Split aeration upflow sludge bed integrated sewage treatment equipment

A kind of sewage treatment equipment, up-flow technology, applied in the direction of water/sludge/sewage treatment, biological water/sewage treatment, water aeration, etc., can solve the problems of reducing sewage treatment efficiency and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

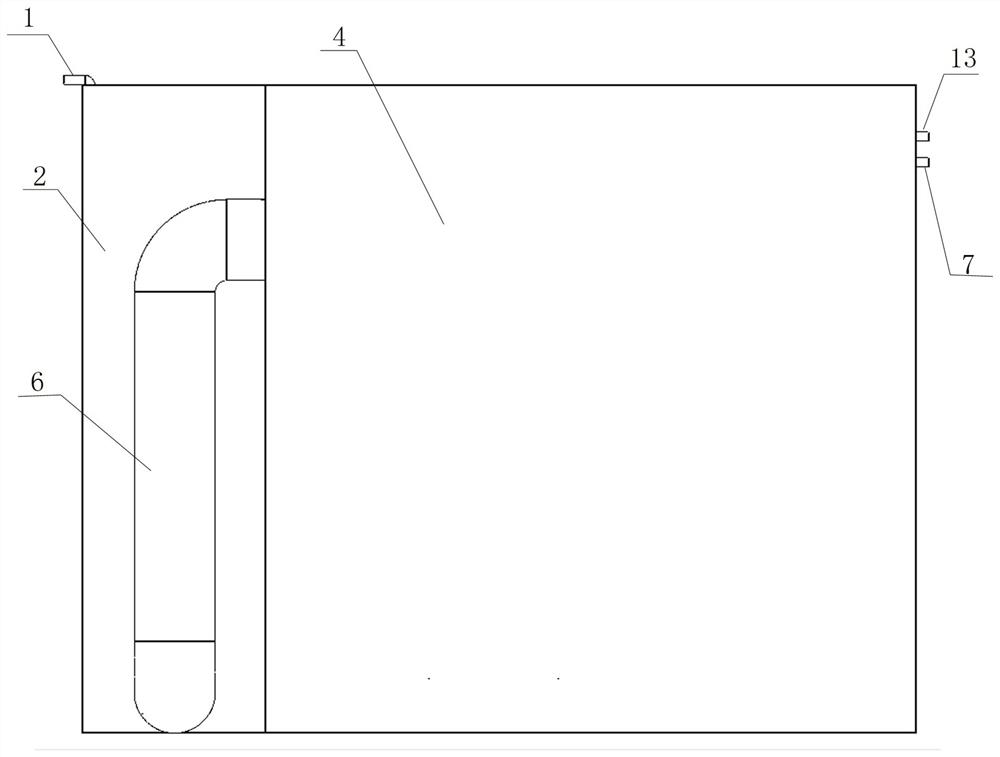

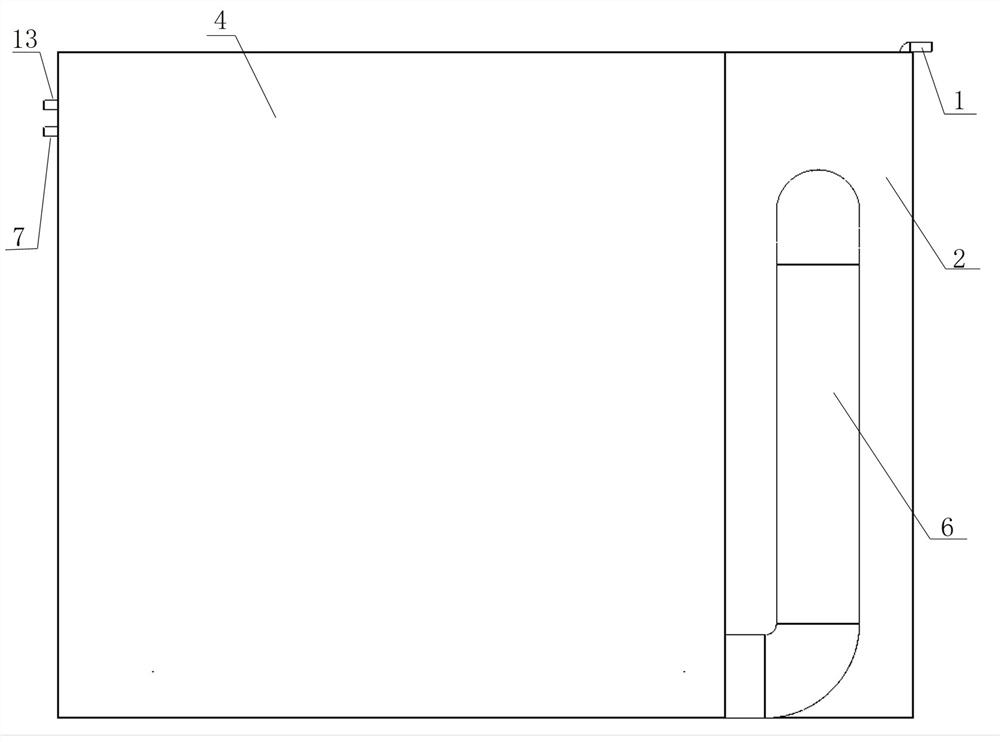

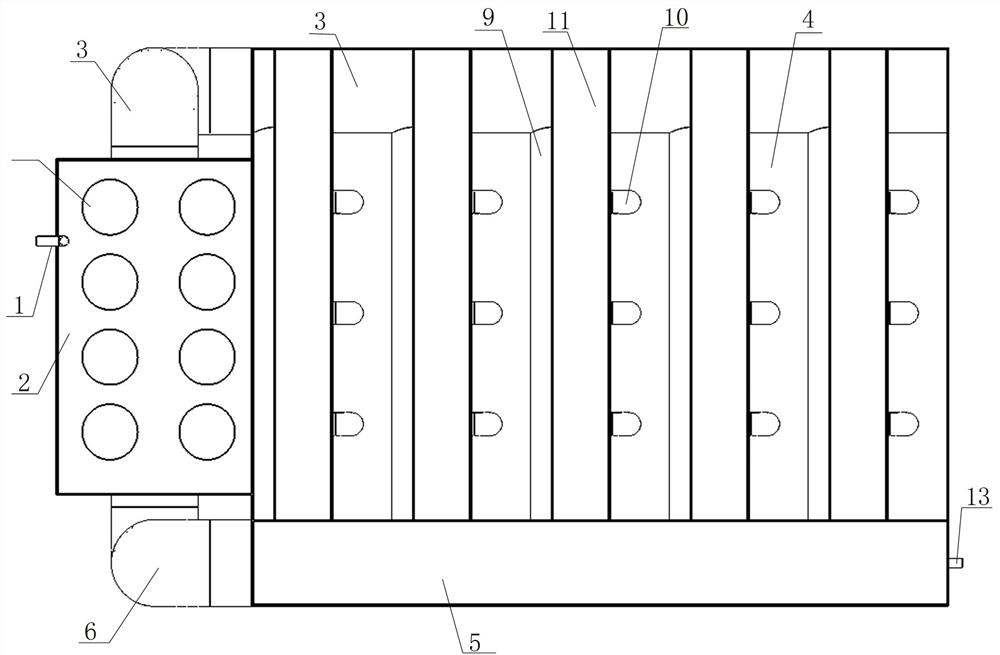

[0028] Such as Figure 1 to Figure 5 As shown, the front view, rear view, top view, left view and perspective view of the separated aerated upflow sludge bed integrated sewage treatment equipment of the present invention are provided respectively, Figure 6 and Figure 7 The cross-sectional views are given, and the integrated sewage treatment equipment shown is composed of water inlet pipe 1, aeration tank 2, reaction tank inlet pipe 3, biochemical reaction tank 4, water collection tank 5, return pipe 6, water outlet pipe 7, aeration The pan 8, the water distribution pipe 9, and the overflow weir 11 are composed, and the water inlet pipe 1 communicates with the top of the aeration tank 2, and is used to feed sewage to be treated in the aeration tank 2. The aeration pan 8 is arranged at the bottom of the aeration tank 2, and the aeration tank 2 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com