Method and device for continuously preparing nano ferroferric oxide through hollow fiber ultrafiltration dual-membrane

A technology of ferric oxide and ultrafiltration membrane, which is applied in the direction of ferric oxide/hydroxide and ferric oxide, which can solve the problems of inability to realize continuous preparation, low particle purity and uneven distribution, and achieve The effect of low price, simple process and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 (reaction device of the present invention)

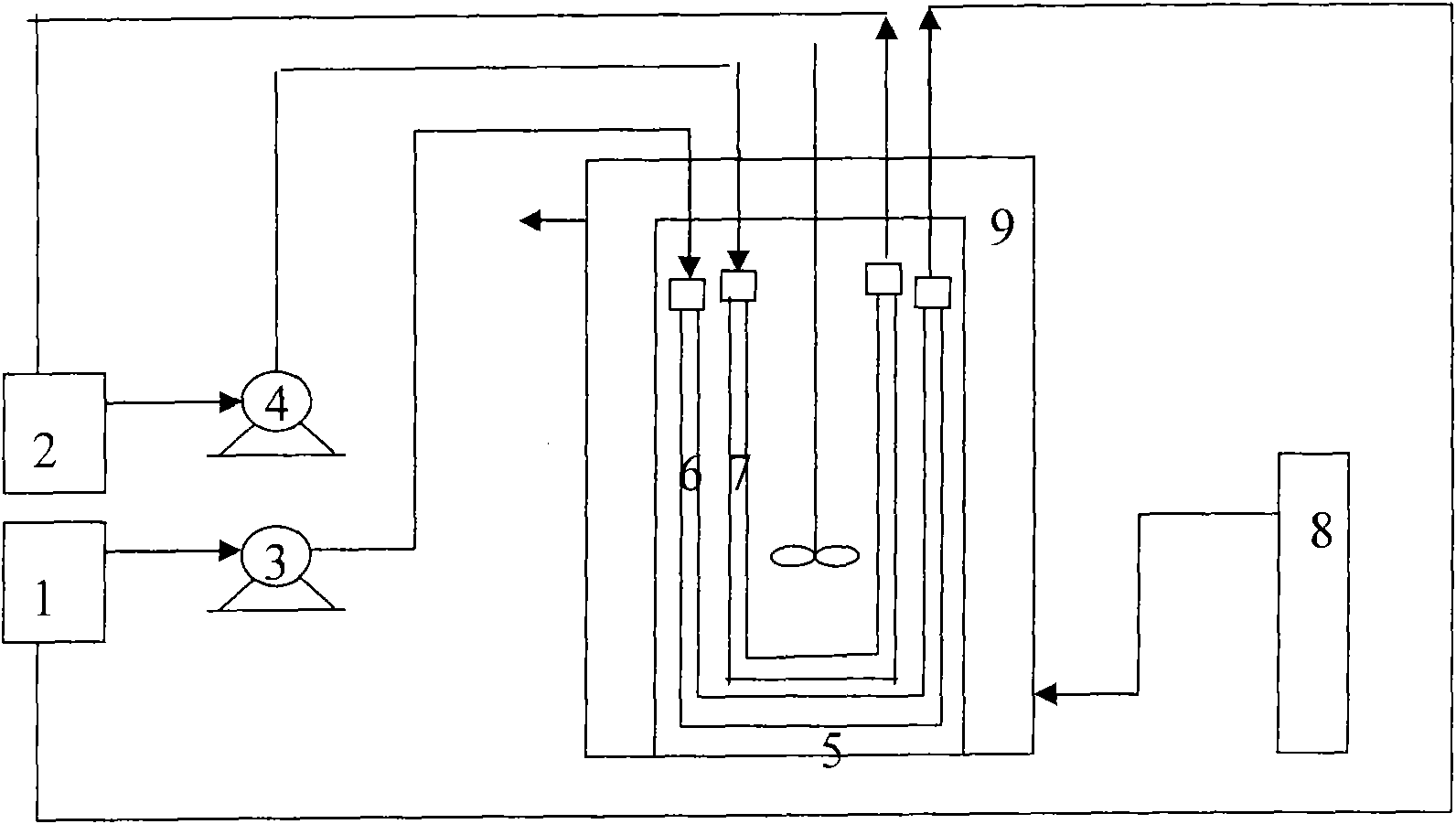

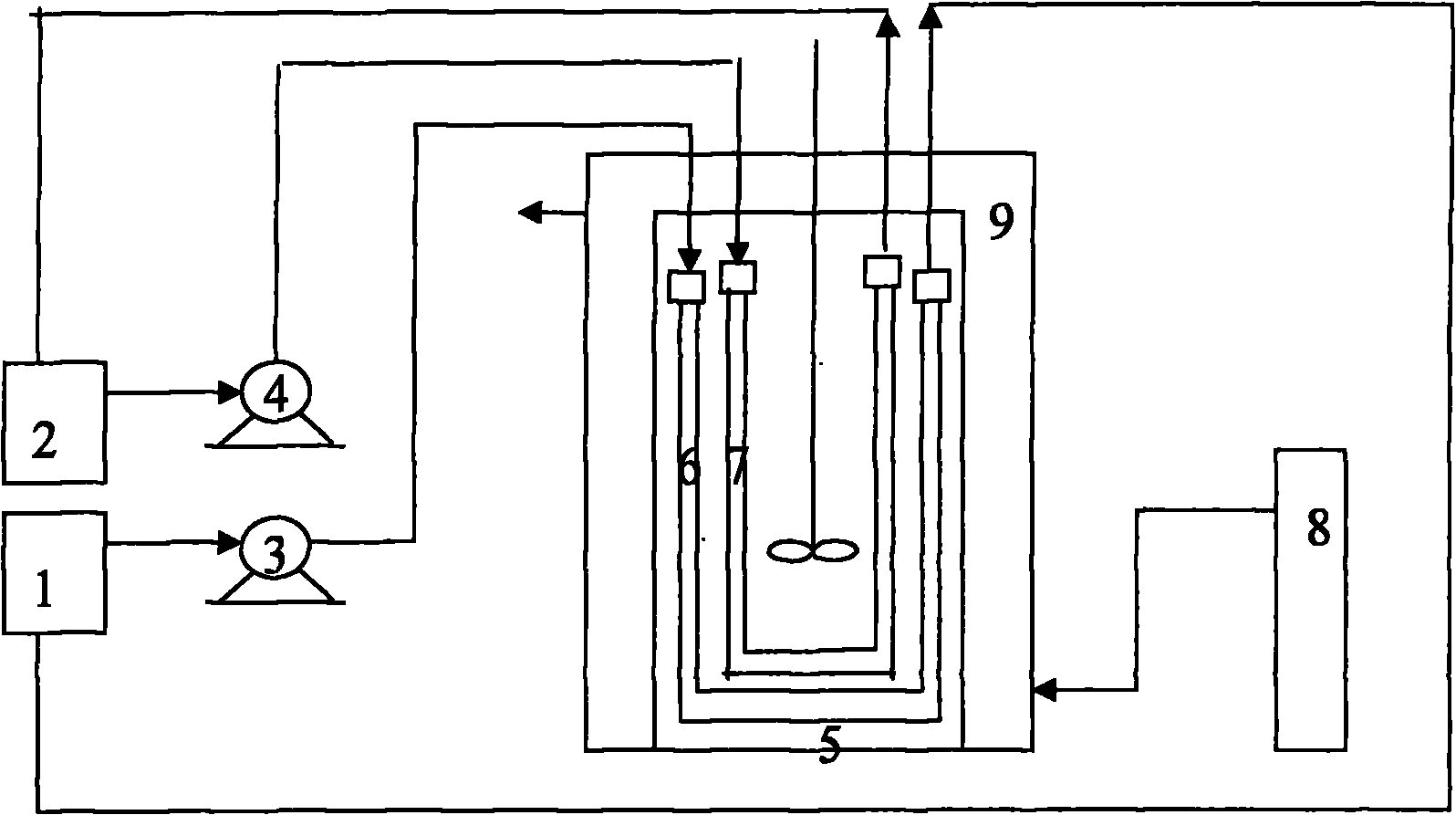

[0035]The device needed to realize the double-membrane continuous preparation of nanometer iron tetroxide by hollow fiber ultrafiltration membrane is mainly composed of reactor 5, protective cover 9, nitrogen bottle 8, pump I 3, pump II 4, storage tank I 1, storage Tank II 2, hollow fiber ultrafiltration membrane module A 6, hollow fiber ultrafiltration membrane module B 7; reactor 5 is equipped with a protective cover 9, and reactor 5 is equipped with agitator and pH meter; protective cover 9 is connected with nitrogen cylinder 8 ; The outlet of the pump I 3 inlet is connected with the storage tank I 1 of the precipitant solution, the outlet of the pump I 3 is connected with the inlet of the hollow fiber ultrafiltration membrane module A 6, and the outlet of the hollow fiber ultrafiltration membrane module A 6 is connected with the precipitant and dispersed The inlet of the storage tank I1 of the agent mixed sol...

Embodiment 2

[0037] Realize the method for continuously preparing nanometer iron tetroxide with double-membrane hollow fiber ultrafiltration membrane, the preparation steps are as follows:

[0038] (1) Preparation of raw materials and precipitant:

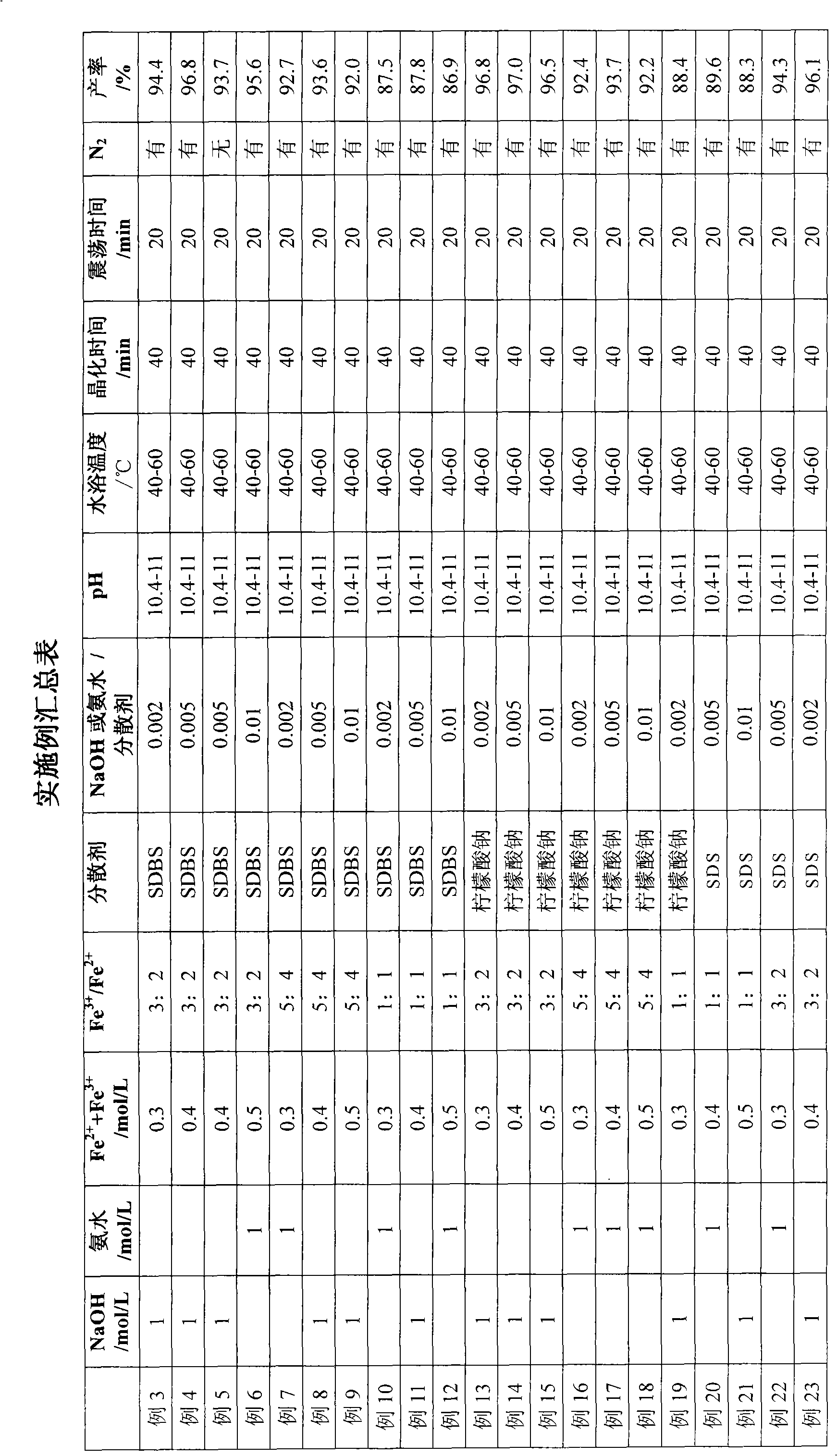

[0039] Press Fe 3+ : Fe 2+ = 1:1~3:2 ratio, configure all iron (Fe 3+ +Fe 2 ) mixed solution with a concentration of 0.3mol / L to 0.5mol / L; NaOH or ammonia water containing a dispersant at a concentration of 1mol / L, wherein the molar ratio of NaOH or ammonia water to the dispersant is 1:0.002 to 1:0.01.

[0040] (2) Mixing and reaction

[0041] Add distilled water or desalted water, which accounts for 1 / 2-2 / 3 of the reactor volume, into the reactor for deoxygenation protection at room temperature; under the action of the pump I, the storage tank I contains sodium hydroxide or ammonia water as a dispersant The mixed solution enters the hollow fiber ultrafiltration membrane module A and circulates back to the storage tank I, and part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com