Manufacturing equipment of light-weight, waterproof and environment-friendly composite board

A composite board, environmentally friendly technology, applied in other manufacturing equipment/tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of reducing the safety of composite boards, leaving safety, hidden dangers, etc., to improve the safety of use The effect of safety, convenience, and elimination of hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

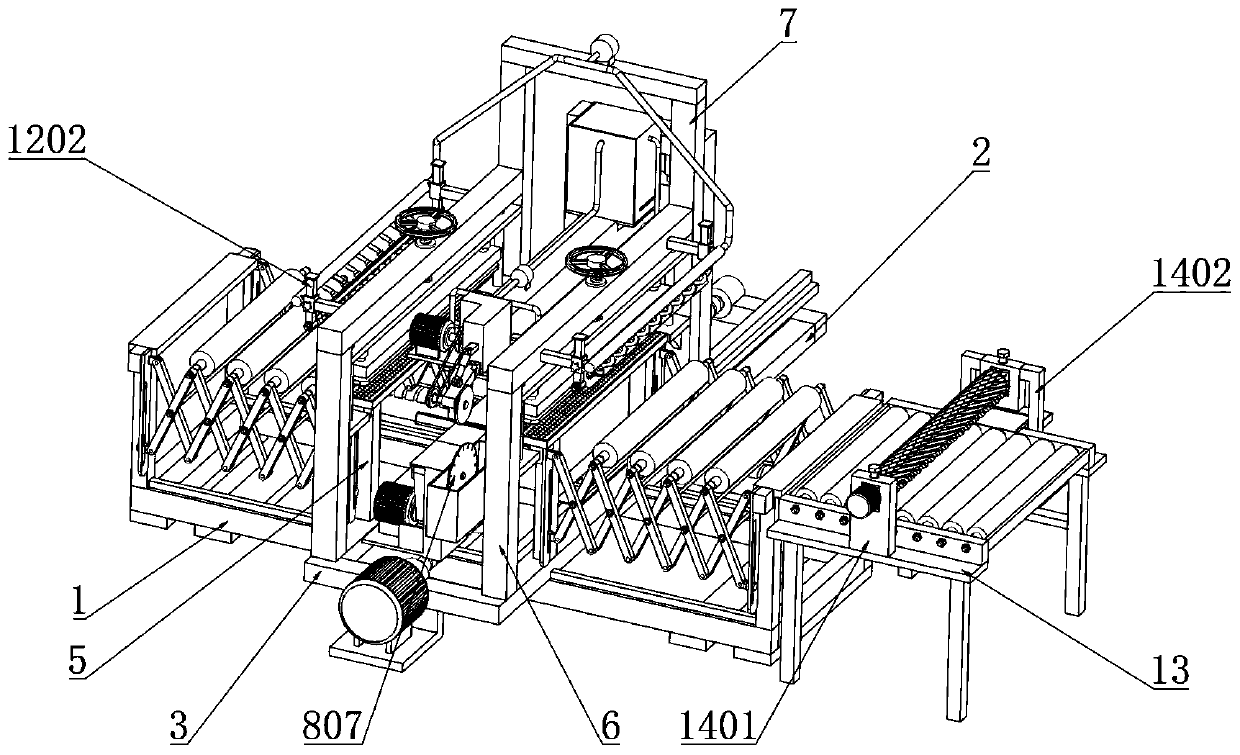

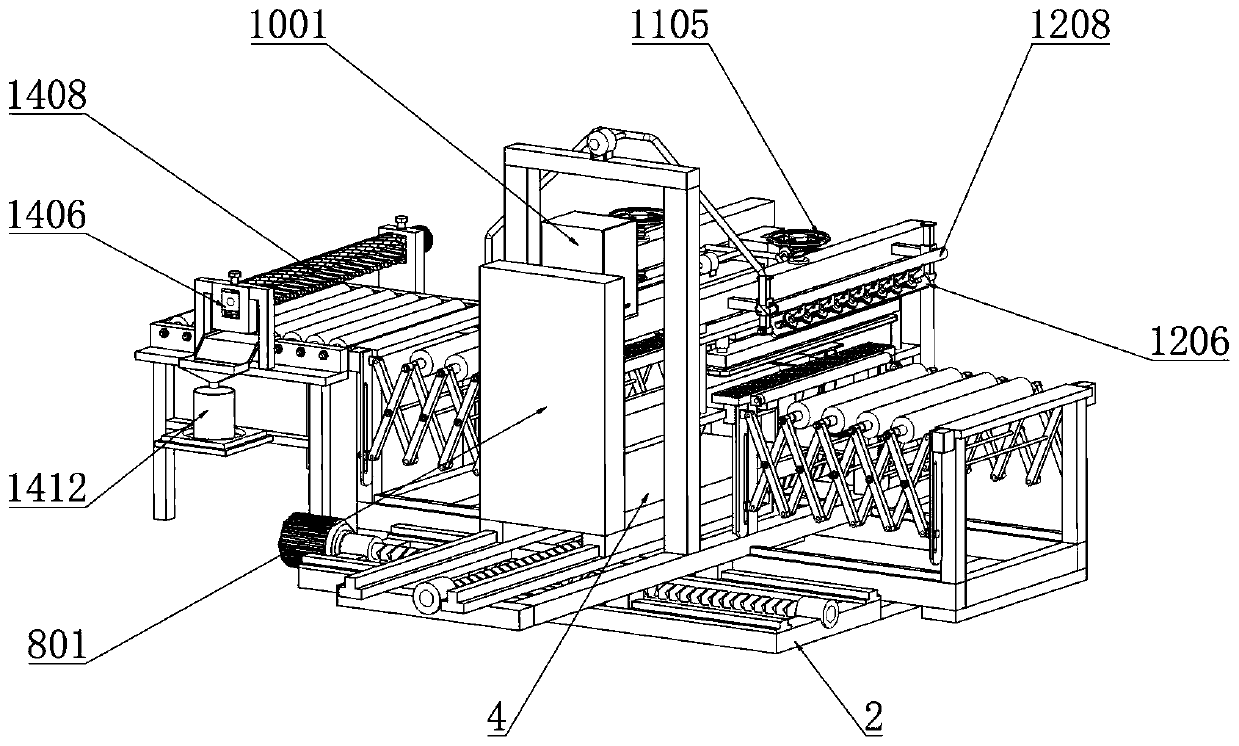

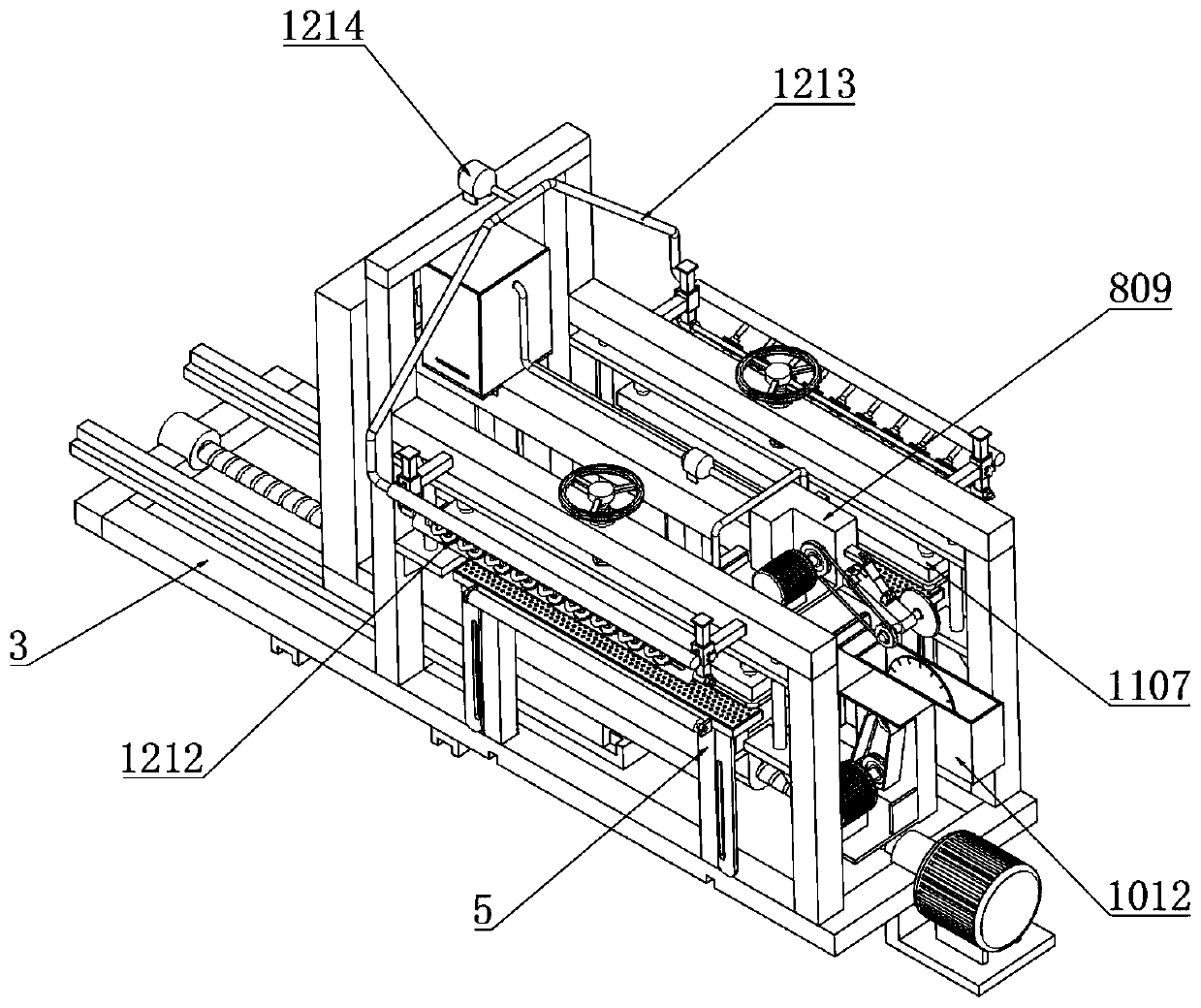

[0059] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a manufacturing equipment of a lightweight waterproof and environmentally friendly composite board, including a lower support frame 1, one side of the lower support frame 1 is fixedly connected with a side support frame 2, and the middle part of the top of the lower support frame 1 is movable Connected with the middle sliding frame 3, the middle part of the top of the middle sliding frame 3 is movably connected with the upper sliding frame 4, the top of the middle sliding frame 3 is fixedly connected with the inner support frame 5 at the positions on both sides of the upper sliding frame 4, the middle The outer support frame 6 is fixedly connected to the outer positions of the inner support frame 5 on both sides of the top of the sliding frame 3, and the side support frame 7 is fixedly connected to one end of the outer support frame 6 at one end of the top of the middle sliding fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com