Making method of anti-sticking polyurethane elastomer lining plate

A technology of polyurethane elastomer and lining plate, applied in the field of preparation of anti-stick polyurethane elastomer lining plate, can solve the problems of reducing material mechanical properties, environmental pollution, etc., and achieves reduction of production labor intensity, production cost, and good comprehensive mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Implementation of the present invention for the preparation of the above-mentioned anti-adhesive polyurethane elastomer liner The specific preparation process is as follows: (feeding amount is carried out in parts by mass)

[0031] 1) Melt 100 parts of polyester polyol and place it in a blue sand mill, add 0.5 parts of molybdenum disulfide micropowder and 1 part of colloidal graphite micropowder, and disperse 8 to 10 parts in the blue sand mill at 1000r / min. / min, then move all the above materials into the reaction kettle, heat up to 120-130 ℃, keep the vacuum at 0.08-0.09 Mpa, under the action of stirring, vacuumize and dehydrate for 2 hours, then stop vacuuming. Then lower the temperature of the material in the reactor to about 40°C, then add 15.5 parts of toluene diisocyanate and 22.5 parts of diphenylmethane diisocyanate, raise the temperature to 80±2°C and keep it warm for 2.5 hours of polymerization reaction, then start the vacuum device for defoaming for 30 minute...

specific Embodiment approach 2

[0037] 1) Melt 100 parts of polyester polyol and place it in a blue sand mill, add 2 parts of molybdenum disulfide micropowder and 2 parts of colloidal graphite micropowder, and disperse in the blue sand mill at 1000r / min for 8-10 / min, then move all the above materials into the reaction kettle, heat up to 120-130 ℃, keep the vacuum at 0.08-0.09 Mpa, under the action of stirring, vacuumize and dehydrate for 2 hours, then stop vacuuming. Then lower the temperature of the material in the reactor to about 40°C, then add 17.0 parts of toluene diisocyanate and 24.5 parts of diphenylmethane diisocyanate, raise the temperature to 80±2°C and keep it warm for polymerization reaction for 2.5 hours, then start the vacuum device for defoaming for 30 minutes , and a polyurethane prepolymer with a free isocyanate group-NCO mass content of 6% was obtained.

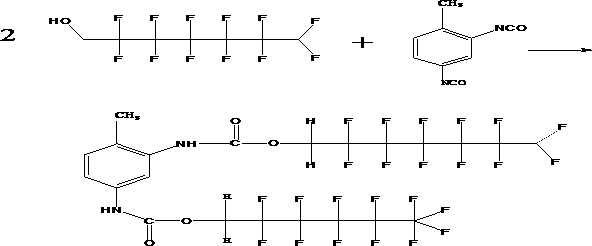

[0038] 2) Take 100 parts of the above polyurethane prepolymer in the mixing device, add 2 parts of dodecafluoroheptanol and TDI-100 com...

Embodiment 2

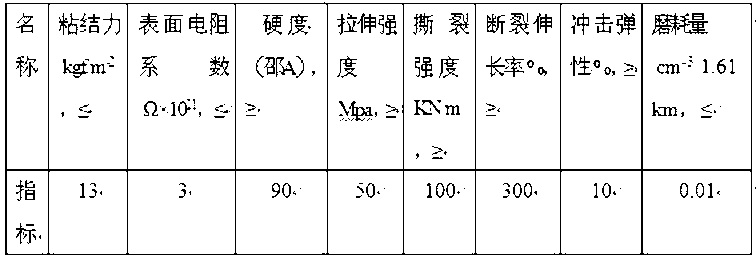

[0043] Embodiment 2 actual test results are shown in Table 3

[0044] Table 3. Properties of Anti-Stick Polyurethane Elastomer Liners

[0045] .

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com