Method of fast hydrogen passivation to solar cells made of crystalline silicon

A technology of solar cells and crystalline silicon, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of hydrogen passivation effect damage, hydrogen atoms detachment from wafers, etc., to reduce harmful effects and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

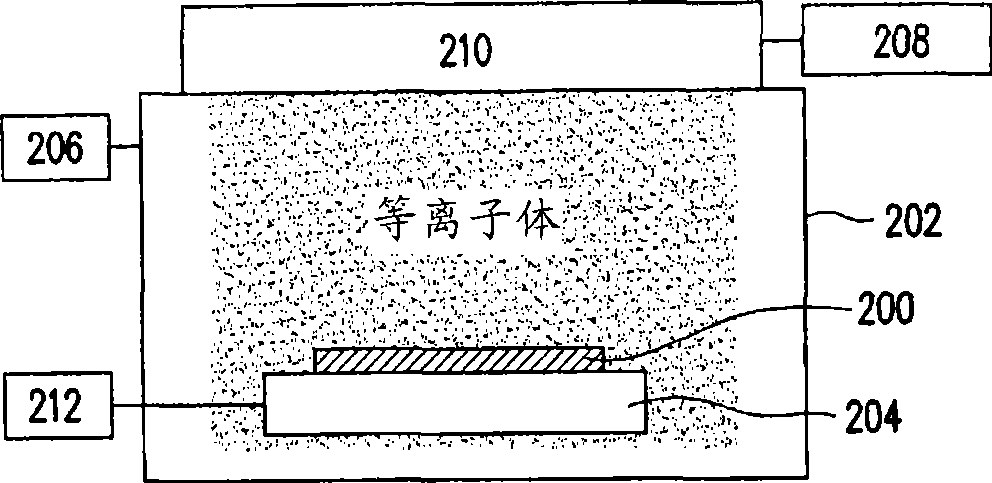

[0052] In this embodiment, the bottom pressure of the vacuum chamber is 10 -6 Torr, then input hydrogen as the working gas and increase the pressure to 2mTorr. The plasma was excited with RF power (13.56 MHz) through an inductively coupled antenna. The power is 200W. The plasma density is about 10 11 cm -3 , and a pulse voltage of -4kV was used to bias the solar cell. The pulse width is 10 μsec and the pulse frequency is 200 Hz. This experiment does not provide power to heat the solar cell, because the temperature of the sample will increase to about 100 °C during plasma ion implantation. The total process time is 10 minutes.

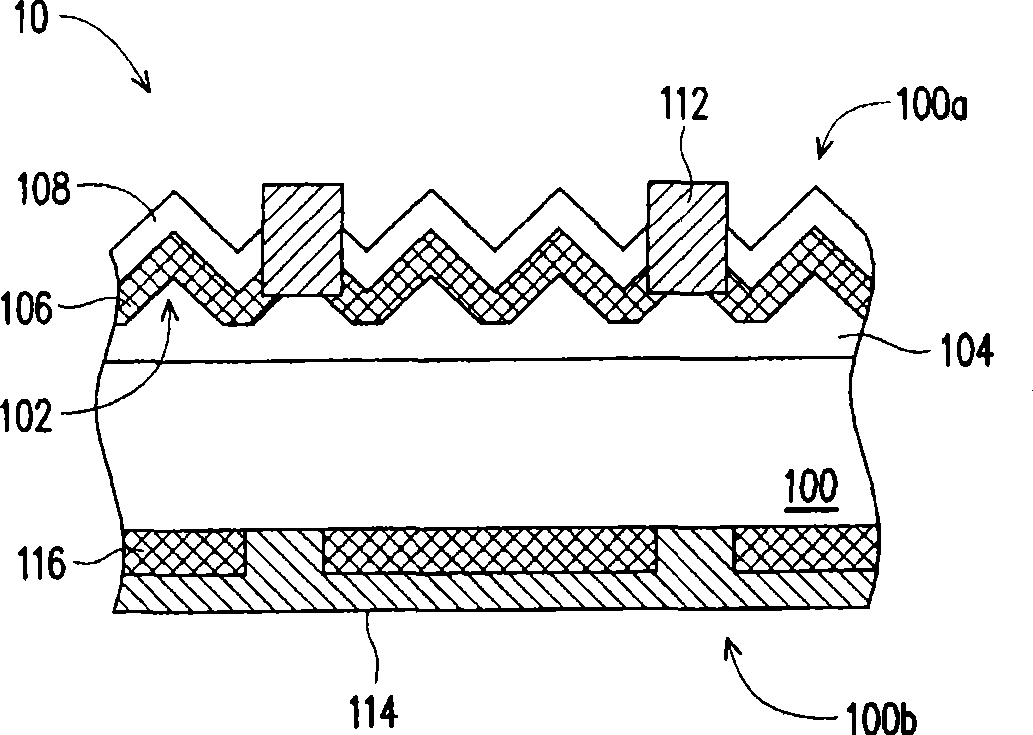

[0053] Solar cells are made of p-type, boron-doped to 1×10 20 cm -3 Made of polysilicon wafer (mc-Si wafer). Their mean grain size is about 5 mm. Corner pyramid structures have been fabricated on the surface of the wafer. N + P bonding uses POCL at 850°C 3 Diffused for 20 minutes to make. Next, a layer of 20nm SiO is formed by a thermal ox...

Embodiment 2

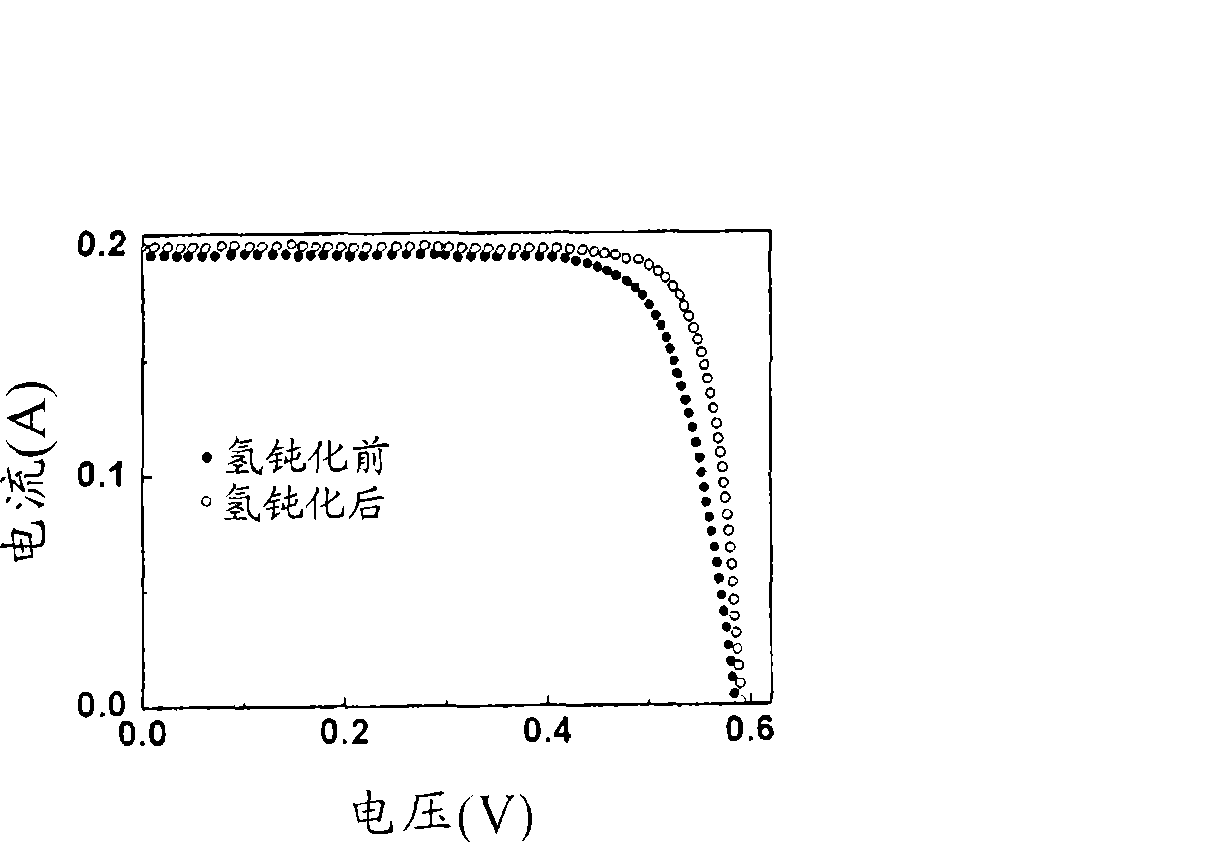

[0056] In this example, a monocrystalline silicon solar cell was fabricated. The structure and process of making are the same as the first embodiment. In addition, the plasma conditions and processing conditions are also the same. Figure 4 For the comparison of the current-voltage characteristics of solar cells before and after the hydrogen passivation process, the results show that the fill factor results increased from 75.00% to 80.77%. At the same time, the short-circuit current increased from 0.23A to 0.25A, and the open-circuit voltage also increased from 0.59V to 0.6V. These improvements increased the conversion efficiency from 14.25% to 17.06%.

[0057] In summary, compared with the prior art, the present invention can greatly reduce the time and cost of the hydrogen passivation process, and effectively improve the efficiency of crystalline silicon solar cells. Moreover, the equipment used is relatively simple and economical, and is suitable for mass production. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com