Measuring method for sulfate radical in gas

A determination method and technology for sulfate radicals are applied in the preparation of test samples, measurement of color/spectral properties, sampling devices, etc., which can solve the problems of high equipment cost, difficulty in measuring trace components, and low detection limit, and achieve sampling operation Rigorous, reduce measurement error, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The mensuration of sulfate radical concentration in the chlorine in embodiment 1 electrolytic chlorine technology

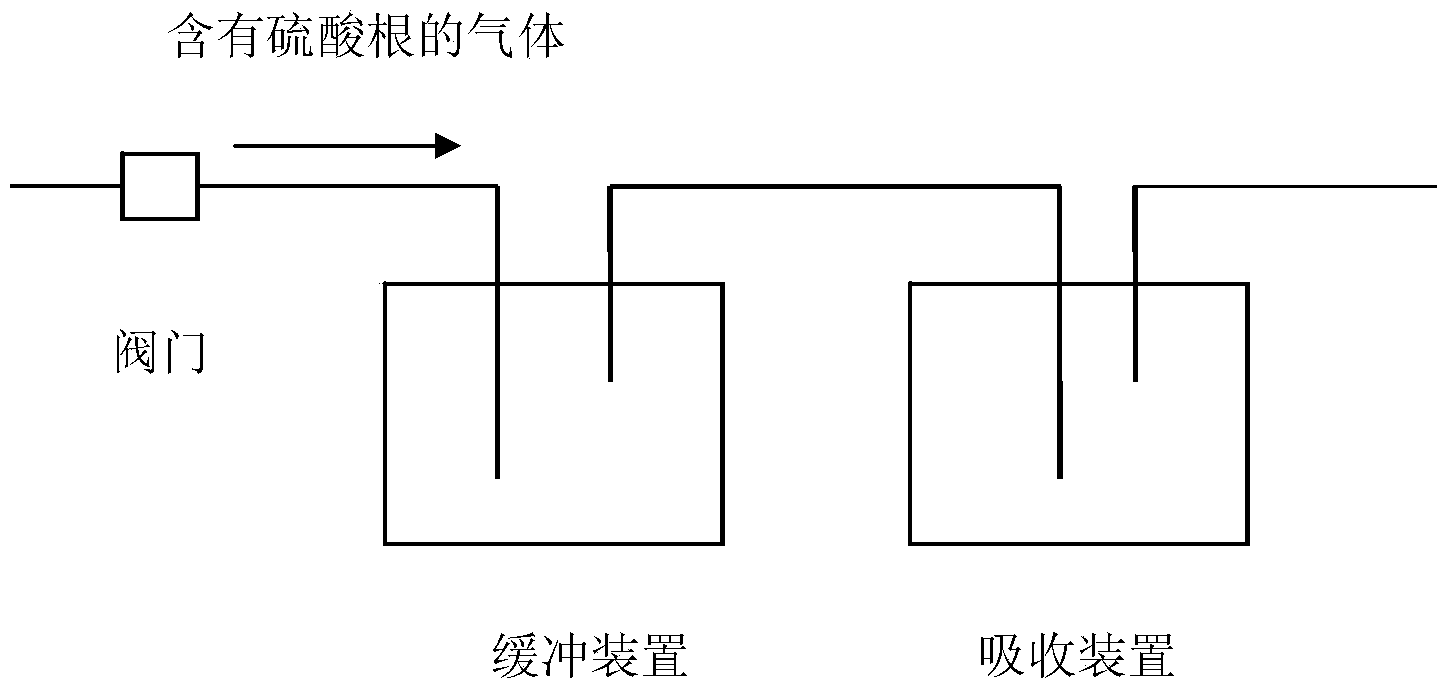

[0073] 1. Sampling and sample preparation: first establish the figure 1In the sampling and sample preparation device shown, chlorine gas containing sulfate radicals is sequentially passed into a buffer bottle and an absorption bottle, and the absorption bottle contains 700mL of NaOH solution with a mass fraction of 20%. The mouth of the buffer bottle and the absorption bottle is sealed with a matching rubber stopper, and the buffer bottle and the absorption bottle are connected by a latex tube. Open the valve, feed chlorine gas at a rate of 1 mL / min, close the valve after 1 hour, and complete the sampling of electrolytic chlorine gas; then use nitrogen to purge the chlorine gas in the buffer bottle; finally let the absorption bottle cool to room temperature to obtain test solution A. Wherein the weight of the absorption bottle before absorption is 382.01g...

Embodiment 2

[0076] The mensuration of sulfate radical concentration in the hydrogen chloride gas of embodiment 2

[0077] 1. Sampling and sample preparation: First, set up a sampling and sample preparation device, and then pass hydrogen chloride gas containing sulfate radicals into a buffer bottle and an absorption bottle in turn, and the absorption bottle contains 700mL of NaOH solution with a mass concentration of 20%. The mouth of the buffer bottle and the absorption bottle is sealed with a matching rubber stopper, and the buffer bottle and the absorption bottle are connected by a latex tube. Open the hydrogen chloride gas valve, let it flow in at a rate of 1 mL / min for 1 hour, close the valve, and complete the sampling of hydrogen chloride gas. Then use nitrogen to purge the hydrogen chloride gas in the buffer bottle, and finally let the absorption bottle cool to room temperature to obtain test solution A. Among them, the weight of the absorption bottle before absorption is 382.01g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com