Self-permeability-increasing high-permeability acid-resistant epoxy resin waterproof coating material and preparation method therefor

A technology of epoxy resin and waterproof coating, applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problems of general low temperature toughness, no permeability, poor acid resistance, etc., achieve excellent acid resistance, overcome acid resistance Fair, good coating flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

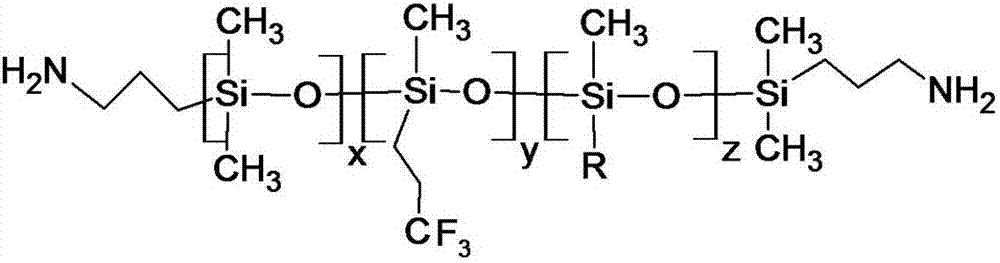

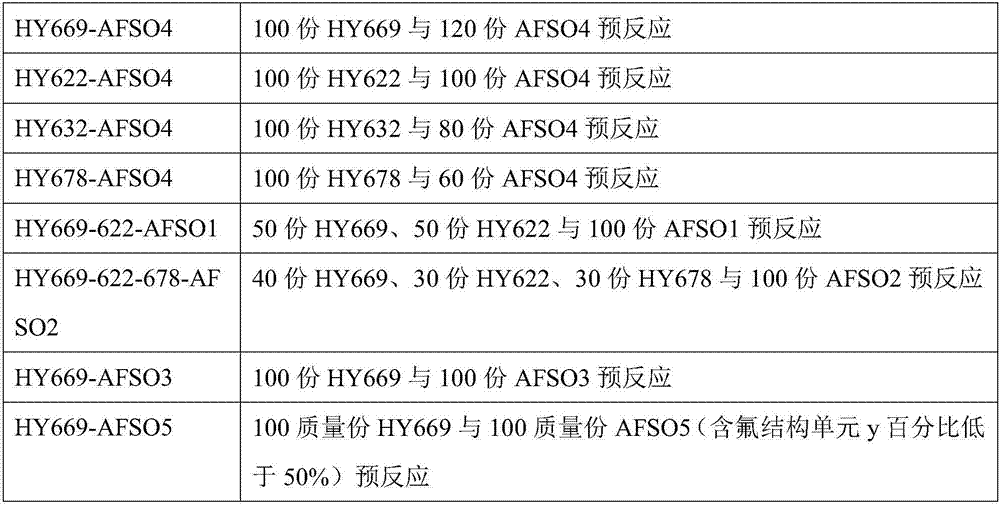

[0068] Amino Fluorinated Silicone Polymer AFSO1

[0069] Add 100g of γ-trifluoropropylmethylcyclotrisiloxane, 30g of octamethylcyclotetrasiloxane, 1,3-bis(3-aminopropyl base)-1,1,3,3-tetramethyldisiloxane 7g (the mass ratio of the three is 100:30:7), N-β-aminoethyl-γ-aminopropylmethyldiethoxy 8g of silane, and 0.14g of tetramethylammonium hydroxide (the total mass of the aforementioned materials is 0.1wt%), and the temperature is raised to 100°C under nitrogen protection, and the reaction is carried out for 6h; The object is denoted as AFSO1. The weight-average molecular weight of the prepared amino-fluorine-containing silicone polymer was detected by gel permeation chromatography, and the result was 3395; the amino group content in the product was determined by acid-base titration method, and the amino group content was 2.79 wt%.

[0070] The proton NMR spectrum data of the product are as follows:

[0071] 1 H NMR (300MHz, CDCl 3 )δ0~0.19ppm(-CH 3 ),0.40~0.49ppm(-CH 2 ...

Synthetic example 2

[0074] Amino Fluorinated Silicone Polymer AFSO2

[0075] Add 100g of γ-trifluoropropylmethylcyclotrisiloxane, 15g of octamethylcyclotetrasiloxane, 1,3-bis(3-aminopropyl base)-1,1,3,3-tetramethyldisiloxane 5g (the mass ratio of the three is 100:15:5), tetramethylammonium hydroxide 0.12g (the total mass of the aforementioned materials is 0.1wt%), The temperature was raised to 90°C under the protection of nitrogen, and the reaction was carried out for 6 hours; the low boilers and the solvent were removed by distillation under reduced pressure to obtain an amino-fluorine-containing organosilicon polymer, which was denoted as AFSO2. The weight-average molecular weight of the prepared amino fluorine-containing silicone polymer was detected by gel permeation chromatography, and the result was 4895; the amino content in the product was determined by acid-base titration, and the amino content was 0.70 wt%.

[0076] The proton NMR spectrum data of the product are as follows:

[0077] ...

Synthetic example 3

[0080] Amino Fluorinated Silicone Polymer AFSO3

[0081] Add 100g of γ-trifluoropropylmethylcyclotrisiloxane, 10g of octamethylcyclotetrasiloxane, 1,3-bis(3-aminopropyl base)-1,1,3,3-tetramethyldisiloxane 8g (the mass ratio of the three is 100:10:8), γ-aminopropylmethyldiethoxysilane 9g and tetramethylhydrogen Ammonium oxide 0.13g (the total mass of the aforementioned materials is 0.1wt%), heated to 100°C under nitrogen protection, and reacted for 6h; the low boilers and solvent were removed by distillation under reduced pressure to obtain an amino fluorine-containing silicone polymer, which is designated as AFSO3. The weight-average molecular weight of the prepared amino-fluorine-containing silicone polymer was detected by gel permeation chromatography, and the result was 3105; the amino content in the product was determined by acid-base titration, and the amino content was 2.26 wt%.

[0082] The proton NMR spectrum data of the product are as follows:

[0083] 1 H NMR (300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com