Method for preparing MnZn ferrite magnetic core by multi-physical field coupling

A ferrite core, multi-physics technology, applied in inductor/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problem of segregation of manganese-zinc ferrite bulk composition and uneven particle size distribution , affecting the discharge between particles, etc., to achieve the effect of shortening the preparation time, shortening the heating time, and reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

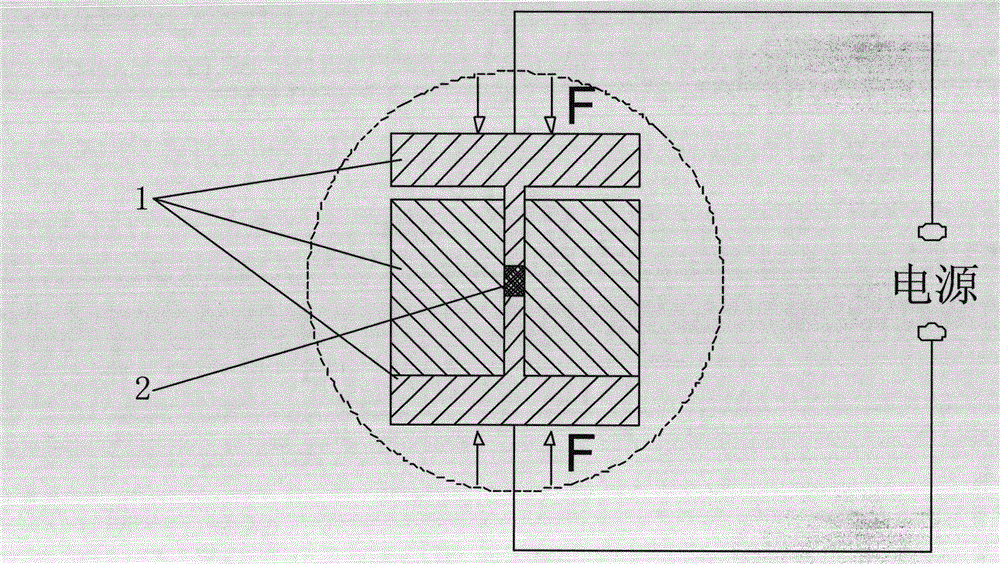

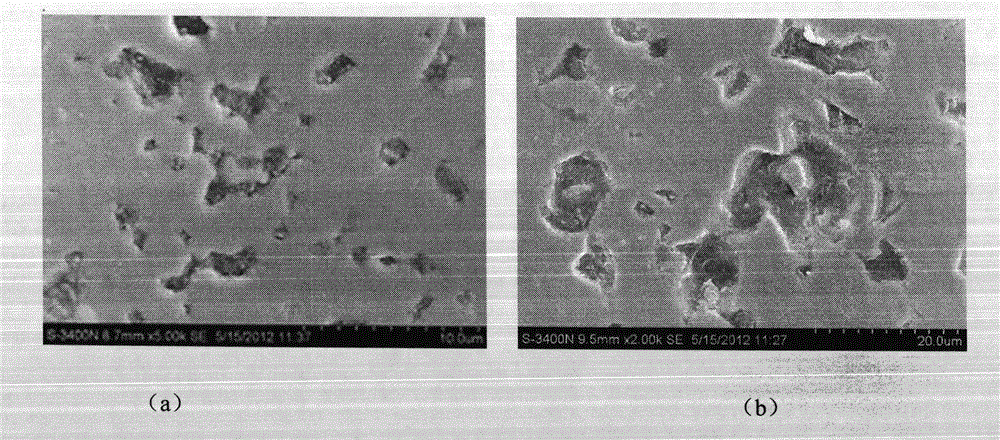

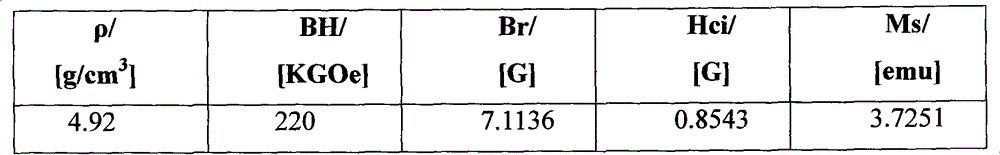

[0019] The prepared pre-fired MnZn ferrite powder with a particle size of 1 μm was weighed and filled in the mold, fixed with a chuck, and placed in a 10 -2 Under the vacuum condition of Pa, a force of 70Mpa is applied to both ends of the mold, a current is passed through to heat the powder, and the temperature rise rate is controlled at 15°C / s to 900°C, and then cooled to room temperature at 15°C / s, and the magnetic core is taken out. Can. Then the magnetic properties of the sample were measured at 1 MHz with a Lake shore7410 vibrating sample magnetometer, and the results are shown in Table 1.

[0020] Table 1

[0021]

Embodiment 2

[0023] The prepared pre-fired MnZn ferrite powder with a particle size of 1 μm was weighed and filled in the mold, fixed with a chuck, and placed in a 10 -2 Under the vacuum condition of Pa, a force of 70Mpa is applied to both ends of the mold, and a current is applied to heat the powder, and the temperature rise rate is controlled at 15°C / s to 800°C, and then the temperature is lowered to 400°C at 15°C / s, and the heating cycle is 5 times , keep warm at 800°C for 4min, cool to room temperature at 15°C / s, and take out the magnetic core. Then, the magnetic properties of the sample were measured at 1 MHz with a Lake shore7410 vibrating sample magnetometer, and the results are shown in Table 2.

[0024] Table 2

[0025]

Embodiment 3

[0027] The prepared pre-fired MnZn ferrite powder with a particle size of 1 μm was weighed and filled in the mold, fixed with a chuck, and placed in a 10 -2 Under the vacuum condition of Pa, a force of 70Mpa is applied to both ends of the mold, and a current is applied to heat the powder, and the heating rate is controlled to rise to 900°C at 15°C / s, and then to drop to 500°C at 15°C / s, and the heating cycle is 5 times , cool to room temperature at 15°C / s, and take out the magnetic core. Then the magnetic properties of the sample were measured at 1 MHz with a Lake shore7410 vibrating sample magnetometer, and the results are shown in Table 3.

[0028] table 3

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com