Gas and solid separator of recirculating fluidized bed boiler and boiler containing same

A technology of gas-solid separator and circulating fluidized bed, which is applied in the direction of fluidized bed combustion equipment, separation method, dispersed particle separation, etc., can solve the problems of large amount of fly ash, high concentration of smoke and dust emission, high power consumption of induced draft fan, etc. Achieve the effects of improving overall energy efficiency, reducing smoke and dust emissions, and simplifying manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

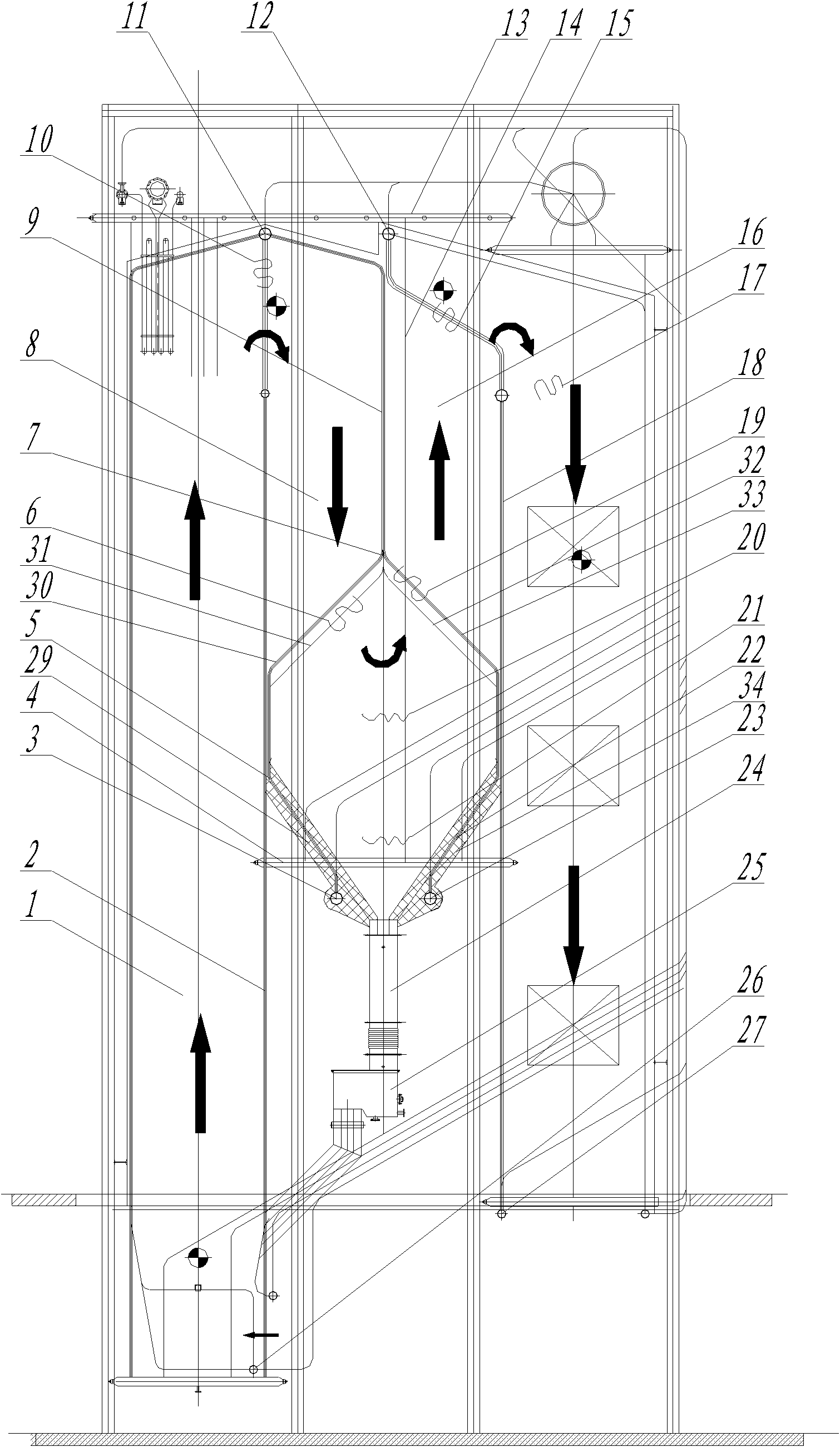

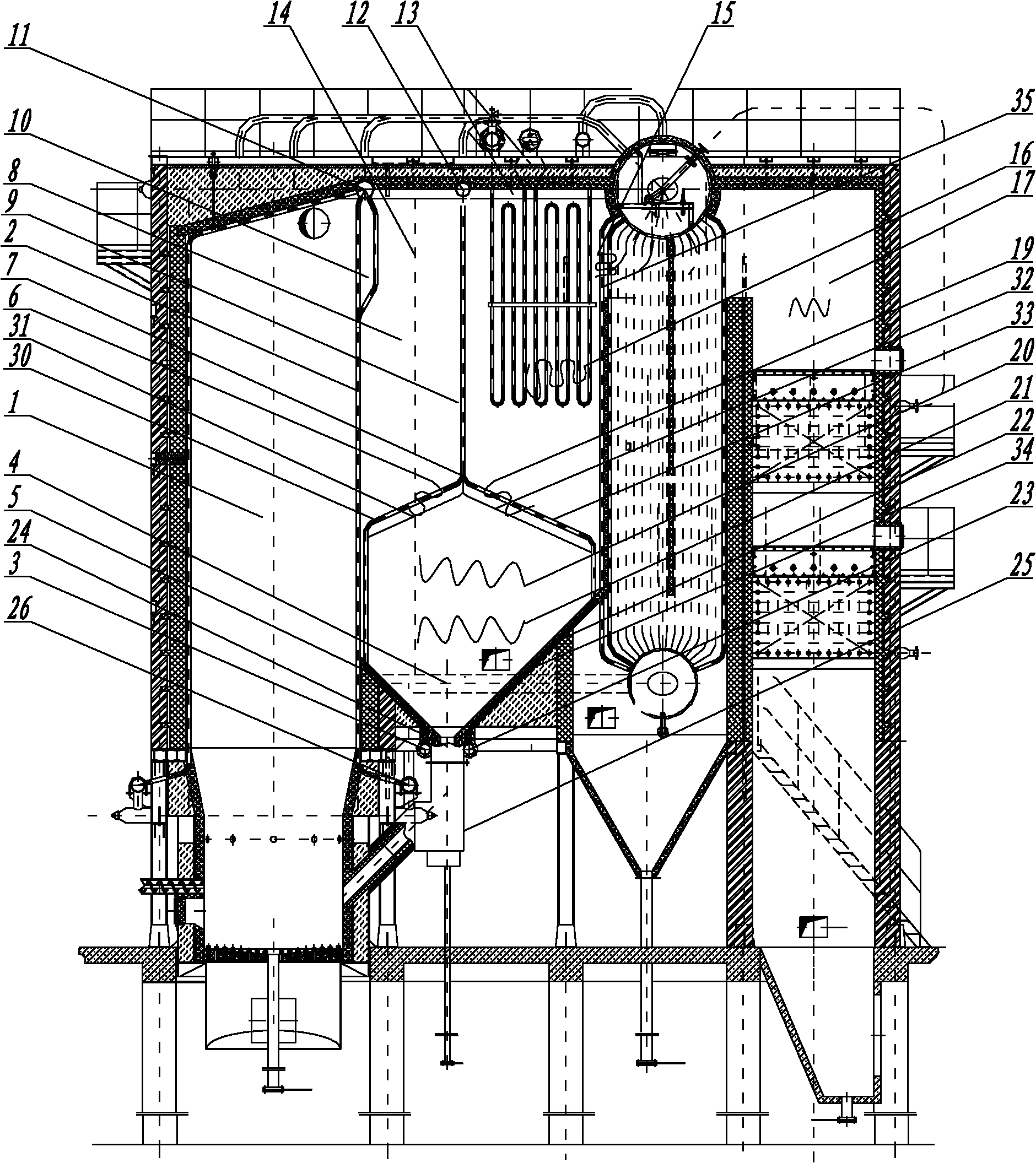

[0028] see figure 1 with figure 2 A gas-solid separator for a circulating fluidized bed boiler is characterized in that the flue gas inlet and outlet of the turning channel 20 form a flow-balanced separation tube bundle that is beneficial to the flow-balanced collision inertial separation of smoke and dust. The gas-solid separator is arranged at the rear of the furnace 1, and includes a downgoing flue 8 and an upgoing flue 16 separated from front to back by the lower and upper turning membrane screen 9 leading to the flue gas. exist figure 1 Among them, the lower and upper folding membrane screen 9 for guiding the flue gas is in the middle or in front of the rear wall 2 of the furnace and the front wall 18 of the shaft flue. figure 2 Among them, the lower and upper folding membrane screen 9 for guiding the flue gas is in the middle or front of the rear wall 2 of the furnace and the front row of convection tube bundles 35. figure 1 Among them, the upper end of the lower an...

Embodiment 2

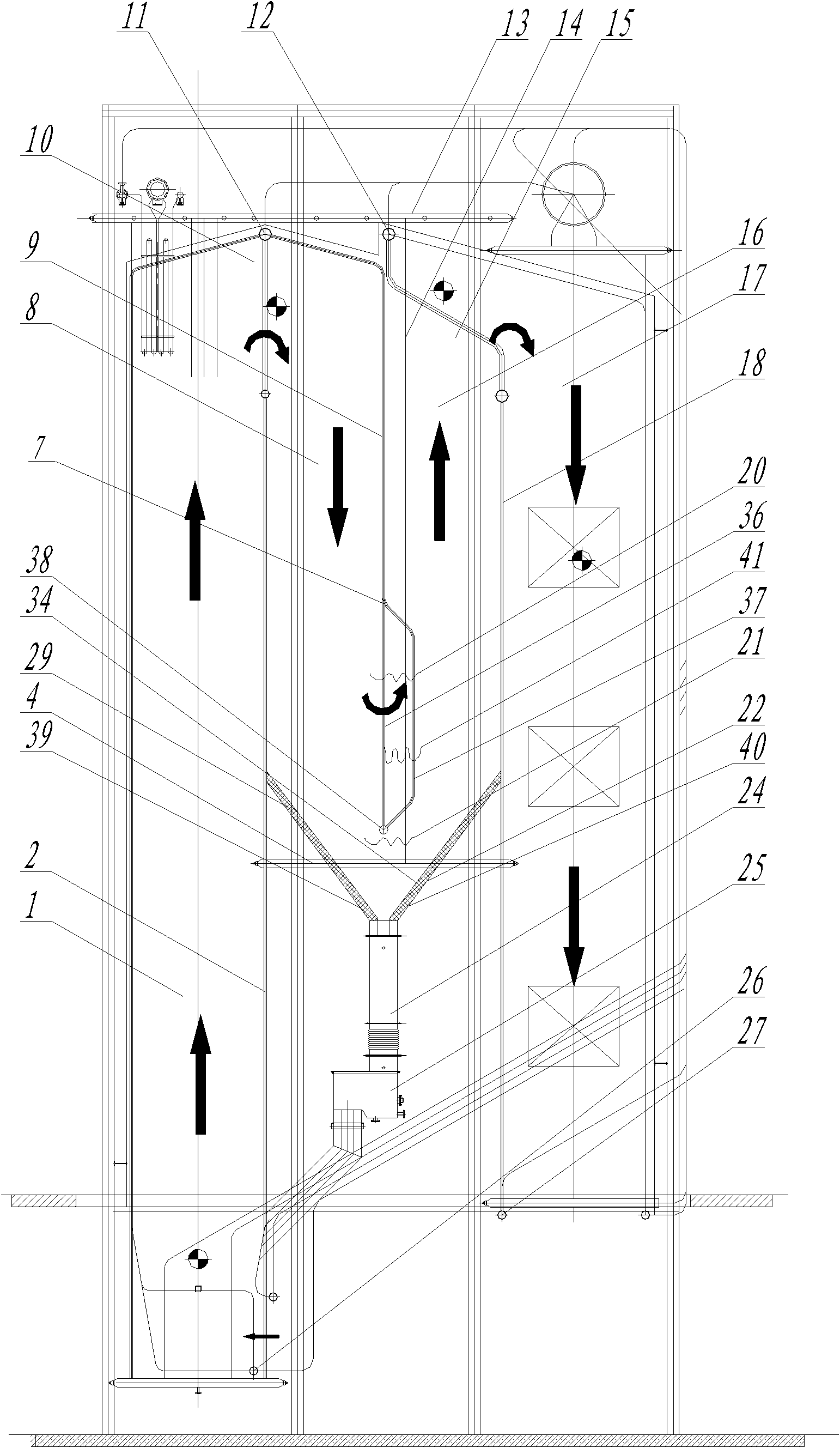

[0034] see image 3 with Figure 4 , and the difference from Embodiment 1 is that two rows of tube bundles 36, 37 are formed on the turning channel at the lower part of the bifurcation 7 of the membrane screen. The specific structure is: the lower part of the membrane-type screen bifurcation 7 divides two rows of tube bundles with loose spacing, the lower end of the front row of tube bundles 36 communicates with the center of the upper part of the lower horizontal header 38 of the tube bundles, and the rear row of tube bundles 37 is a distance away from the front row of tube bundles 36. Its lower end communicates radially with the rear wall of the lower horizontal header 38 of the tube bundle. The front row of tube bundles 36 and the rear row of tube bundles 37 constitute the flow-equalizing and separating tube bundles on the turning channel. The upper end of the feed bin front wall supporting plate 39 is closely sealed with the furnace rear wall, and its lower end is closel...

Embodiment 3

[0039] see Figure 5 , and the difference from Embodiment 1 is that: the lower end of the upper and lower folding membrane screen 9 leading to the flue gas is provided with a horizontal header 43 under the membrane screen connected to it, and the lower and upper folding membrane screen 9 of the guiding smoke passes through The transverse header 43 under the membrane screen communicates with the front outer tube bundle 30 , the front inner tube bundle 31 , the rear inner tube bundle 32 and the rear outer tube bundle 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com