Inorganic filler and natural latex mixing equipment

A technology of inorganic fillers and natural rubber latex, applied in the field of rubber processing equipment, can solve the problems of easy sedimentation of inorganic fillers, product loss, and difficulty in discharging materials, and achieve the effects of good reaction and solidification, improved production efficiency, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The core of the present invention is to provide an inorganic filler and natural rubber latex mixing equipment, which can significantly improve rubber processing efficiency, improve product quality, and save processing costs.

[0028] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

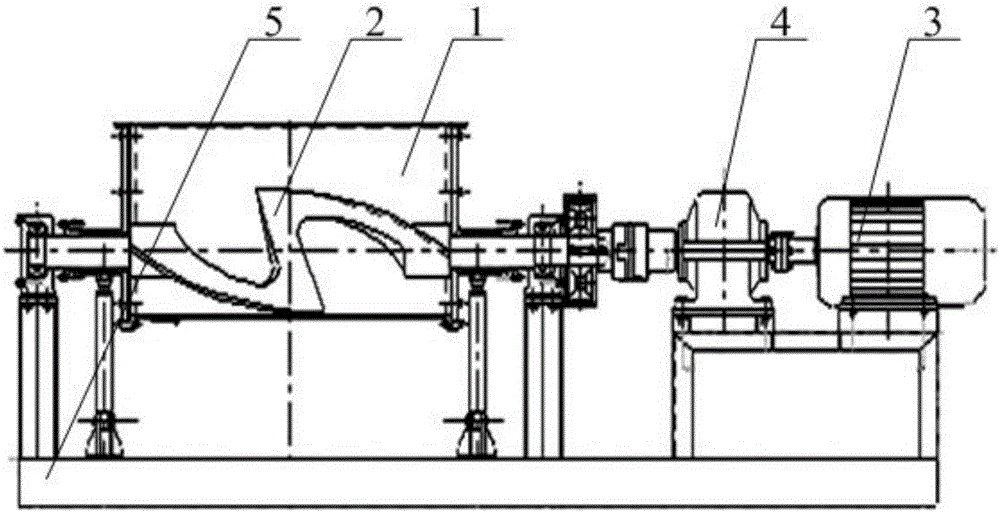

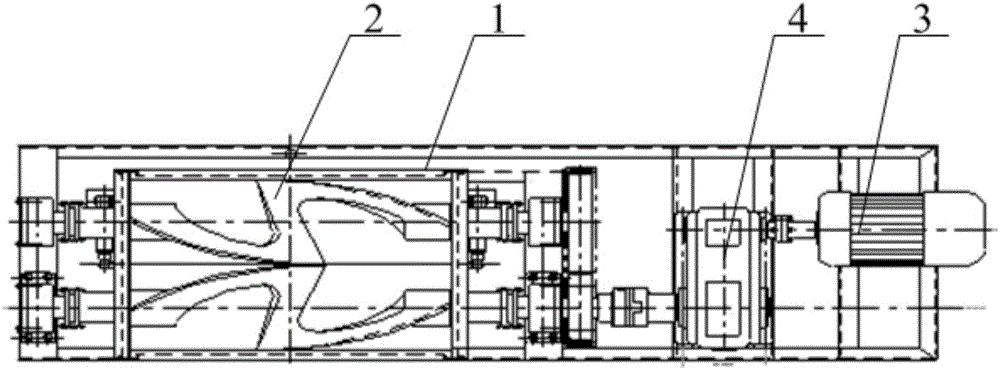

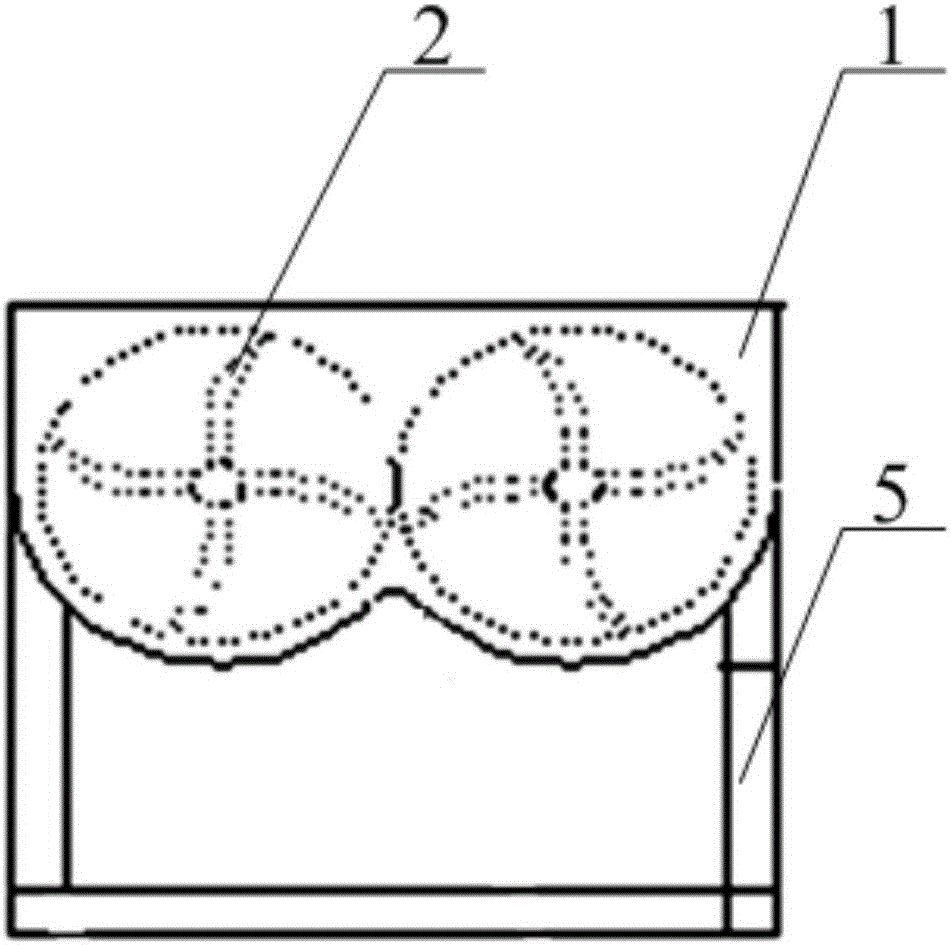

[0029] Please refer to Figure 1 to Figure 4 , figure 1 It is a front view of a specific embodiment of the inorganic filler and natural rubber latex mixing equipment provided by the present invention; figure 2 A top view of a specific embodiment of the inorganic filler and natural rubber latex mixing equipment provided by the present invention; image 3 for figure 1 The structural schematic diagram of the container body of the mixing equipment shown; Figure 4 for figure 1 The structure schematic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com