Connecting rod cleaning machine of cam shaft

A cleaning machine and camshaft technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of long cleaning time, low cleaning quality, high cleaning intensity, etc., and reduce cleaning intensity , reliable connection, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

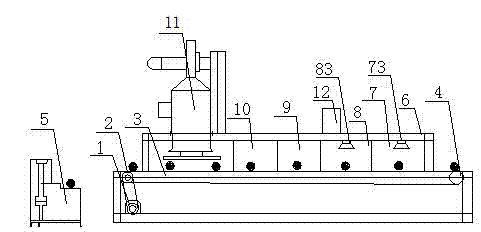

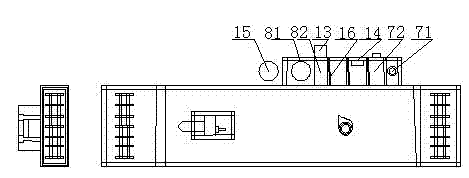

[0014] Such as figure 1 It is a structural schematic diagram of the present invention, a camshaft connecting rod cleaning machine, including a conveying reducer 1, a main drive shaft 2, a conveyor belt 3, a driven shaft 4, a lifting oil immersion machine 5, an upper cover 6, and a cleaning spray Device 7, rinsing and spraying device 8, manual rewashing oil channel 9, manual drying oil channel 10, hot air circulation system 11 and condensing oil mist device 12, cleaning nozzle 73 and rinsing nozzle 83, conveying reducer 1 and main drive shaft 2 connection, the main transmission shaft 2 is connected with the driven shaft 4 through the conveyor belt 3, the lifting type oil immersion machine 5 is installed on the side of the conveyor belt 3, the conveyor belt 3 and the lifting type oil immersion machine 5 are independent, and the upper part of the conveyor belt 3 is set There is an upper cover 6, a cleaning spray device 7 is provided between the conveyor belt 3 and the upper cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com