Method for preparing carbon/carbon composite material

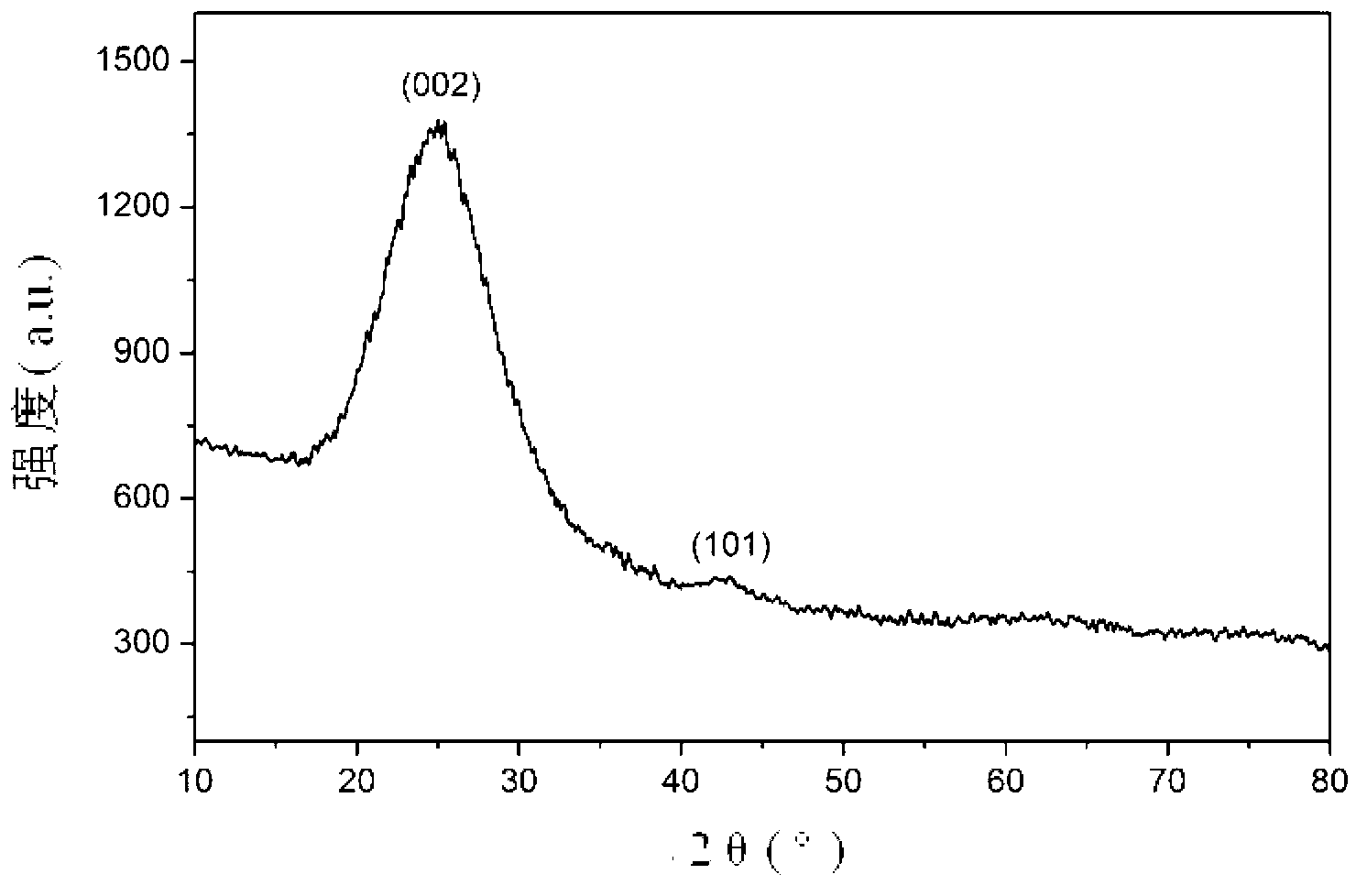

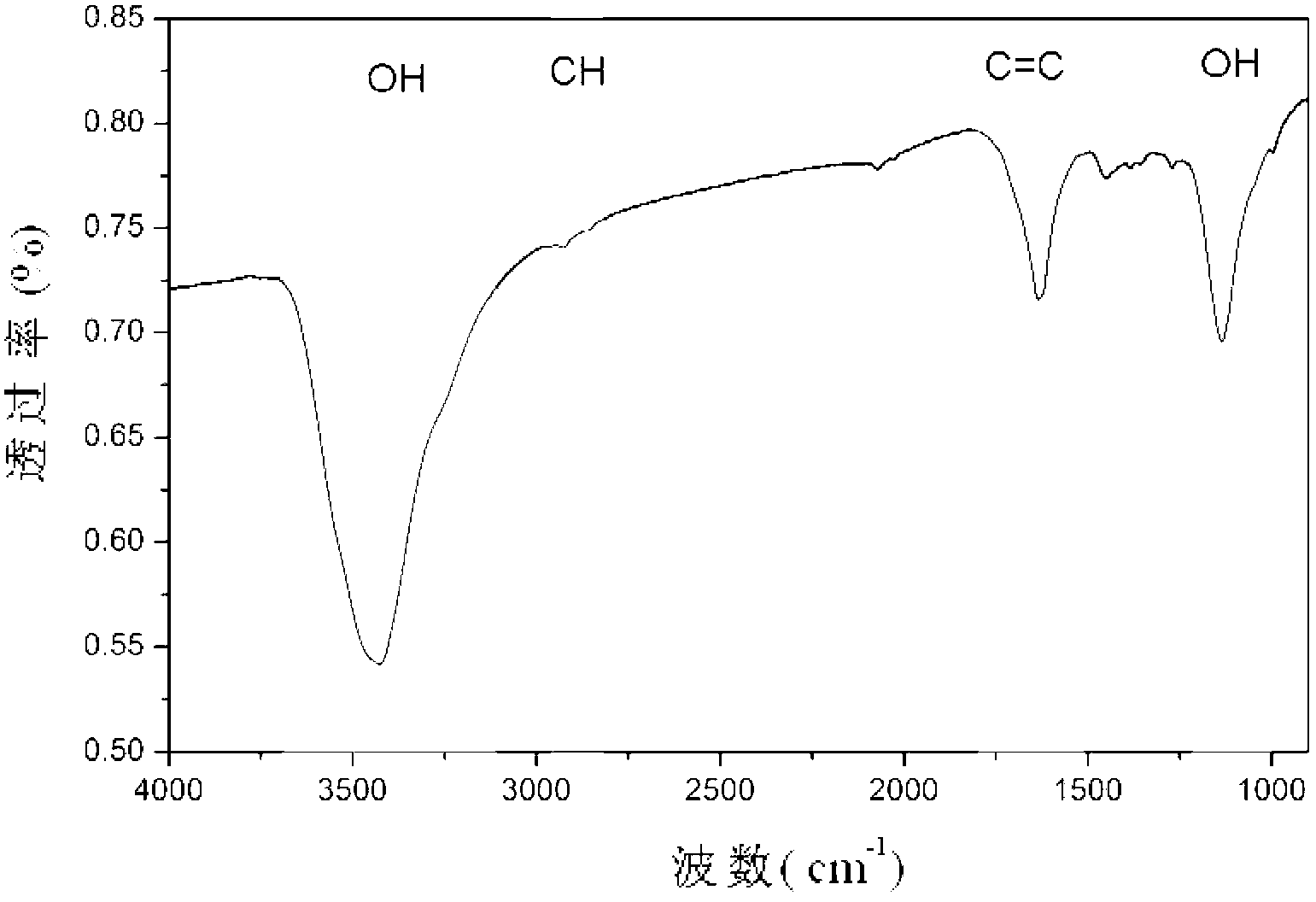

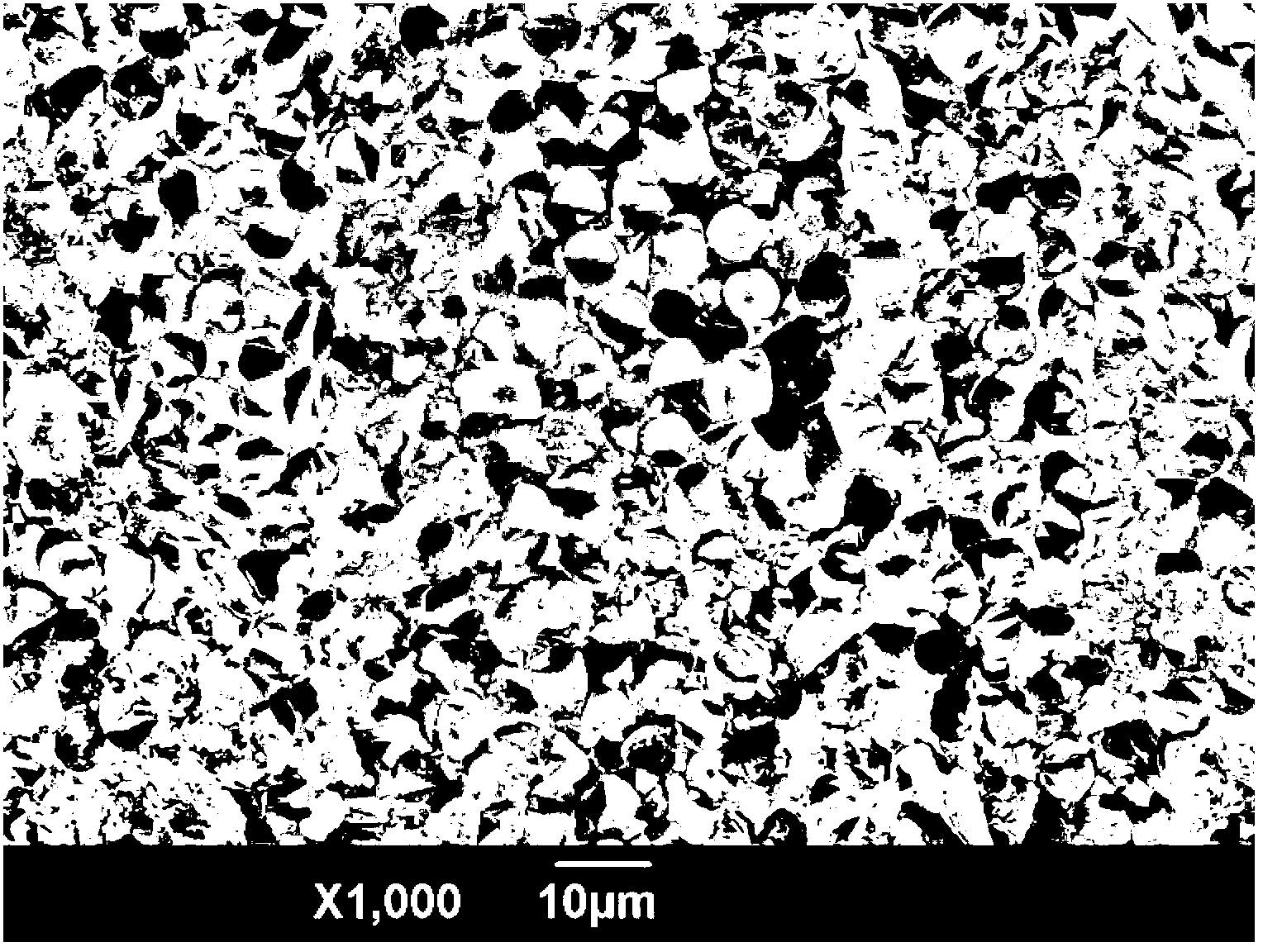

A technology of carbon composite materials and prefabricated bodies, which is applied in the field of preparing carbon/carbon composite materials, can solve the problems of long densification time, achieve the effects of promoting diffusion and mass transfer, expanding application fields, and high carbon fixation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Dissolve glucose in water to obtain a glucose solution with a concentration of 50g / L, that is, glucose dispersion liquid;

[0032] 2) Add the glucose solution into the hydrothermal kettle, and then add the integral carbon felt preform (Jiangsu Yixing Tianniao High Technology Co., Ltd.) with a fiber volume fraction of 10%, so that the glucose solution is immersed in the integral carbon felt preform to obtain the reaction system A ; Assemble the hydrothermal kettle, and then react the reaction system A in the hydrothermal kettle at 180°C for 3h under the condition of resistance heating, and naturally cool to room temperature after the reaction, take out the whole carbon felt prefabricated body deposited with glucose and Washing with water to obtain a carbon / carbon composite material; wherein, the filling ratio of the hydrothermal kettle in step 2) is controlled at 0.4.

Embodiment 2

[0034] 1) Dissolve glucose in water to obtain a glucose solution with a concentration of 50g / L, that is, glucose dispersion liquid;

[0035] 2) Add the glucose solution into the hydrothermal kettle, and then add the integral carbon felt preform (Jiangsu Yixing Tianniao High Technology Co., Ltd.) with a fiber volume fraction of 10%, so that the glucose solution is immersed in the integral carbon felt preform to obtain the reaction system A ; Assemble the hydrothermal kettle, and then react the reaction system A in the hydrothermal kettle at 180°C for 3h under the condition of resistance heating, and naturally cool to room temperature after the reaction, take out the whole carbon felt prefabricated body deposited with glucose and Wash it with water; wherein, the filling ratio of the hydrothermal kettle in step 2) is controlled at 0.4;

[0036] 3) Immerse the whole carbon felt prefabricated body that has been washed and deposited glucose in the glucose solution obtained in step 1...

Embodiment 3

[0043] 1) Dissolve starch in water to obtain a starch solution with a concentration of 100g / L, that is, starch dispersion liquid;

[0044]2) Add the starch solution into the hydrothermal kettle, and then add the needle-punched carbon felt preform (Jiangsu Yixing Tianniao High Technology Co., Ltd.) with a fiber volume fraction of 20%, so that the starch solution is immersed in the needle-punched carbon felt preform to obtain a reaction System A: Assemble the hydrothermal kettle, and then react the reaction system A in the hydrothermal kettle at 220°C for 2 hours under the condition of microwave heating, and naturally cool to room temperature after the reaction, and prefabricate the needle-punched carbon felt deposited with starch The body was taken out and washed with water to obtain a carbon-carbon composite material; wherein, the filling ratio of the hydrothermal kettle in step 2) was controlled at 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com