Method for recycling tungsten in liquids after tungsten smelting exchanges

A recovery method, scheelite technology, applied in chemical instruments and methods, metallurgical wastewater treatment, process efficiency improvement, etc., can solve problems such as unsatisfactory use effect, incomplete tungsten precipitation, incomplete tungsten precipitation, etc., and achieve cost saving , The effect of low recycling process cost and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

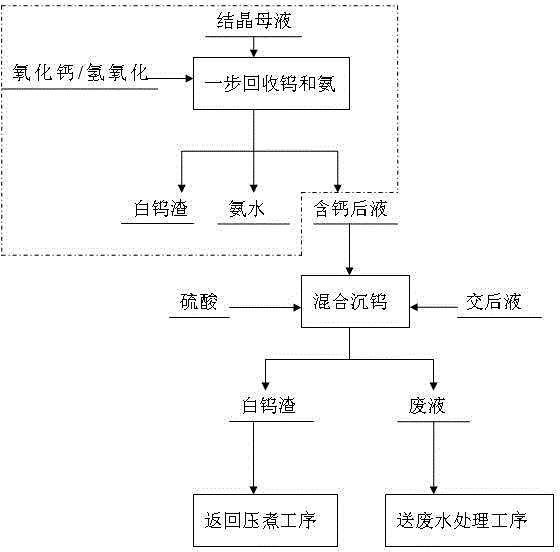

Method used

Image

Examples

Embodiment 1

[0022] After exchange, the liquid contains 150mg / L tungsten trioxide, the volume of the solution is 500mL, and the initial pH of the solution is 13-14. When the pH value is adjusted to 8 by sulfuric acid, add 10mL of the crystallization mother liquor containing 40g / L of calcium ions to treat the liquid, and the reaction temperature The temperature is 70°C-80°C, fully stirred for more than one hour, the concentration of tungsten at the end of the reaction is 5mg / L, and the content of scheelite precipitated tungsten trioxide is 66.56%.

Embodiment 2

[0024] The solution after exchange contains 150mg / L of tungsten trioxide, the volume of the solution is 500mL, the initial pH of the solution is 13-14, when the pH value is adjusted to 9 by sulfuric acid, add 10mL of the crystallization mother liquor containing 40g / L of calcium ions to treat the solution, and the reaction temperature The temperature is 70°C-80°C, fully stirred for more than one hour, the concentration of tungsten at the end of the reaction is 8mg / L, and the content of scheelite precipitated tungsten trioxide is 65.32%.

Embodiment 3

[0026] The solution after exchange contains 150mg / L tungsten trioxide, the volume of the solution is 500mL, and the initial pH of the solution is 13-14. When the pH value is adjusted to 10 by sulfuric acid, add 10mL of the crystallization mother solution containing 40g / L of calcium ions to treat the solution, and the reaction temperature The temperature is 70°C-80°C, fully stirred for more than one hour, the concentration of tungsten at the end of the reaction is 10mg / L, and the content of scheelite precipitated tungsten trioxide is 64.81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com