Novel aqueous light-cured alicyclic epoxy acrylic acid emulsion and preparation method thereof

A technology of epoxy acrylic and cycloaliphatic epoxy, applied in the direction of coating, etc., can solve the problems of pollution, weather resistance, poor heat and humidity resistance, etc., and achieve the effects of good weather resistance, chemical arc resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

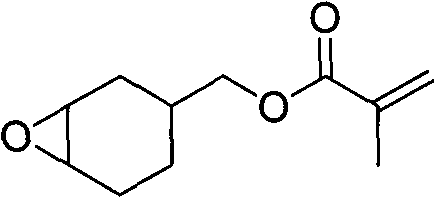

[0030] 1) Take 15g of 3,4-epoxycyclohexylmethyl methacrylate, 2.25g of acrylic acid, 42.5g of butyl acrylate, 28.5g of methyl methacrylate, 1.4g of N-methylolacrylamide and n-dodecane Base mercaptan 0.2g, and mix well. The structural formula of above-mentioned cycloaliphatic epoxy resin is:

[0031]

[0032] Formula 2) Take 1g of alkylphenol polyoxyethylene ether and 0.4g of sodium bicarbonate, dissolve them in 97mL of pure water, add them into a reactor equipped with a stirrer and a thermometer, and when stirring and preheating to 50°C, the step 1 ) solution into the reaction vessel, reflux insulation 0.5h.

[0033] 3) Dissolve 0.26g of ammonium persulfate in 3mL of pure water, add 1 / 4 of this solution and 1 / 4 of the solution in step 2) to the reactor equipped with a stirrer, thermometer and constant pressure dropping funnel , heat up to 80°C, start adding the solution in the remaining step 2) dropwise when the blue light is emitted, add 1 / 4 of the solution in step 2) af...

Embodiment 2

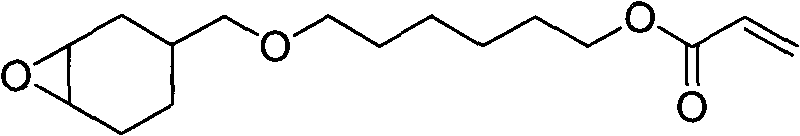

[0036] 1) Take 15g of 3,4-epoxycyclohexyl acrylate 6-methoxyhexyl ester, 2.5g of acrylic acid, 42.5g of butyl acrylate, 28.75g of methyl methacrylate, 1.6g of N-methylolacrylamide and normal Dodecyl mercaptan 0.24g, and mix well. The structural formula of above-mentioned cycloaliphatic epoxy resin is:

[0037]

[0038] 2) Take 1g of alkylphenol polyoxyethylene ether and 0.475g of sodium bicarbonate, dissolve them in 100mL of pure water, add them into a reactor equipped with a stirrer and a thermometer, stir and preheat to 50°C, and put step 1) The medium solution was added to the reaction vessel, and kept at reflux for 0.5h.

[0039] 3) Dissolve 0.27g of ammonium persulfate in 12mL of pure water, add 1 / 4 of this solution and 1 / 4 of the solution in step 2) to the reactor equipped with a stirrer, thermometer and constant pressure dropping funnel , heat up to 80°C, start adding the solution in the remaining step 2) dropwise when the blue light is emitted, add 1 / 4 of the solu...

Embodiment 3

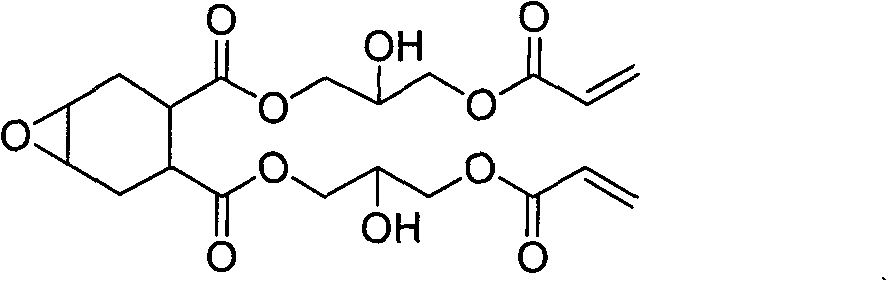

[0042] 1) Take 15g of 4,5-epoxycyclohexylphthalate (1-glyceryl acrylate), 1.5g of acrylic acid, 42.5g of butyl acrylate, 28.75g of methyl methacrylate, and N-methylolacrylamide 1.6g and n-dodecylmercaptan 0.24g, and mix well. The structural formula of above-mentioned cycloaliphatic epoxy resin is:

[0043]

[0044] 2) Take 1g of alkylphenol polyoxyethylene ether and 0.475g of sodium bicarbonate, dissolve them in 96mL of pure water, add them into a reactor equipped with a stirrer and a thermometer, stir and preheat to 50°C, and put step 1) The medium solution was added to the reaction vessel, and kept at reflux for 0.5h.

[0045] 3) Dissolve 0.28g of ammonium persulfate in 4mL of pure water, add 1 / 4 of this solution and 1 / 4 of the solution in step 2) to the reactor equipped with a stirrer, thermometer and constant pressure dropping funnel , heat up to 80°C, start adding the solution in the remaining step 2) dropwise when the blue light is emitted, add 1 / 4 of the solution in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com