Bag chamber air inlet device of bag type dust collector

A technology of bag dust collector and air inlet device, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as large air inlet resistance, influence on dust cleaning effect, and large wear of filter bags, and achieve Reduce the adsorption capacity and filtration resistance, increase the natural sedimentation capacity, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

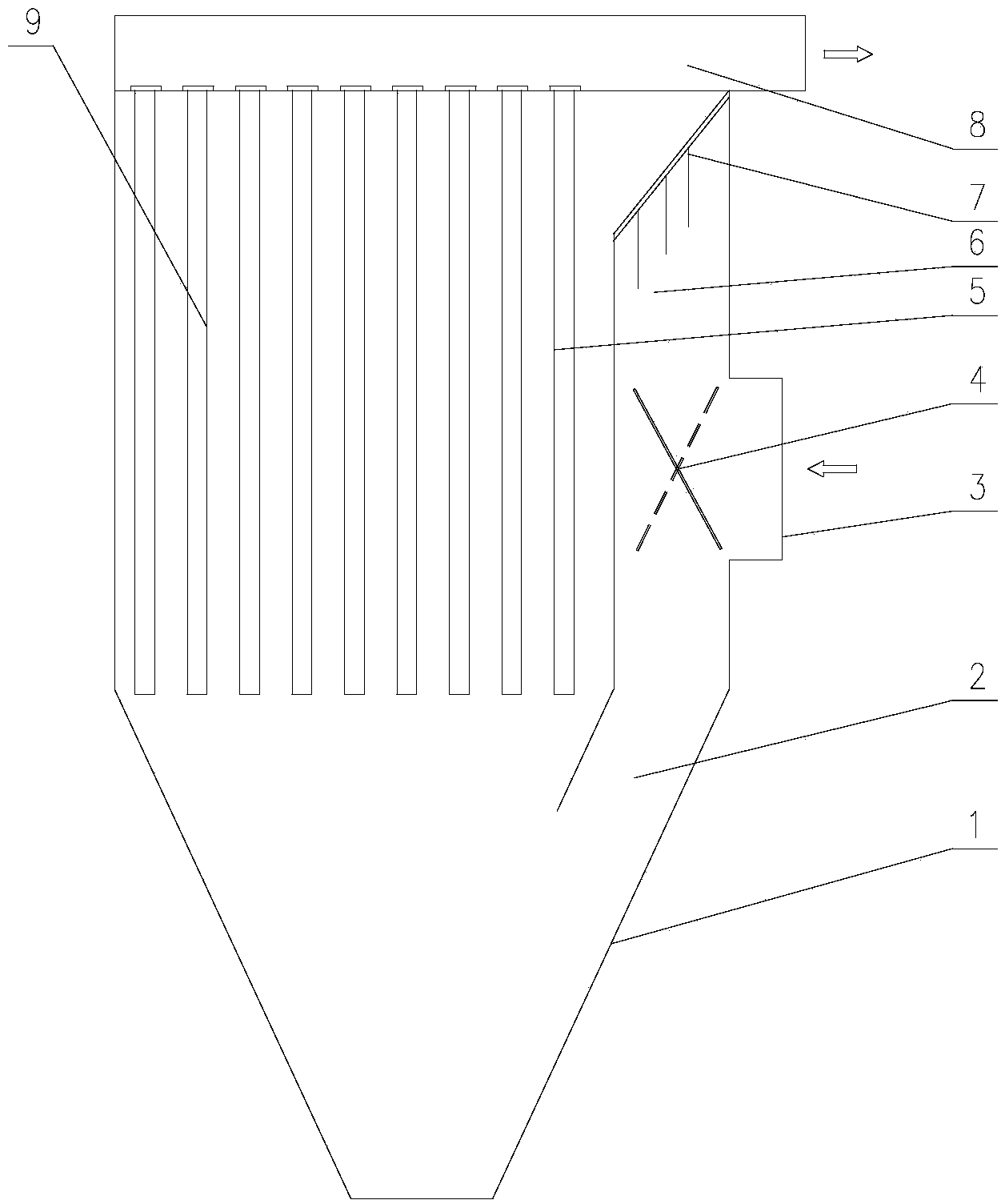

[0010] Such as figure 1 As shown, a baghouse air intake device for a bag filter includes a baghouse, a filter bag, an ash hopper, a windshield, an air inlet, and a lower air inlet channel that communicates with the bottom of the baghouse through the ash hopper. The upper part of the pocket chamber 9 is provided with an upper air inlet channel 6 communicating with the air inlet 3 .

[0011] A guide baffle 4 is provided between the upper and lower air inlets 6 and 2 in the air inlet 3; a louvered air equalizer 7 is provided at the part where the upper part of the baghouse communicates with the upper air inlet 6. By adjusting the angle of the deflector baffle and the louver-type air uniformity plate, a very good air uniformity effect can be obtained, so that the same filter load can be obtained in the bag room.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com