A device and production method for improving performance of cerium-doped scintillation crystal

A technology for scintillation crystals and production methods, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as blackening of iridium crucibles and affecting the integrity of growing crystals, and achieve economical production methods, ensure integrity, and improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

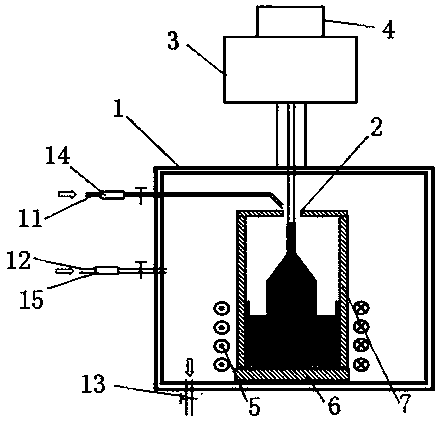

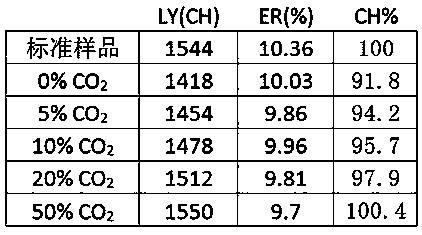

[0037] The prepared cerium-doped yttrium lutetium silicate (Lu(1-x)Yx) 2 SiO 5 : The Ce raw material is put into the iridium crucible with the temperature field set up, the seed crystal is installed, and the lifting and rotating mechanism is adjusted;

[0038] Evacuate the air in the furnace cavity to 5Pa, open the second valve 15, and fill with N 2 Shielding gas to 1.01*10 5 Pa~1.2*10 5 Pa;

[0039] Raise the temperature of the chemical material, open the exhaust valve at the lower part of the furnace chamber, and discharge the exhaust gas through the filter bottle. Mix a good proportion of N 2 :CO 2 (CO 2 The concentration is 5%) connected to the first air intake pipe 11, the first valve 14 is opened, the air intake flow is adjusted to 0.5L / min, and the growth crystal is planted;

[0040] For the grown crystals, cut samples of the same size (3.6*3.6*20mm) at the same part, the surface of the sample is fully polished, and stand in a dark room for 12 hours;

[0041] T...

Embodiment 2

[0043] The prepared cerium-doped yttrium lutetium silicate (Lu (1-x) Y x ) 2 SiO 5 : The Ce raw material is put into the iridium crucible with the temperature field set up, the seed crystal is installed, and the lifting and rotating mechanism is adjusted;

[0044] Evacuate the air in the furnace cavity to 5Pa, open the second valve 15, and fill with N 2 Shielding gas to 1.01*10 5 Pa~1.2*10 5 Pa;

[0045] Raise the temperature of the chemical material, open the exhaust valve at the lower part of the furnace chamber, let the exhaust gas flow through the filter bottle, and then discharge the pure CO 2 Connect the first air intake pipe 11, open the first valve 14, adjust the air intake flow rate to 0.05L / min, adjust the second valve 15, the flow rate is 0.5L / min, and plant the growth crystal;

[0046] For the grown crystals, cut samples of the same size (3.6*3.6*20mm) at the same part, the surface of the sample is fully polished, and stand in a dark room for 12 hours;

[0...

Embodiment 3

[0049] The prepared cerium-doped yttrium lutetium silicate (Lu (1-x) Y x ) 2 SiO 5 : The Ce raw material is put into the iridium crucible with the temperature field set up, the seed crystal is installed, and the lifting and rotating mechanism is adjusted;

[0050] Evacuate the air in the furnace cavity to 5Pa, open the second valve 15, and fill with N 2 Protective gas to 1.01*105Pa~1.2*105Pa.

[0051] Raise the temperature of the chemical material, open the gas outlet valve at the lower part of the furnace chamber, and let the exhaust gas flow through the filter bottle. Adjust the flow rate of No. 2 air inlet to 0.5L / min. Mix a good proportion of N 2 :CO 2 (CO 2 Concentration 50%) connected to the first intake pipe 11, open the first valve 14, adjust the intake flow rate to 0.02L / min, plant the growth crystal;

[0052] For the grown crystals, cut samples of the same size (3.6*3.6*20mm) at the same part, the surface of the sample is fully polished, and stand in a dark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com