Hydrogen passivation method for solar cell

A technology for solar cells and solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as weak passivation, and achieve the effects of easy industrialization, improved conversion efficiency, and high practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

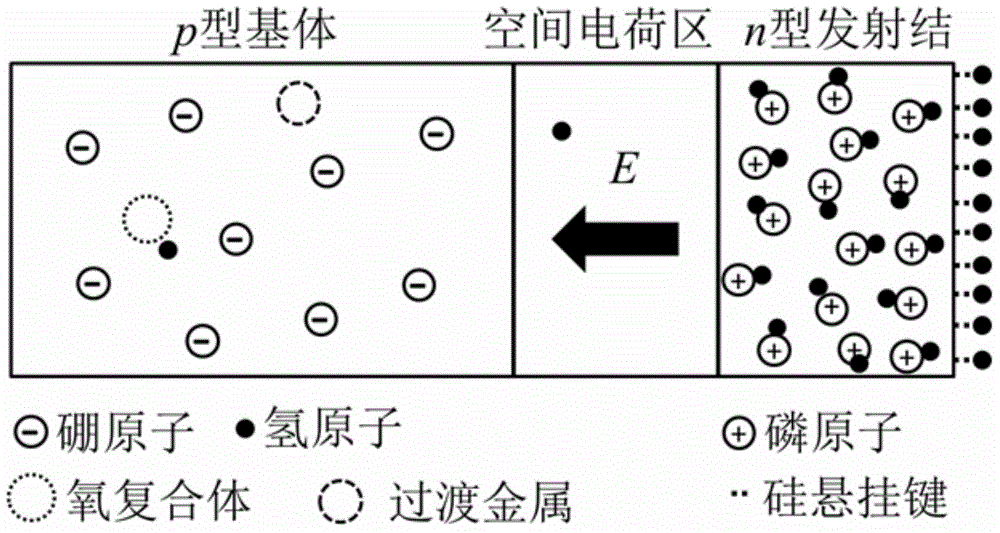

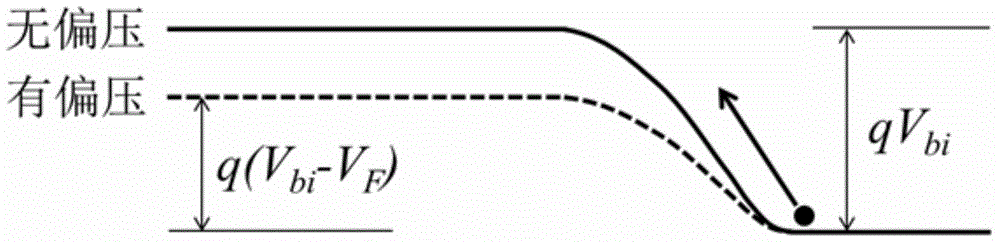

Problems solved by technology

Method used

Image

Examples

Embodiment 1

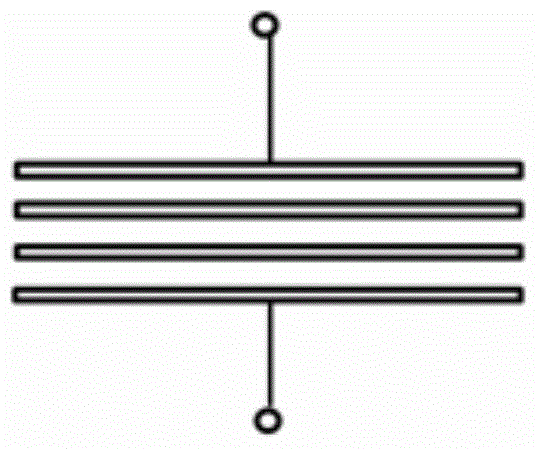

[0041] Select a boron-doped p-type monocrystalline silicon solar cell, and attach the cell to the image 3 stacked in a manner. When stacking, you can choose to insert conductive aluminum foil at intervals between the cells. The advantage is that it can protect the electrodes of the cells from scratching or wearing each other. Even so, it still needs to be handled carefully and lightly.

[0042] The cells are placed in a vacuum chamber, which has a built-in temperature-controlled heating platform and a constant-voltage DC power supply. Evacuate the vacuum chamber to reduce the air pressure to below 0.1 Torr.

[0043] Set the temperature of the heating table to 220°C to heat the solar cells; at the same time, apply a forward bias voltage to the cells, and set the voltage that each cell withstands to 0.4V. The cells were subjected to hydrogen passivation treatment under the above conditions, and the treatment time was set to 60 minutes according to formula 1. The processing i...

Embodiment 2

[0046] A boron-doped p-type polysilicon solar cell is selected, and hydrogen passivation treatment is performed as in the process in Example 1. Processing conditions Set the temperature of the heating platform at 240°C to heat the solar cells; at the same time, apply a forward bias voltage of 0.6V to the cells. The treatment time was set at 40 minutes. The processing is then complete and the cells are taken out to cool in the air.

[0047] attached Figure 6 Shown is the performance comparison of the polycrystalline silicon solar cell before and after applying the treatment of the present invention. For the 156 polycrystalline cells, after treatment, the open-circuit voltage increases by 1mV, the short-circuit current increases by 0.03A, and the absolute value of the conversion efficiency increases by 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com