Method for rapidly sintering Nd-Fe-B ferromagnet

A rapid sintering, NdFeB technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of reduced magnet performance, low magnetic performance, shortening, etc., to achieve shortened sintering time, low sintering temperature, The effect of short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~19

[0021] 1. Calculate the composition as Nd in atomic percentage 15 Fe 78.3 B 6.7 、Nd 13.8 Fe 80 B 6.2 and Nd 12.4 Fe 81.6 B 6.0 Under the protection of Ar gas, the NdFeB alloys are respectively melted in the vacuum melting furnace according to the conventional process conditions, and then the melted ingots are roughly crushed by hydrogen explosion and ball milled into 3-5μm NdFeB alloy fine powder, and put into the mold , after being oriented by a magnetic field, press the relative density listed in the table to form a cylindrical compact with a diameter of 13mm and a height of 6mm (for comparison);

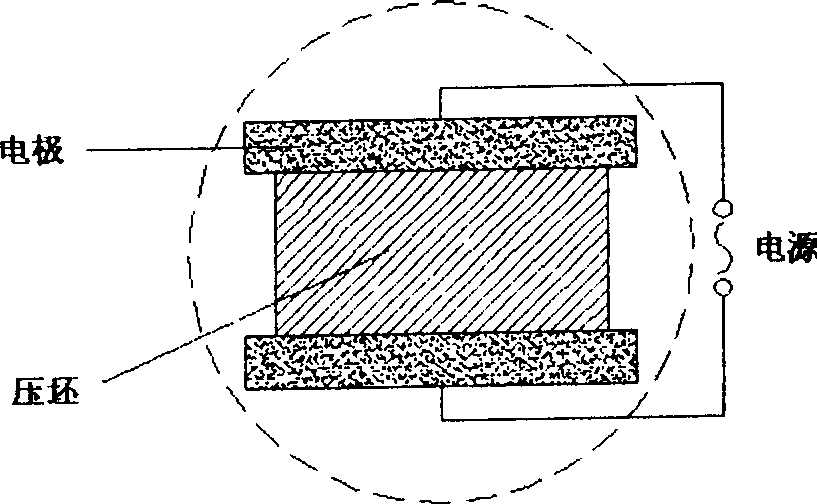

[0022] 2. Press figure 1 As shown, after the prepared green compact is fixed with the chuck, in 10 -3 Under the vacuum condition of Pa, adjust the current of the control system according to the corresponding heating and temperature rise rates of each embodiment determined in the table, and use the current to pass through the compact to make it rapidly heated. When a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com