Uvioresistant antibacterial release paper and preparation method thereof

An anti-ultraviolet, release paper technology, used in paper, papermaking, paper coatings, etc., can solve problems such as damaged products, damage, product bacterial erosion, etc., and achieve the effect of good flexibility and strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

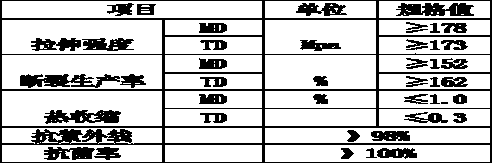

[0016] Embodiment 1: Preparation of anti-ultraviolet and antibacterial release paper

[0017] Coat one or both sides of the base paper of the release paper with a coating layer, and then coat a layer of release layer on the surface of the coating layer, and perform super calendering on it after coating the release layer. The specific steps of super calendering are as follows: : After the base paper of the release paper coated with the film layer is heated at 200°C for bridging, heated and melted at 320°C, then extruded with a pressure of 6Mpa, and then coated with a layer of antibacterial agent on the surface of the release layer Obtain an antibacterial layer, coat a layer of PET film on the surface of the antibacterial layer, and dry it at 20°C to obtain an anti-ultraviolet antibacterial release paper. The PET film layer is made of the following raw materials: 100 parts of PET chips, 25 parts of modified rosin resin, 10 parts of VAE emulsion, and 2 parts of additives. The pre...

Embodiment 2

[0019] Coat one or both sides of the base paper of the release paper with a coating layer, and then coat a layer of release layer on the surface of the coating layer, and perform super calendering on it after coating the release layer. The specific steps of super calendering are as follows: : After the base paper of the release paper coated with the film layer is heated at 230°C for bridging, heated and melted at 350°C, extruded with a pressure of 15Mpa, and then coated with a layer of antibacterial agent on the surface of the release layer Obtain an antibacterial layer, coat a layer of PET film on the surface of the antibacterial layer, and dry it at 25°C to obtain an anti-ultraviolet antibacterial release paper. The PET film layer is made of the following raw materials: 150 parts of PET chips, 30 parts of modified rosin resin, 20 parts of VAE emulsion, and 10 parts of additives. The preparation method of the PET film layer is the same as that of the ordinary PET film layer. ...

Embodiment 3

[0021] Coat one or both sides of the base paper of the release paper with a coating layer, and then coat a layer of release layer on the surface of the coating layer, and perform super calendering on it after coating the release layer. The specific steps of super calendering are as follows: : After the release paper base paper coated with the film layer is heated at 220°C for bridging, heated and melted at 330°C, extruded with a pressure of 10Mpa, and then coated with a layer of antibacterial agent on the surface of the release layer Obtain an antibacterial layer, coat a layer of PET film on the surface of the antibacterial layer, and dry it at 23°C to obtain an anti-ultraviolet antibacterial release paper. The PET film layer is made of the following raw materials: 125 parts of PET chips, 27 parts of modified rosin resin, 15 parts of VAE emulsion, and 6 parts of additives. The preparation method of the PET film layer is the same as that of the ordinary PET film layer. Modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com