High-quality-factor yttrium-doped zirconium oxide microwave dielectric ceramic material and preparation method thereof

A technology of yttrium-doped zirconia and microwave dielectric ceramics, which is applied in the field of high-quality factor yttrium oxide-doped zirconia microwave dielectric ceramic materials and its preparation, can solve problems that cannot meet the application requirements of microwave devices, and achieve quality factor improvement, Improved quality factor and simple sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

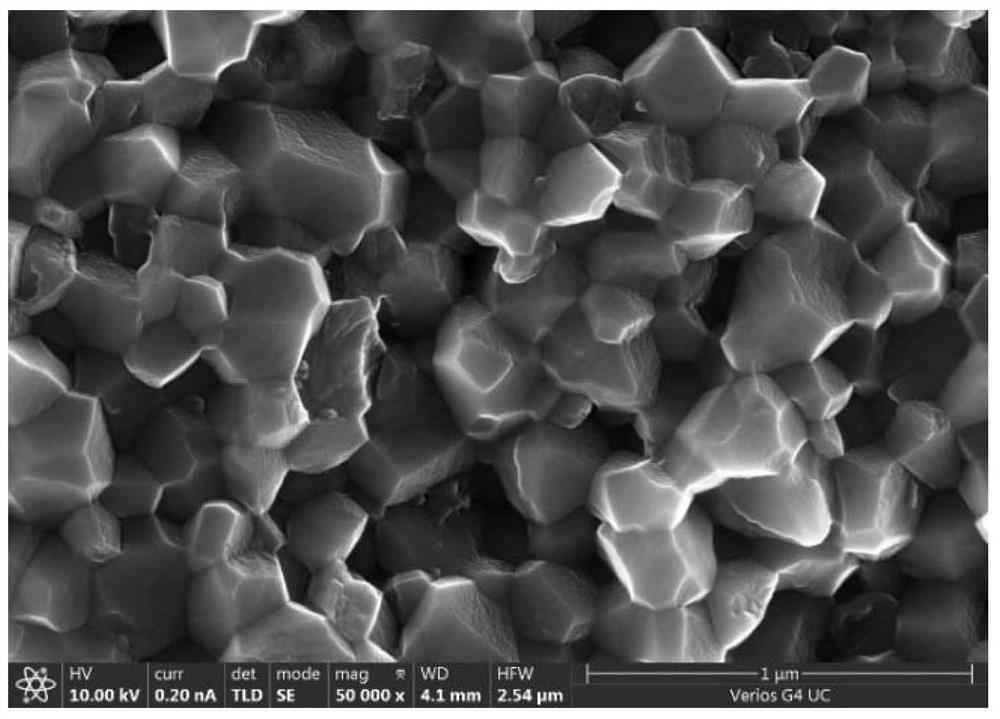

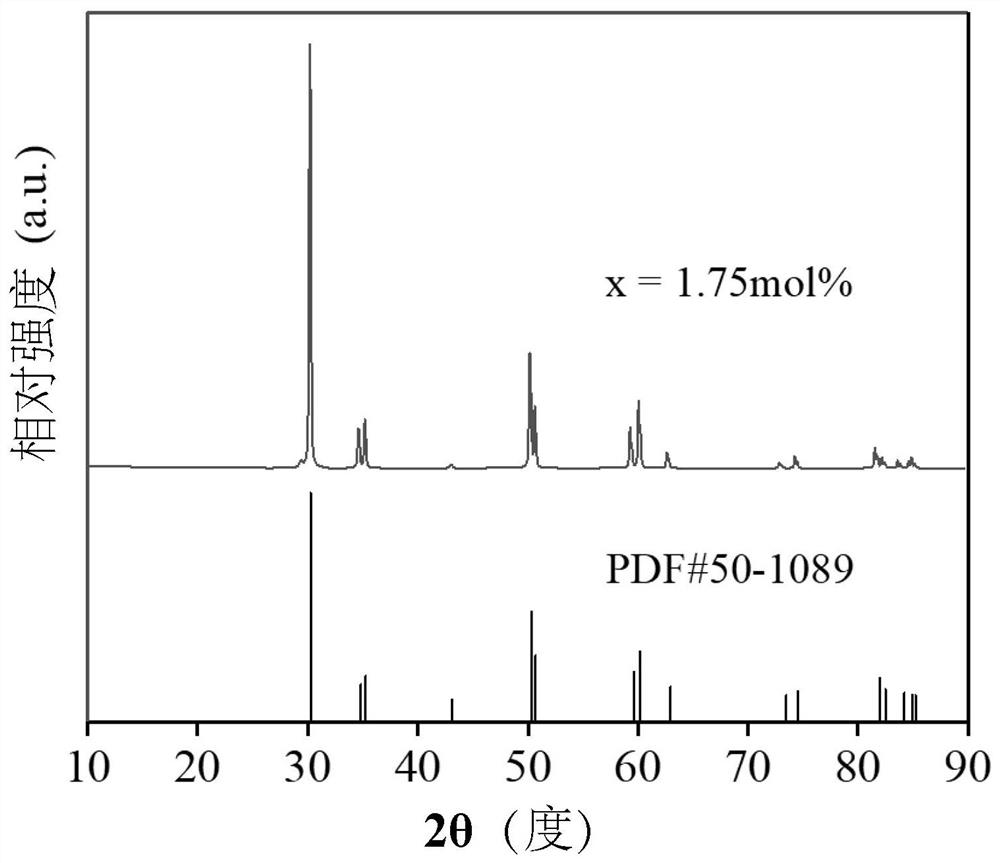

[0045] The invention provides a high-quality factor yttrium-doped zirconia microwave dielectric ceramic material and a preparation method thereof. The chemical composition of the material is ZrO 2 -x mol%Y 2 o 3 -y wt%Al 2 o 3 -z wt% SiO 2 , where x is the molar ratio, 1.5≤x≤2, y and z are mass percentages, 0.04≤y≤0.06, 0.001≤z≤0.002. The raw material is selected from 3mol% yttrium doped zirconia nano powder (20-80nm), zirconia nano powder (20-40nm), alumina powder and silicon dioxide powder (20-80nm). Table 1 shows the mass percentage of each raw material in the total amount of raw materials in the examples. The raw materials were weighed and mixed by ball milling at a speed of 270-360 rpm.

[0046] Specifically described method comprises the following steps:

[0047] (1) Ingredients: According to the general chemical formula ZrO 2 -x mol%Y 2 o 3 -y wt%Al 2 o 3 -z wt% SiO 2 , the raw material is selected from 3mol% yttrium-doped zirconia nano-powder, zirconia nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com