperature operation, field locking, and commonly available closed-cycle cold fingers. One major challenge in implementing CryoMAS is solving the problem of gas leakage from the spinner bearing, drive, and exhaust nitrogen into the cold zone, as some components will necessarily be ceramic, some plastic, and some metal. It is not desirable to use helium for the spinner bearing and drive gases for cost reasons and to prevent risk of degradation of o-ring-sealed magnet cryostats. A pressurized helium atmosphere in the cold zone may be utilized to prevent nitrogen flow from the spinner exhaust streams or atmosphere into the cold zone. The drawback to a pressurized cold zone is that the heat transfer coefficient in dense helium at low temperatures is very high, making it challenging to cool the sample coils and all the large, critical, circuit components in a practical manner. Part of the solution here is to use a first-stage cooling-jacket around the major heat leaks near the spinner exhaust flows. The critical components may be insulated with fine glass wool or teflon foam and conduction cooled without cooling much of the cold zone below the temperature of the first-stage cooling. The use of coaxial sapphire capacitors allows the noise contributions from the most critical capacitors to be reduced to a minor fraction of the total.

Owner:DOTY SCI

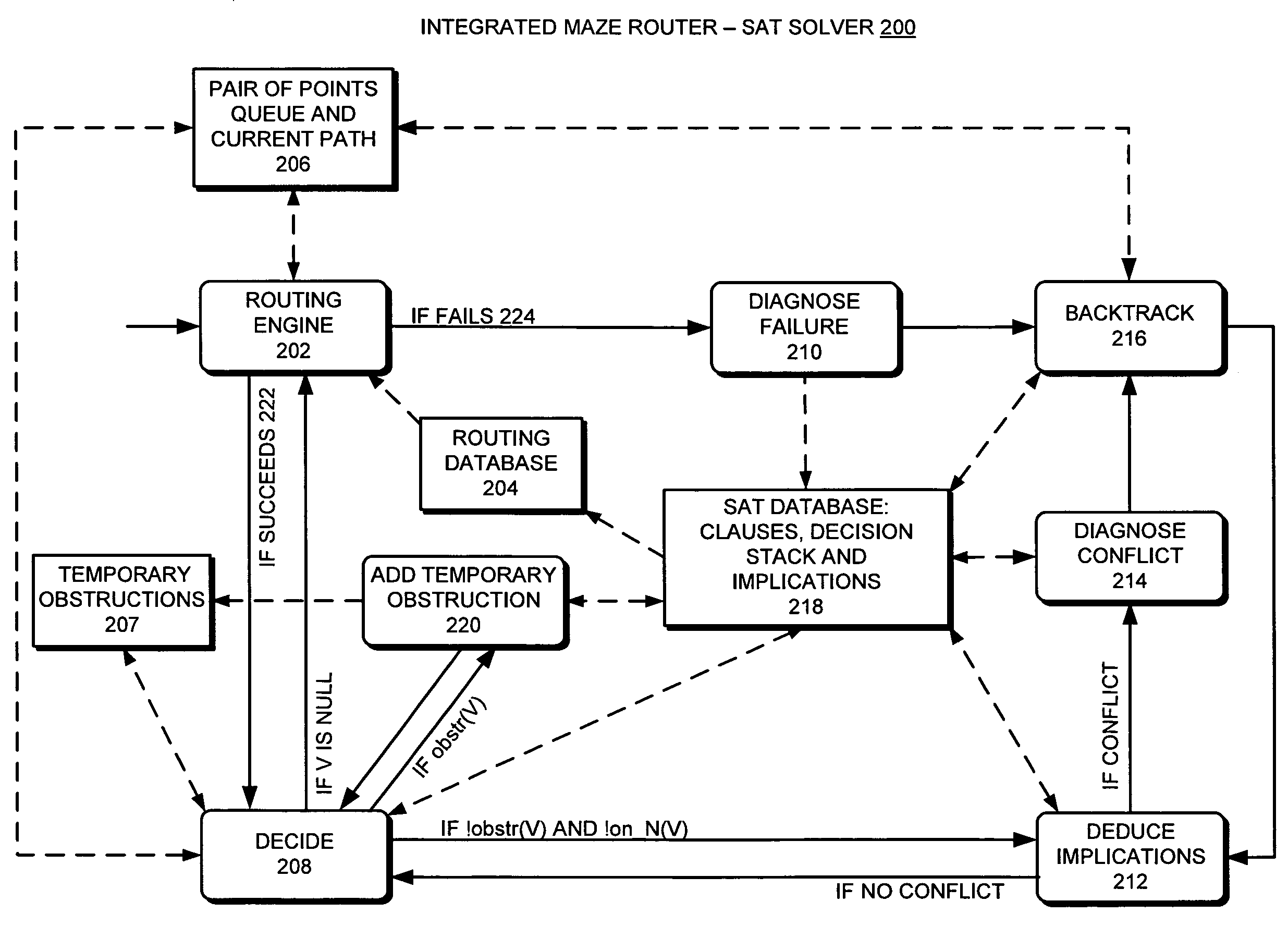

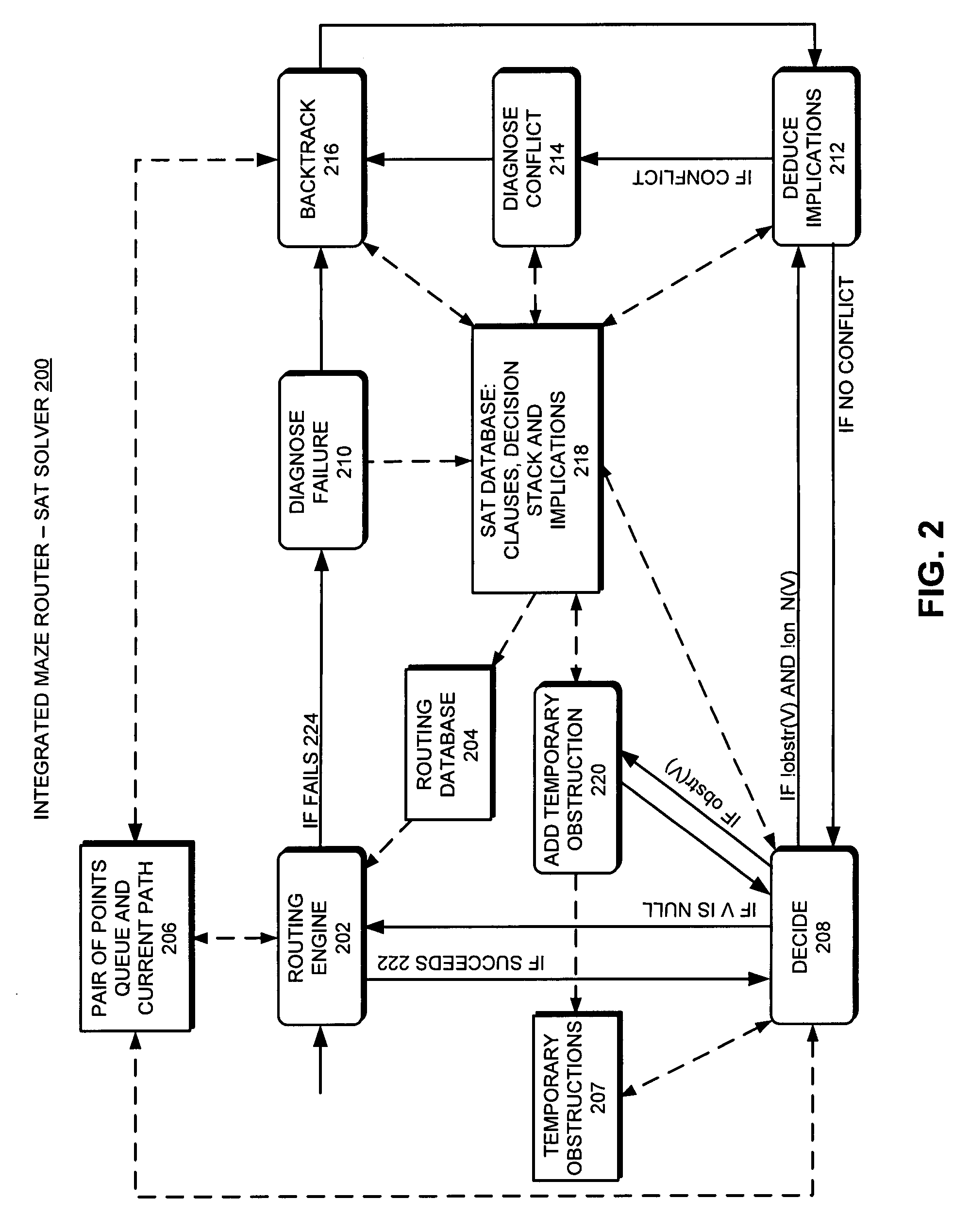

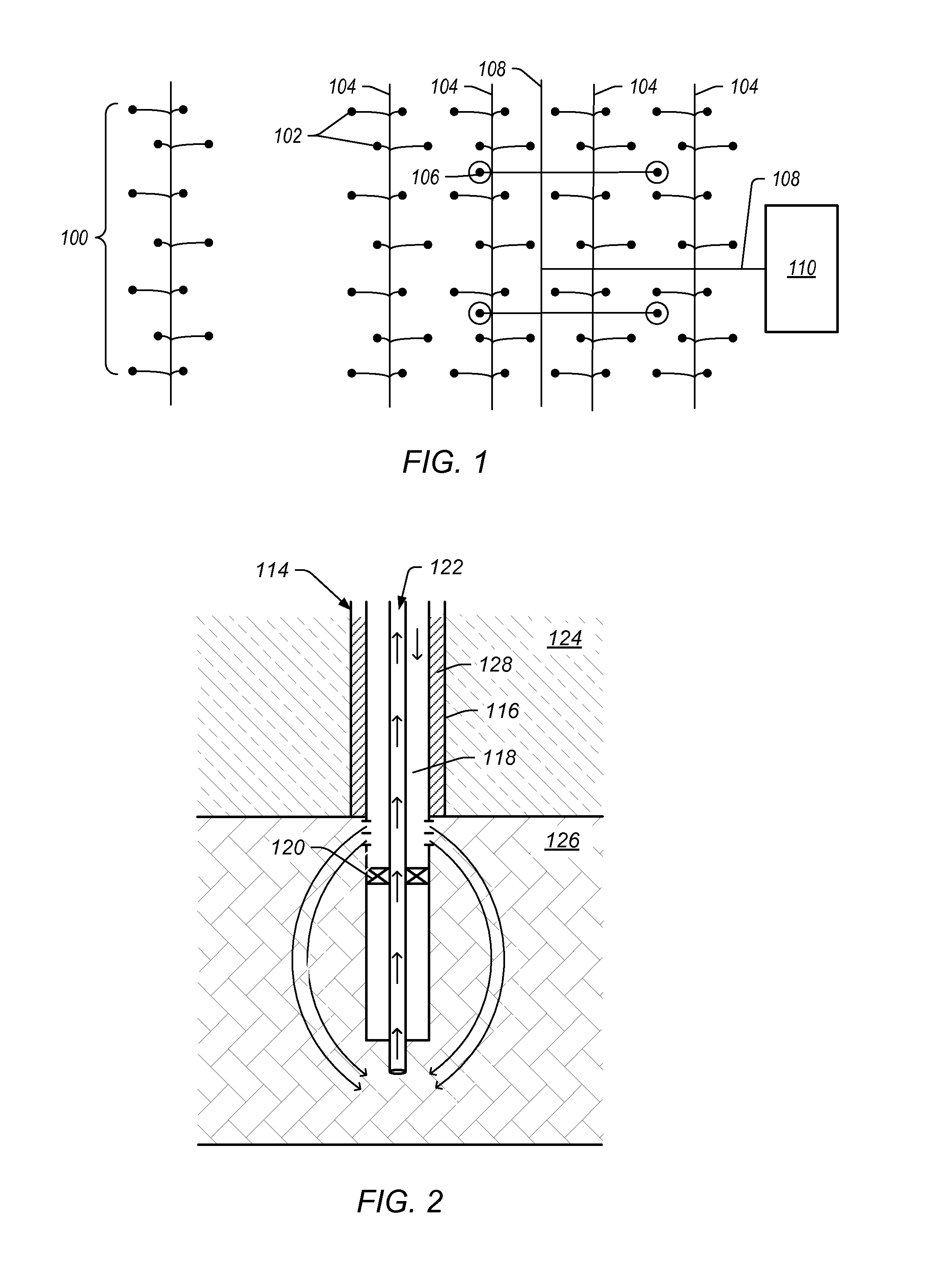

Integrating a boolean SAT solver into a router

ActiveUS7904867B2Computer aided designSpecial data processing applicationsPartial solutionSatisfiability

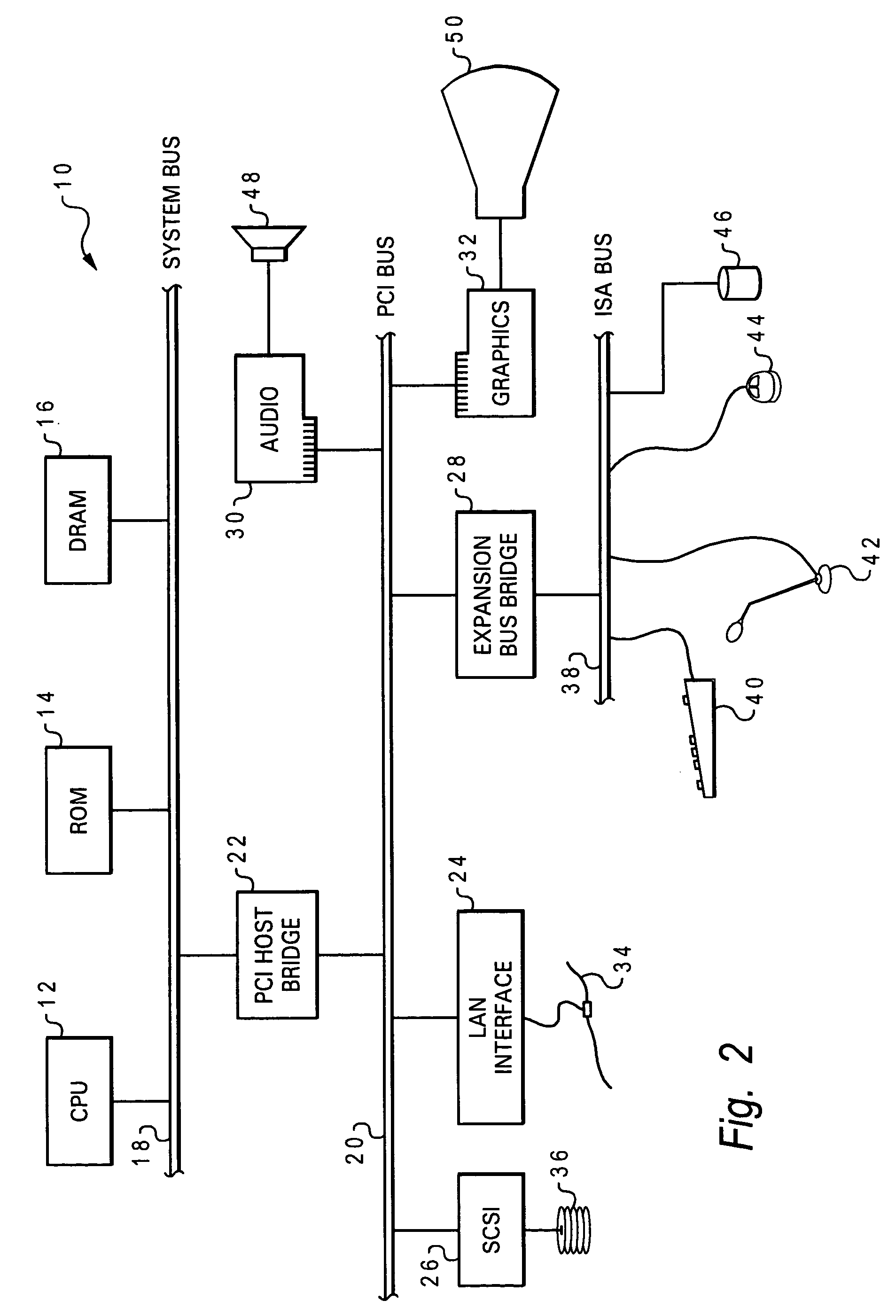

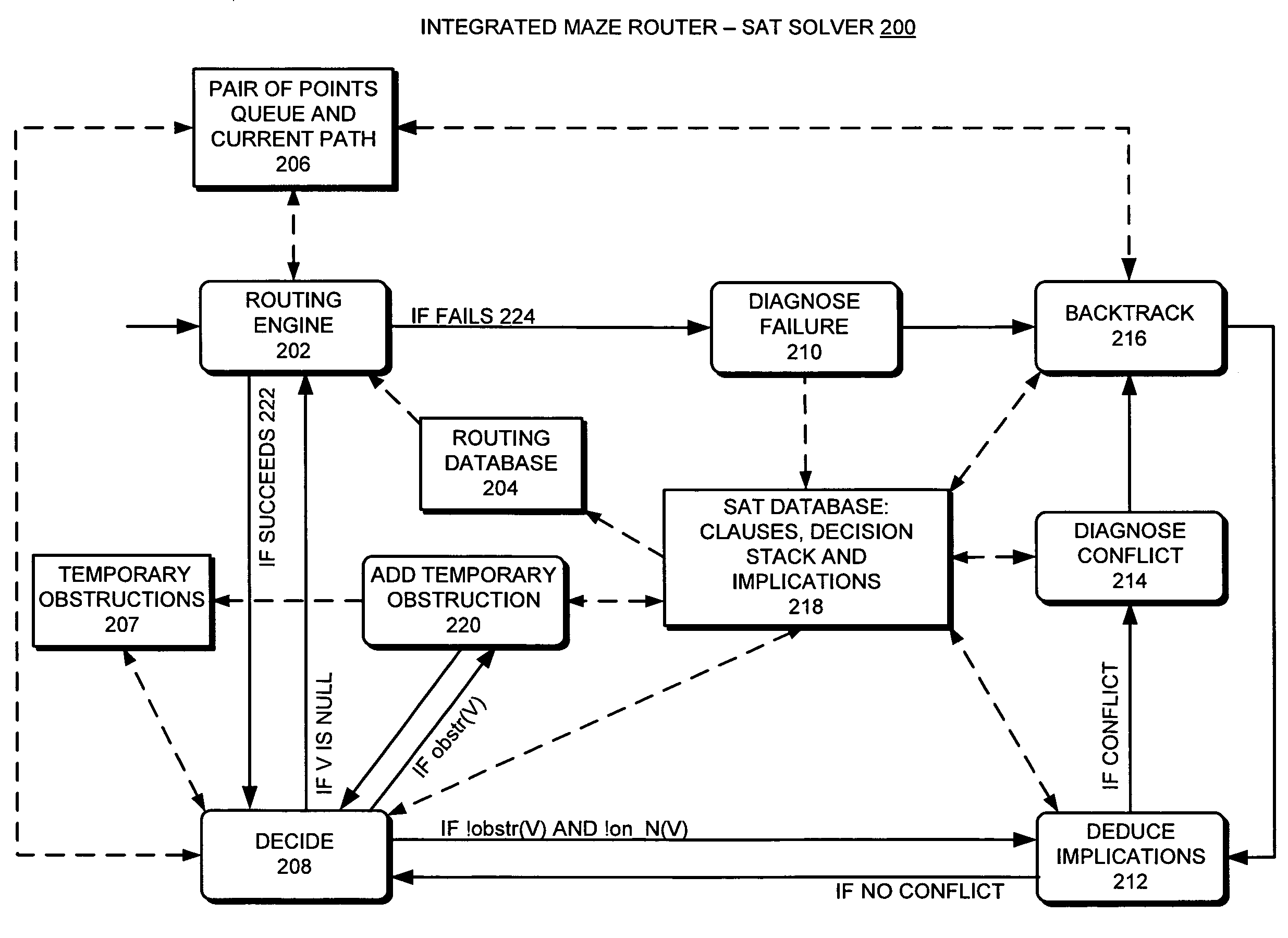

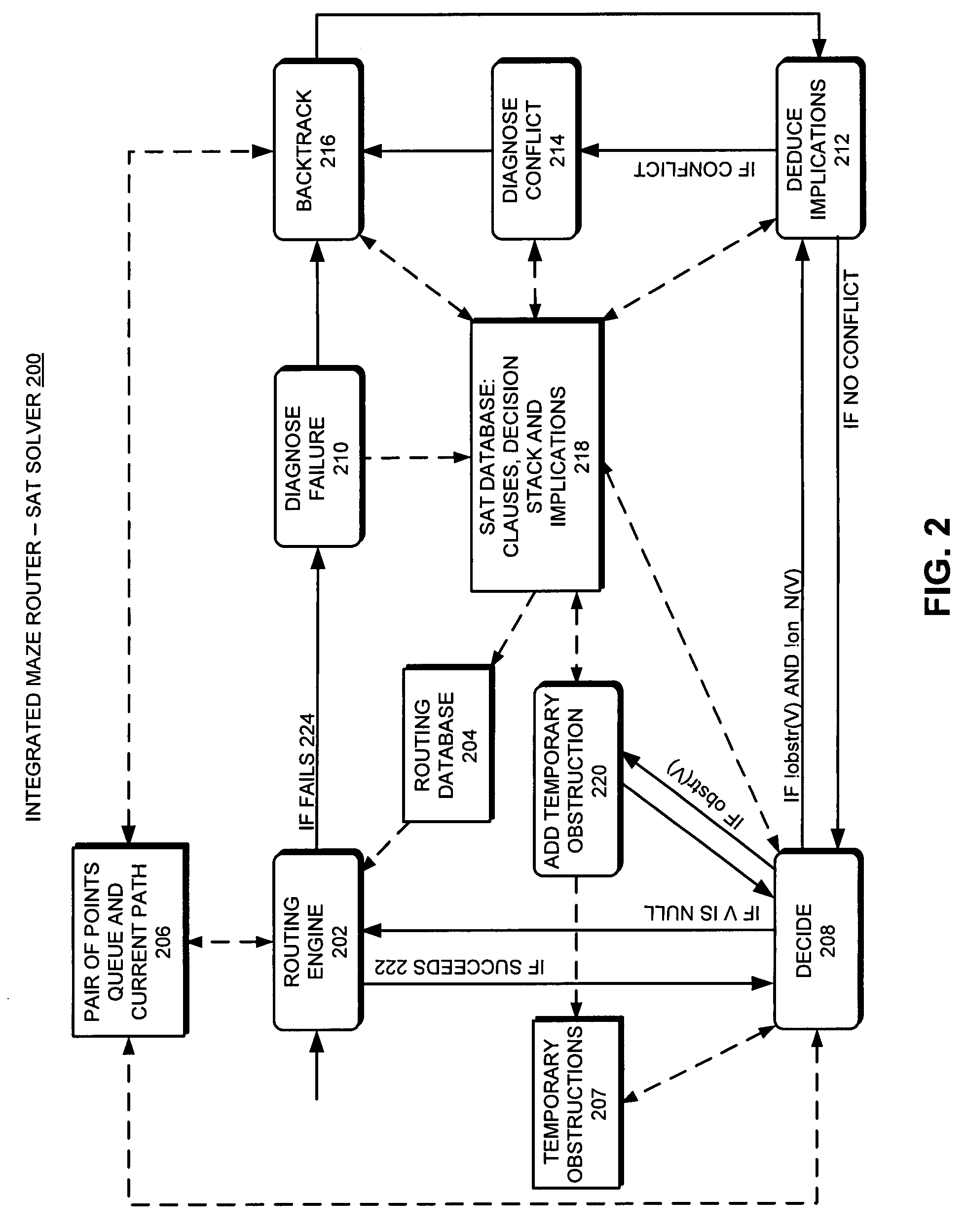

One embodiment of the present invention provides a system that routes a set of pairs of points during the design of an integrated circuit (IC) chip. The system comprises a routing engine which is configured to search for a path to connect a current pair of points in the set of pairs of points, wherein the path comprises a set of rectangles and vertices. The routing engine uses a routing database, which keeps track of previously routed nets that can obstruct the routing of the current pair of points. The system further comprises a satisfiability (SAT) solver which is capable of solving a set of constraints, wherein the set of constraints are associated with the routability of the set of pairs of points. The SAT solver additionally comprises a SAT database which maintains the set of constraints and a current partial solution to the set of constraints. The SAT database is used to update the routing database if the current partial solution changes.

Owner:SYNOPSYS INC

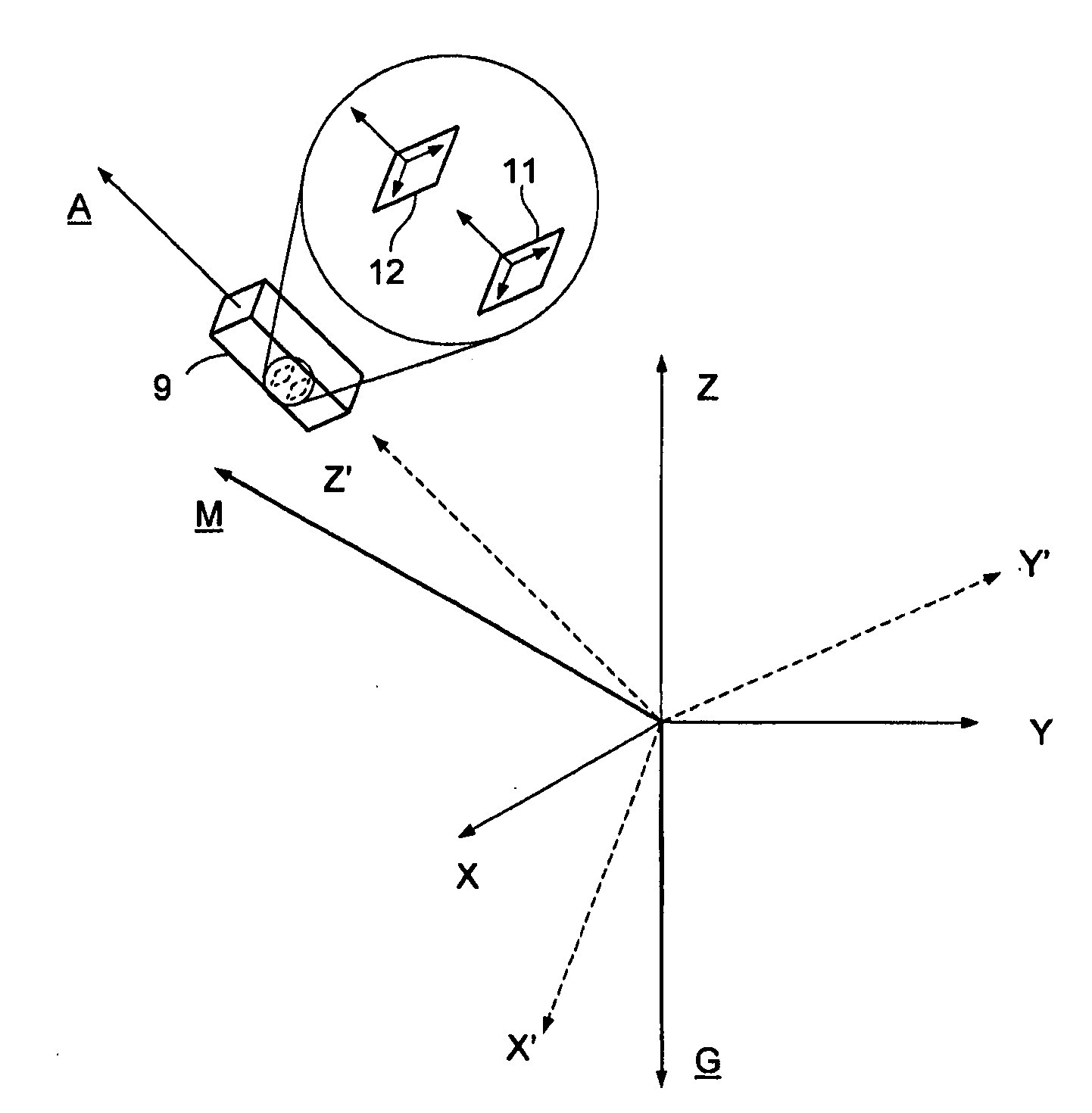

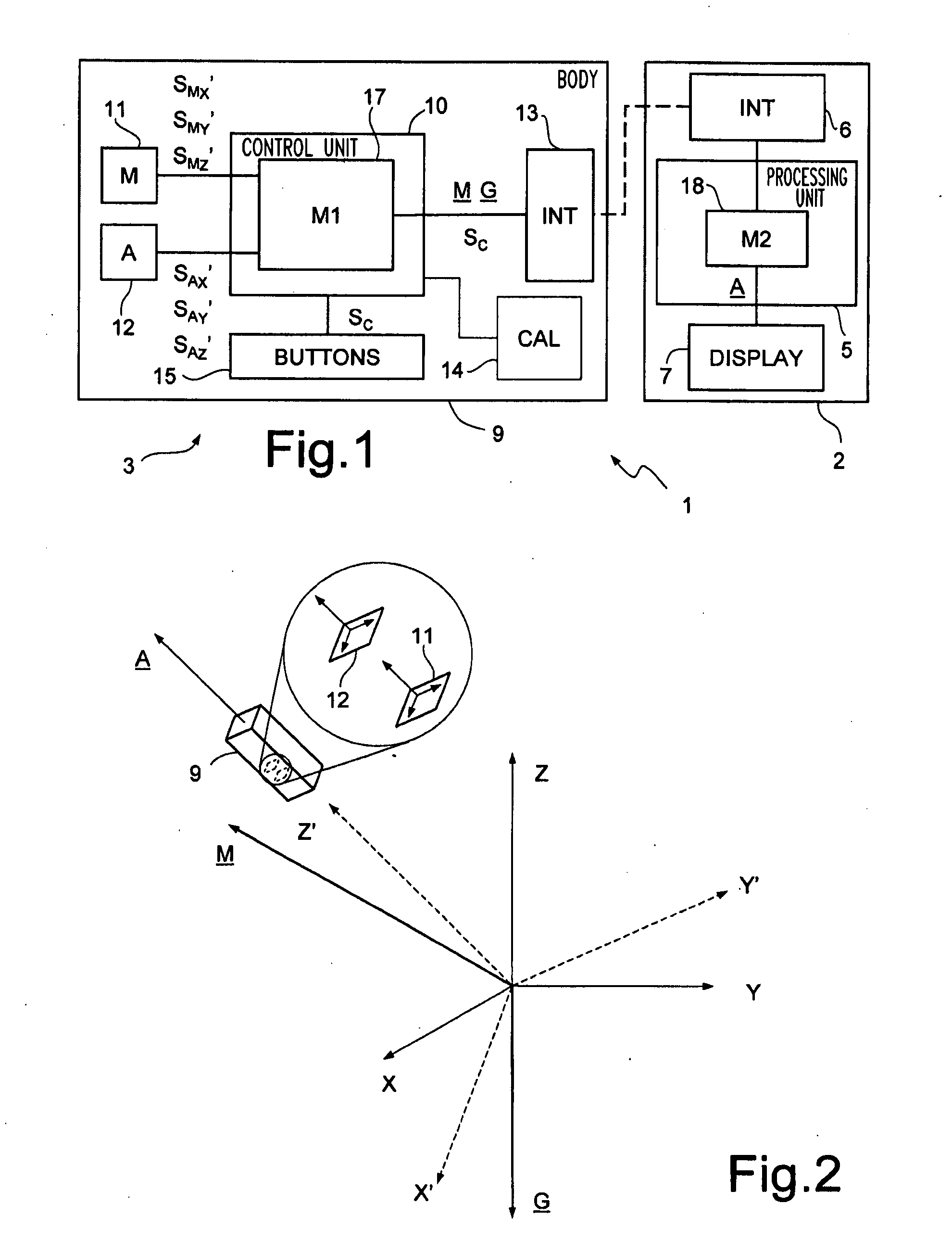

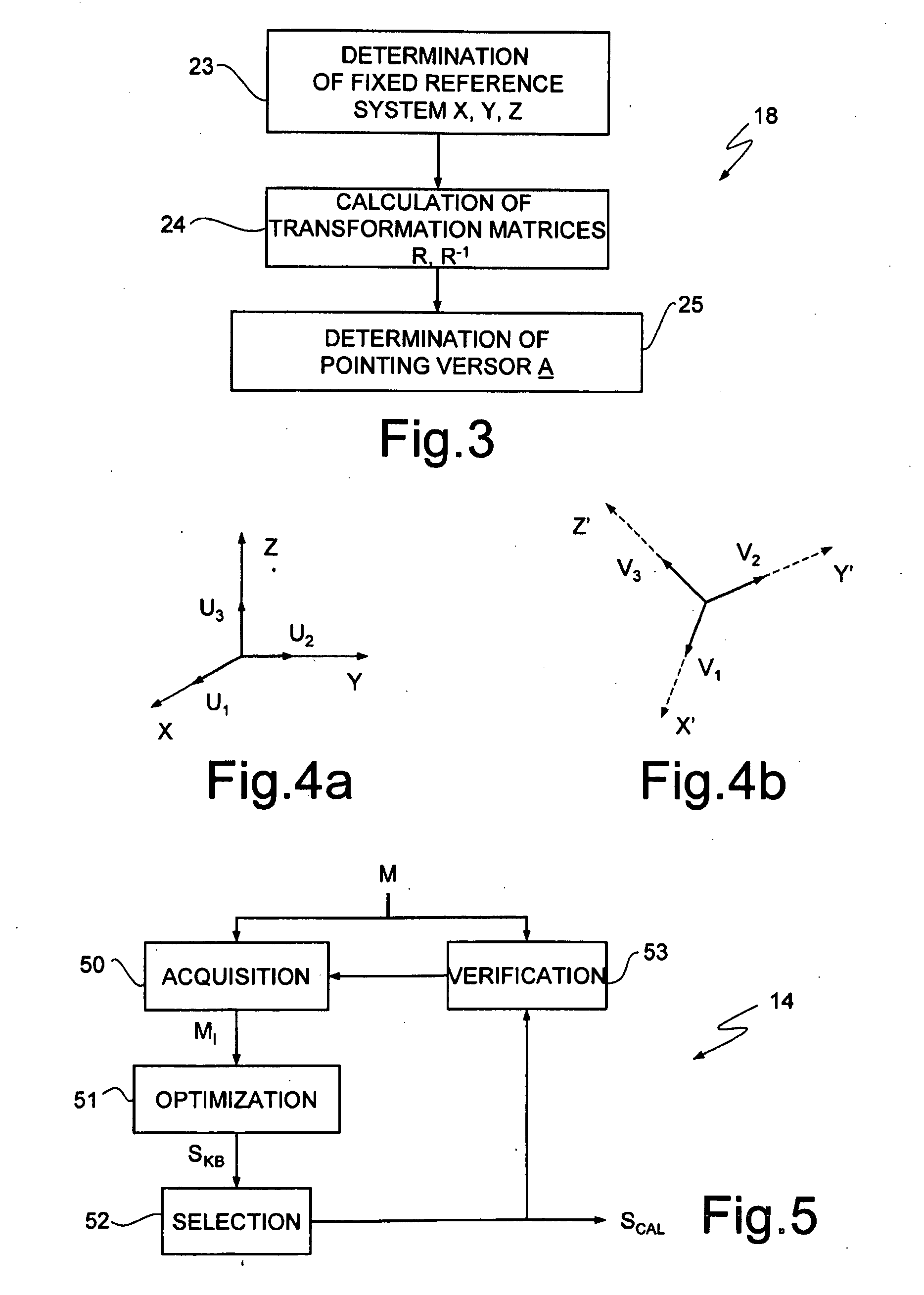

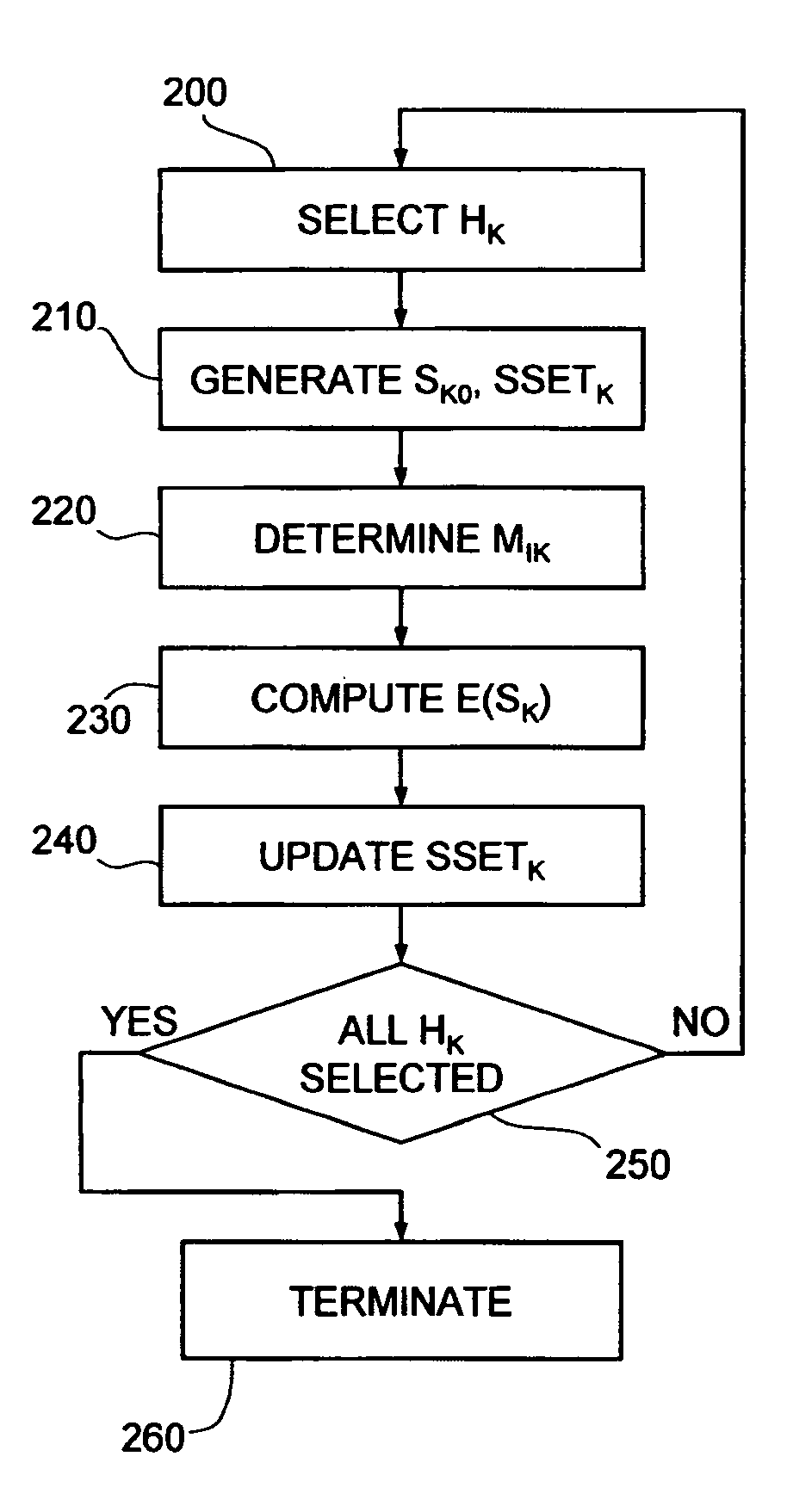

Method and device for calibrating a magnetic sensor

InactiveUS20090070056A1Overcome limitationsTesting/calibration of speed/acceleration/shock measurement devicesSpecial data processing applicationsConfidence intervalPartial solution

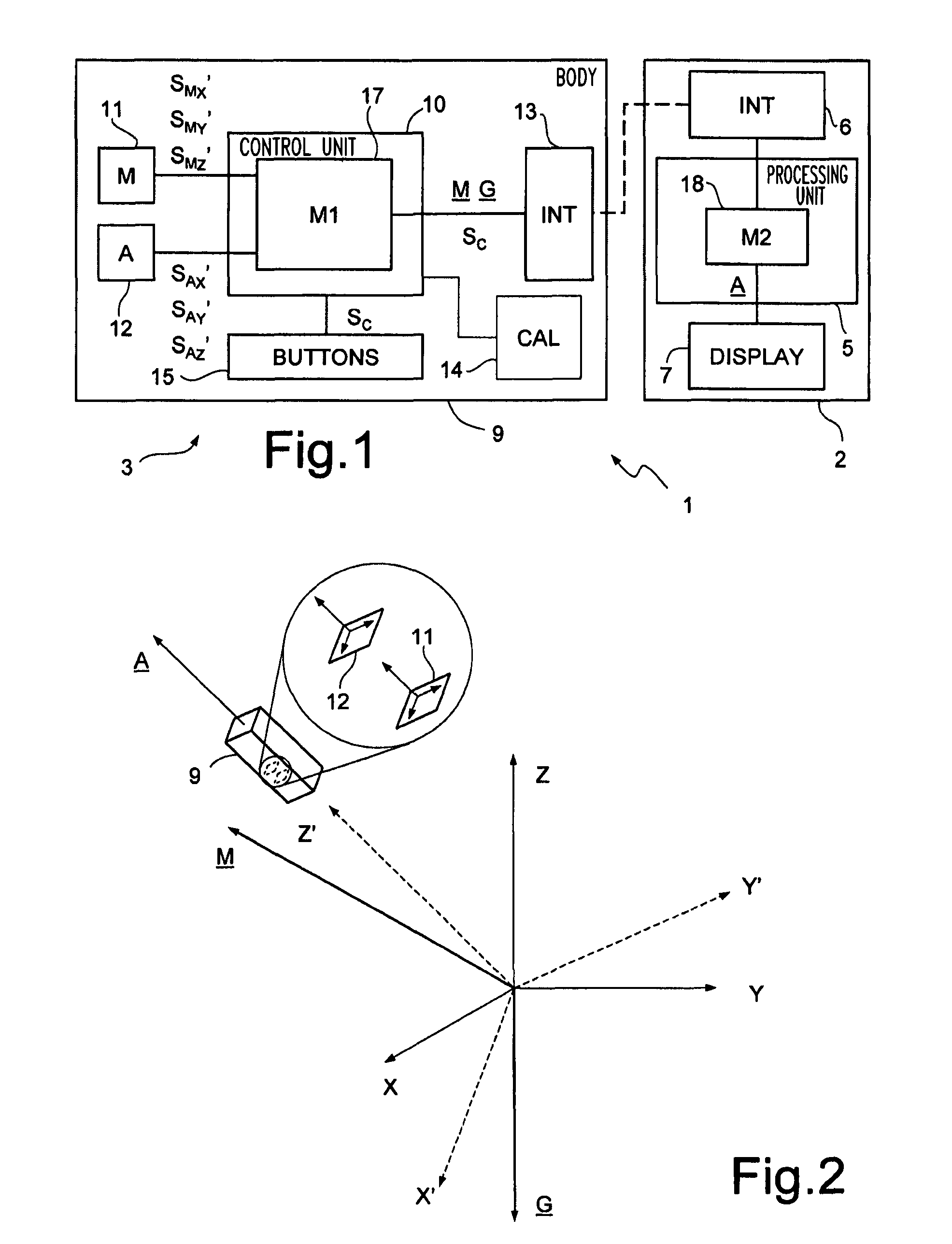

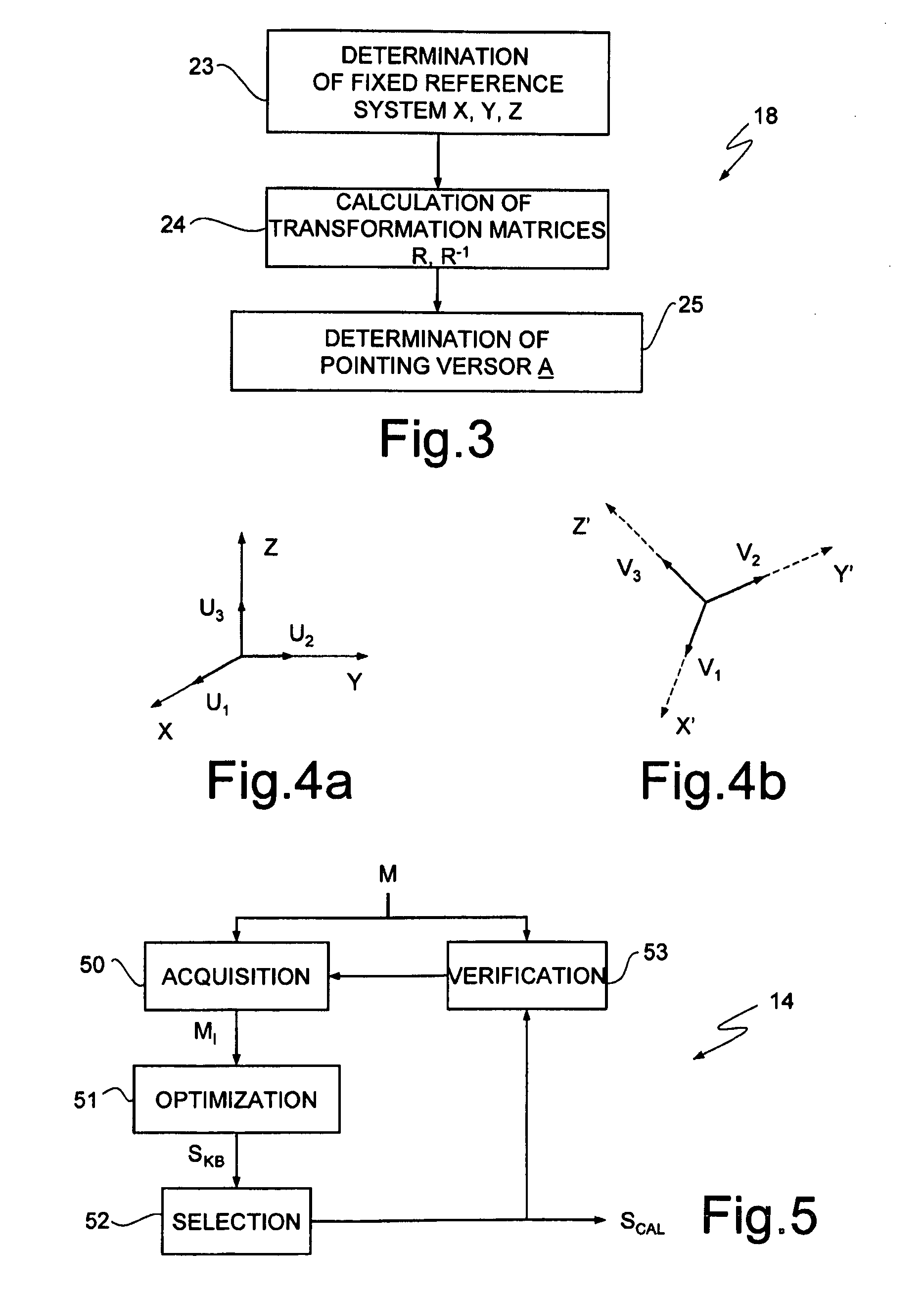

Measurements are acquired from a magnetic sensor during a non-pre-ordered movement, and a plurality of sets of solutions are determined for respective expected values of intensity of the Earth's magnetic field. The solutions are defined by a plurality of parameters, including at least one gain value for each detection axis of the magnetic sensor. For each solution, a figure of merit is determined, correlated to a calibration error, and a partial solution is selected in each set of solutions, based on the figure of merit. Once a gain confidence interval has been defined, a calibration solution is selected based on the figure of merit, from among the partial solutions having respective gain values all falling within the gain confidence interval.

Owner:STMICROELECTRONICS SRL

Method and device for calibrating a magnetic sensor

InactiveUS7835879B2Testing/calibration of speed/acceleration/shock measurement devicesSpecial data processing applicationsConfidence intervalPartial solution

Owner:STMICROELECTRONICS SRL

Method for making products used in sequential micronutrition and uses of resulting products

A method for making products used in micronutrition which includes selecting for at least two among the following types: trace element, plant, food principle, microorganism, vitamin, one or several active substances of each type depending on the functions required for the system; sequentially combining the active substances of each type by introducing sequentially each of them in an intermediate container in the form of a liquid solution, so as to obtain a partial solution; and combining sequentially and in the following order: trace element, plant, food principle, microorganism, vitamin, the resulting partial solutions by introducing sequentially each partial solution into a final container.

Owner:CAENAZZO ELISABETH

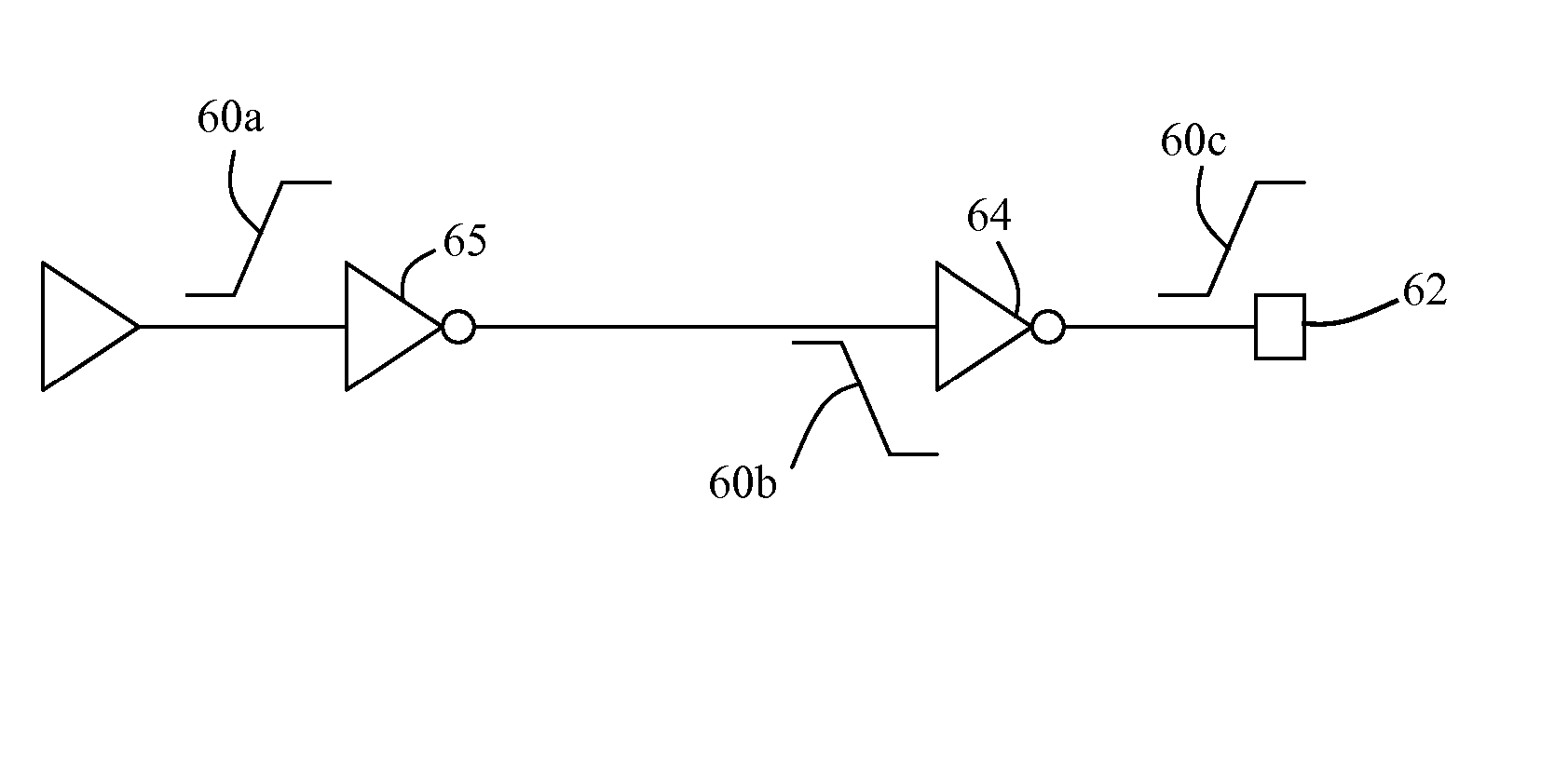

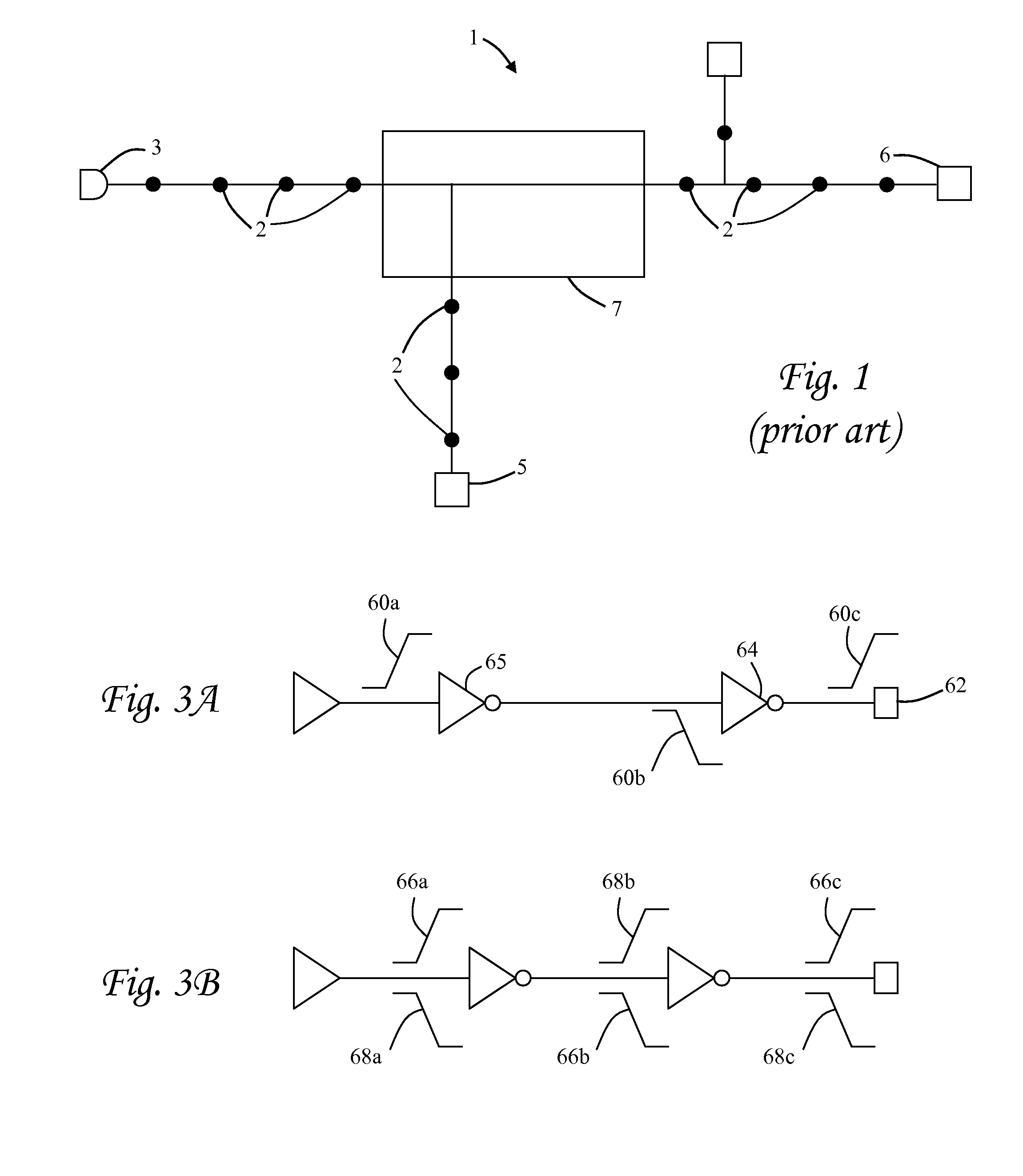

Techniqes for super fast buffer insertion

InactiveUS20060112364A1Simple methodConvenient timeCAD circuit designSoftware simulation/interpretation/emulationCapacitanceElectrical resistance and conductance

A method of determining buffer insertion locations in an integrated circuit design establishes candidate locations for inserting buffers into a net, and selects buffer insertion locations from among the candidates based on slew constraints. The selection of buffer insertion locations preferably optimizes slack and buffer cost while keeping slew from any buffered node to any sink less than a required slew rate. The slew analysis computes an output slew SL(v) of a given buffer b inserted at a node v as SL(v)=RS(b)·C(v)+KS(b), where C(v) is the downstream capacitance at v, RS(b) is the slew resistance of buffer b, and KS(b) is the intrinsic slew of buffer b. The delay through a given buffer may also be computed based on signal polarity. However, the invention still preferably uses worst-case slew resistance and intrinsic slew in considering the slew constraints. If the selection of the buffer insertion locations results in no locations being selected due to slew violations, the present invention may advantageously find a partial solution by relaxing the slew constraint.

Owner:GLOBALFOUNDRIES INC

Integrated technology for capturing and mineralizing carbon dioxide

InactiveCN102794093AAvoid desorptionAvoid compressionCalcium/strontium/barium carbonatesProductsDesorptionHigh energy

The invention relates to an integrated technology for capturing and mineralizing carbon dioxide, which is characterized in that renewable ammonium salt (NH4HSO4) is used for obtaining a calcium and magnesium ions-containing leachate from ores or solid wastes, the leached residual slag is a small-size particle with high content of silicon oxide, the leachate is subjected to separation, impurities removal and precious metal purification, partial solution is directly used for capturing renewable ammonia gas to obtain a calcium and magnesium containing ammonia-rich liquid, CO2 is captured by the ammonia-rich liquid under normal temperature to generate ammonium carbonate salt, then the ammonium carbonate salt is subjected to rapid reaction with another part of the leachate for depositing to obtain magnesium(calcium) salt product with high purity, and a reaction-finished solution is further heated to regenerate ammonium salt (NH4HSO4) and ammonia gas for pretreating ores and capturing CO2. According to the invention, the steps of the technology enable complete closed circulation, thereby the chemical agent amount and three wastes are reduced, two high energy consumption steps of CO2 capturing desorption and compression in a traditional method can be avoided, the efficiency for each step is more than 90%, the waste heat in a power plant can be simultaneously used for assisting the regeneration of ammonium salt, and total energy consumption of the technology can be reduced.

Owner:HUANENG CLEAN ENERGY RES INST

Integrating a boolean SAT solver into a router

ActiveUS20080250376A1Computer aided designSpecial data processing applicationsPartial solutionPoint pair

One embodiment of the present invention provides a system that routes a set of pairs of points during the design of an integrated circuit (IC) chip. The system comprises a routing engine which is configured to search for a path to connect a current pair of points in the set of pairs of points, wherein the path comprises a set of rectangles and vertices. The routing engine uses a routing database, which keeps track of previously routed nets that can obstruct the routing of the current pair of points. The system further comprises a satisfiability (SAT) solver which is capable of solving a set of constraints, wherein the set of constraints are associated with the routability of the set of pairs of points. The SAT solver additionally comprises a SAT database which maintains the set of constraints and a current partial solution to the set of constraints. The SAT database is used to update the routing database if the current partial solution changes.

Owner:SYNOPSYS INC

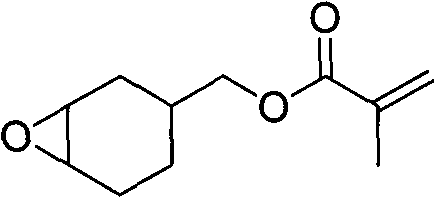

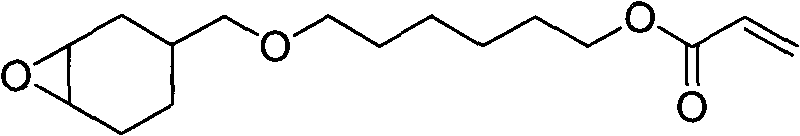

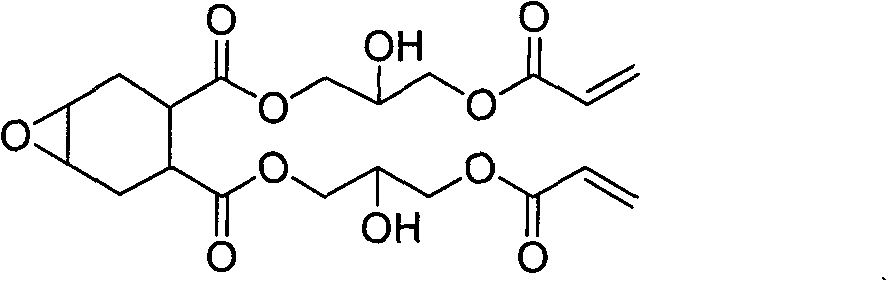

Novel aqueous light-cured alicyclic epoxy acrylic acid emulsion and preparation method thereof

InactiveCN102659976AGood chemical arc resistanceGood UV aging resistanceCoatingsCross-linkSolubility

The invention relates to a novel aqueous light-cured alicyclic epoxy acrylic acid emulsion and a preparation method thereof. The method comprises the following steps: adding an emulsifier and a regulator in a reactor, preheating to 50 DEG C, then adding epoxy resin, cross-linking monomers, polymerization degree regulator and acrylic acid monomers, preserving the heat of reflux for 0.5h; heating partial solution and an initiator to 80 DEG C, when glowing blue, adding dropwisely the rest solution in 2.5 h, and refilling the initiator, preserving the heat of reflux for 1h, cooling to room temperature after the reaction, and then adding a photoinitiator. The invention provides a light-cured alicyclic epoxy acrylic acid emulsion with stability and good water-solubility, overcomes the defects of bad weatherability and bad resistance to heat and humidity of existing bisphenol-A epoxy resin, and simultaneously prevents the environment from being polluted by traditional solvent-based coating. The emulsion can be used for preparing outdoor coatings, light-cured printing ink, craft paints and the like, has the advantages of excellent performance, simple technology, and low cost, and is an environment friendly material with a wide market prospect.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

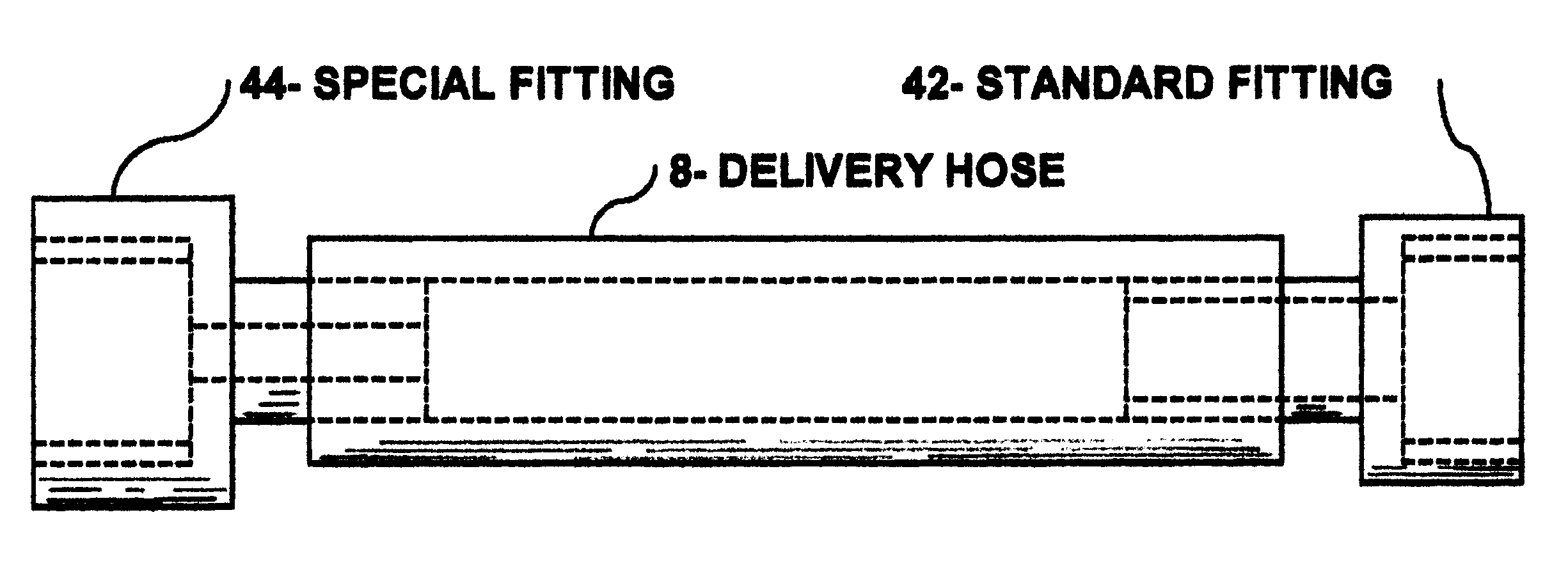

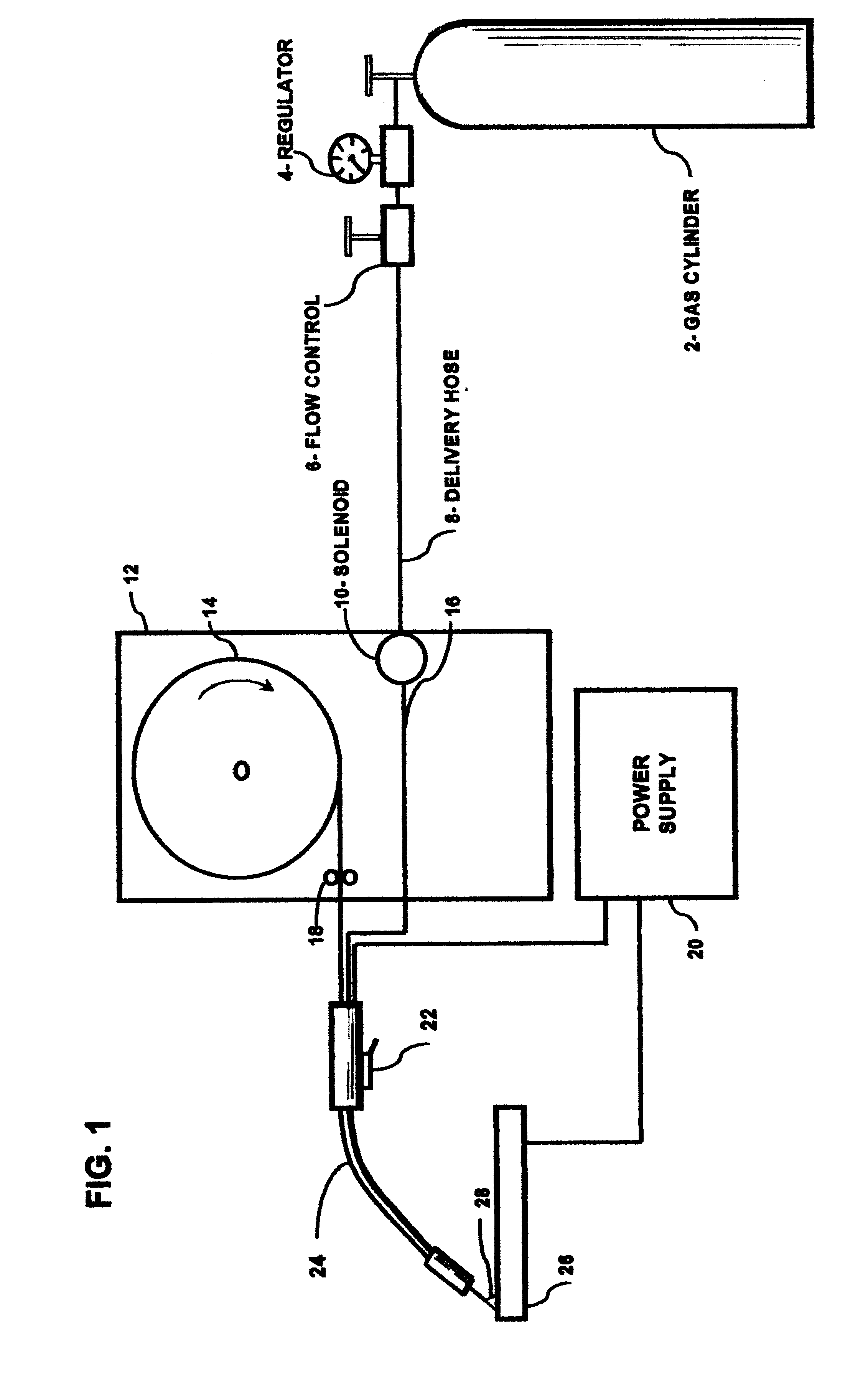

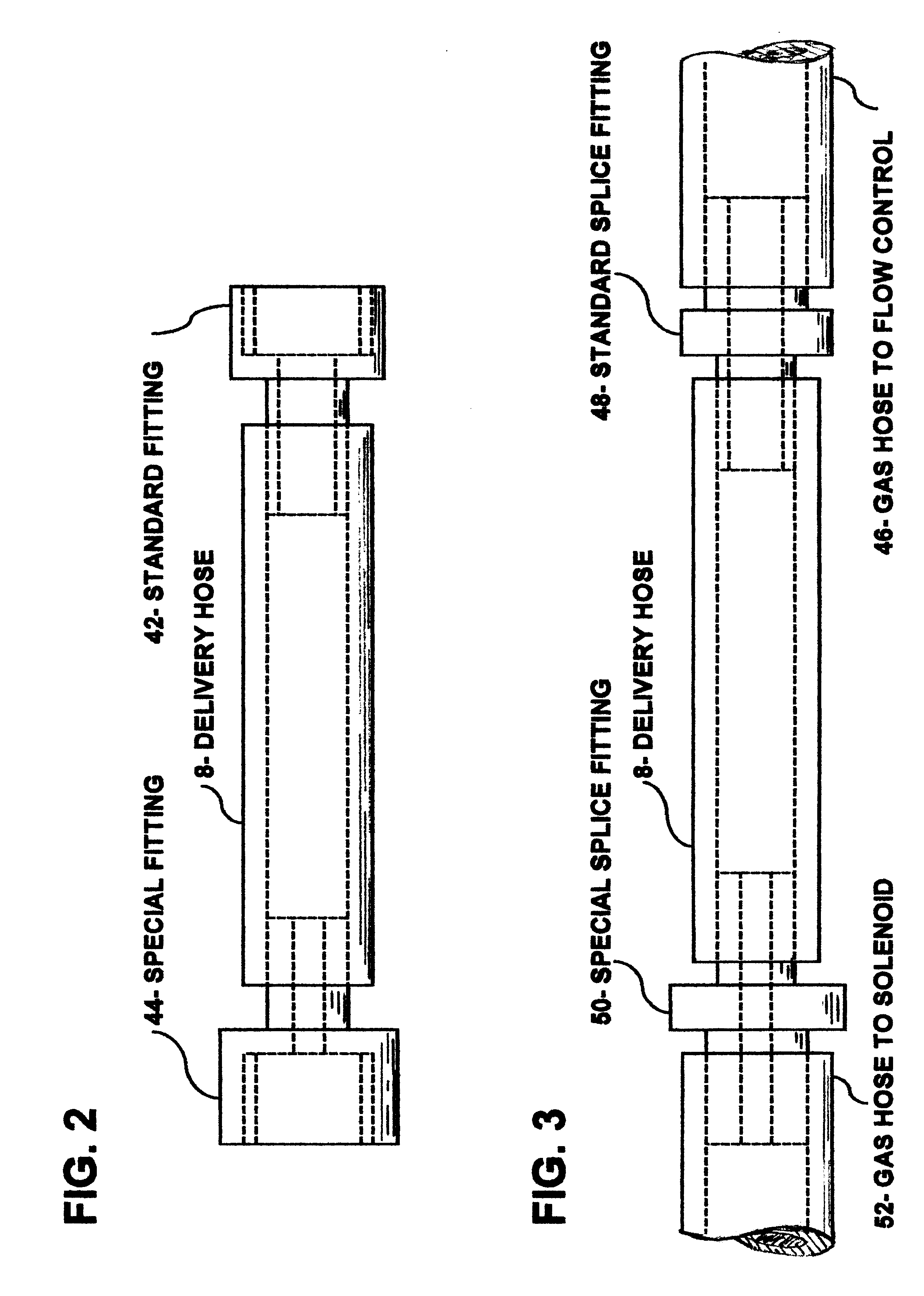

Welding shielding gas saver device

InactiveUS6610957B2Minimize storageAvoid wastingShielding gas supply/evacuation devicesWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

This device significantly reduces major reasons for shielding gas waste primarily in metal inert gas welding. Excess shielding gas stored at the end of each weld in the shielding gas delivery hose connecting the gas source to the welding machine creates a shielding gas flow-surge at the next weld start. This gas flow-surge creates shielding gas waste and can cause poor weld start performance. Other methods employed over the years to reduce shielding gas waste have been either complex, leaked, were not sufficiently robust for the environment, provided only partial solutions or did not provide shielding gas savings for welds longer than about 3 seconds. This device includes a delivery hose connecting the shielding gas supply to the welding machine, which has a small internal volume and a gas surge-restricting orifice at the gas solenoid end of the hose.

Owner:UTTRACHI GERALD DANIEL

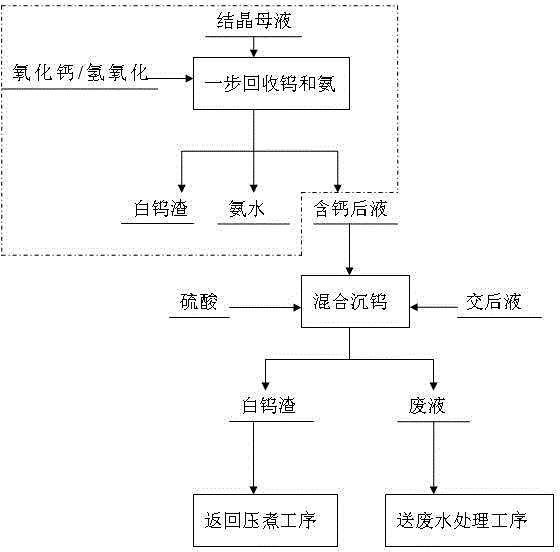

Method for recycling tungsten in liquids after tungsten smelting exchanges

InactiveCN102912129AResidue reductionCutting costsWater contaminantsWaste water treatment from metallurgical processLiquid wasteTungstate

The invention discloses a method for recycling tungsten in liquids after tungsten smelting exchanges. The method includes pH of liquids after exchanges is regulated to 8 to 10 by using sulfuric acids; calcium in liquids after a mother liquor is crystallized by using ammonium tungstate (APT) in calcium oxide or calcium hydroxide with tungsten and ammonia recycled to serve as a precipitating agent for precipitating tungsten, and a temperature of a reaction process is raised to 70 DEG C to 80 DEG C; the mixture is mixed fully to form scheelite precipitation; and filter residues are returned to a press cooking leaching process after filtration, and waste liquids are sent to a wastewater treatment process for treatment. According to the method, a method for recycling tungsten and ammonia in a tungsten smelted APT crystallization mother liquor with the application number of 20110307349.0 is combined, and partial solutions containing calcium chloride serve as precipitant materials for recycling tungsten in liquids after exchanges, accordingly, resources are recycled, salt discharges are reduced, costs for buying calcium chloride material are reduced in terms of economic benefits, and internal circulation is achieved. According to the method recycling tungsten in liquids after tungsten smelting exchanges, the technological process is simple, the tungsten precipitation rate is high, and the economic benefit is good.

Owner:ZHONGXIANG TUNGSTEN IND

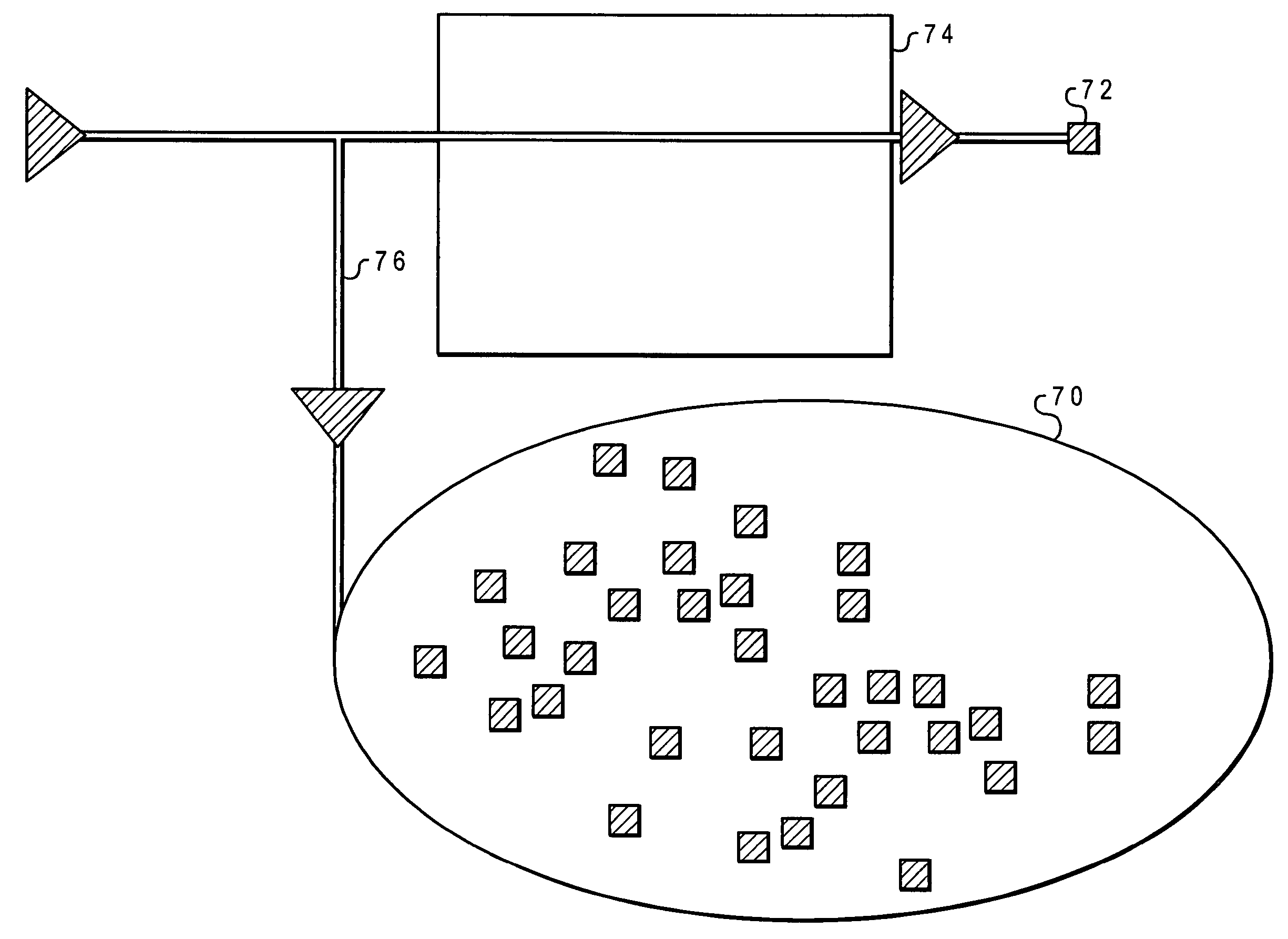

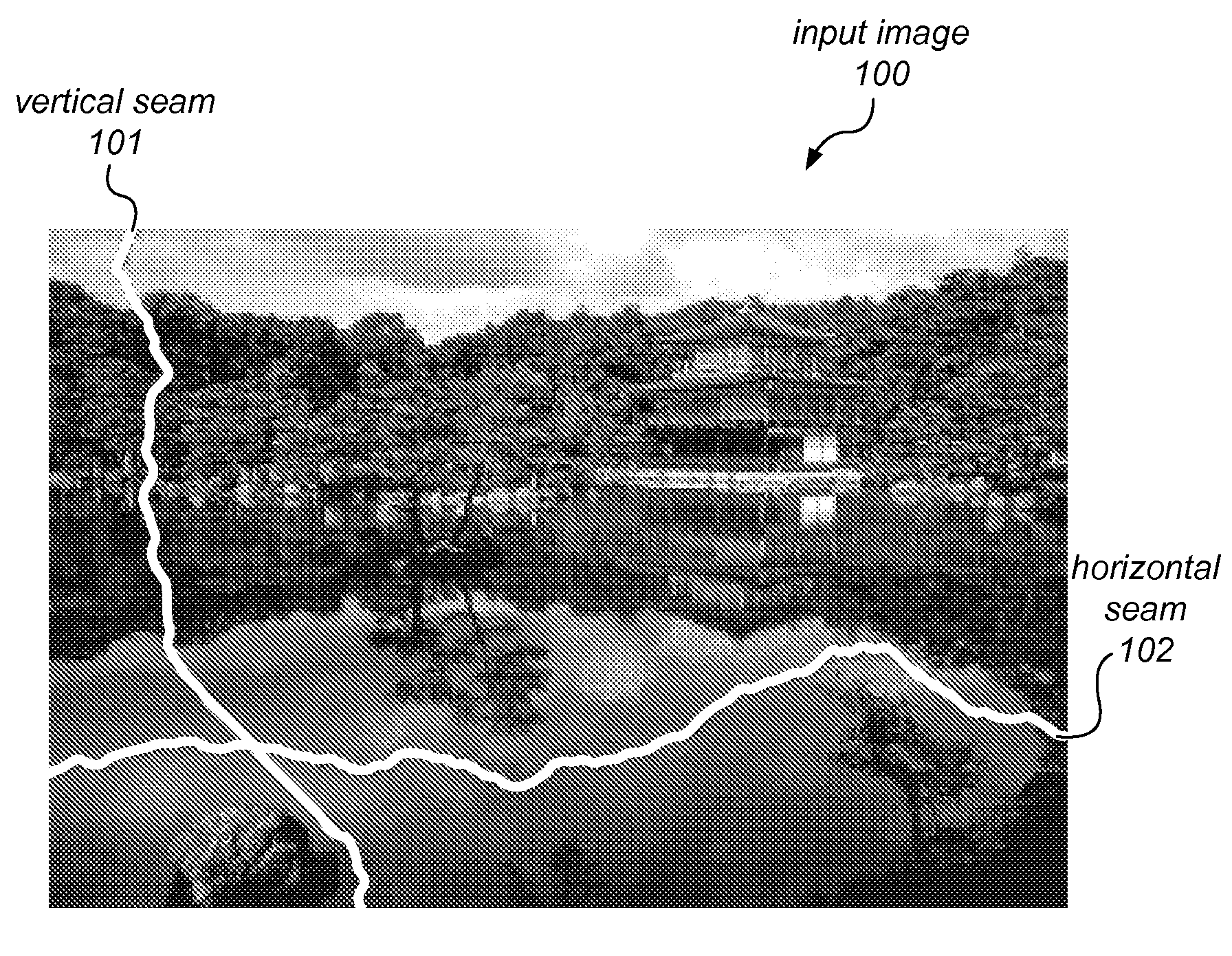

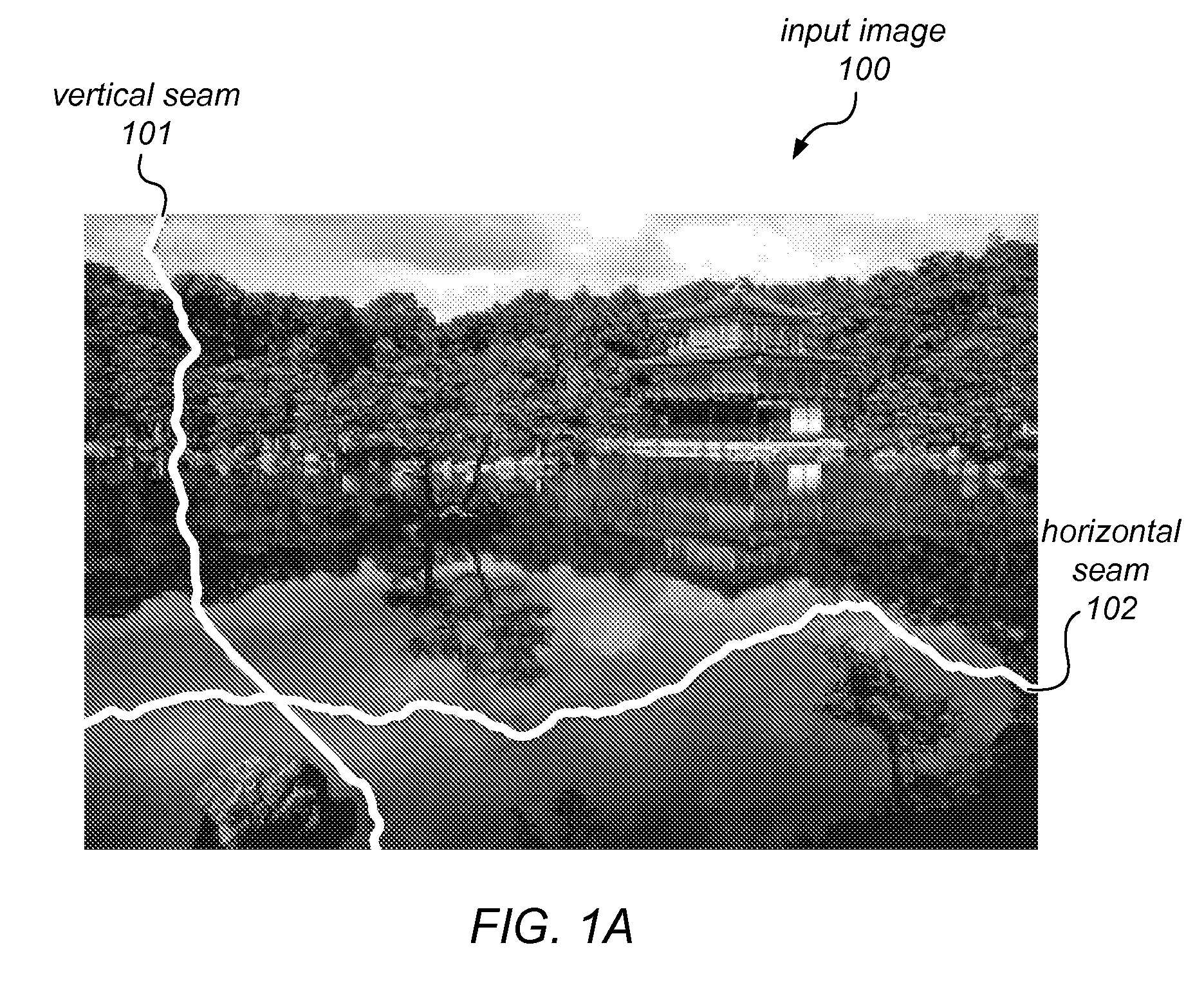

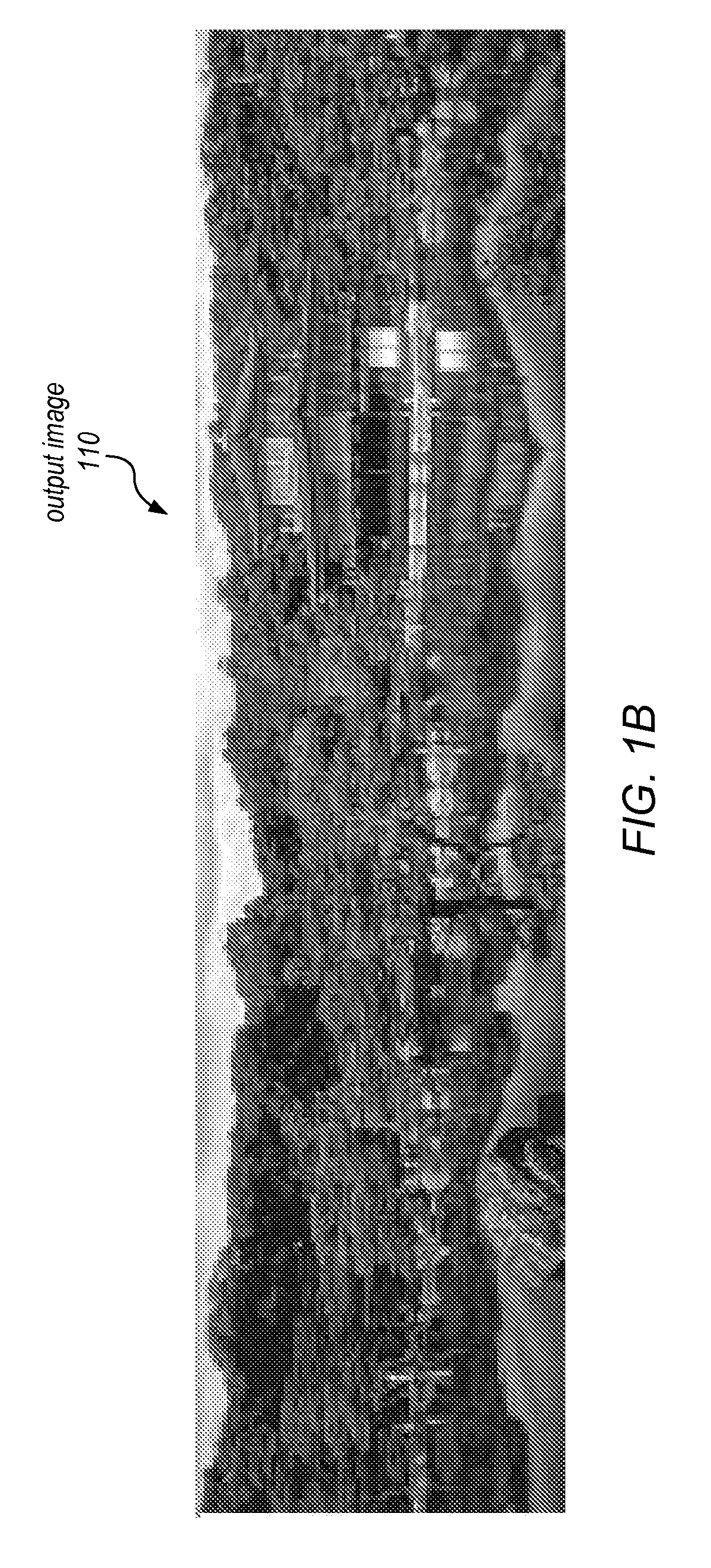

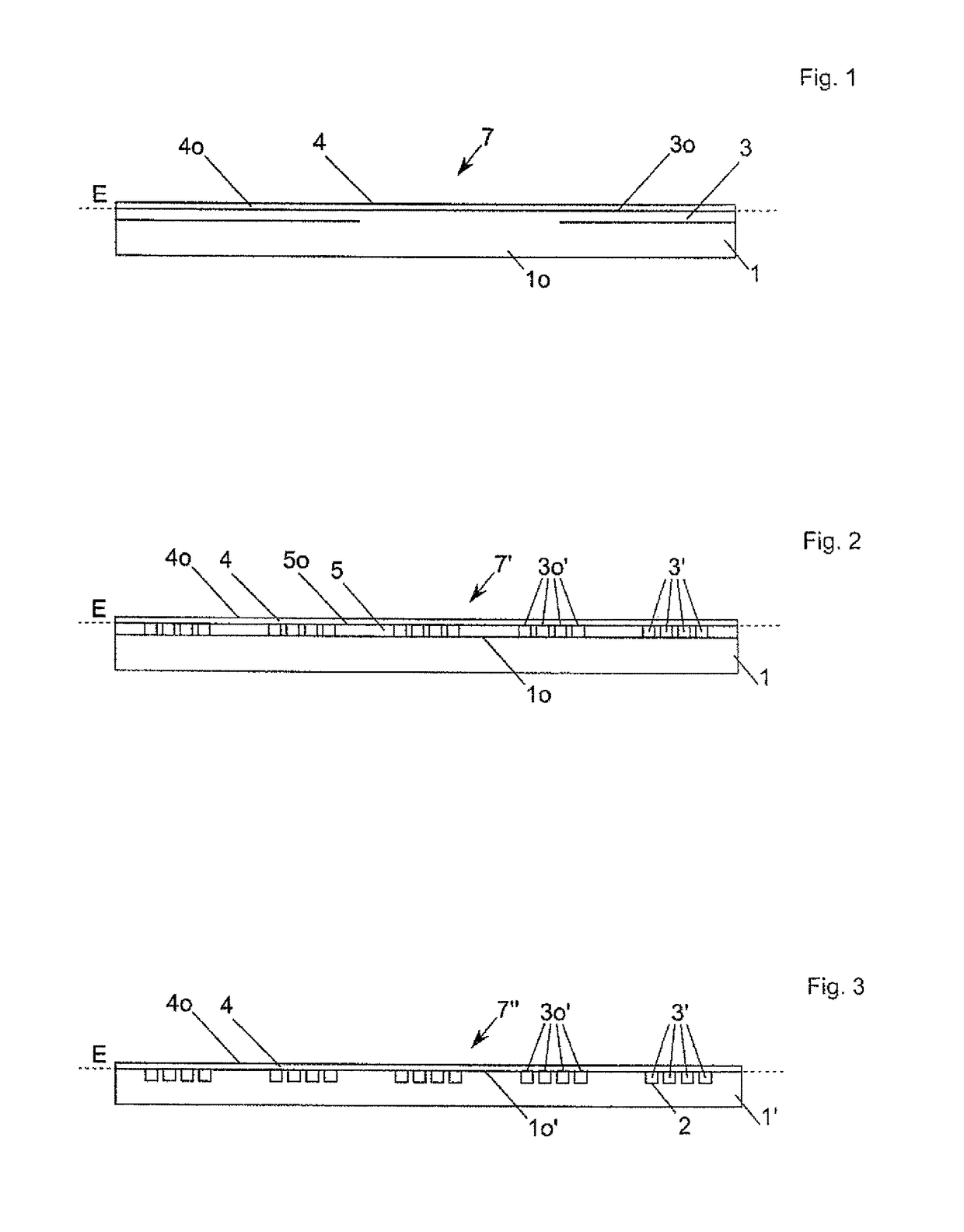

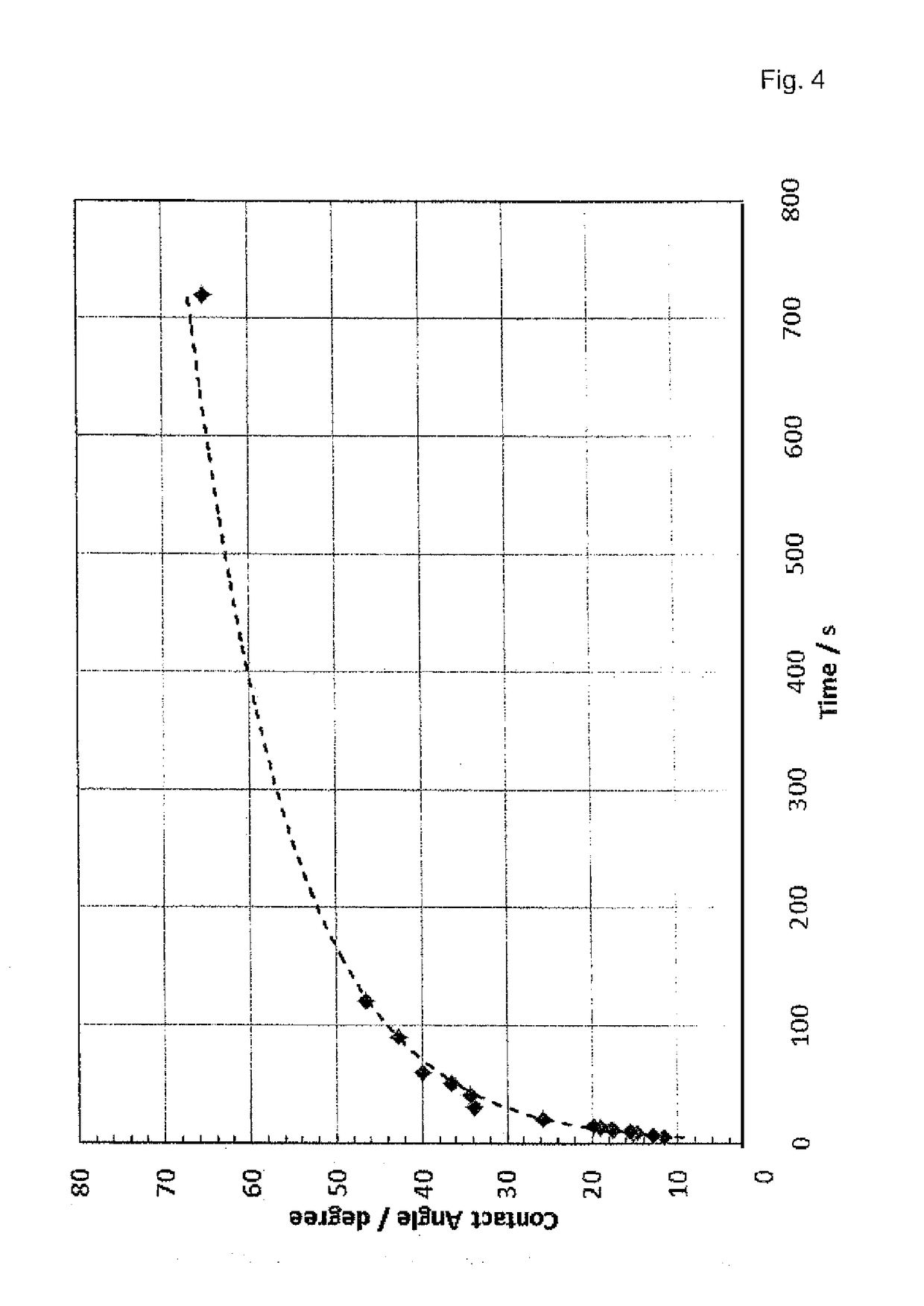

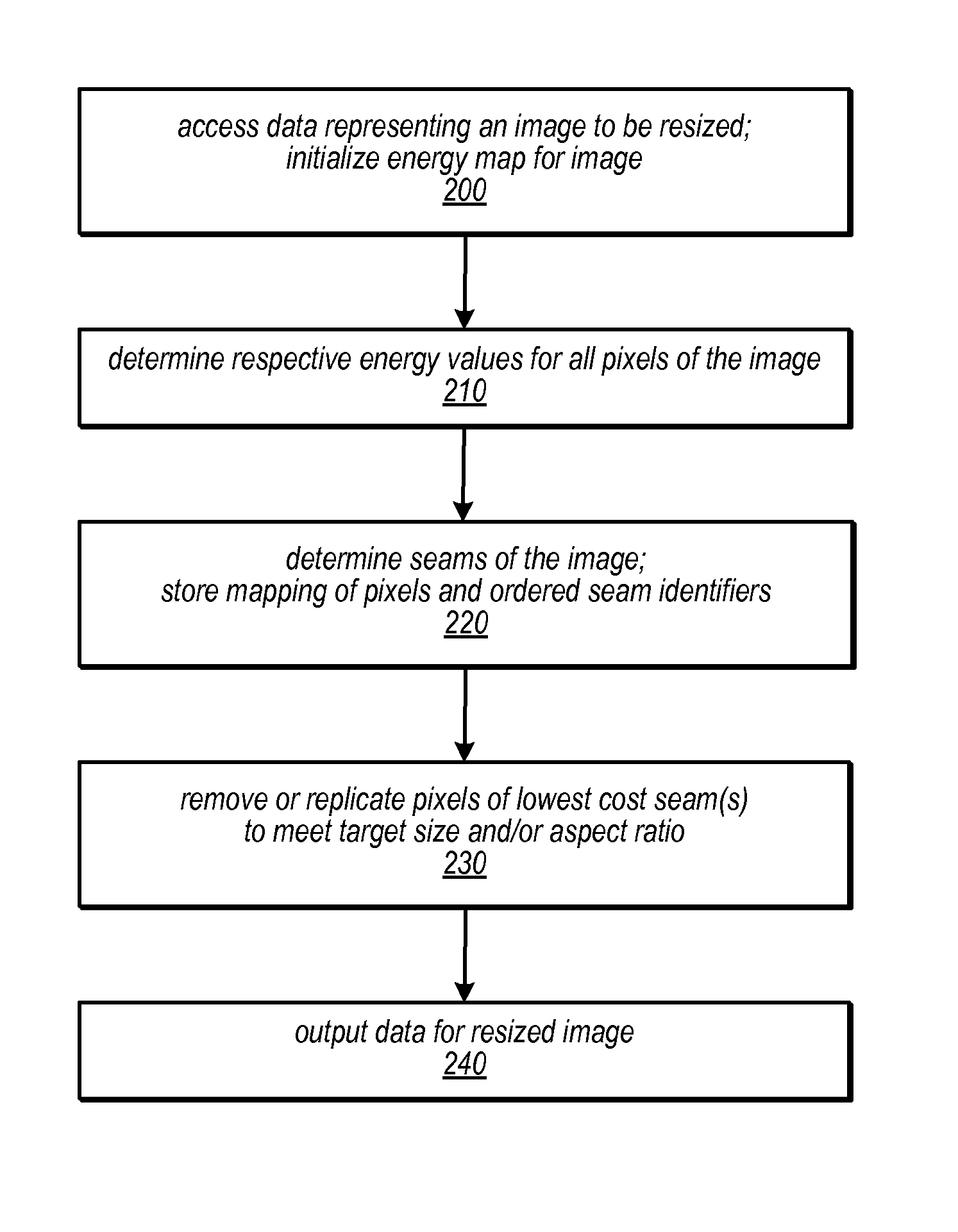

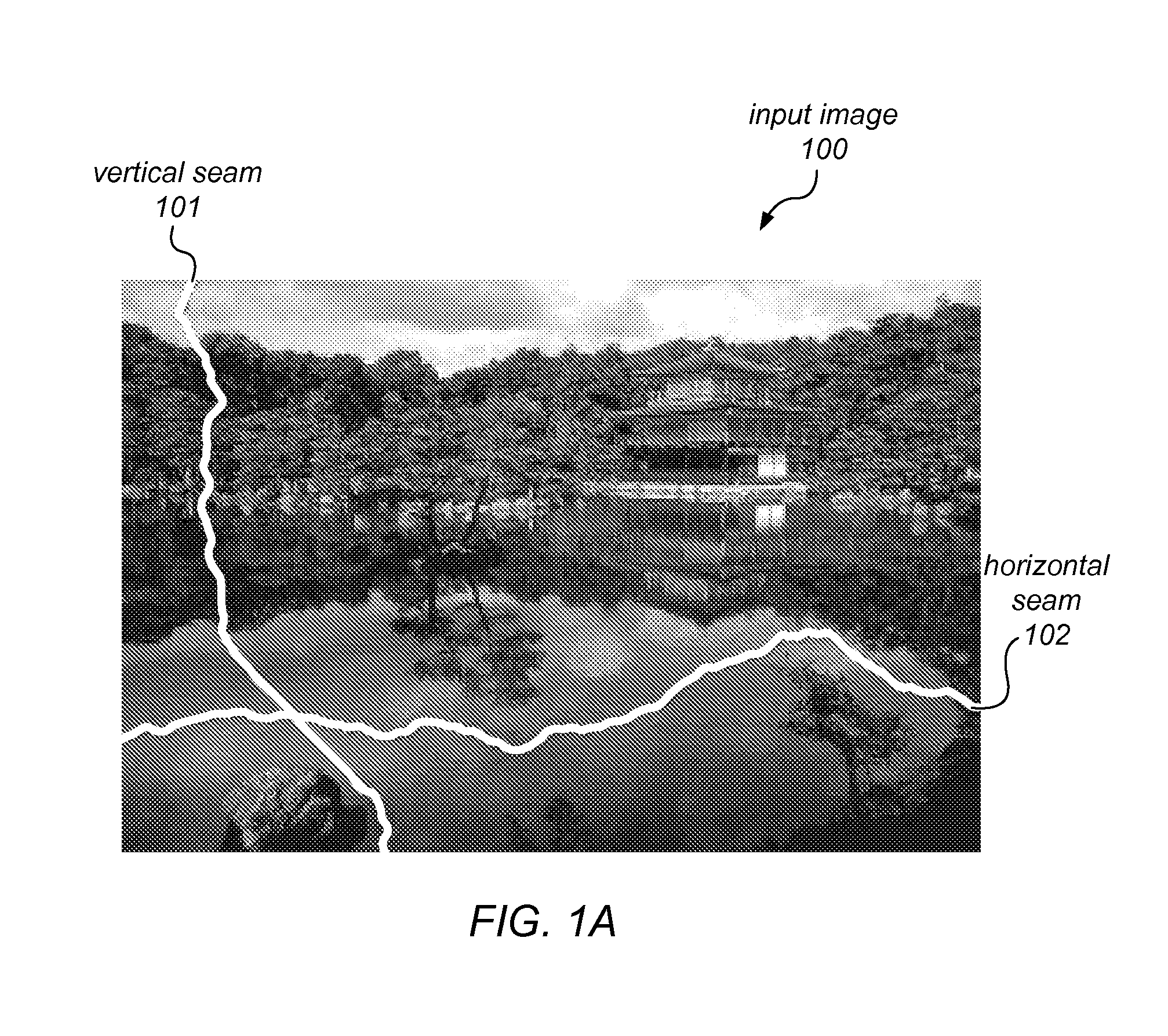

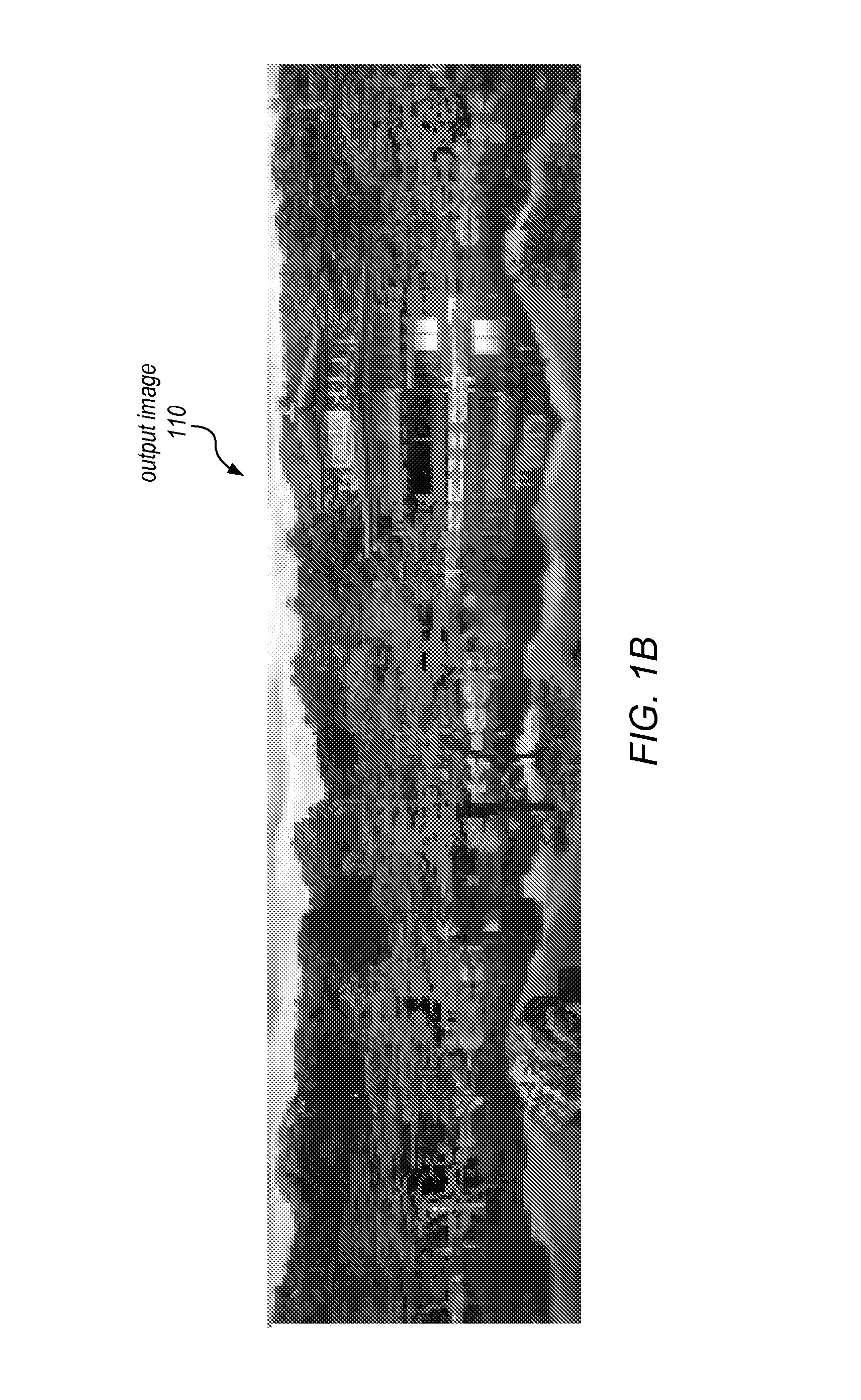

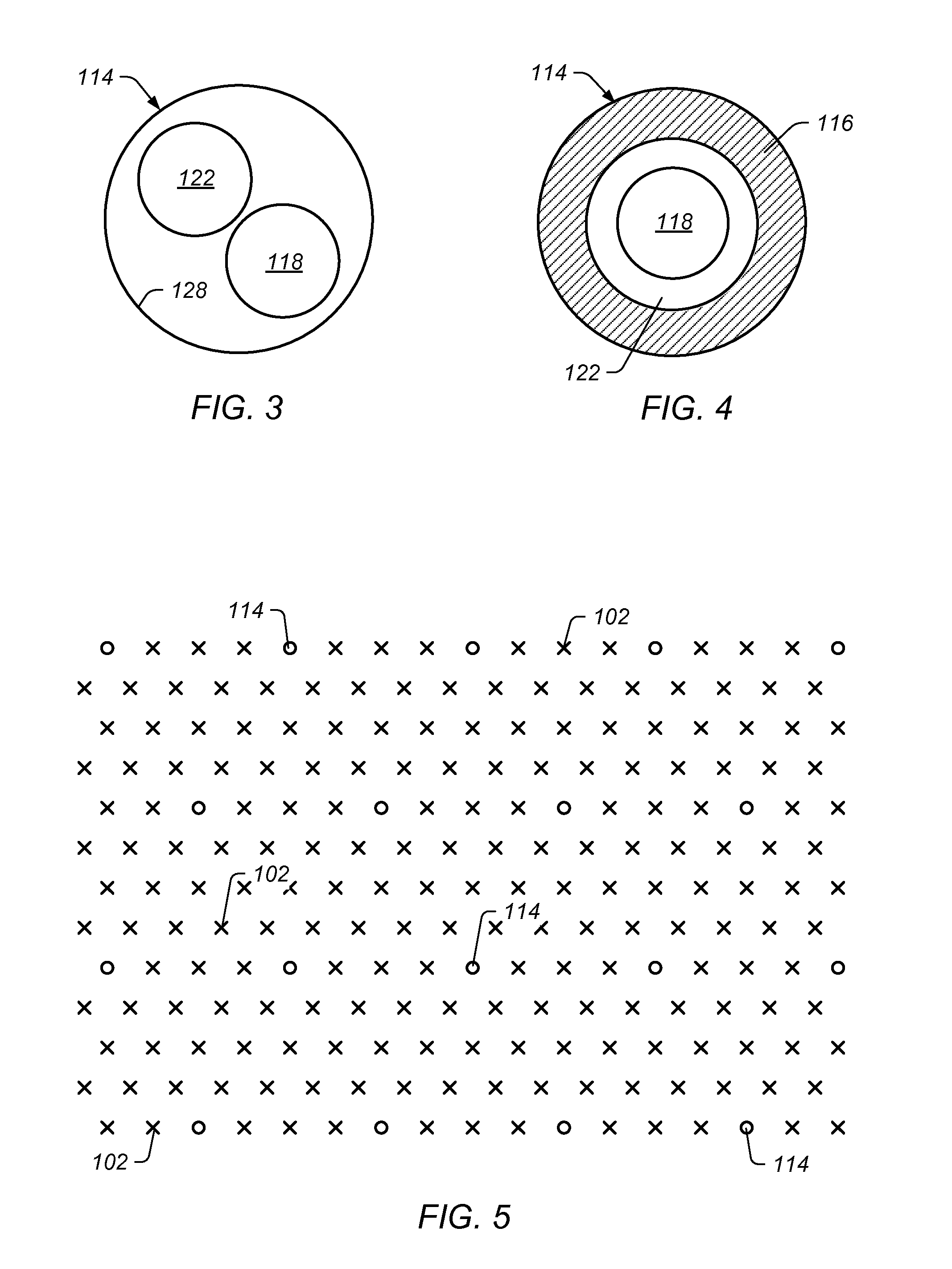

Seam-Based Reduction and Expansion of Images Using Partial Solution Matrix Dependent on Dynamic Programming Access Pattern

Systems, methods, and computer-readable storage media for resizing images using seam carving techniques may include generation of a partial solution matrix by at least partially isolating dependencies between sub-problems of a dynamic programming problem corresponding to its solution within different regions of an input image. The number and / or shape of the isolated (or partially isolated) sub-problems may be dependent on the access pattern used by a dynamic programming operation to identify seams in the input image. Multiple sub-problems may be processed independently and in parallel on respective processor core(s) or threads thereof to generate the partial solution matrix. The partial solution matrix may then be processed to identify one or more low-cost seams of the input image. The methods may be implemented as stand-alone applications or as program instructions implementing components of a graphics application, executable by a CPU and / or GPU configured for parallel processing.

Owner:ADOBE INC

Techniques for super fast buffer insertion

InactiveUS20080072202A1Simple methodConvenient timeCAD circuit designSoftware simulation/interpretation/emulationCapacitanceElectrical resistance and conductance

A method of determining buffer insertion locations in an integrated circuit design establishes candidate locations for inserting buffers into a net, and selects buffer insertion locations from among the candidates based on slew constraints. The selection of buffer insertion locations preferably optimizes slack and buffer cost while keeping slew from any buffered node to any sink less than a required slew rate. The slew analysis computes an output slew SL(v) of a given buffer b inserted at a node v as SL(v)=RS(b)·C(v)+KS(b), where C(v) is the downstream capacitance at v, RS(b) is the slew resistance of buffer b, and KS(b) is the intrinsic slew of buffer b. The delay through a given buffer may also be computed based on signal polarity. However, the invention still preferably uses worst-case slew resistance and intrinsic slew in considering the slew constraints. If the selection of the buffer insertion locations results in no locations being selected due to slew violations, the present invention may advantageously find a partial solution by relaxing the slew constraint.

Owner:GLOBALFOUNDRIES INC

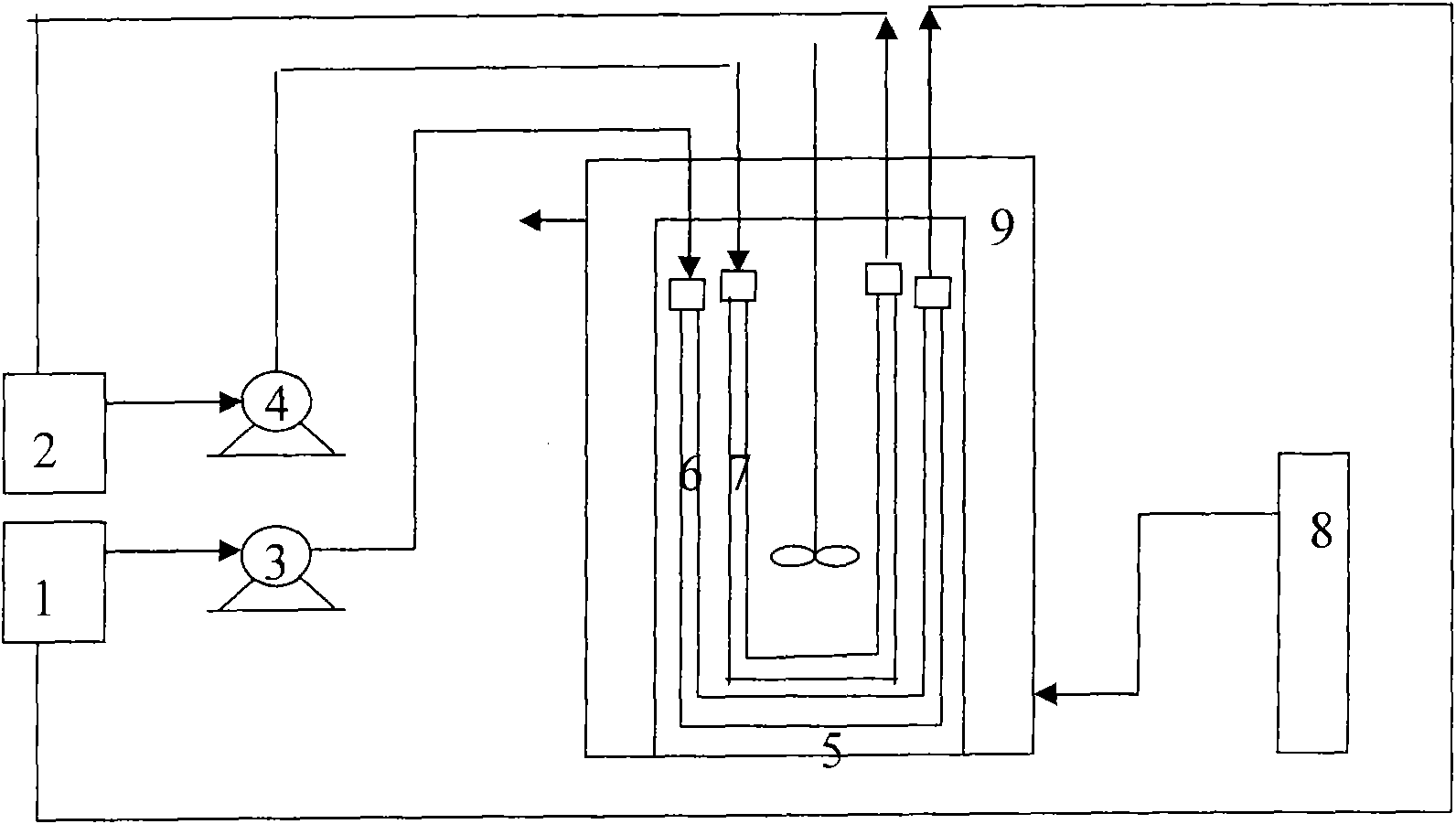

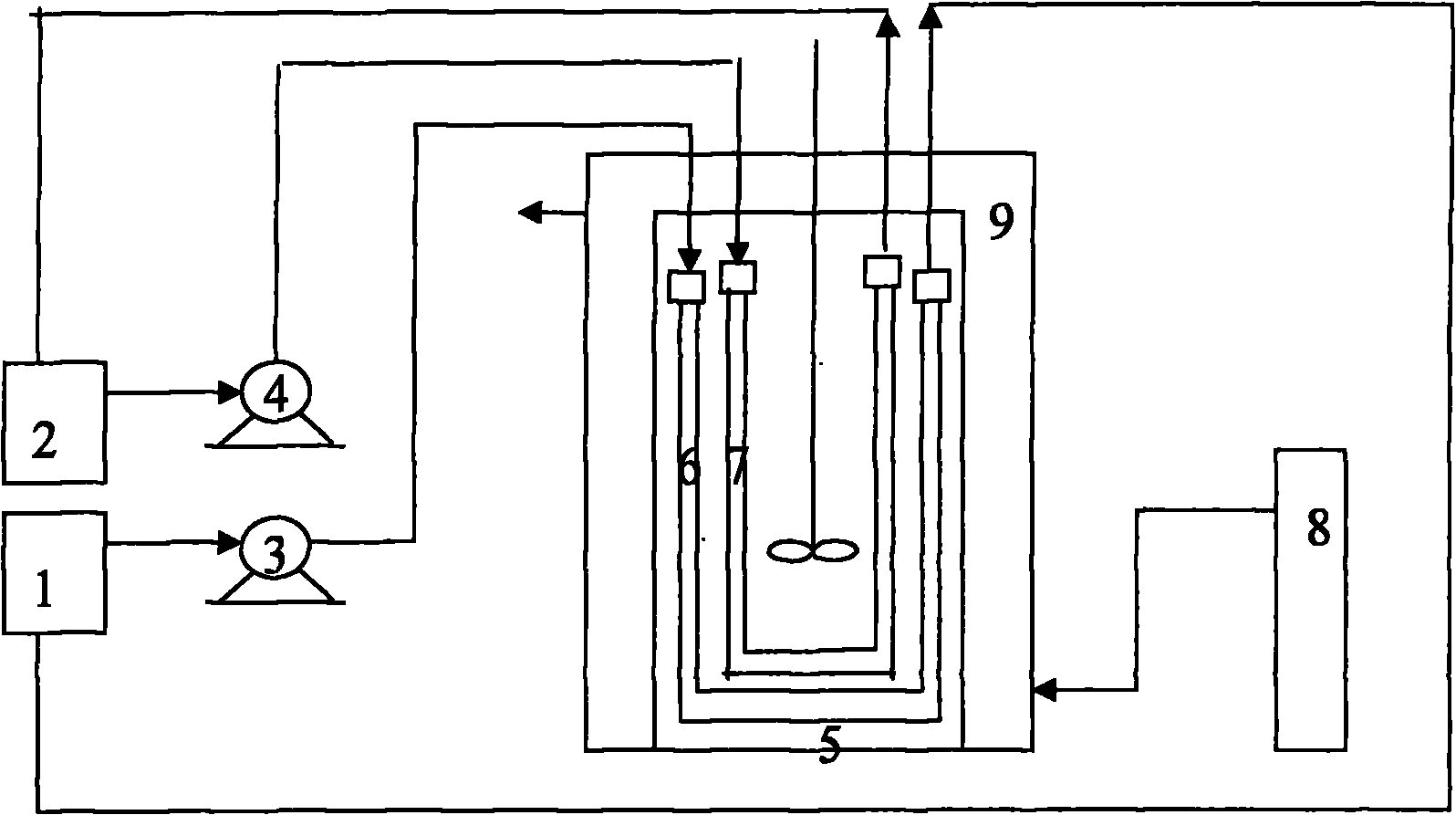

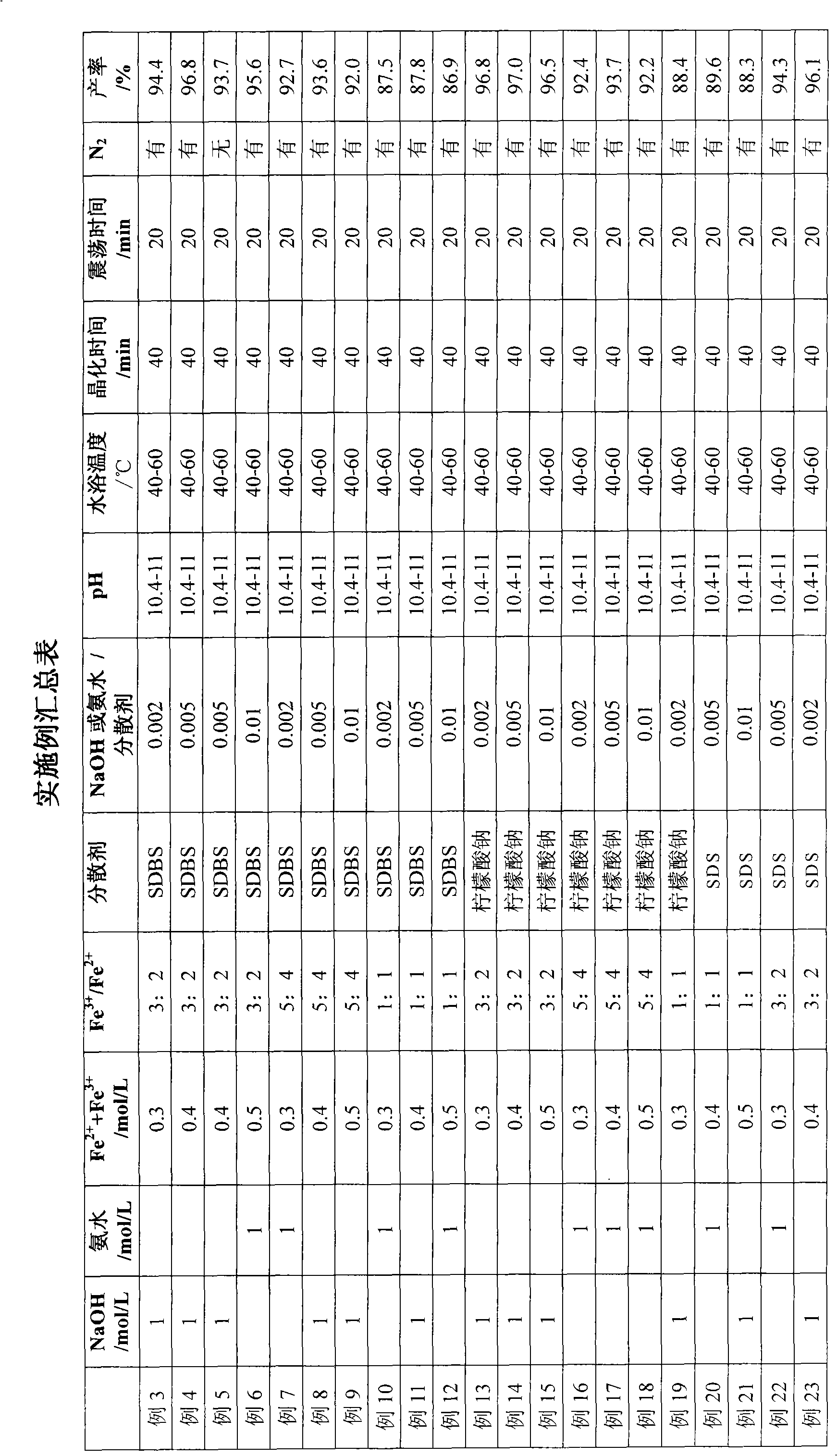

Method and device for continuously preparing nano ferroferric oxide through hollow fiber ultrafiltration dual-membrane

InactiveCN101774649AHighlight substantive featuresSignificant progressFerroso-ferric oxidesWater bathsHollow fibre

The invention relates to a method and a device for continuously preparing nano ferroferric oxide through a hollow fiber ultrafiltration dual-membrane. Distilled water or desalted water is added into a reactor and nitrogen is fed in to remove oxygen protection; a pump I is started up to enable NaOH or ammonia water solution in a storage tank I to enter a membrane assembly A, partial solution enters the reactor through the membrane assembly A and partial solution flows back to the storage tank I in a circulating way; when pH value of solution in the reactor is increased to about 10.40, a pump II is started up to enable Fe2+ and Fe3+ mixed solution in a storage tank II to enter a membrane assembly B, partial solution enters the reactor through the membrane B and partial solution flows back to the storage tank II in a circulating way; the flow of raw materials and precipitant is controlled, the pH value of solution in the reactor is kept to be 10.4-11 and Fe3O4 is generated through reaction under agitation. The Fe3O4 is crystallized in water bath, is separated through a magnetic seat, is water-washed to a state with pH value of 7, is shocked through ultrasonic wave and is dried under a vacuum condition to obtain black nano Fe3O4, wherein the grain size of the black nano Fe3O4 is 10-20nm.

Owner:中国大唐集团科学技术研究总院有限公司

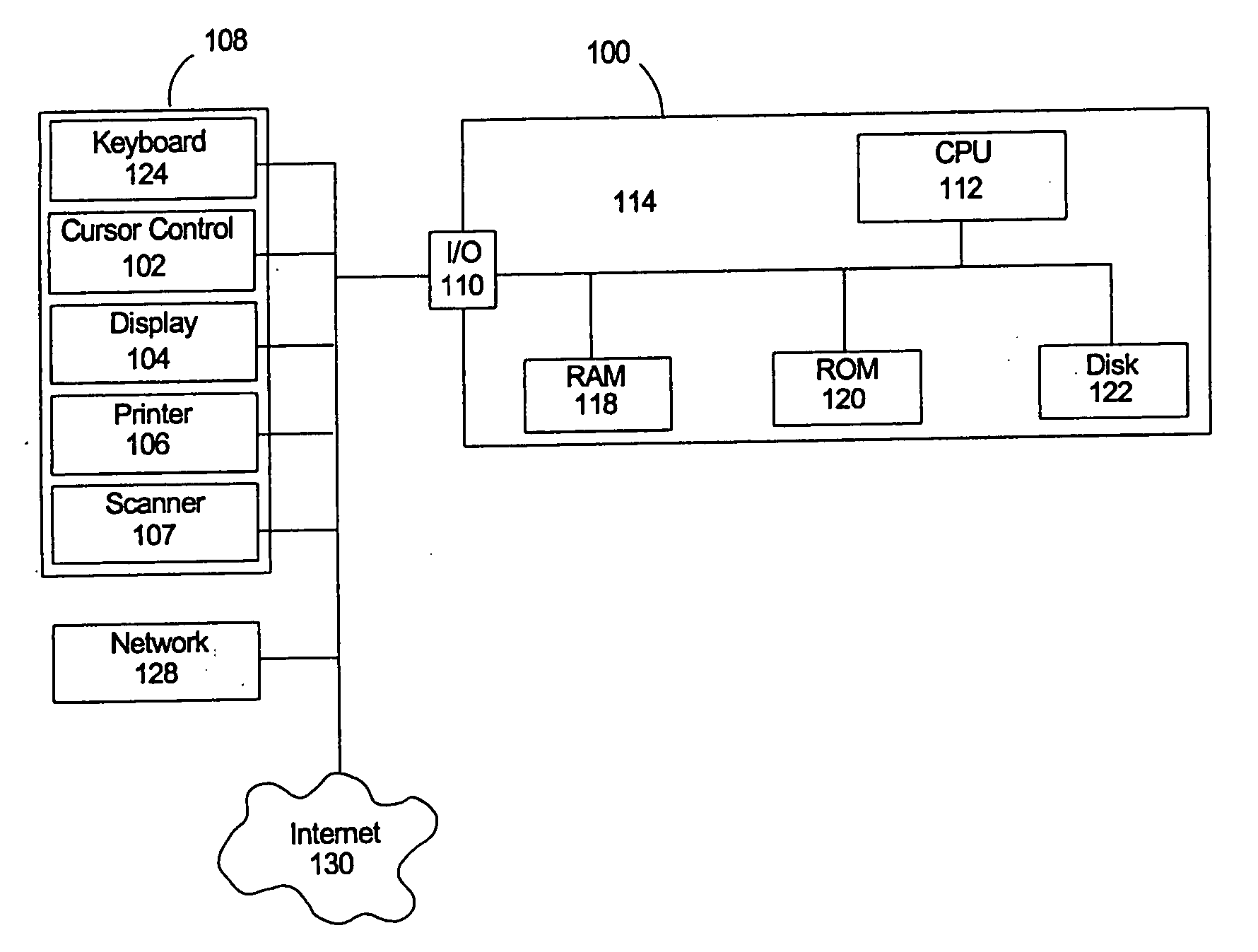

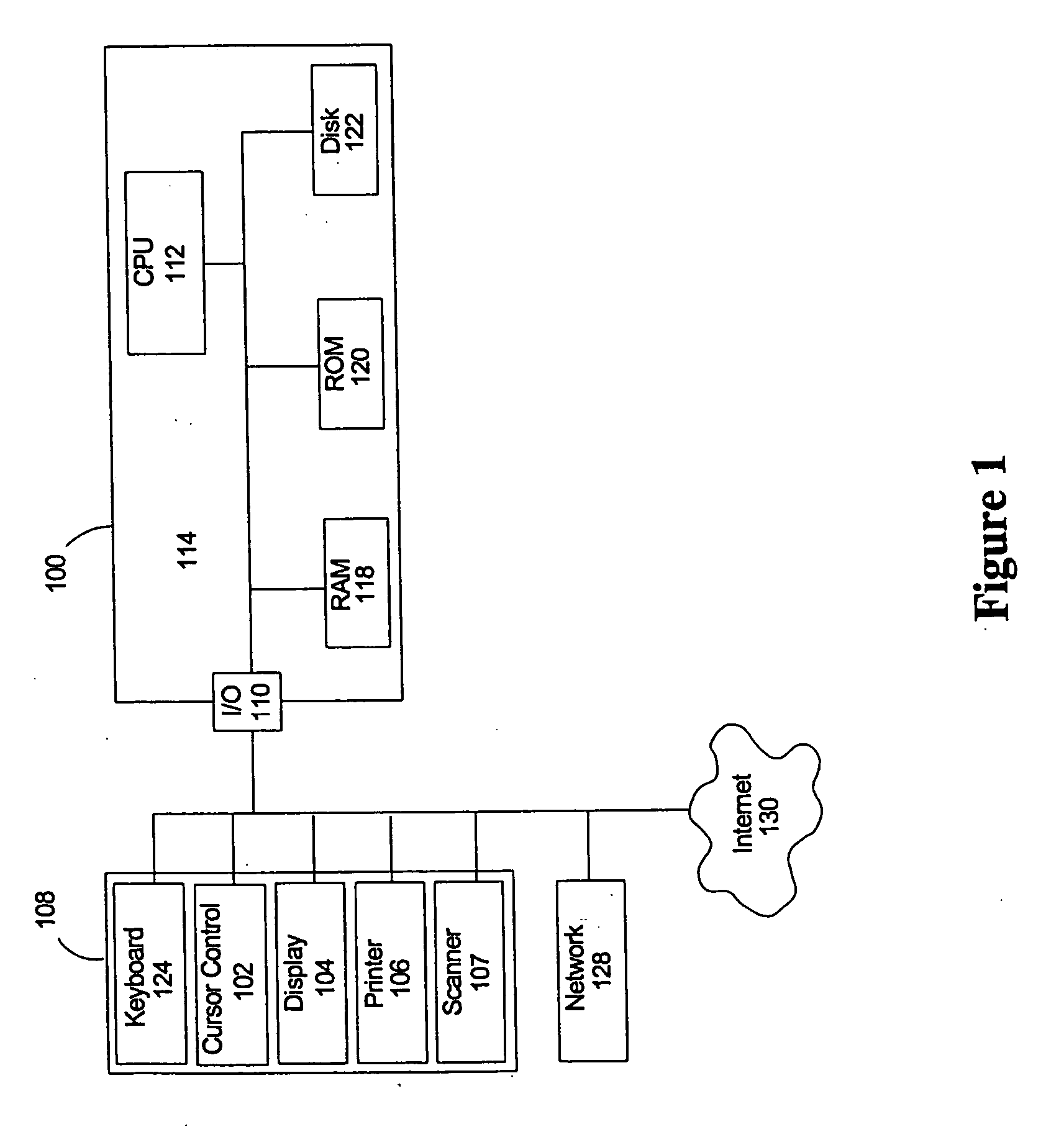

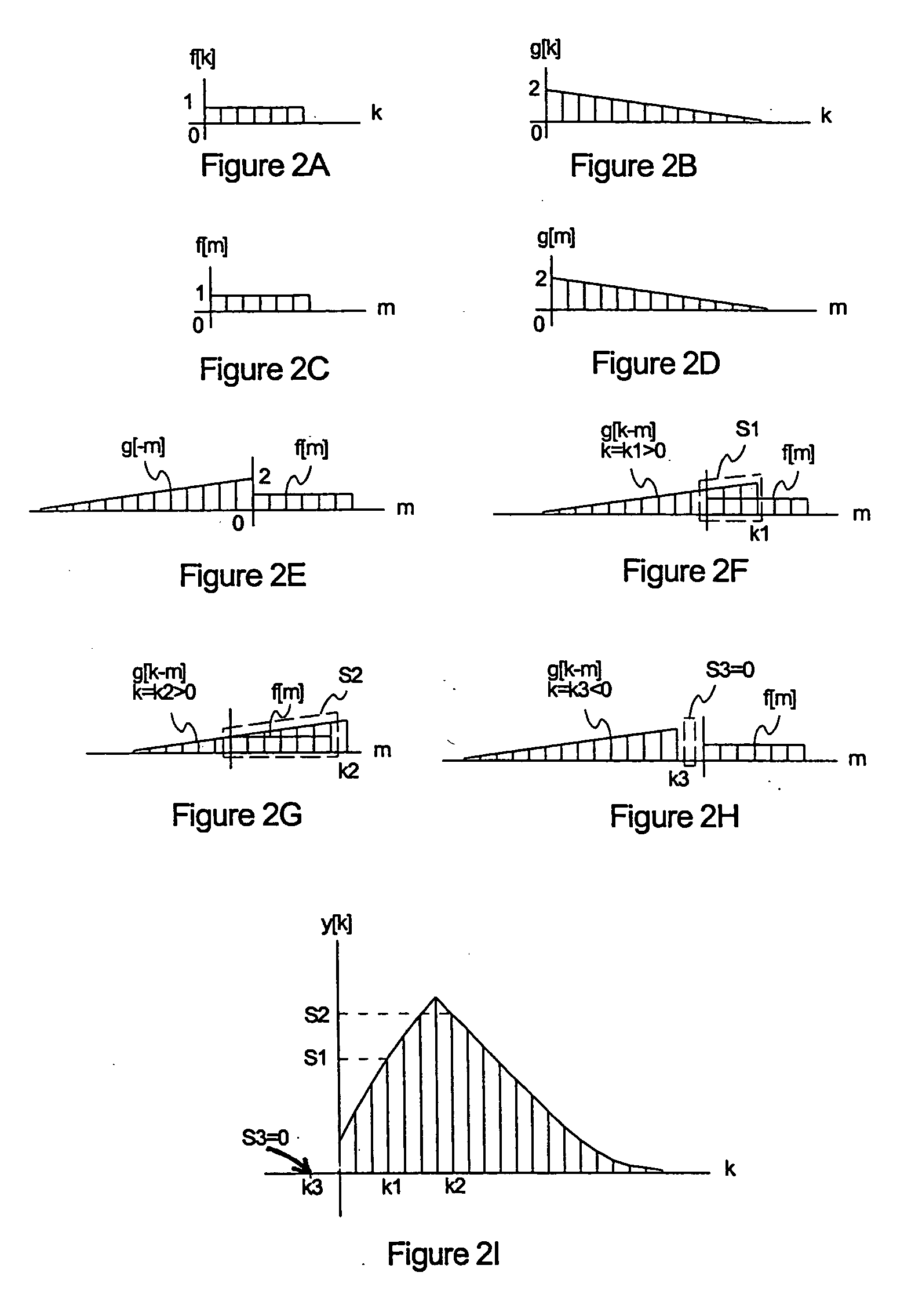

Single-channel convolution in a vector processing computer system

InactiveUS20070005674A1Complex mathematical operationsComputation using denominational number representationData streamAlgorithm

The invention provides a system and method for performing convolution in a single channel of a vector processing computer system. The invention takes advantage of the parallel computing capability of the vector processing system and the distributed properties of the discrete-time convolution sum by performing convolution on portions of an overall data stream, or data chunks, simultaneously. Partial solutions are thereby obtained and superimposed to achieve an overall solution data stream. To simplify the convolution sum and eliminate the need for calculating products, an embodiment of the invention utilizes a specialized data signal or vector in the convolution operation. Specifically, a specialized vector comprising a series of ones may be used to simplify calculations.

Owner:APPLE INC

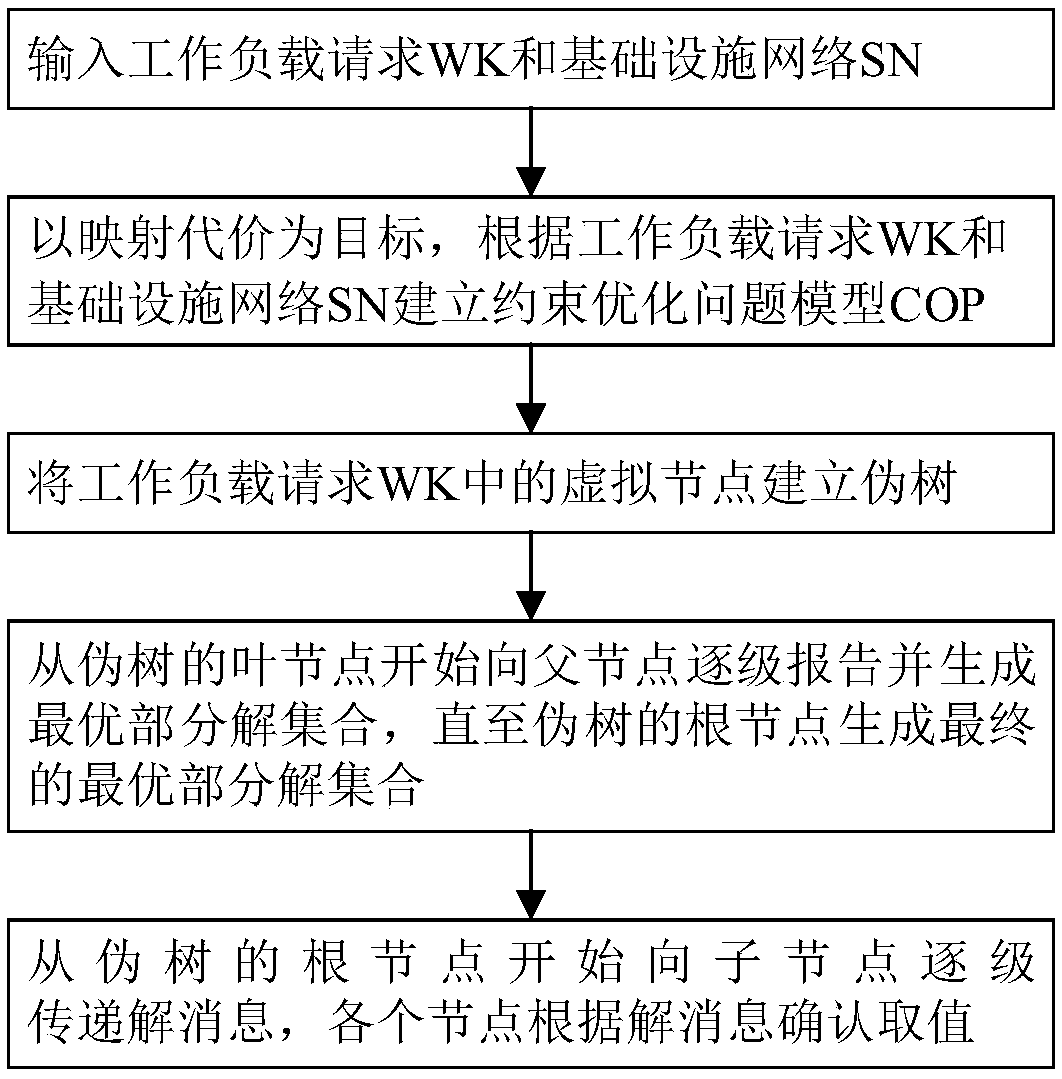

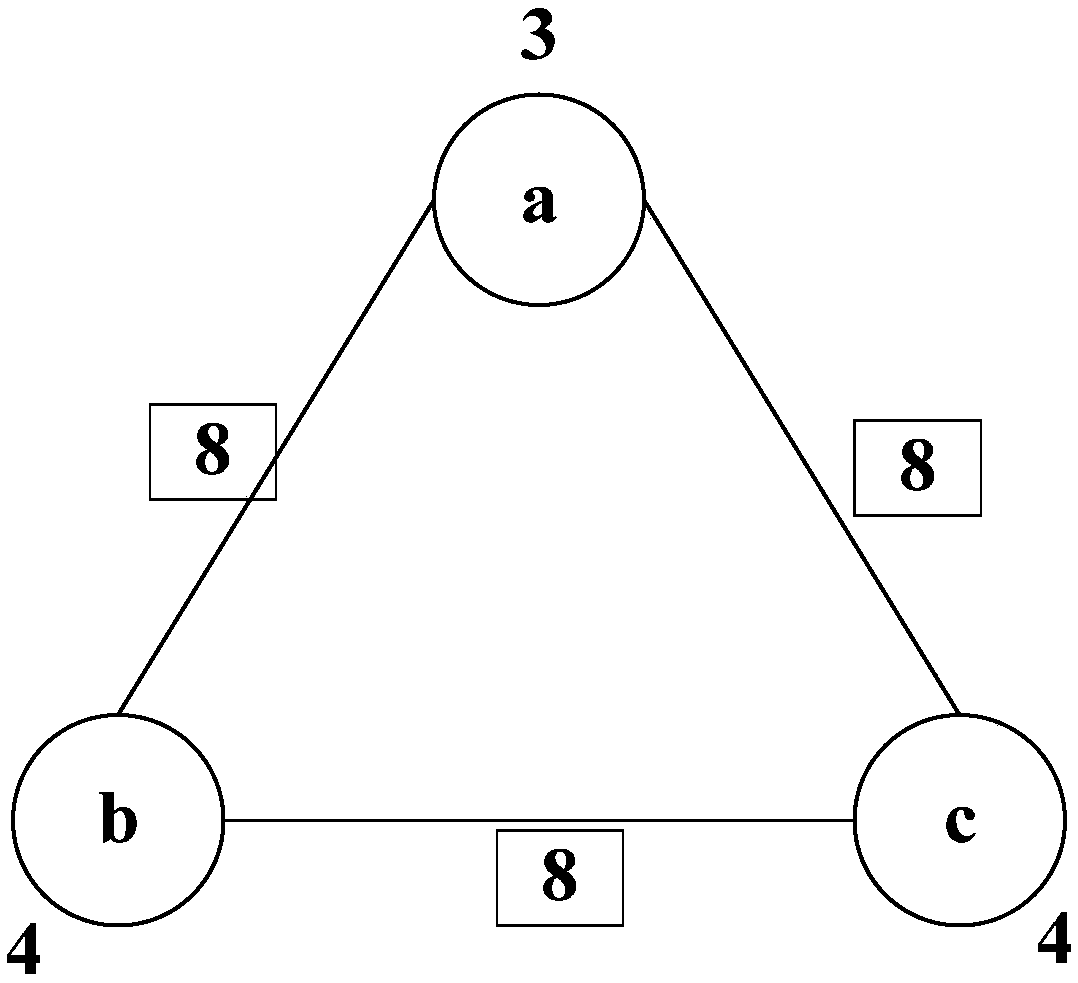

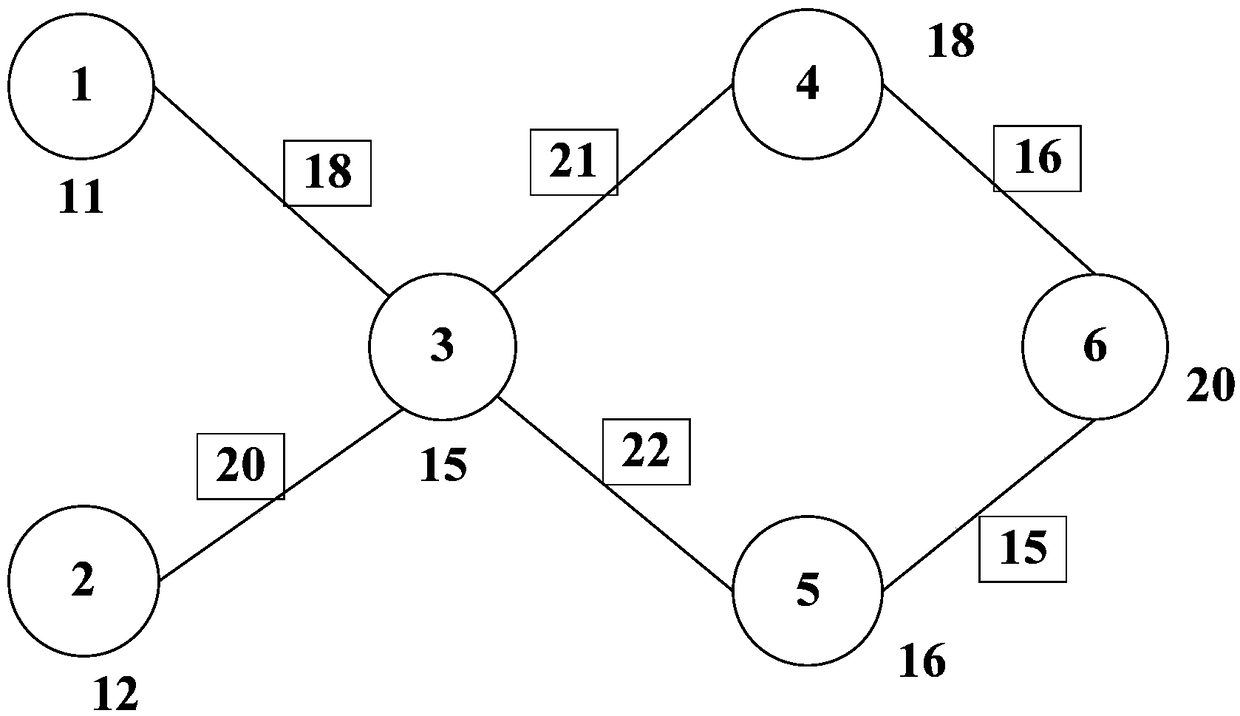

Optimal task scheduling method and system based on pseudo-tree structure in data center network

ActiveCN108924192AAvoid overheadReduce computational overheadData switching networksSubstrate networkData center

The invention discloses an optimal task scheduling method and system based on a pseudo-tree structure in a data center network, wherein the mapping cost is the target; a constraint optimization problem model COP is established according to a workload request WK and a substrate network SN; a pseudo-tree is established for a virtual node in the workload request WK; starting from a leaf node of the pseudo-tree, a parent node is reported to step by step and an optimal partial solution set is generated until a root node of the pseudo-tree generates a final optimal partial solution set; starting from the root node of the pseudo-tree, a solution message is transmitted to the child node step by step; and each node confirms the value according to the solution message. The optimal task scheduling method and system based on a pseudo-tree structure in the data center network in the invention can realize applications such as virtual network mapping in a moderately sized environment and resource allocation under a data center network, thereby realizing efficient and even optimal task resource scheduling.

Owner:NAT UNIV OF DEFENSE TECH

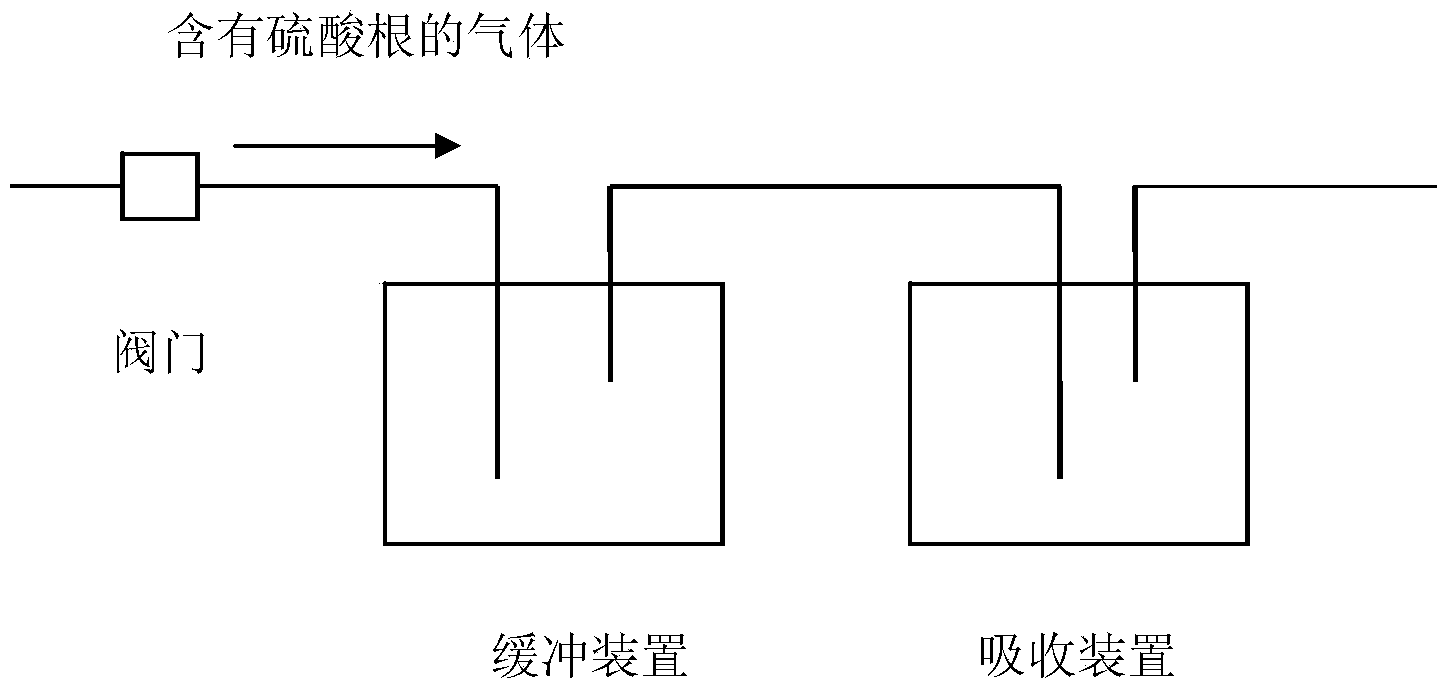

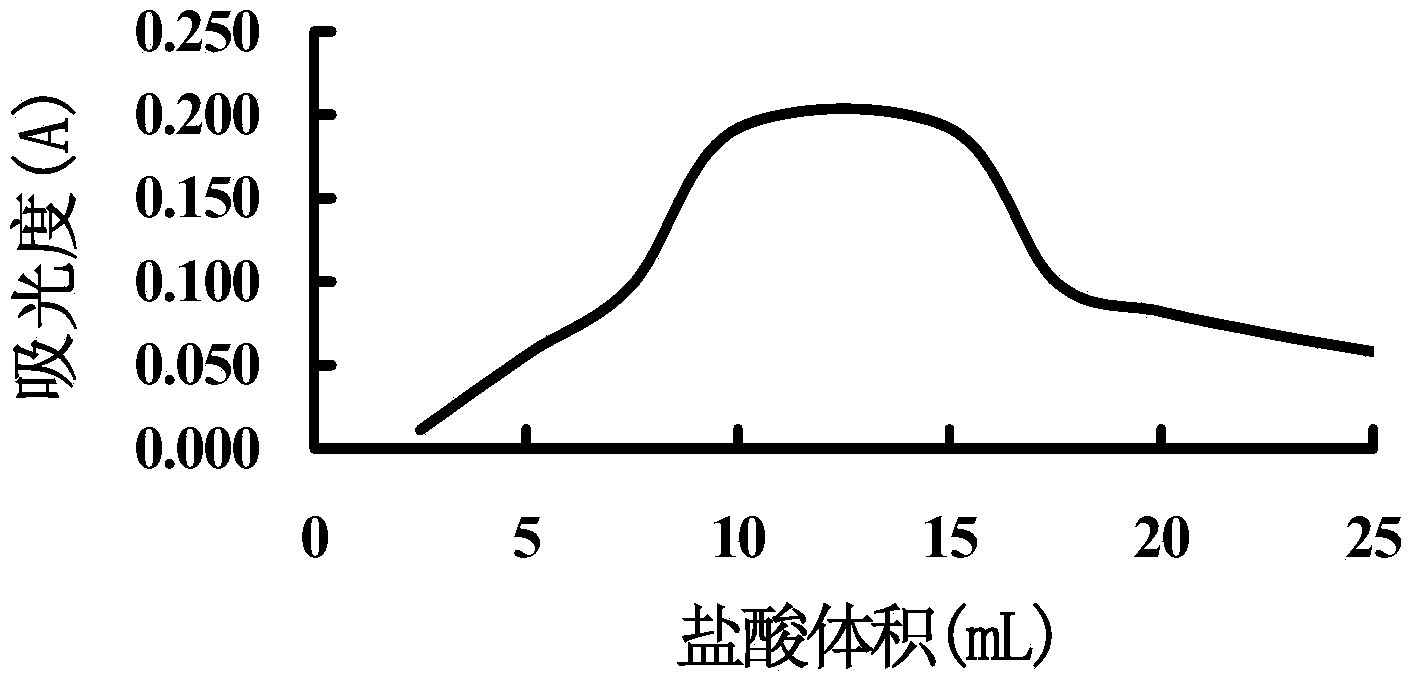

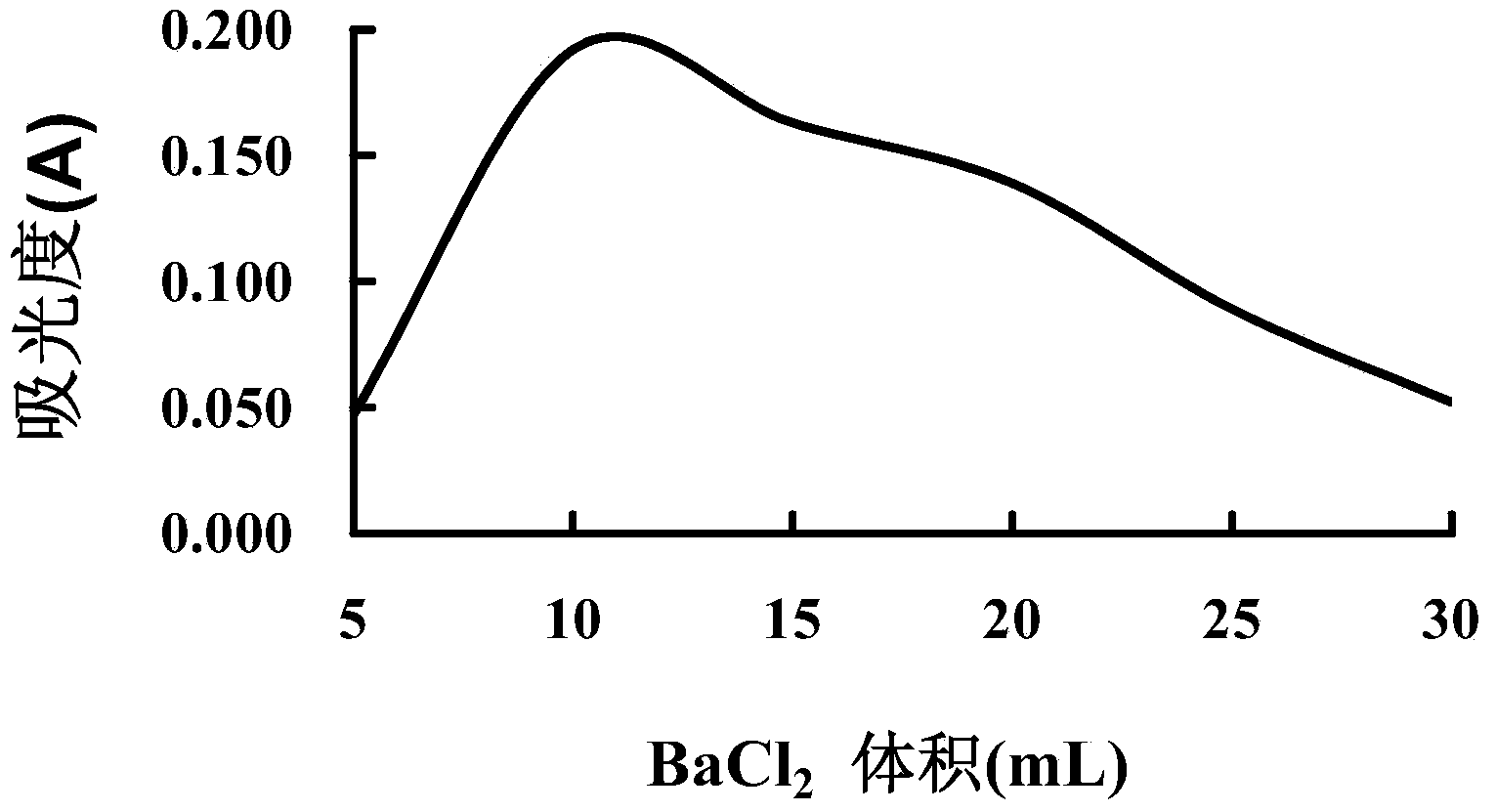

Measuring method for sulfate radical in gas

InactiveCN103674628AImprove accuracyIncreased dispersionWithdrawing sample devicesPreparing sample for investigationBarium dichlorideSulfate radicals

The invention relates to a measuring method for sulfate radical in gas, and belongs to measuring methods for impurities in gas. The technological problem to solve is to provide the method for quickly and precisely measuring the sulfate radical in gas. The method comprises the following steps: a, sampling and preparing a sample: introducing gas containing sulfate radical into a buffering device and an absorbing device, and cooling the absorbing device to the indoor temperature to obtain a sample solution A after the gas is absorbed by a solution in the cooling device; b, treating the sample: transferring partial solution A to an instrument with constant volume, adding hydrochloric acid, a dispersing agent and a barium chloride solution sequentially to enable the sulfate radical in the solution to be settled and dispersed uniformly, shaking up, fixing the volume, and standing to the indoor temperature to obtain a sample solution B; c, measuring: measuring absorbancy value of the sample solution B by adopting a spectrophotometer to obtain the weight of the sulfate radical, and finally, calculating the concentration of the sulfate radical in the gas. The concentration of the sulfate radical measured by adopting the method provided by the invention is 10-524 ppm. The method is simple and quick to operate, and the precision of the measured result is high.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

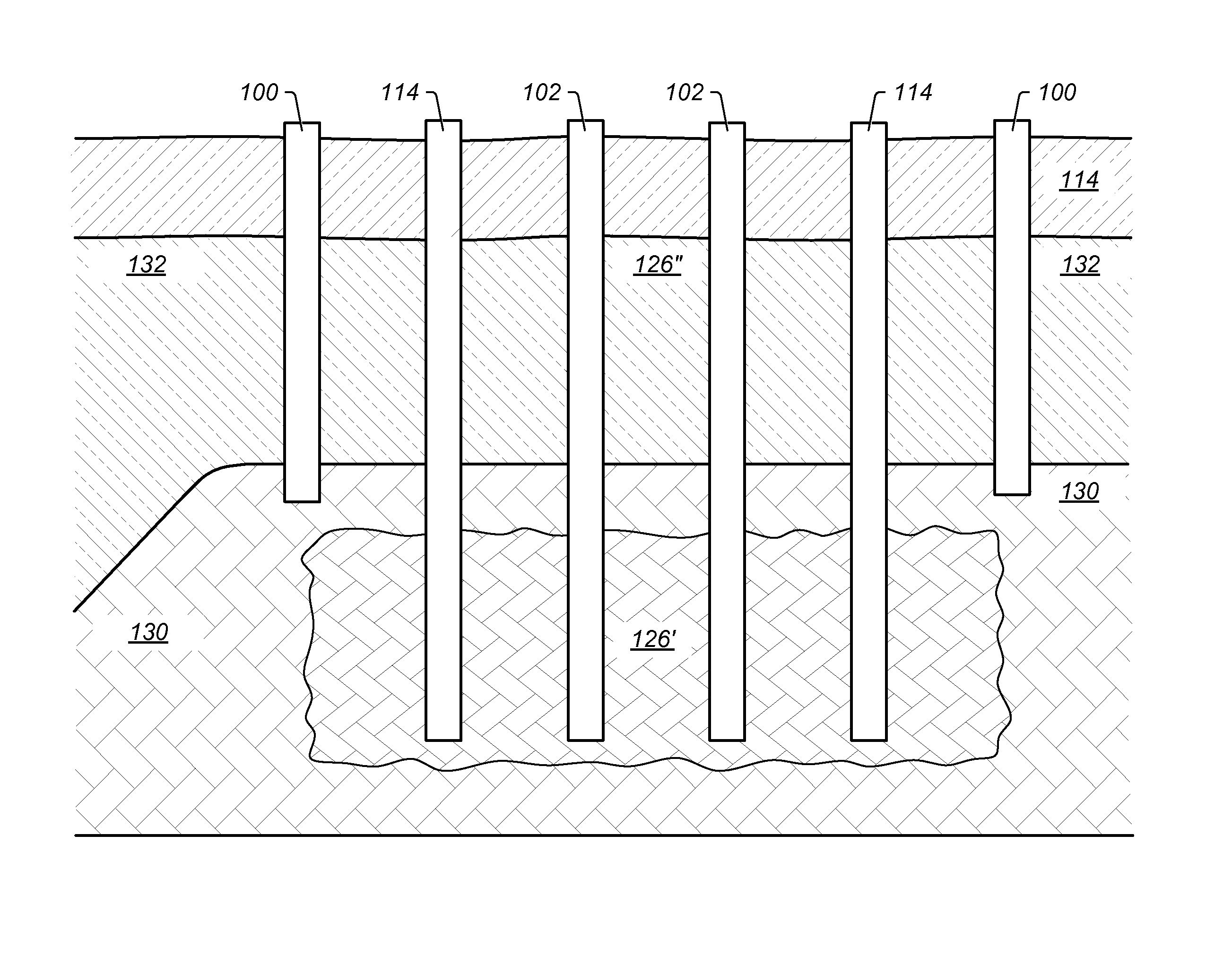

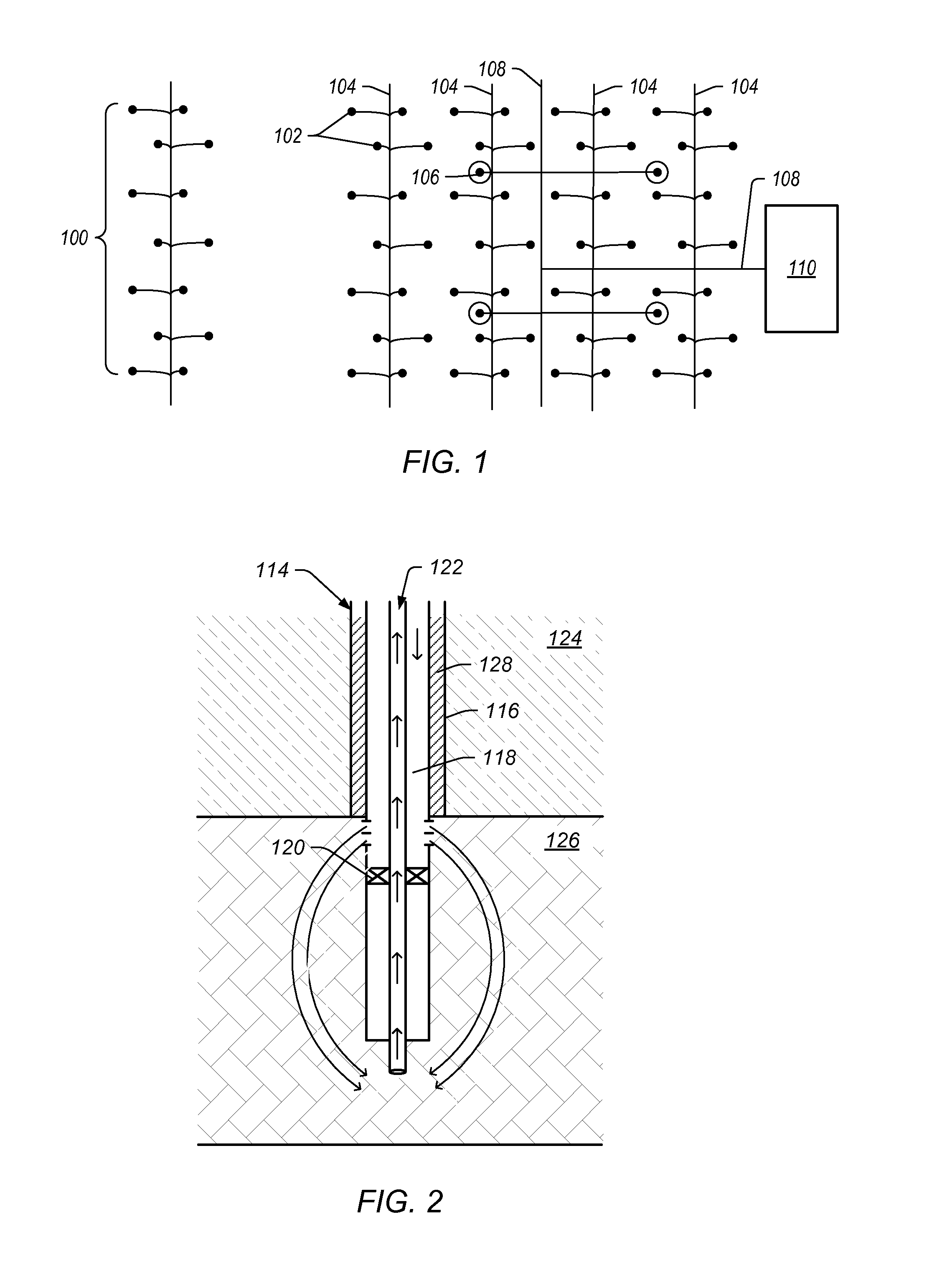

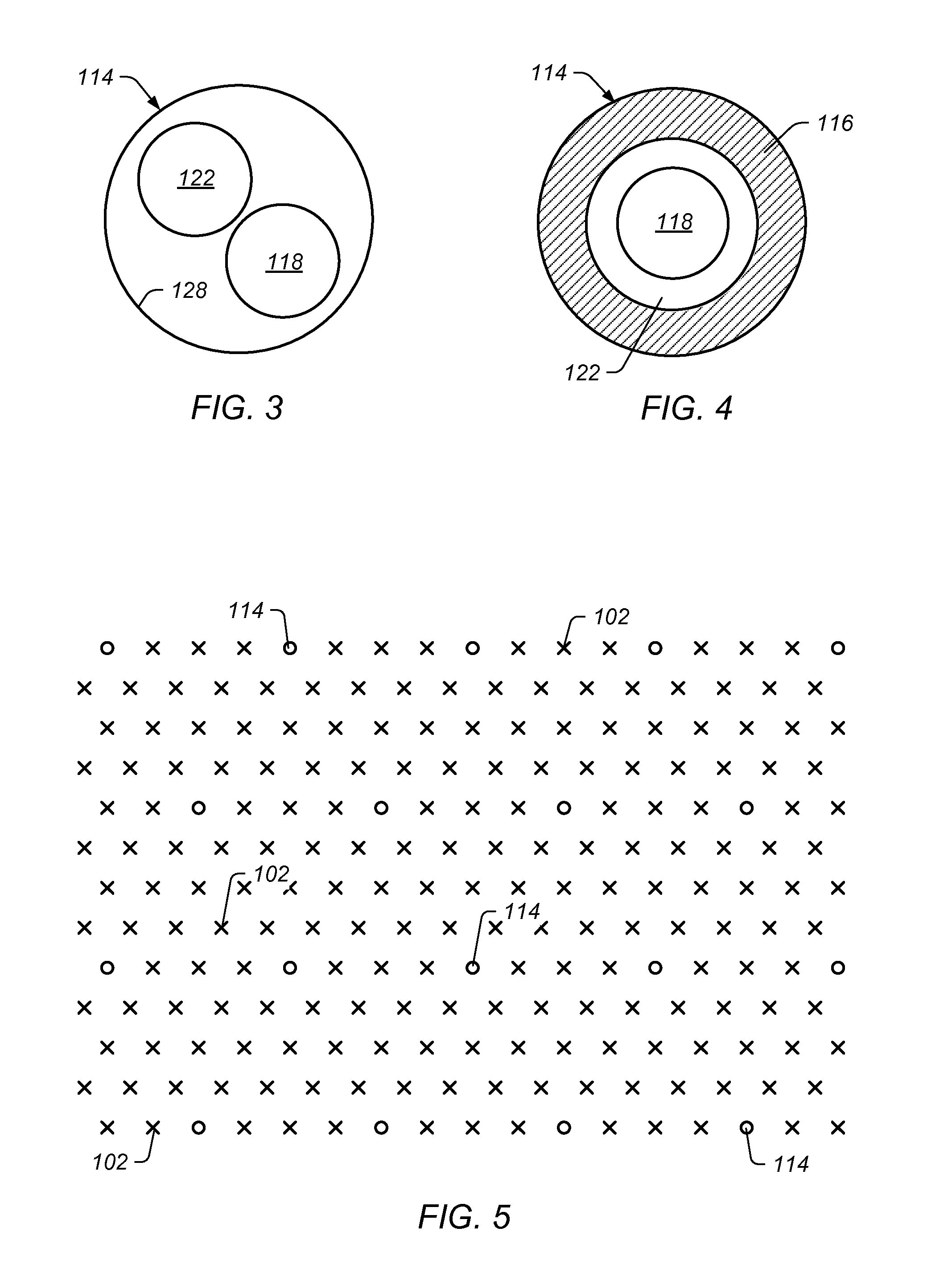

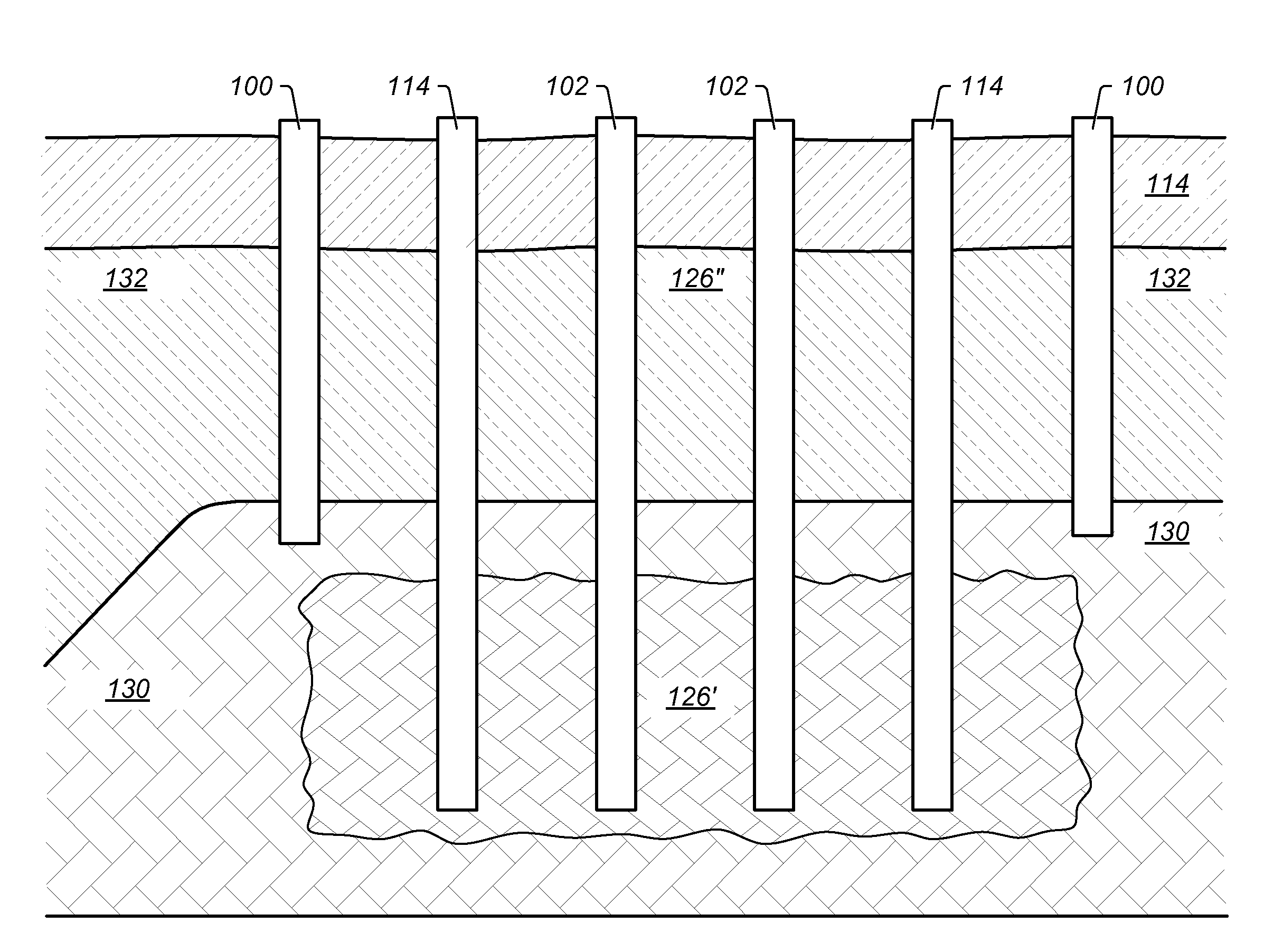

Partial solution mining of hydrocarbon containing layers prior to in situ heat treatment

A method for treating a hydrocarbon containing layer in a subsurface formation is described. The method may include removing at most about 20% by weight of the nahcolite from one or more intervals in the hydrocarbon containing layer that include at least about 40% by weight nahcolite. Heat may be provided from a plurality of heaters to the hydrocarbon containing layer such that at least some hydrocarbons in the hydrocarbon containing layer are mobilized. At least some mobilized hydrocarbons may be produced through at least one production well.

Owner:SHELL OIL CO

Method for bonding metallic contact areas with solution of a sacrificial layer applied on one of the contact areas

ActiveUS9640510B2Inhibition formationDiffusion fastSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPartial solutionMetal

A method for bonding of a first, at least partially metallic contact surface of a first substrate to a second, at least partially metallic contact surface of a second substrate, with the following steps, especially the following progression: application of a sacrificial layer which is at least partially, especially predominantly soluble in the material of at least one of the contact surfaces to at least one of the contact surfaces, bonding of the contact surfaces with at least partial solution of the sacrificial layer in at least one of the contact surfaces.

Owner:EV GRP E THALLNER GMBH

Seam-based reduction and expansion of images using partial solution matrix dependent on dynamic programming access pattern

Systems, methods, and computer-readable storage media for resizing images using seam carving techniques may include generation of a partial solution matrix by at least partially isolating dependencies between sub-problems of a dynamic programming problem corresponding to its solution within different regions of an input image. The number and / or shape of the isolated (or partially isolated) sub-problems may be dependent on the access pattern used by a dynamic programming operation to identify seams in the input image. Multiple sub-problems may be processed independently and in parallel on respective processor core(s) or threads thereof to generate the partial solution matrix. The partial solution matrix may then be processed to identify one or more low-cost seams of the input image. The methods may be implemented as stand-alone applications or as program instructions implementing components of a graphics application, executable by a CPU and / or GPU configured for parallel processing.

Owner:ADOBE SYST INC

Partial solution mining of hydrocarbon containing layers prior to in situ heat treatment

A method for treating a hydrocarbon containing layer in a subsurface formation is described. The method may include removing at most about 20% by weight of the nahcolite from one or more intervals in the hydrocarbon containing layer that include at least about 40% by weight nahcolite. Heat may be provided from a plurality of heaters to the hydrocarbon containing layer such that at least some hydrocarbons in the hydrocarbon containing layer are mobilized. At least some mobilized hydrocarbons may be produced through at least one production well.

Owner:SHELL OIL CO

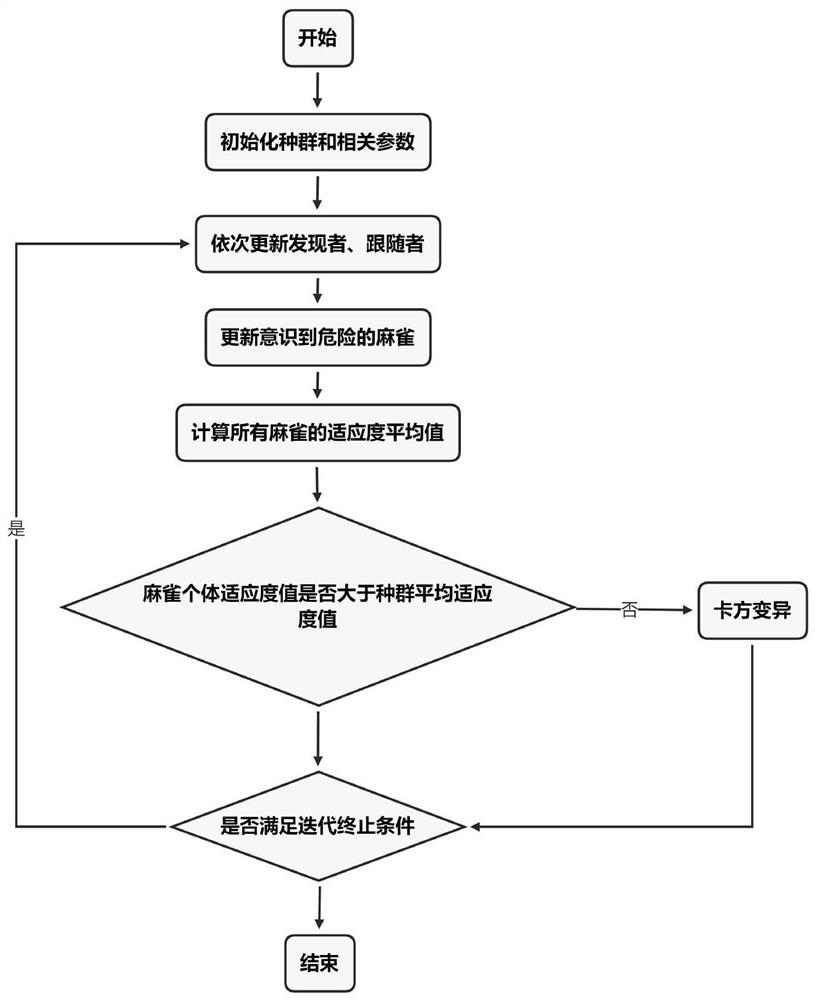

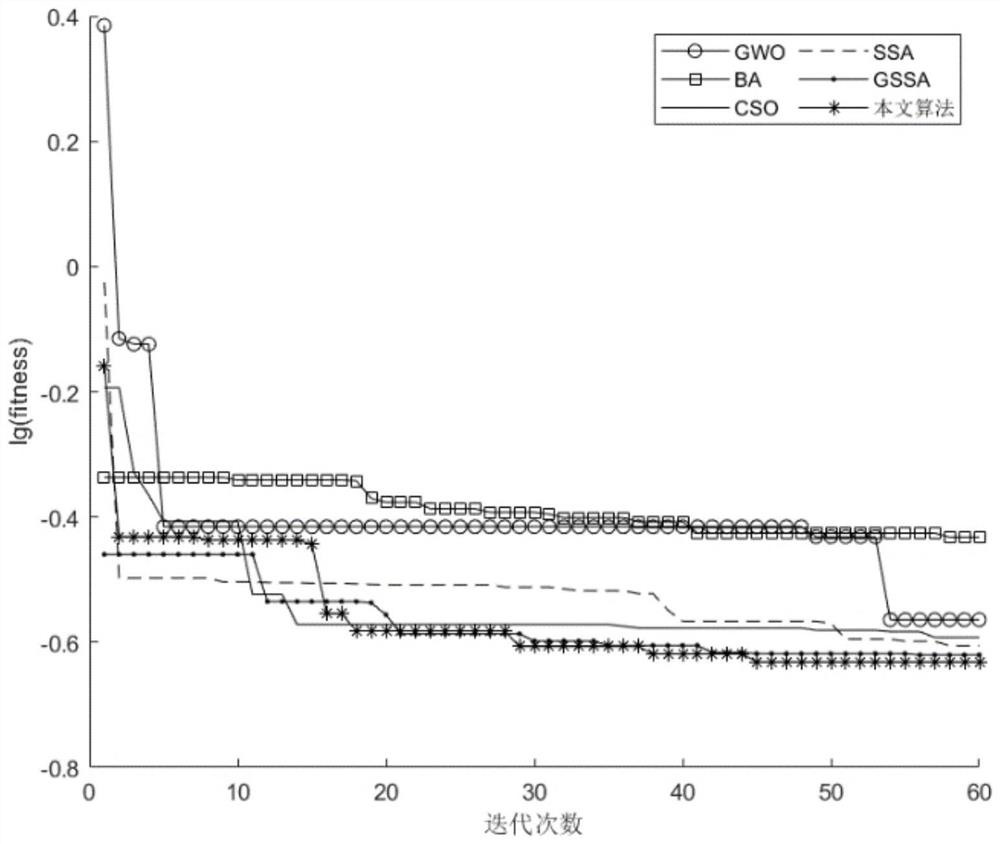

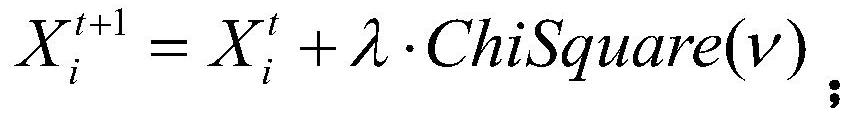

Optimization method based on improved sparrow search algorithm

PendingCN112990419AImprove local search capabilitiesImprove search abilityArtificial lifeLocal search (optimization)Local optimum

The invention discloses an optimization method based on an improved sparrow search algorithm. Sparrows in the sparrow search algorithm are divided into discoverers, followers grabbing food of the discoverers and followers needing wide search due to starvation and windlass according to a fitness ascending order; chi-square variation is introduced into a discoverer updating formula to update a discoverer, a follower is updated according to a discoverer updating result, and then sparrows aware of danger are randomly selected and updated; chi-square variation is performed on the individuals with the fitness values smaller than the average value of all the sparrow fitness values; and if the current number of iterations is smaller than the maximum number of iterations, the step S2 is returned to until the maximum number of iterations is reached. By introducing chi-square variation and sacrificing partial solution duration, certain local search ability of Gaussian variation is reserved, global search ability is improved, the problem that SSA is prone to falling into a local optimal solution in the later stage can be improved, and optimization ability and robustness of SSA are improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Peanut resveratrol extraction method

InactiveCN103172498AEasy to recycleWide variety of sourcesOrganic chemistryOrganic compound preparationPartial solutionSolvent

The invention relates to a resveratrol extraction method. The peanut resveratrol extraction method provided by the invention comprises the following steps of: (1) cleaning a digestion tank and a concentration tank; (2) adding peanut shells and a digestion solvent into the digestion tank; (3) after the feeding, performing digestion: sealing the digestion tank, opening a pressure valve, and keeping pressure in the digestion tank at (-0.01)-(-0.1)MPa for 10-150 minutes; (4) extracting the digestion liquid in the digestion tank and concentrating in the concentration tank; (5) after the concentration, taking out the concentrated liquid, and fetching upper-layer partial solution of the concentrated liquid while the concentrated liquid is hot; (6) cleaning the concentration tank, and washing out residual effective components in the concentration tank; (7) drying the fetched upper-layer partial solution in spray drying equipment, and drying the precipitate of the effective components in vacuum drying equipment; and (8) after the water content is reduced below 10%, taking out the product and grinding. The method provided by the invention is easy to realize and suitable for large-scale production.

Owner:SHANDONG PEANUT RES INST

Large-area automobile sunshade net and using method

InactiveCN102061827AImprove cooling effectImprove installation efficiencyTents/canopiesPartial solutionEngineering

The invention discloses a large-area automobile sunshade net and a using method. The large-area automobile sunshade net is characterized by mainly comprising a sunshade net body (1), supporting pull ropes (4) and supporting upright posts (5); and the designer takes numerous problems of sun protection, energy conservation and emission reduction of automobiles as an integral problem, and integral solution replaces the conventional partial solution, namely a sunshade parking lot is made. The large-area automobile sunshade net has simple structure and is convenient to operate or fold.

Owner:XIAN COMEN ELECTRONICS TECH

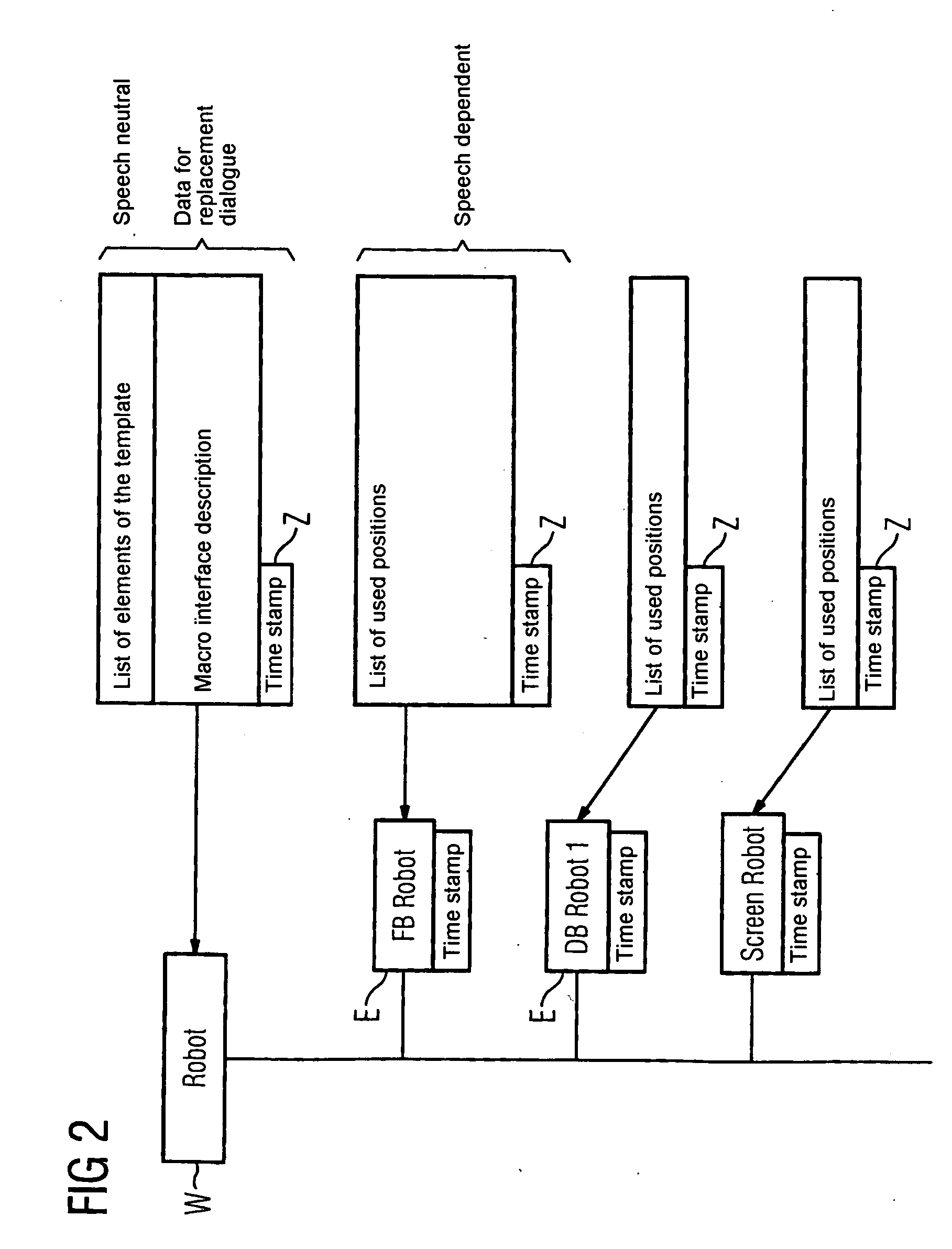

System and method for reusing project planning data

InactiveUS20060155481A1Programme controlAnalogue computers for chemical processesPartial solutionData mining

The invention relates to a system and a method for managing and / or providing partial solutions consisting of elements. With the aid of the system and method, existing partial solutions can be reused and updated. Here at least one partial solution is created, especially by a user, with the at least one partial solution serving as a template for creating a copy. The created partial solution is saved in a library and a copy of a saved partial solution (2l..2n) is created. The at least one copy of the partial solution thus serves for use in creating a solution, in particular an automation solution.

Owner:SIEMENS AG

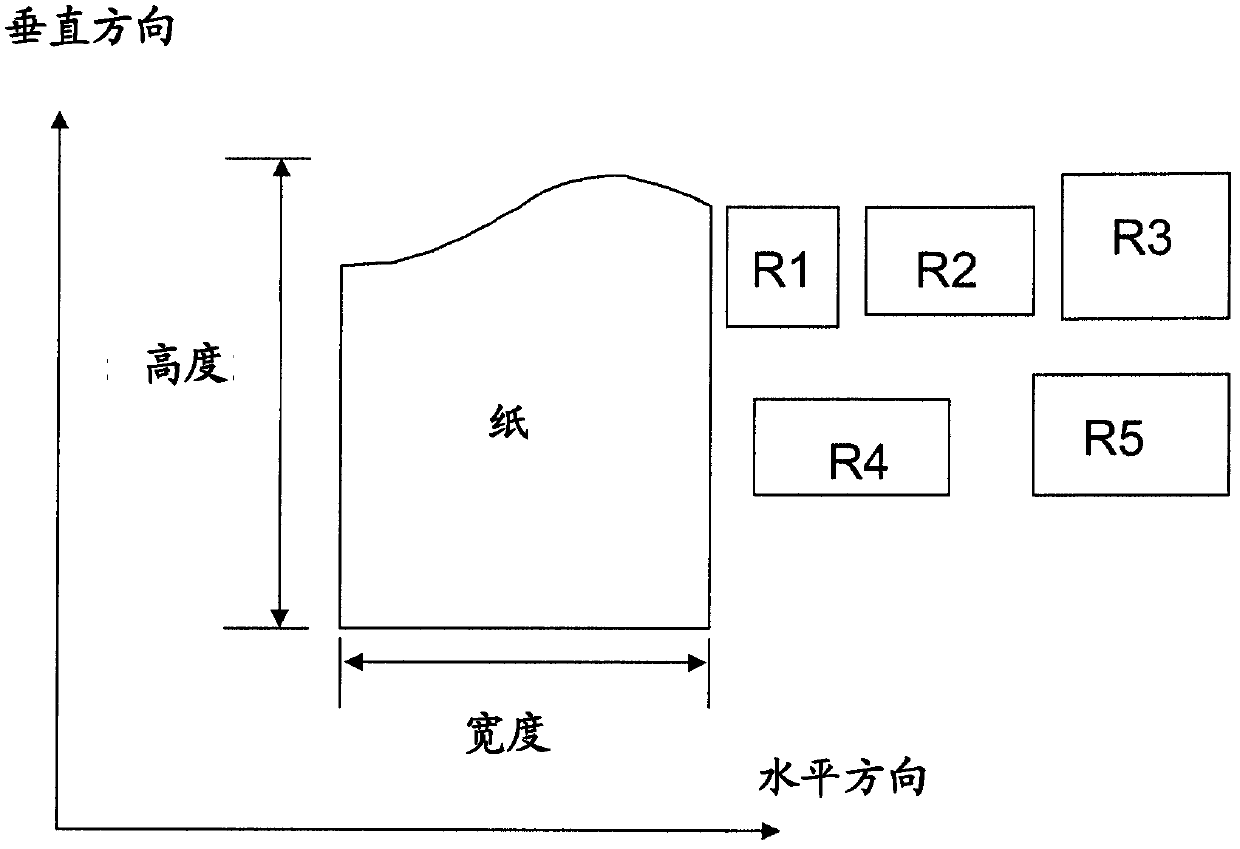

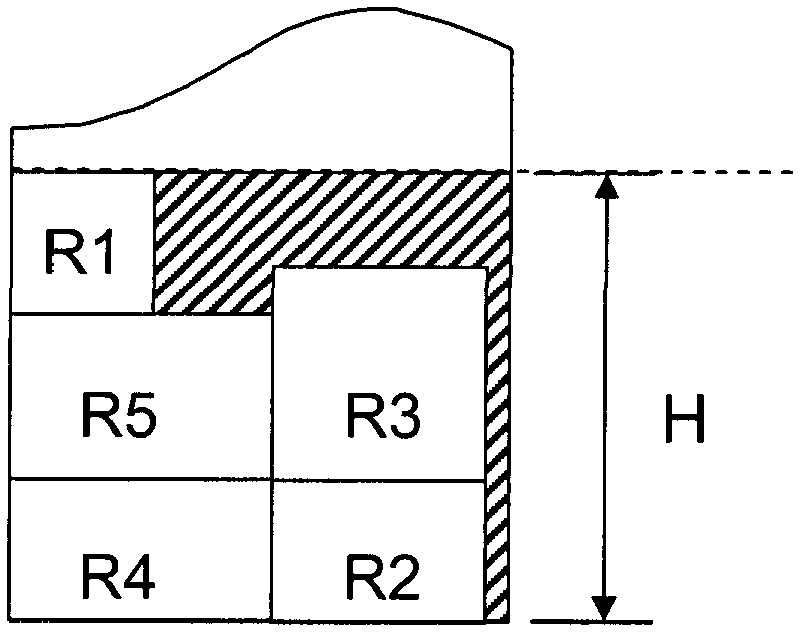

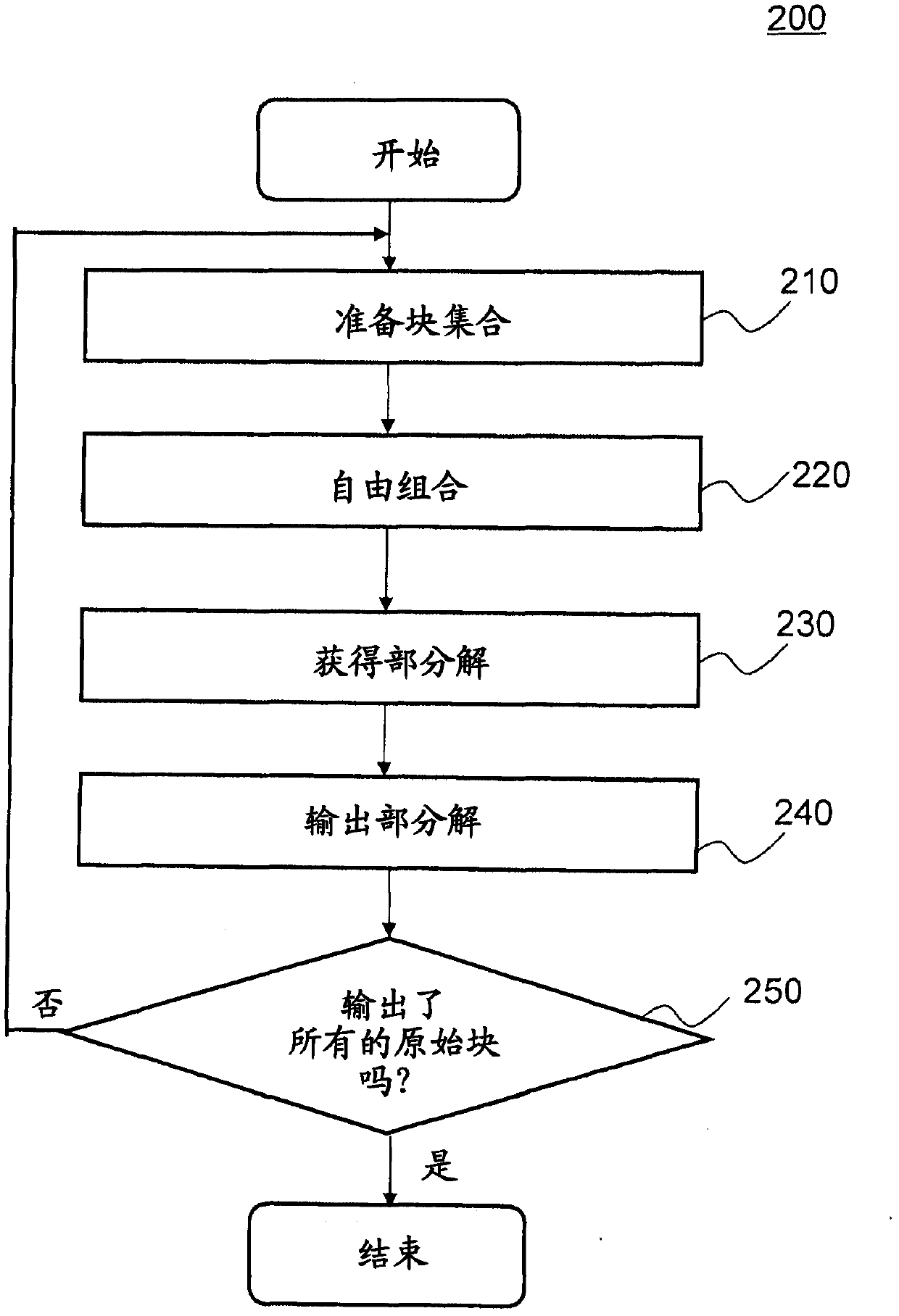

Typesetting method and typesetting device

ActiveCN103324606AReduce wasteLess typography effectNatural language data processingSpecial data processing applicationsParallel computingPartial solution

The invention provides a typesetting method and a typesetting device. The typesetting method sequentially comprises the following steps: block set preparation: preparing a first block set comprising the primary block; large block determination: determining whether a large block satisfying the first condition is included in the first block set; generation of a first candidate combined block set: generating a candidate combined block set in a limited area when the situation that the first block set includes a large block is determined, or generating a candidate combined block set in all areas of sheet material when the large block is not included in the first block set; partial solution obtaining: obtaining a block satisfying the first partial solution condition and serving as partial solution from the candidate combined block set. The typesetting method and the typesetting device can limit the process of combination via regulating the typesetting order of the blocks to achieve fewer poor typesetting effects and further lower wastage rate of material.

Owner:CANON KK

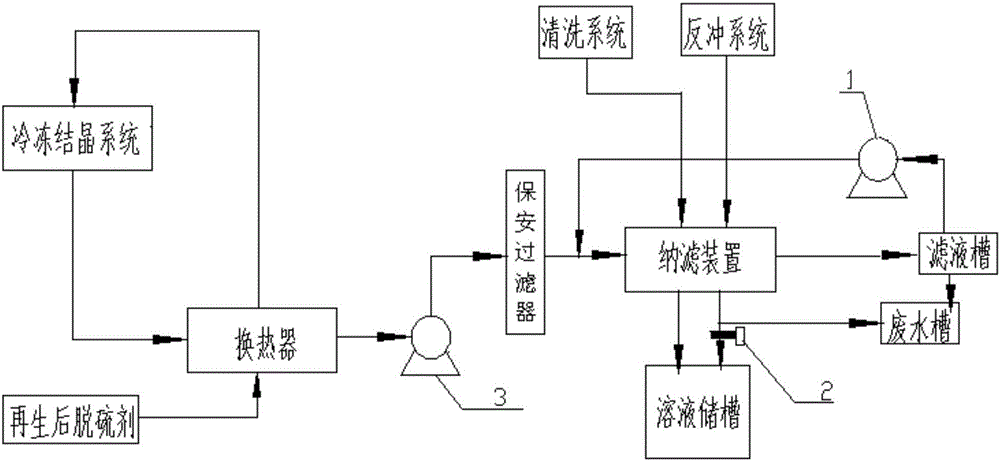

Purification device and purification method of organic amine desulfurizing agent in organic amine method desulfurizing process

ActiveCN106422675ASolving the Problem of Heat-Stable Salt LoadingStable and cleanDispersed particle separationPurification methodsPlate heat exchanger

The invention discloses a purification device and a purification method of an organic amine desulfurizing agent in an organic amine method desulfurizing process. A regenerated desulfurizing agent solution is subjected to heat exchange through a plate heat exchanger, and is then pumped into a safety filter by a pressurizing pump to be filtered; obtained filter liquid enters a nanofiltration device; filter liquid obtained after the nanofiltration is discharged into a filter liquid groove; concentrated liquid obtained through nanofiltration is discharged into a solution storage groove; the purification device also comprises a freeze crystallization system connected with the plate heat exchanger; partial solution subjected to heat exchange is subjected to freeze crystallization to remove sodium sulphate; then, the regenerated desulfurizing agent solution subjected to the sodium sulphate removal is guided into the plate heat exchanger to be subjected to heat exchange again; next, obtained liquid and the regenerated desulfurizing agent solution in a pipeline are jointly pumped into the safety filter by the pressurizing pump to be filtered; the nanofiltration device is connected with a cleaning system and a reverse flushing system. The content of Cl<-> and SO4<2-> in the regenerated desulfurizing agent solution can be continuously reduced; the cleanness of the desulfurizing agent of the desulfurizing system and the stability of the desulfurizing effect can be ensured.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

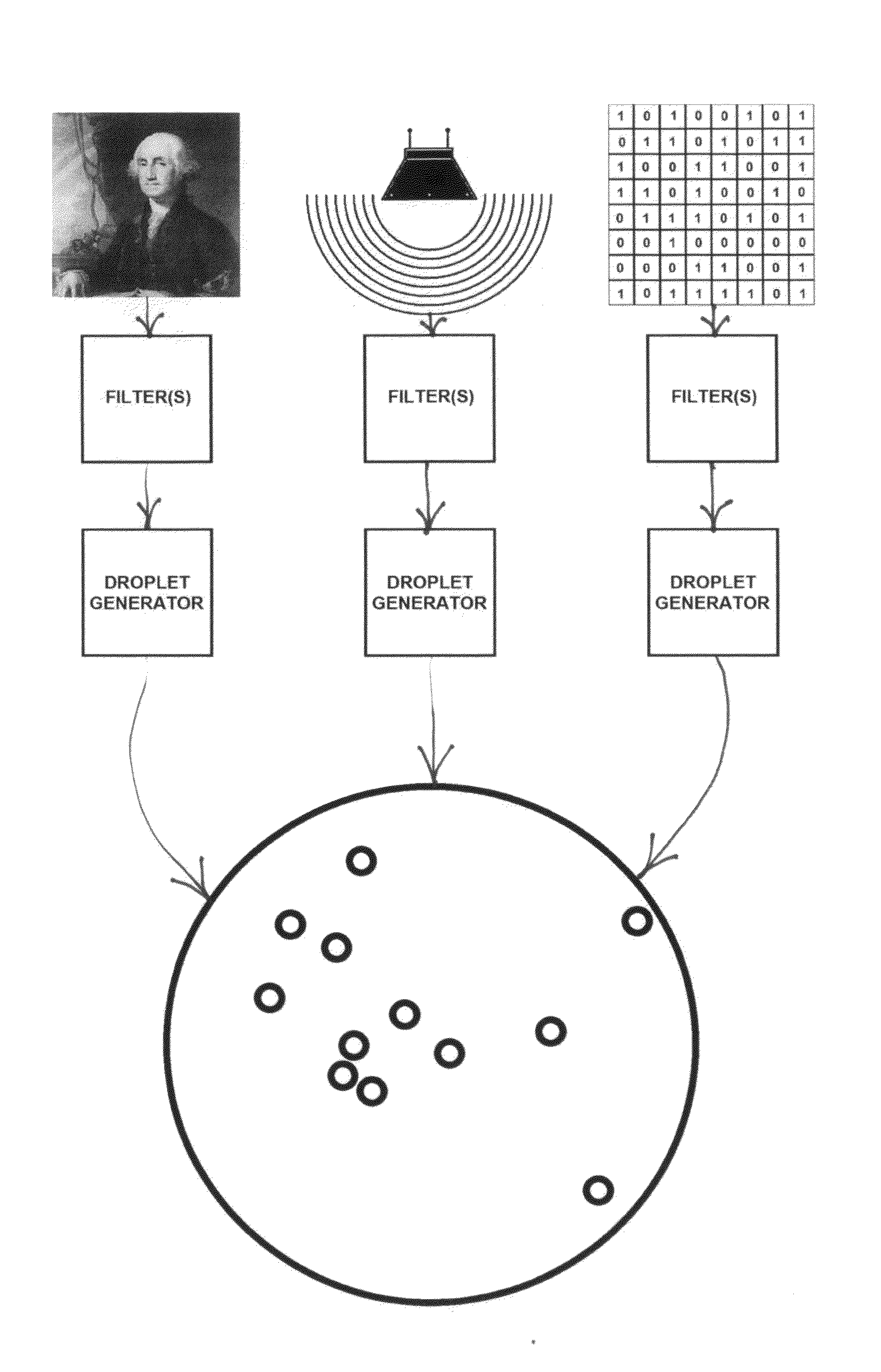

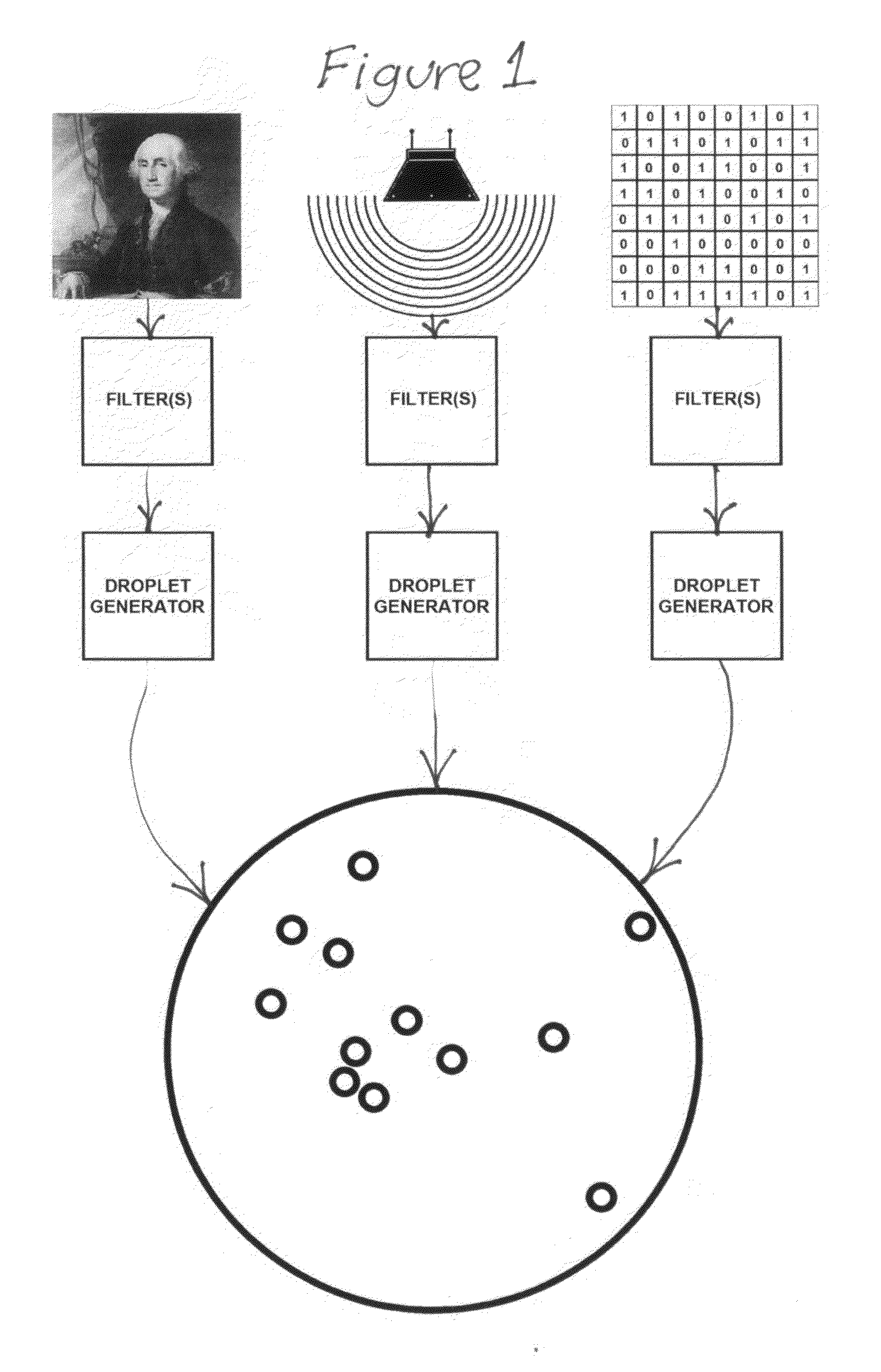

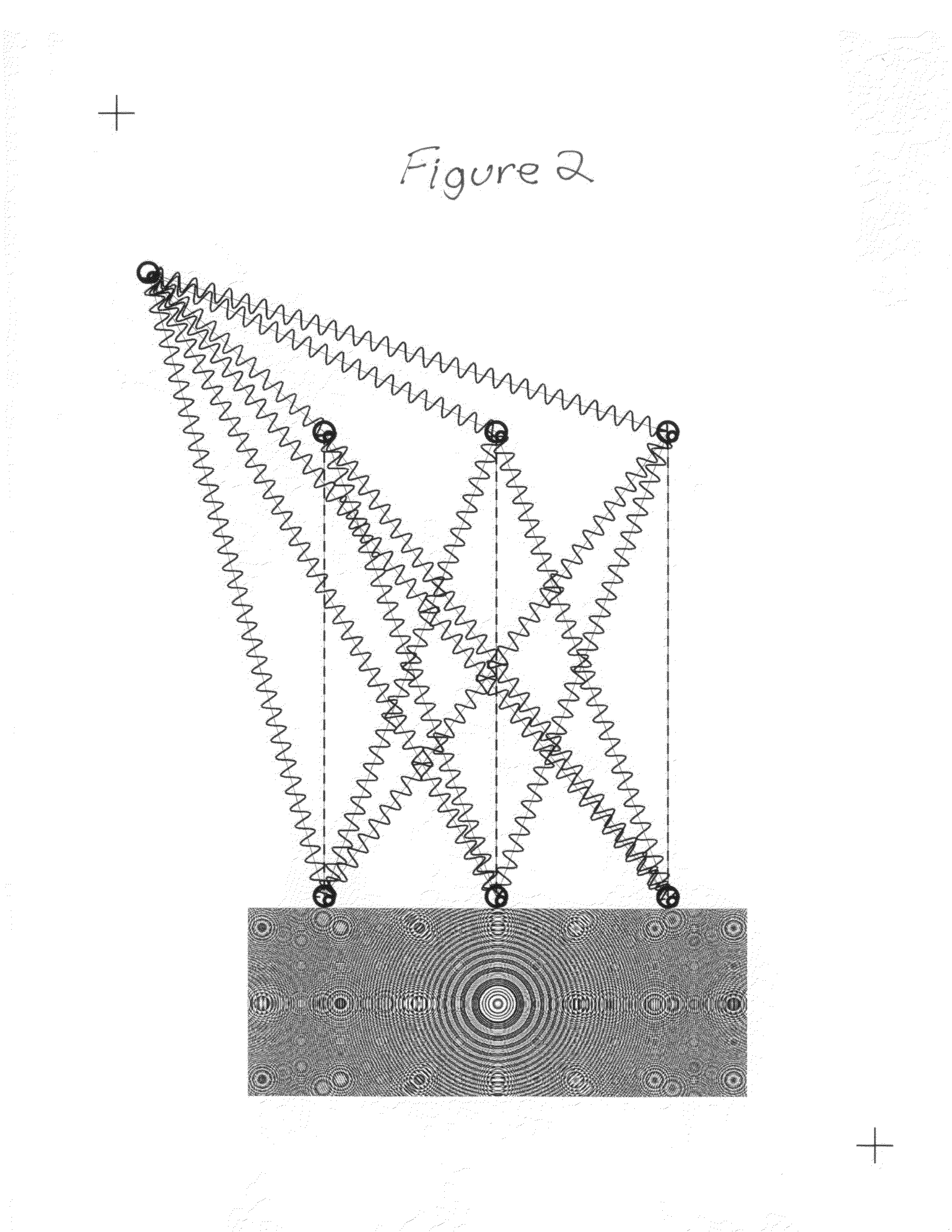

Holographic computer system

ActiveUS20110251982A1High complexityQuantum computersNanoinformaticsPattern recognitionPartial solution

A method and apparatus used for general purpose problem solving using entanglement properties of holography. Intelligent point-based entities having spatial and other electromagnetic properties called DROPLETS [Data-Representative-Object-Particle(s)-Liking-EnTanglement] are generated as delegate objects—avatars—connected to data sources representing situations, event or other problems. A DROPLET's properties are controlled by changes in input data, self-state, feedback, and / or changes of other DROPLETS. Coherent rays are introduced and interact with DROPLETS, generating an INTELLIGENCE WAVEFRONT. Interference patterns are recorded and converted to binary machine codes of a near-infinite set, instructing where to store human / machine-readable content within a plurality of associative memories. Said content includes waveforms, harmonics, codes, data, and other holograms, which are dispersed and stored wholistically throughout using spread spectrum techniques. Upon future recognition of like-patterns of situations, events and other problems, the appropriate content components are retrieved and presented as full or partial solutions. Hardware, software, and hybrid embodiments are envisioned.

Owner:DLUHOS ERIC JOHN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com