Patents

Literature

53results about How to "Guaranteed zero emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

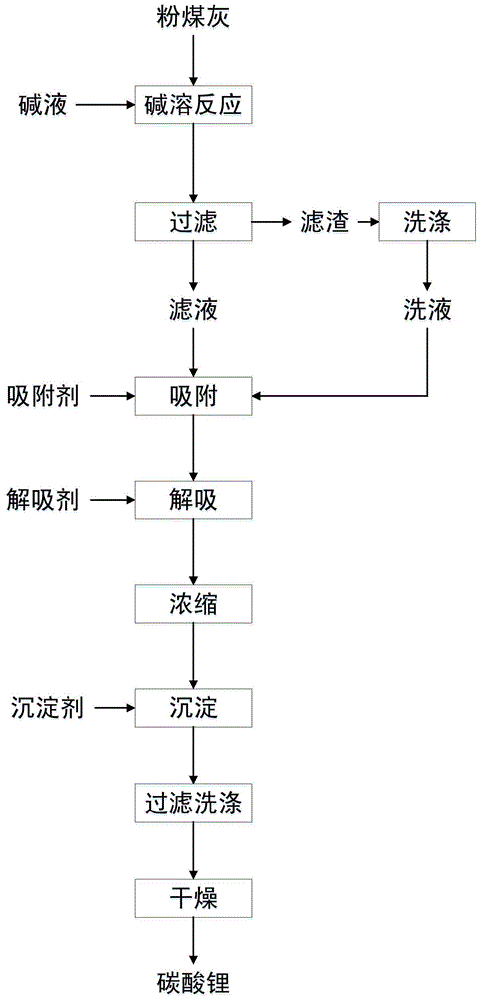

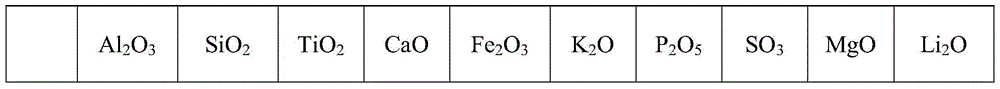

Method for extracting lithium from fly ash

ActiveCN105692659AEfficient recyclingEffectively achieve zero emissionsLithium carbonates/bicarbonatesLithium carbonateFly ash

The invention discloses a method for extracting lithium from fly ash. The method comprises a process including the steps of carrying out one-step alkali dissolving, filtering, washing, adsorbing, desorbing, concentrating and carrying out carbonation precipitation. The main process comprises the following steps: carrying out an alkali dissolving reaction on the fly ash and an alkali solution; after finishing the reaction, carrying out solid-liquid separation and washing, and adsorbing obtained filtrate and washing solution by a lithium ion adsorbent; desorbing lithium ions and concentrating; adding a precipitating agent into a concentrated solution and carrying out lithium precipitation operation; after finishing precipitation, filtering, washing and drying to obtain a solid, namely a lithium carbonate product prepared from the fly ash. The invention provides the simple and efficient method for extracting the lithium from the fly ash; the method has a wide raw material source and has the advantages of simple process, moderate reaction conditions, no influence on subsequent treatment of the filtrate and filter residues and capability of effectively controlling impurities; the extraction rate is more than 60 percent and the method is applicable to industrial popularization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

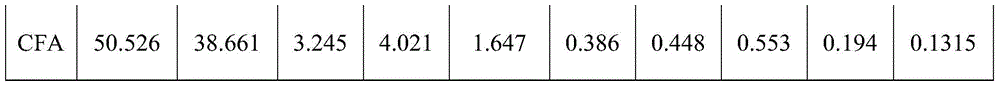

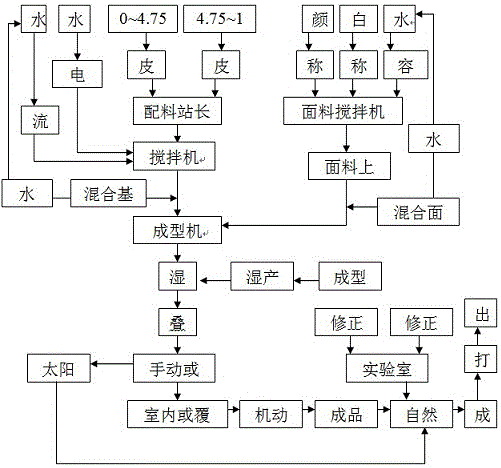

Method for on-site treatment and resource utilization of architectural ornament rubbish

InactiveCN106694526AConvenient operation and managementStrong adaptability to engineering applicationsConstruction waste recoverySolid waste disposalSites treatmentShortest distance

The invention discloses a method for on-site treatment and resource utilization of architectural ornament rubbish. The method comprises the following steps that front end pre-treatment module treatment is conducted, specifically, a torn-down and built site is subjected to leveling and planning firstly, then the architectural ornament rubbish which is distributed in a scattered mode is transshipped to a centralized stacking area of materials at a short distance through a professional vehicle, and part of the light materials which are sorted is subjected to classified stacking through a pre-treatment facility; middle end movable crushing treatment module treatment is conducted, specifically, raw materials which are sorted through manual work are sent to a combined movable crusher to be subjected to processing treatment through an excavator or a loader, and produced aggregates with different specifications are stacked to a finished material stacking area; and rear end resource utilization module treatment is conducted, specifically, the light materials sorted by the front end and the aggregates crushed by the middle end are directly used or treated or subjected to regeneration treatment on site, so that the requirement of resource utilization is met. According to the method for on-site treatment and resource utilization of the architectural ornament rubbish, reasonable and effective resource utilization of the architectural ornament rubbish can be achieved, and the environmental pollution problem caused by random storing of the architectural ornament rubbish is avoided.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD +1

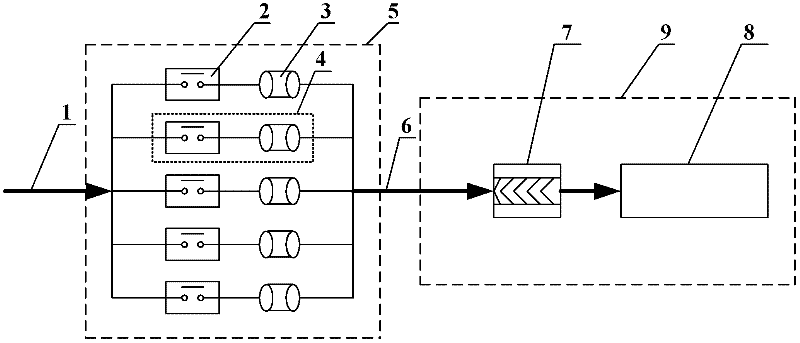

Environment-friendly type real-time detection apparatus for analysis of components in sulfur hexafluoride gas and method used therein

ActiveCN102520121AAvoid cross interferenceAvoid pollutionMaterial analysisGas compositionSulfur hexafluoride

The invention brings forward an environment-friendly type real-time detection apparatus for analysis of components in sulfur hexafluoride (SF6) gas and a method used therein. The apparatus comprises a real-time detection module and an environment-friendly recovery module. The method comprises the following steps: analyzing components in SF6 gas, absorbing and removing impurities in SF6 gas output after composition analysis and recovering SF6 gas. The environment-friendly type real-time detection apparatus and the method provided in the invention can carry out real-time detection of gas components which can reflect the operation state of gas insulation equipment, enable environment-friendly recovery of detection gas to be realized and provide effective guarantee for reliable operation of electric power equipment and safety protection of detection personnel.

Owner:CHINA ELECTRIC POWER RES INST +1

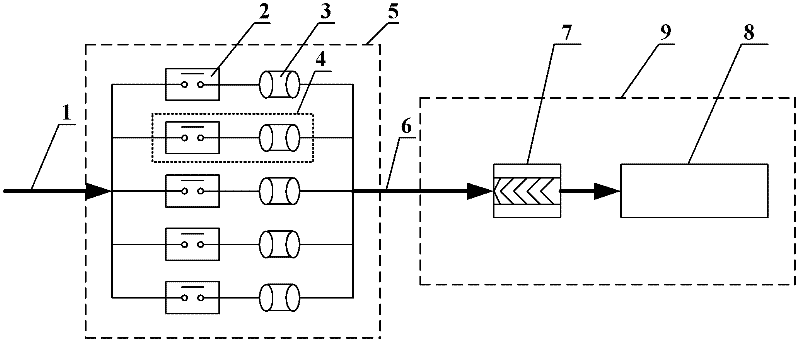

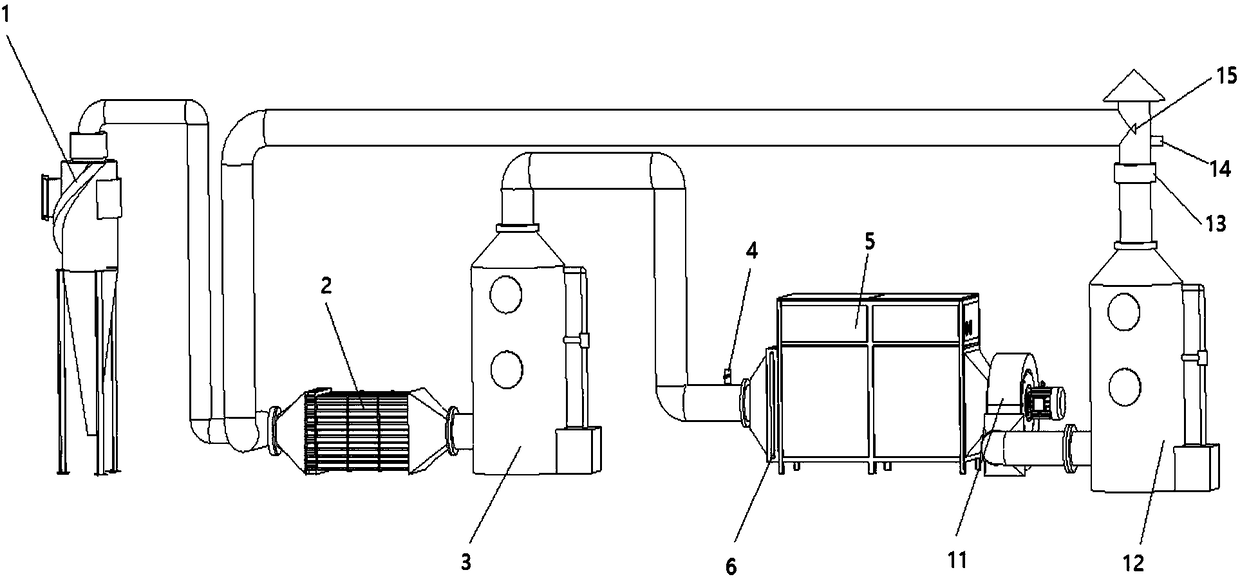

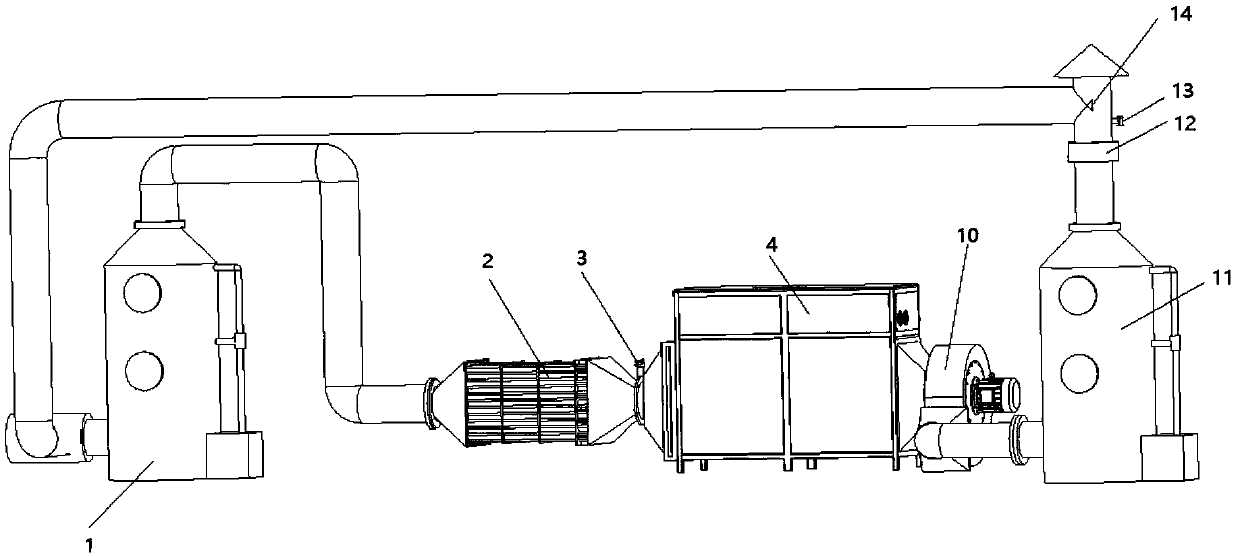

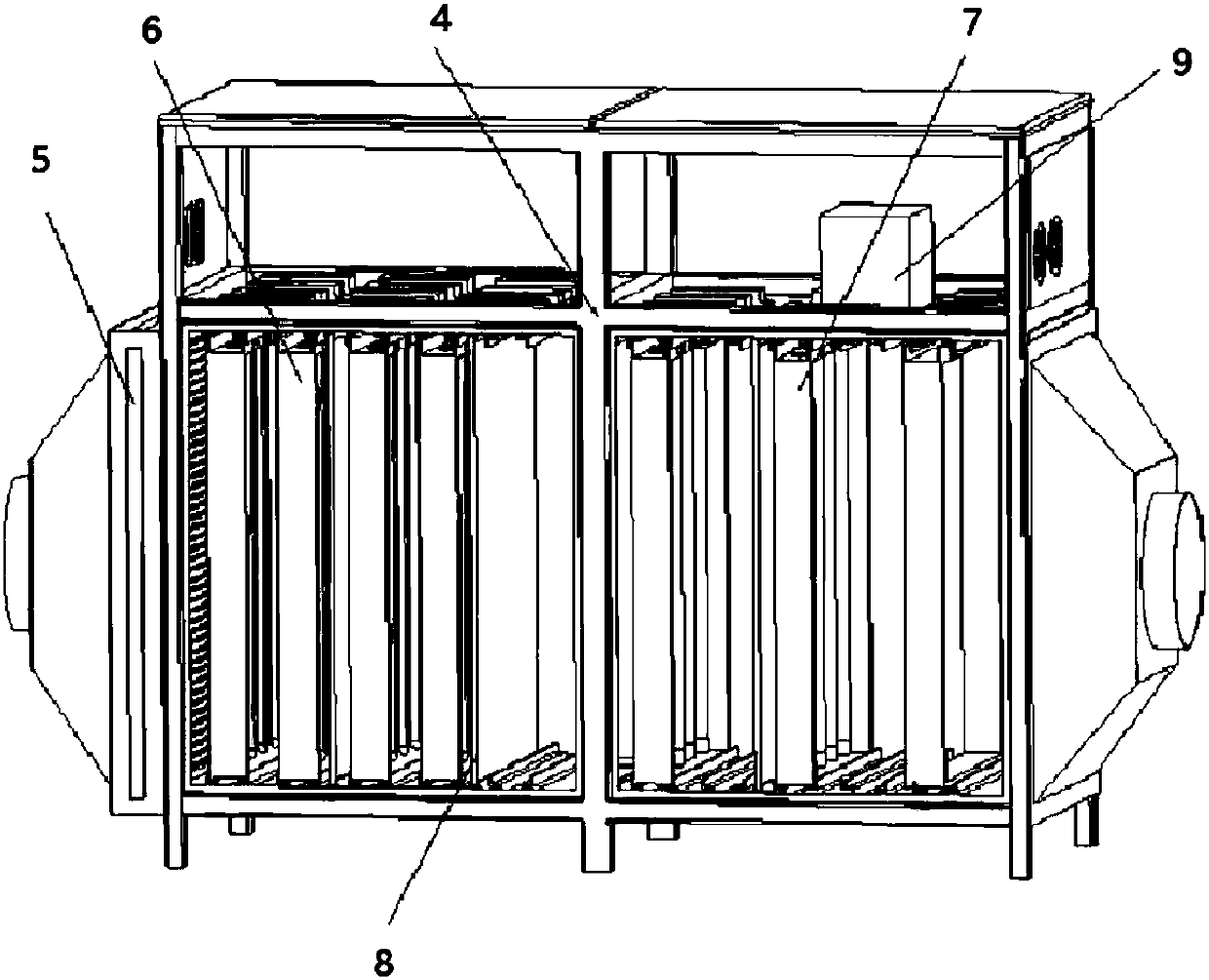

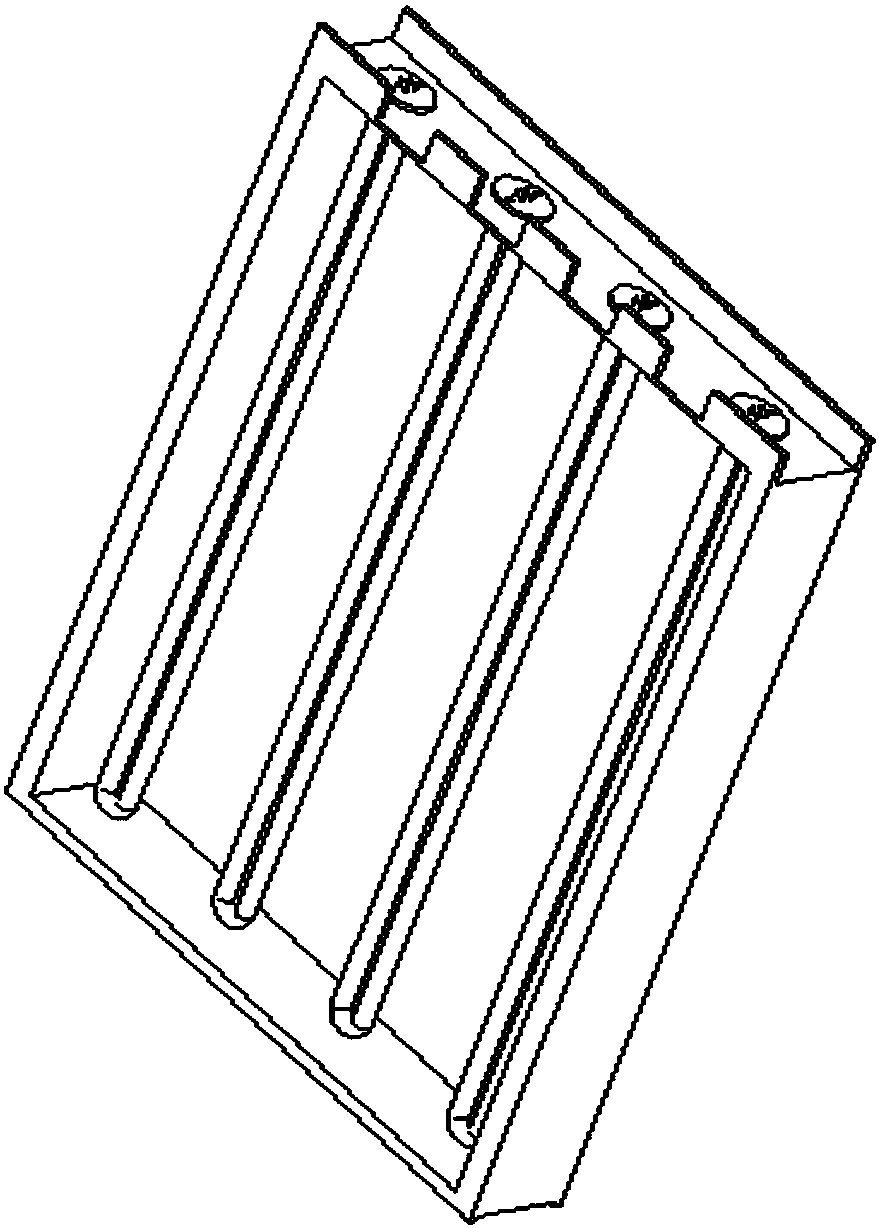

Photolysis oxidation cracking treatment method for tail gas based on volatile oil and gas purification technology

PendingCN108096969AEnergy-saving and efficient processingEasy to handleCombination devicesParticulatesMicrocontroller

The invention discloses a photolysis oxidation cracking treatment method for tail gas based on a volatile oil and gas purification technology. The photolysis oxidation cracking treatment method comprises the following steps: allowing organic waste gas to enter a cyclone defogging and dedusting cooler, allowing macromolecular pollutants to be degraded and decomposed into micro-molecular substancesthrough an oil and gas purifying electric-field device, allowing treated organic waste gas to enter a front-end spraying tower, allowing dust particles to be fixed in a spraying solution, allowing treated organic waste gas to enter a photolysis oxidation cracking cabin through an air pipe, and subjecting waste gas to oxidation treatment; in the oxidation treatment process of the waste gas, allowing a waste gas concentration detection sensor arranged at the inlet position of the photolysis oxidation cracking cabin to detect the concentration of the waste gas in real time and feedback a signal to a single-chip microcomputer control system, and controlling lamp tubes of a high-energy ultraviolet lamp group module and an ozone supply module to regularly and cooperatively open and close; and allowing treated gas to enter a dry flue gas comprehensive treatment tank and an ozone filter screen so as to realize super purified emission after waste gas treatment. The photolysis oxidation crackingtreatment method provided by the invention can realize energy-saving and highly-efficient operation of a whole system, prolongs the service life of a lamp group module, improves the treatment effectof the organic waste gas, avoids the problem of secondary pollution caused by a traditional wet process, and realizes super purified emission.

Owner:QINGDAO UNIV OF SCI & TECH

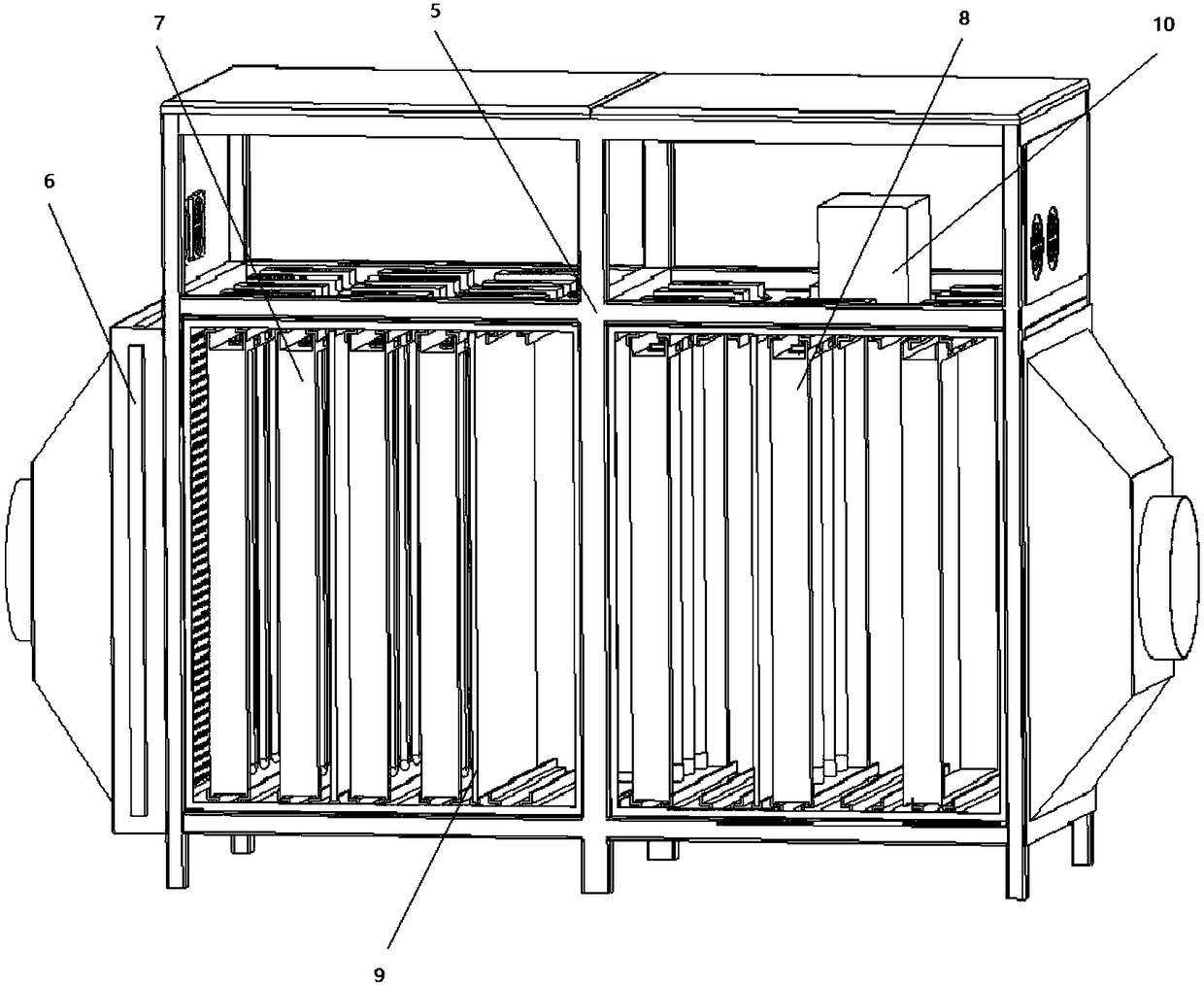

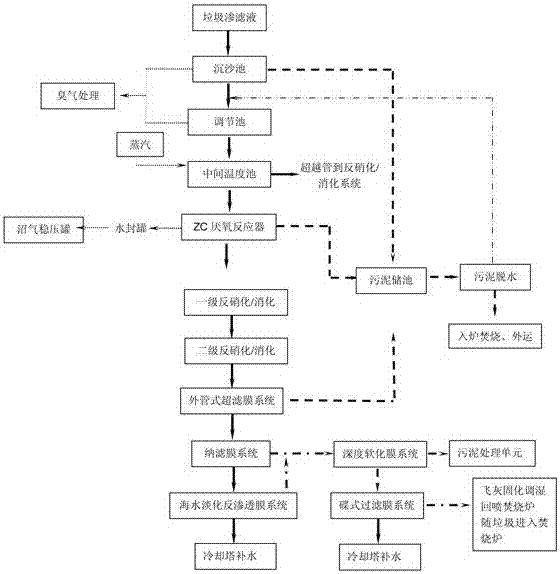

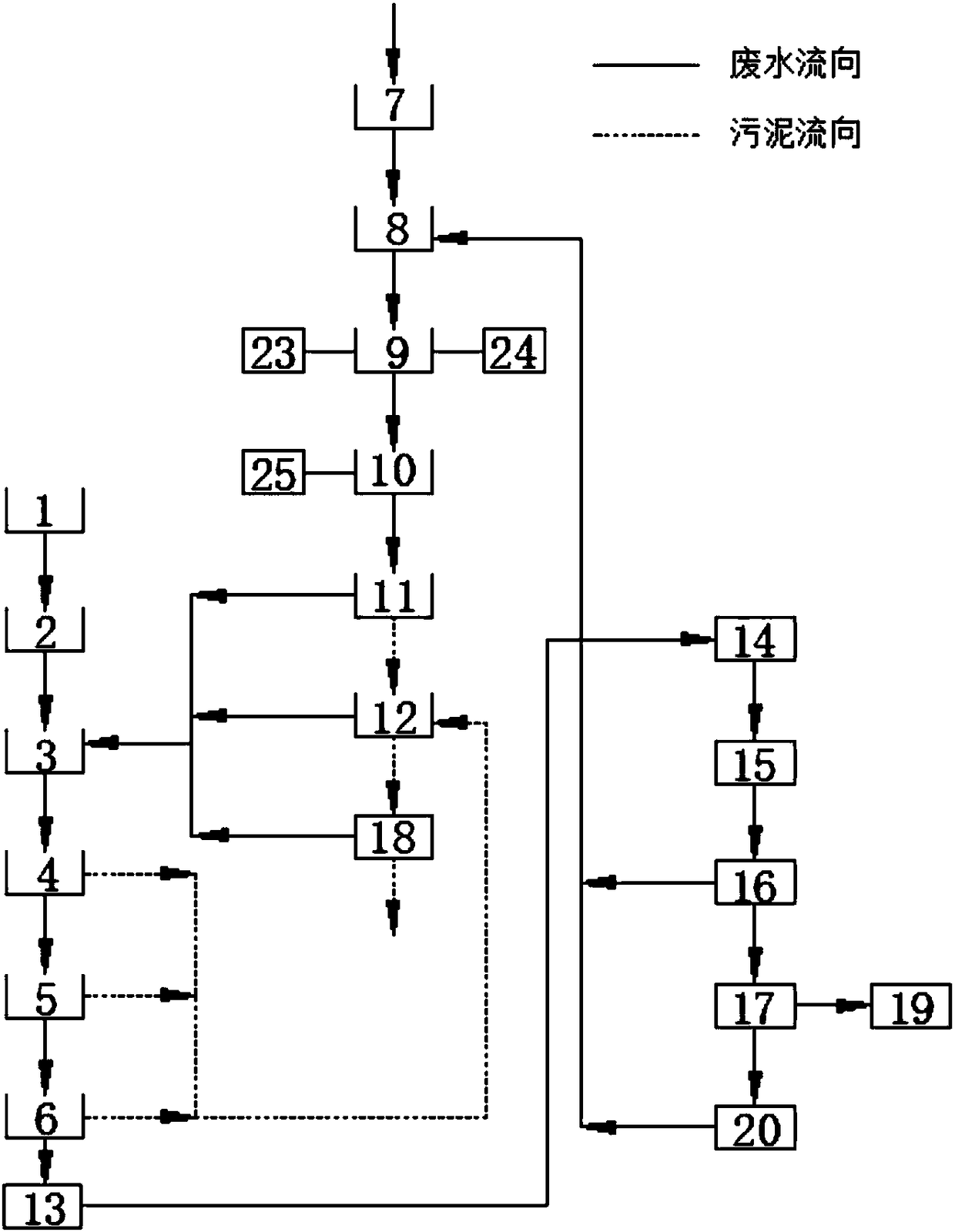

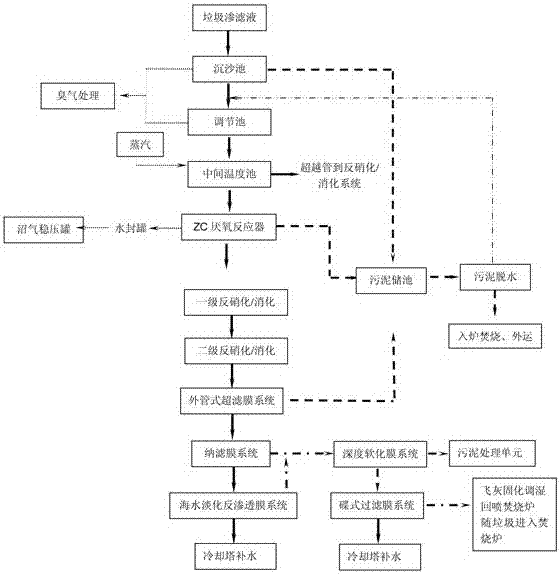

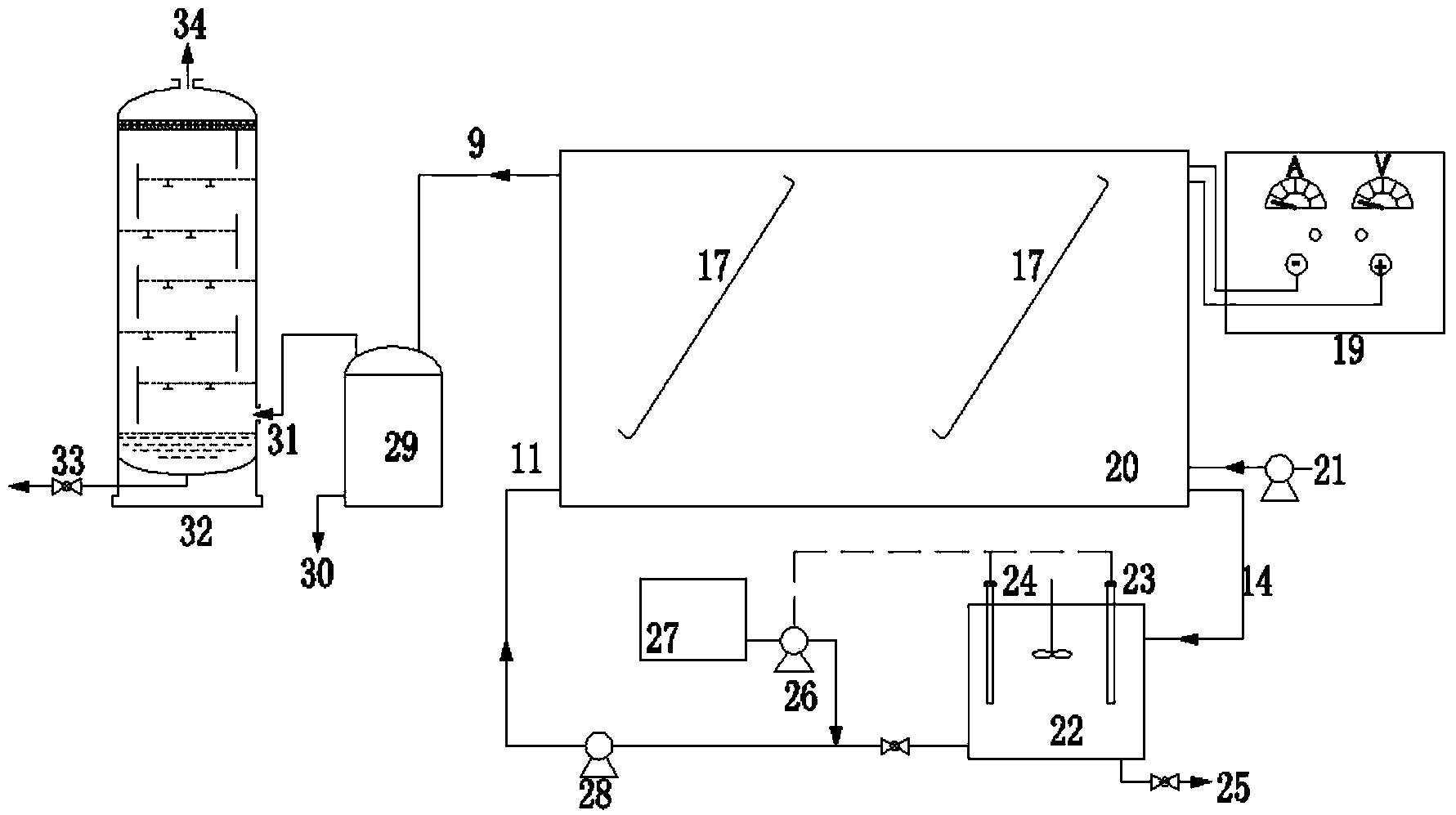

Leachate treatment method of waste incineration power station

InactiveCN107200440AIncrease water production rateGuaranteed normal consumptionWater treatment parameter controlGeneral water supply conservationAnaerobic decompositionAnaerobic reactor

The invention discloses a leachate treatment method of a waste incineration power station. The leachate treatment method comprises the following steps: 1) introducing the waste incineration leachate into a sand settling pond, and preprocessing the waste incineration leachate to remove a great amount of settled sand in sewage; 2) introducing the leachate into a regulating pond, tempering the leachate, so that the PH of the inlet water of the sewage is kept at 5 to 6 in 2 days; 3) enabling the leachate to enter an intermediate temperature pond, introducing steam to adjust the temperature to be between 35 DEG C and 39 DEG C, and homogenizing the sewage temperature by virtue of a stirrer in the intermediate temperature pond; 4) introducing the incineration waste leachate after being processed in the intermediate temperature pond to have anaerobic decomposition, decomposing and converting various complex organic matters into marsh gas, so that the incineration waste leachate is primarily purified; 5) carrying out the denitrification / nitrification treatment; and 6) filtering. By adopting the leachate treatment method, the water yield of a leachate treatment system in the waste incineration power station, the residual concentrated liquid can be ensured to be completely consumed in the waste incineration power station, and the emission of the concentrated liquid can be prevented from severely polluting the environment.

Owner:佛山市银禾工业设计有限公司

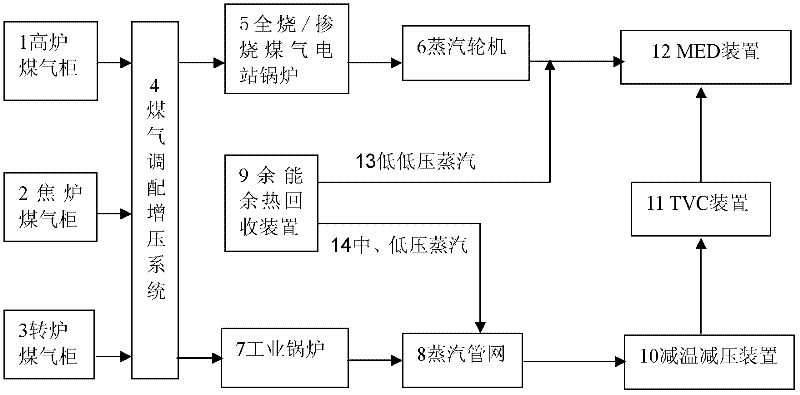

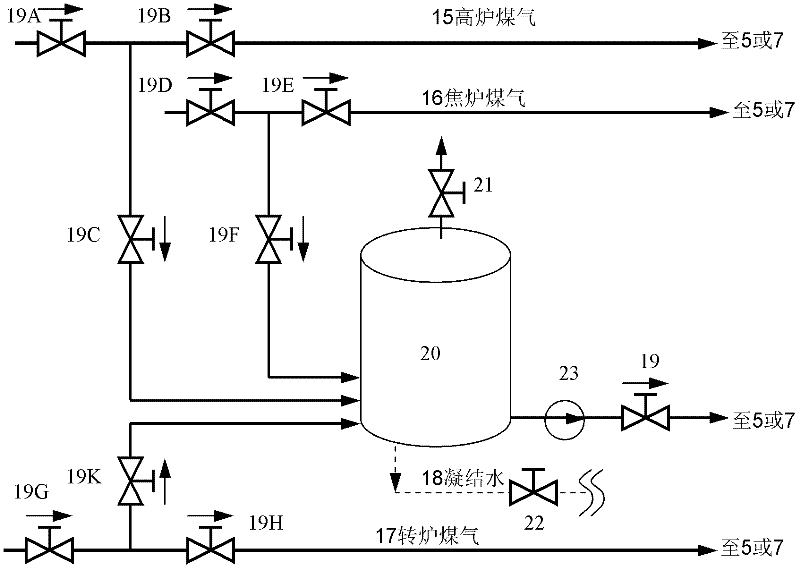

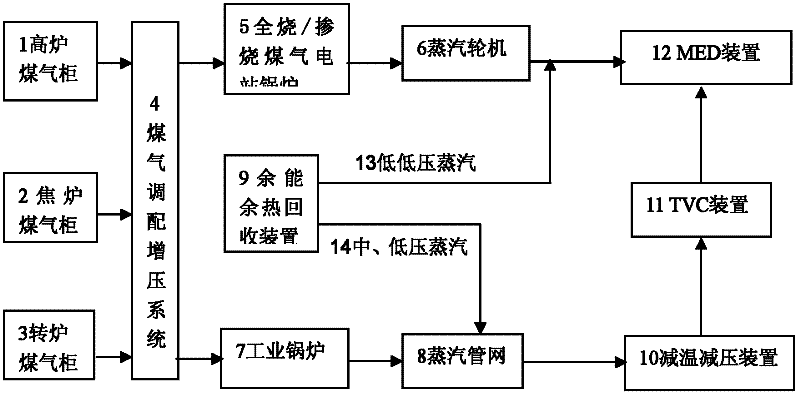

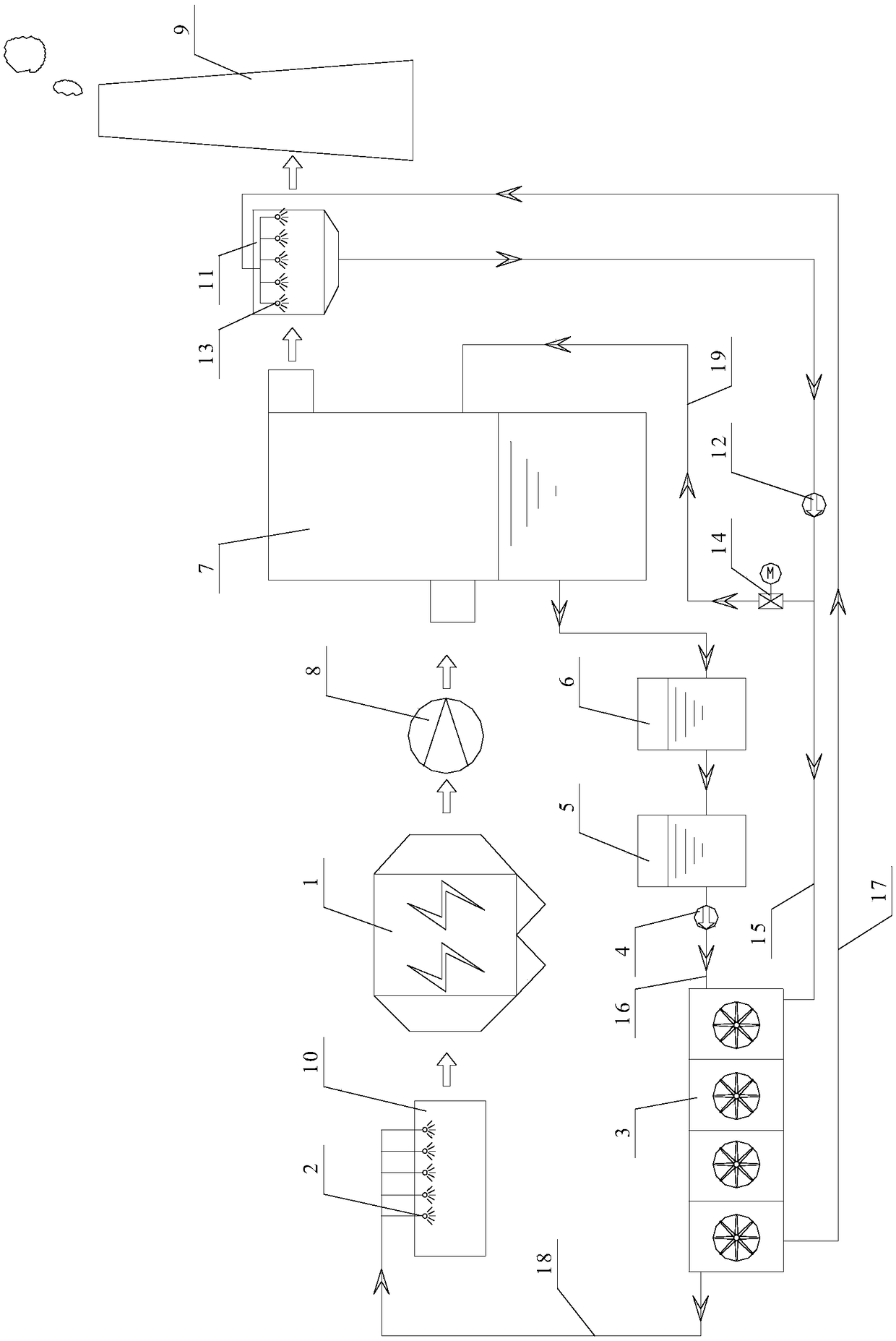

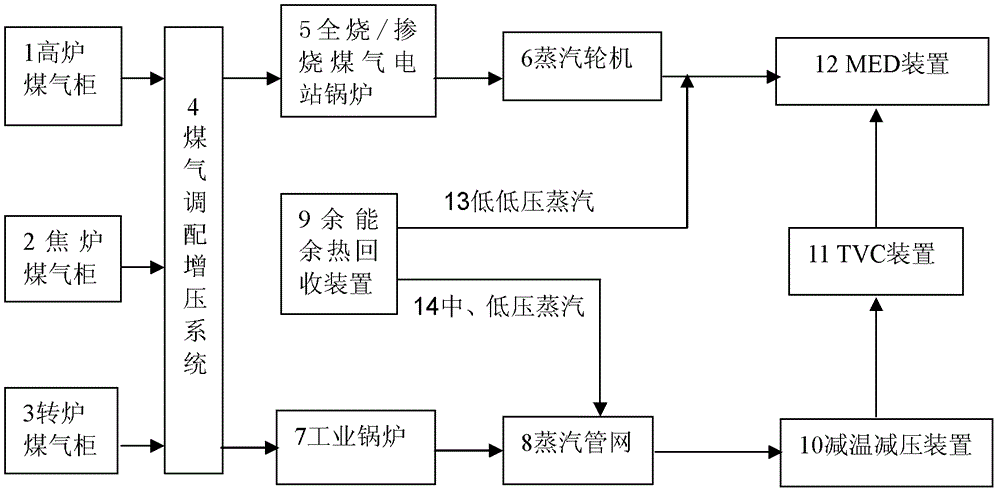

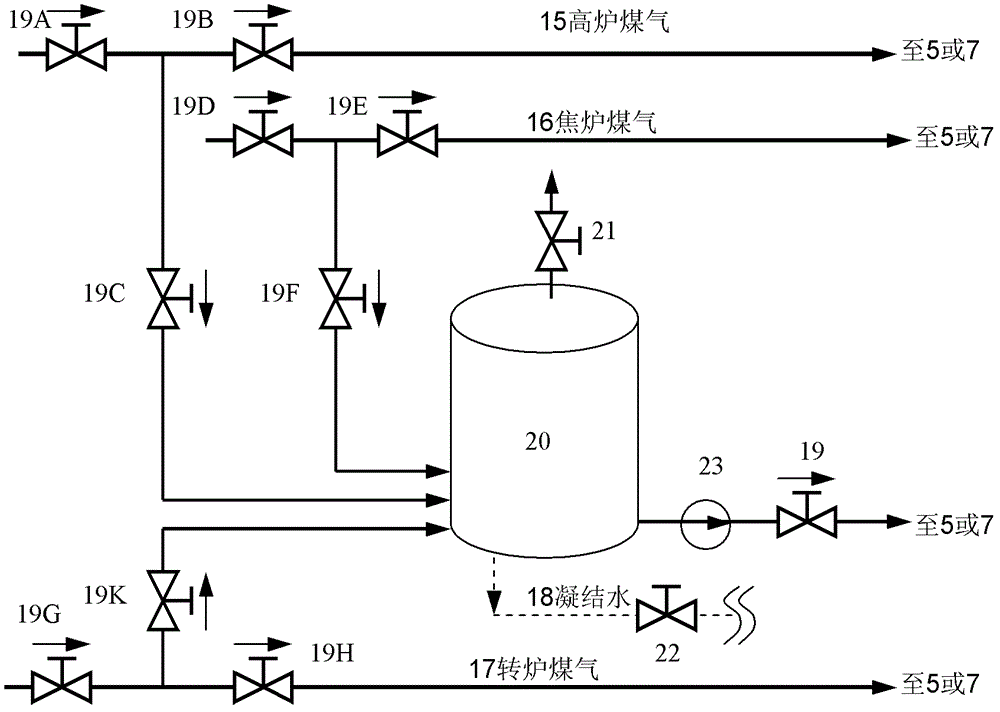

System and process for realizing zero discharge of gas and steam in iron and steel plants by adopting seawater desalination

ActiveCN102502903AEasy to adjustTimely consumptionGeneral water supply conservationSeawater treatmentDistillationSeawater

The invention discloses a system and a process for realizing zero discharge of gas and steam in iron and steel plants by adopting seawater desalination, which belongs to the technical field of secondary energy comprehensive utilization in iron and steel plants, and particularly relates to converting gas and steam into water resource through low-temperature and multiple-effect seawater desalination. The system comprises a blast furnace gas holder, a coke oven gas holder, a converter gas holder, a gas distributing and pressurizing system, a pure combustion / blending combustion gas station boiler, a steam turbine, an industrial boiler, a steam pipe network, a complementary-energy waste-heat recovery device, a temperature and pressure reduction device, a TVC (thermal vapor compressor) device and an MED (multi-effect distillation) device. Residual gas which can not be consumed in production process of the iron and steel plants is used for a pure combustion / blending combustion gas boiler and / or the industrial boiler, and steam is produced through combustion, which is used in preparing desalinated water through the MED device with steam recovered in the iron and steel plants on the premise of reasonable classification. Compared with the prior art, the system and the process can ultimately recover gas and steam in the iron and steel plants, have good economic effects, and are applicable to the energy conservation and emission reduction of coastal iron and steel plants.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

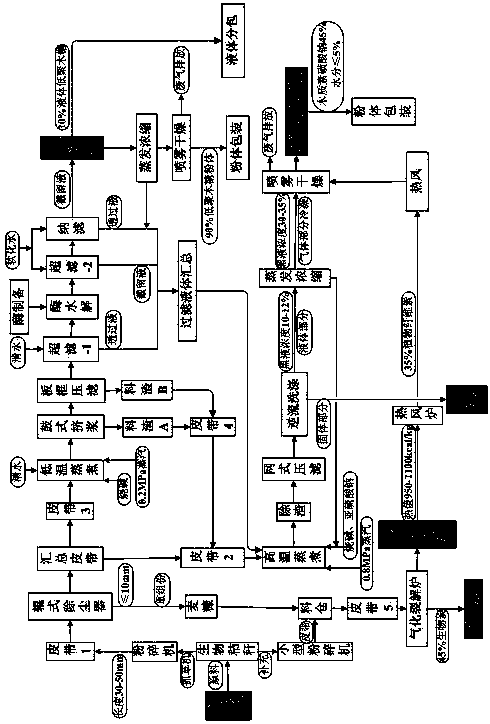

Five-coproduction process for comprehensively utilizing biological straw

PendingCN107586805AMaximize the use of scaleIncrease profitGaseous fuelsBiofuelsUltrafiltrationSlurry

The invention discloses a five-coproduction process for comprehensively utilizing biological straw, aiming at solving the technical problem of expanding the straw utilization scale. The process consists of three lines: the first line is used for producing xylooligosaccharide: smashing biological straw, introducing steam for boiling, passing through an ultrafiltration membrane-1 after filter pressing, passing through an ultrafiltration membrane-2 after enzymatic hydrolysis reaction, enabling penetrating fluid to be subjected to nanofiltration concentration so as to be concentrated by 3-5 timesto obtain the xylooligosaccharide; the second line is used for producing straw pulp and sodium lignosulfonate: smashing the biological straw, enabling the smashed biological straw and waste residue tobe subjected to pressurized high temperature boiling together, enabling obtained serous liquid to be subjected to filter pressing separation, and enabling solid matter obtained after separation to besubjected to adverse current cleaning to obtain wheat straw pulp; enabling black liquor and washing black water obtained after separation to evaporate and concentrate, then performing heat exchange via hot-blast air to obtain sodium lignosulphonate powder; and the third line produces biochar and combustible pyrolysis gas. On the premise of generating remarkable economical benefit, the five-coproduction process is friendly to environment and does not generate waste water so as to achieve zero discharging, solid waste does not exist, and the exhaust gas reaches the standard and is emitted.

Owner:临颍路得生物科技有限公司

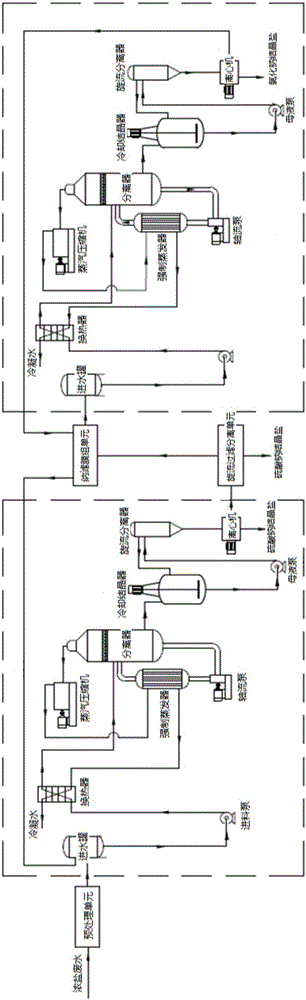

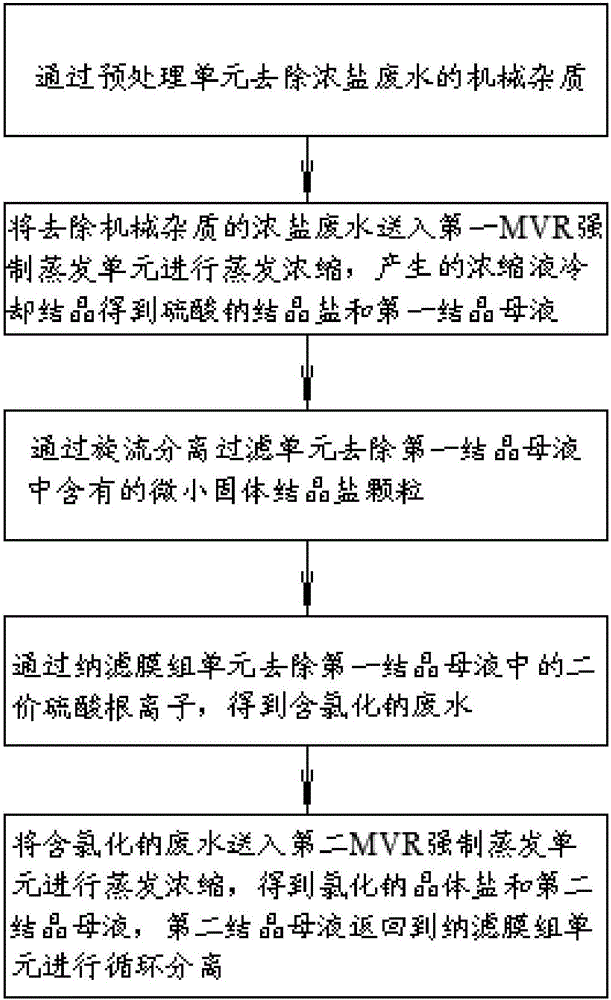

Method and device for salt separation and crystallization of high-salinity wastewater in coal chemical industry

InactiveCN105859003AGuaranteed zero emissionsCannot avoid crystallizationWaste water treatment from quariesTreatment involving filtrationEvaporationCell separation

The invention relates to a method and a device for salt separation and crystallization of high-salinity wastewater in the coal chemical industry. The device comprises a first MVR (mechanical vapor recompression) forced evaporation unit, a cyclone separation filtering unit, a nanofiltration membrane group unit and a second MVR forced evaporation unit. The first MVR forced evaporation unit is used for evaporation of the high-salinity wastewater in the coal chemical industry to obtain sodium sulfate crystalline salt and first crystallization mother liquor; the cyclone separation filtering unit is used for removing tiny solid crystalline salt particles from the first crystallization mother liquor; the nanofiltration membrane group unit is used for removing divalent sulfate ions from the first crystallization mother liquor; the second MVR forced evaporation unit is used for evaporation and concentration of sodium chloride containing waste water to obtain sodium chloride crystalline salt and second crystallization mother liquor; the second MVR forced evaporation unit sends the second crystallization mother liquor into the nanofiltration membrane group unit to realize cyclic separation. The method and the device for salt separation and crystallization of the high-salinity wastewater in the coal chemical industry have advantages that low energy consumption, low cost and freeness of secondary pollution in treatment of the high-salinity wastewater are realized, resource recycling is realized as well, purity in salt separation and crystallization is greatly improved, and zero emission of wastewater is guaranteed.

Owner:WUHAN HONGAO GREEN ENERGY ENG

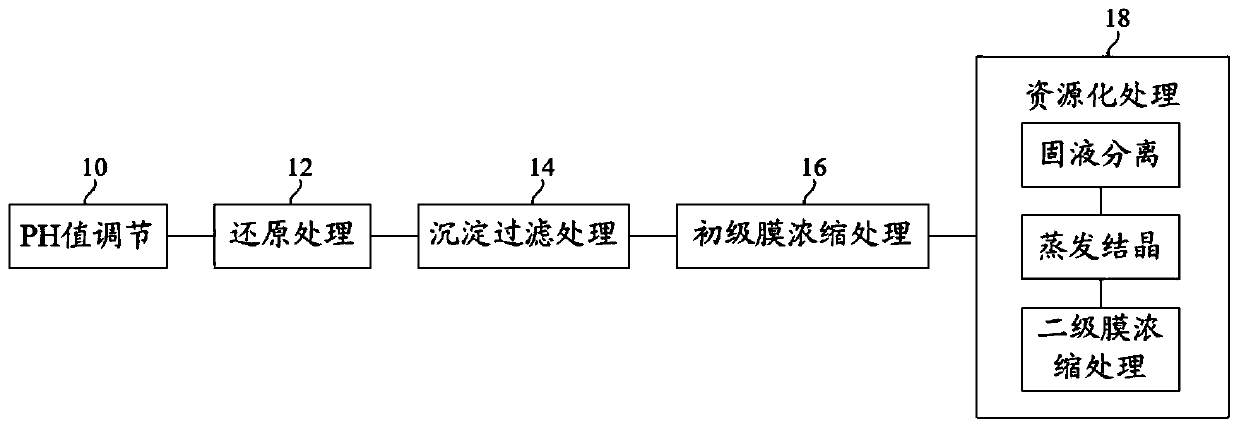

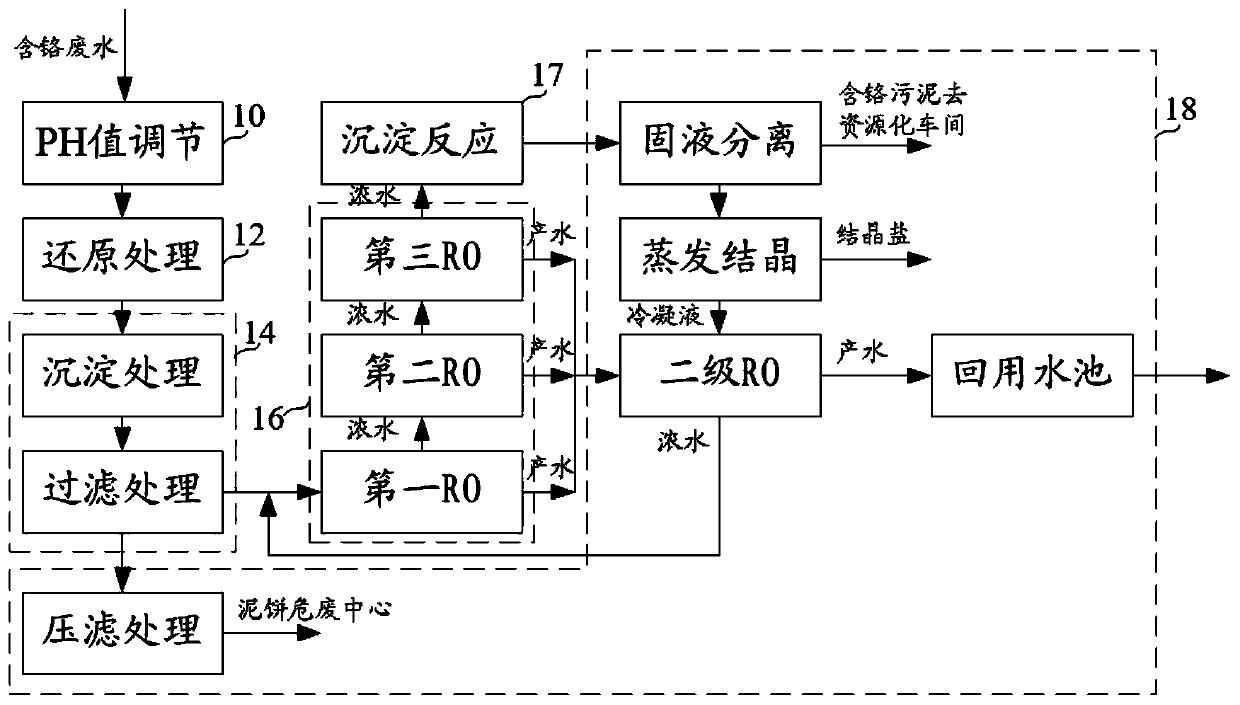

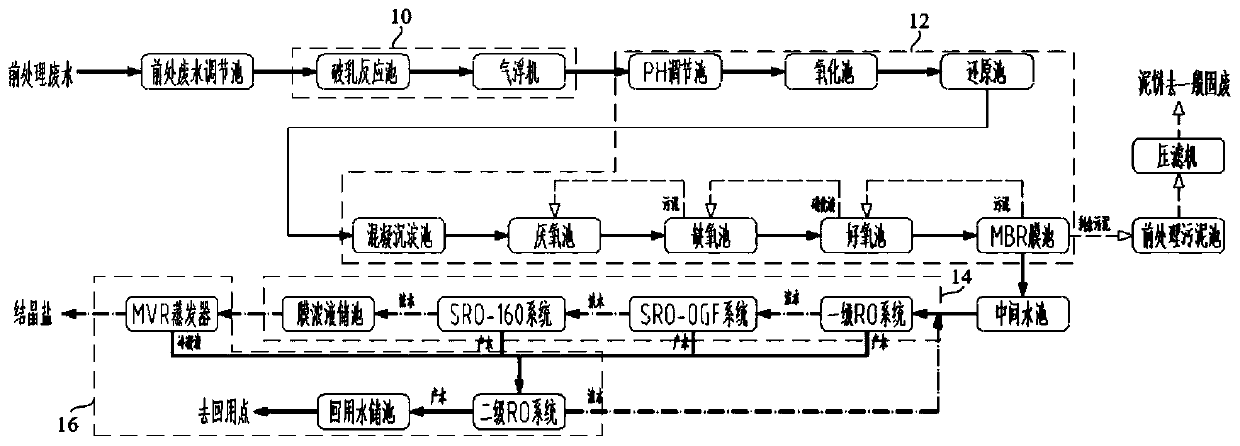

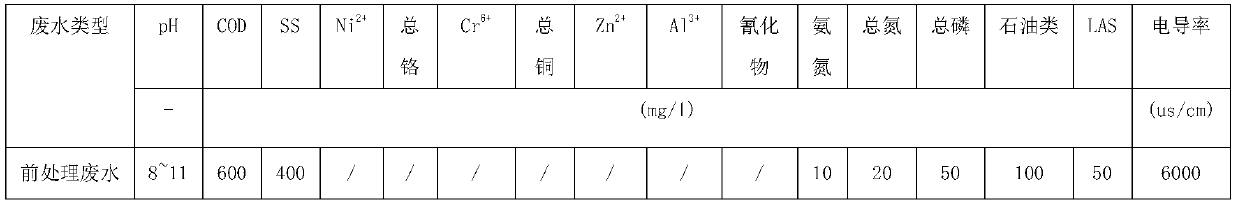

Electroplating wastewater recycling treatment method

InactiveCN110921887AReduce valenceEasy to recycleWater treatment parameter controlWater contaminantsReduction treatmentSludge

An electroplating wastewater recycling treatment method provided by the invention comprises the following steps: pH value regulation, namely, adding a pH regulator into a pH regulating tank to regulate the pH value of electroplating wastewater; reduction treatment, namely, adding a reducing agent after pH value regulation of the electroplating wastewater; precipitation and filtration treatment, namely, precipitating and filtering the electroplating wastewater subjected to the reduction reaction to remove first sludge in the electroplating wastewater, the first sludge being a mixture of suspended solids and precipitates; primary membrane concentration treatment, namely, feeding the electroplating wastewater subjected to precipitation and filtration treatment into primary reverse osmosis membrane treatment equipment to obtain primary produced water and a primary concentrated solution, the primary produced water entering a produced water mixing tank, and the primary concentrated solutionentering a membrane concentrated solution storage tank; and recycling treatment, namely, carrying out solid-liquid separation on the primary concentrated solution to obtain second sludge, crystallinesalt and condensate, mixing the condensate with the primary produced water, and carrying out secondary membrane concentration treatment to obtain a secondary concentrated solution and secondary produced water.

Owner:四川美峰环境治理有限责任公司

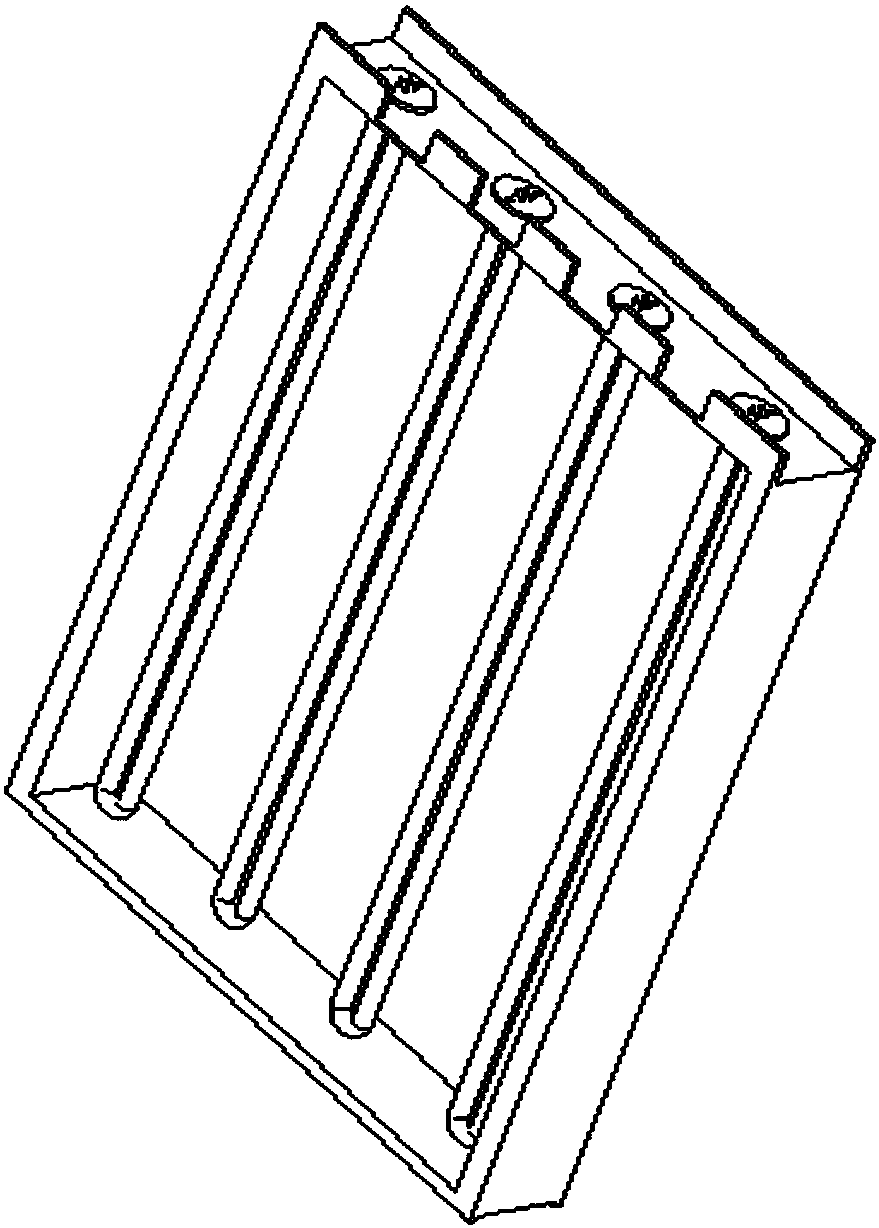

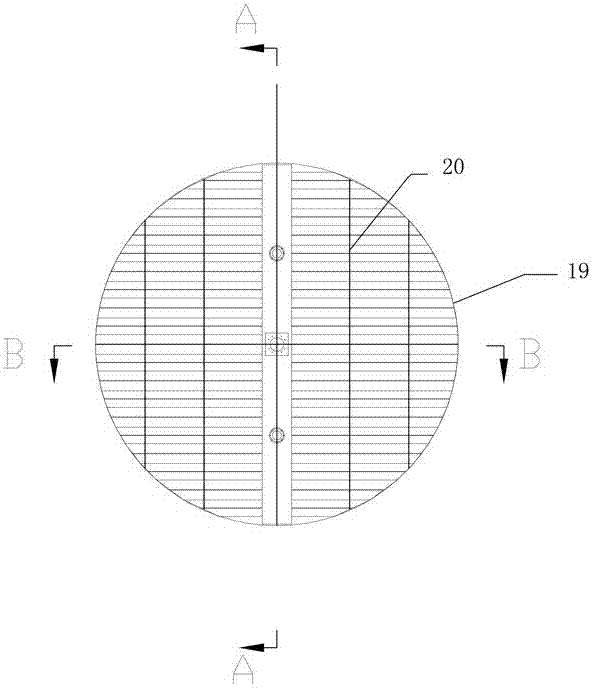

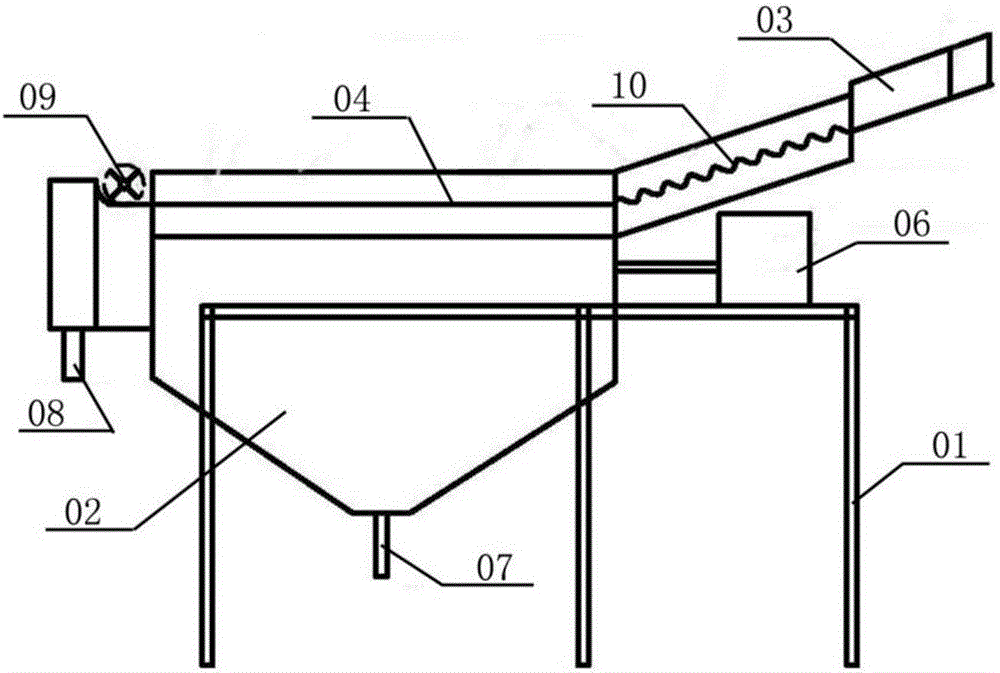

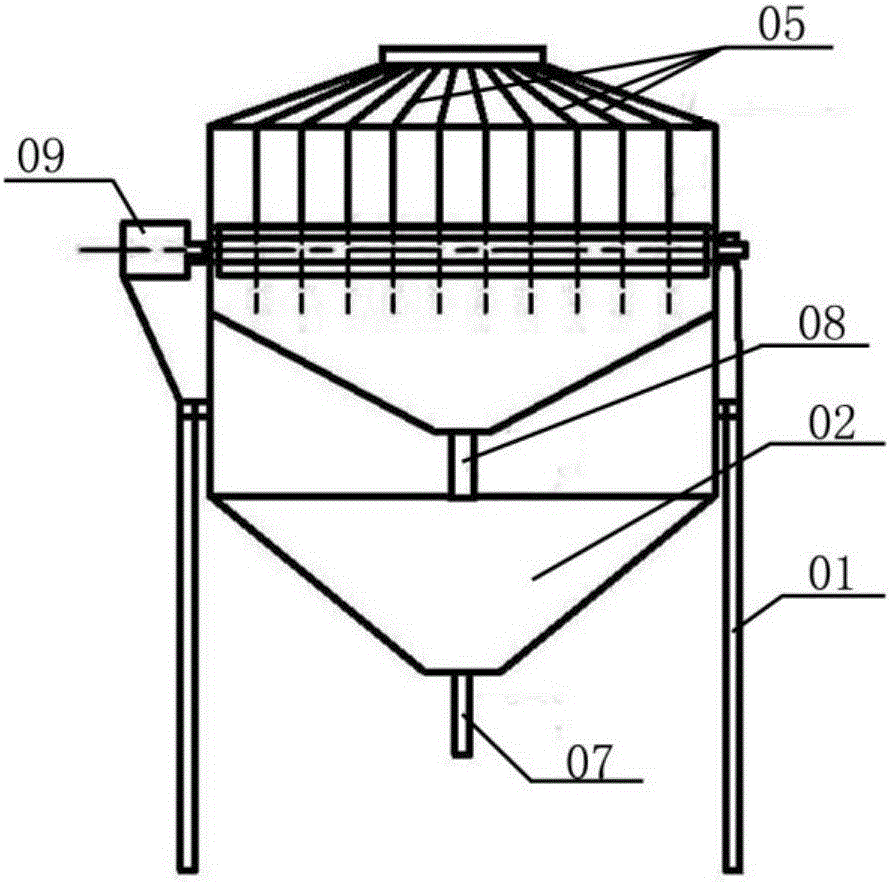

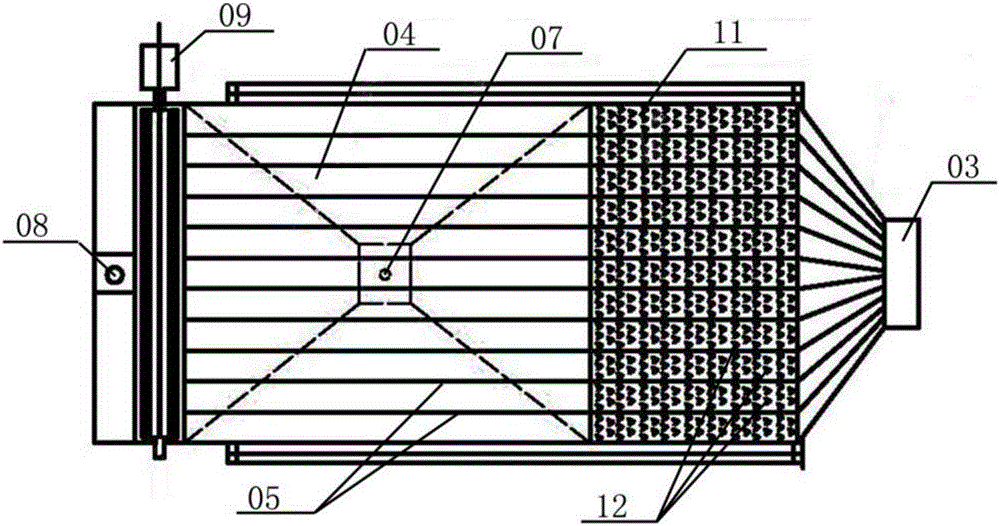

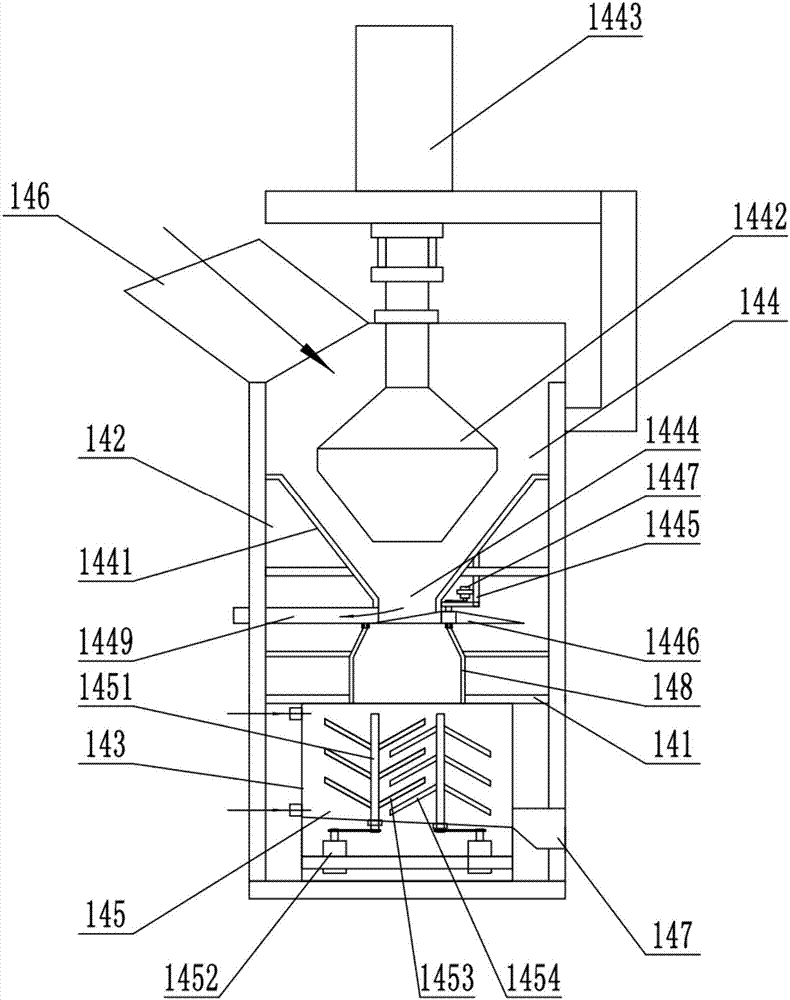

Dielectric field screening concentrating machine and metallurgical slag recovering method

InactiveCN106694523AEfficient and environmentally friendly utilizationGuaranteed zero emissionsElectrostatic separationSolid waste disposalMetallurgical slagDielectric

The invention relates to a dielectric field screening concentrating machine and a metallurgical slag recovering method. The dielectric field screening concentrating machine comprises a supporting frame, a sorting box, an ore feeding part, a dielectric sieve screen, multiple electrode plates, a quick-return mechanism, a tailing outlet and a concentrate outlet. The tail portion of the dielectric sieve screen is provided with a rotary scraping plate connected to the concentrate outlet. The tailing outlet is located in the lower portion of the sorting box. The multiple electrode plates are installed on the dielectric sieve screen and the ore feeding part in parallel. An insulating layer is attached to the outside of each electrode plate. According to the machine, the heat-preserving no-heating method is adopted for enabling ore to be fully crystallized and grow up, additional energy is not needed, according to the crystallization differentiation principle, the efficiency ratio of crystallization and growth of enrichment phases of metallic oxide is maximized, the dielectric chaining and screening method is adopted for separating ultrafine ore, the process is the physical process, then the dielectric liquid physical method is adopted for carrying out recovering to ensure zero emission of pollutants in the whole process, and useful metallic oxide in the metallurgical slag can be utilized efficiently and environmentally friendly.

Owner:攀枝花市焱乾富慧科技有限公司

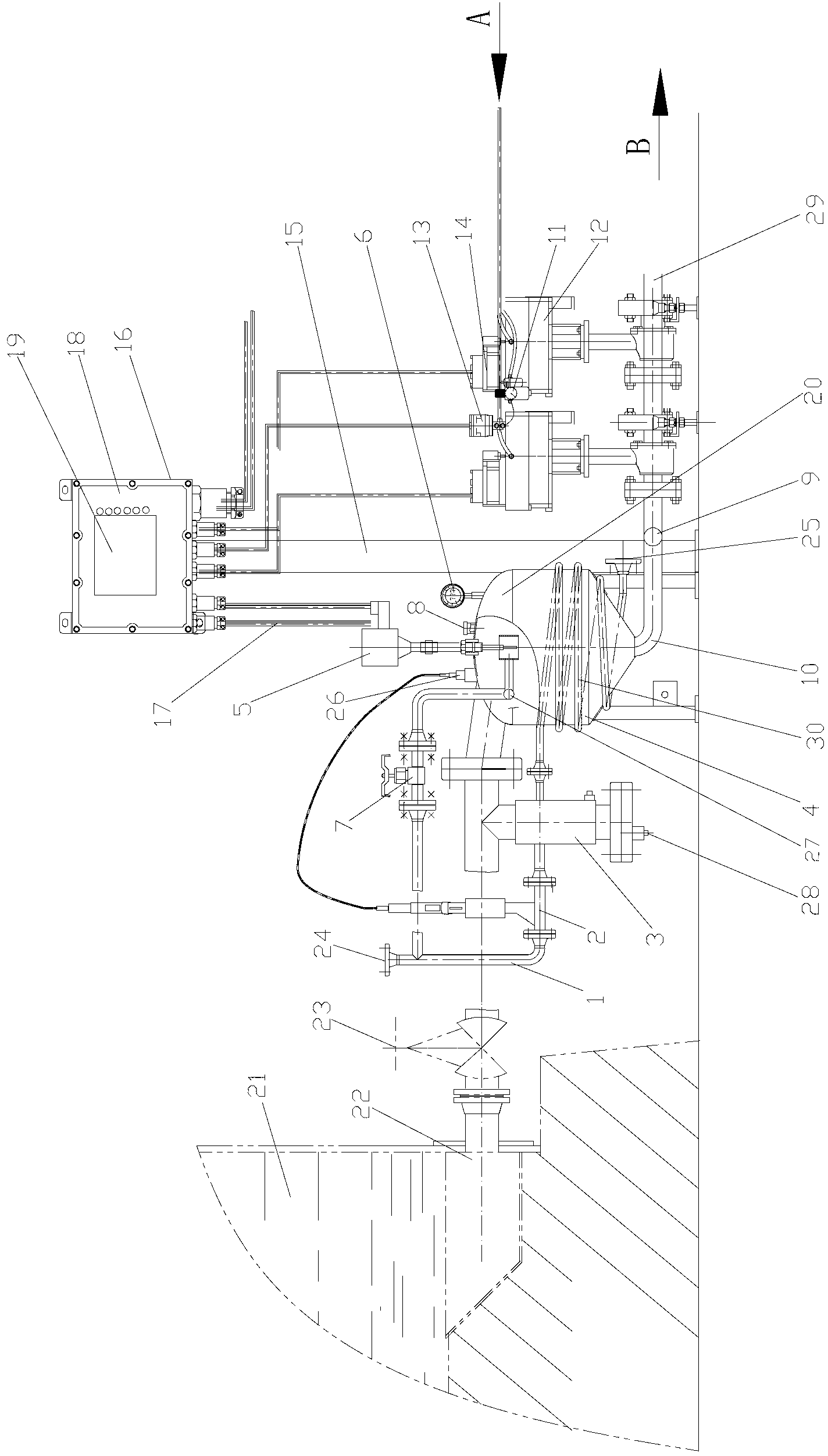

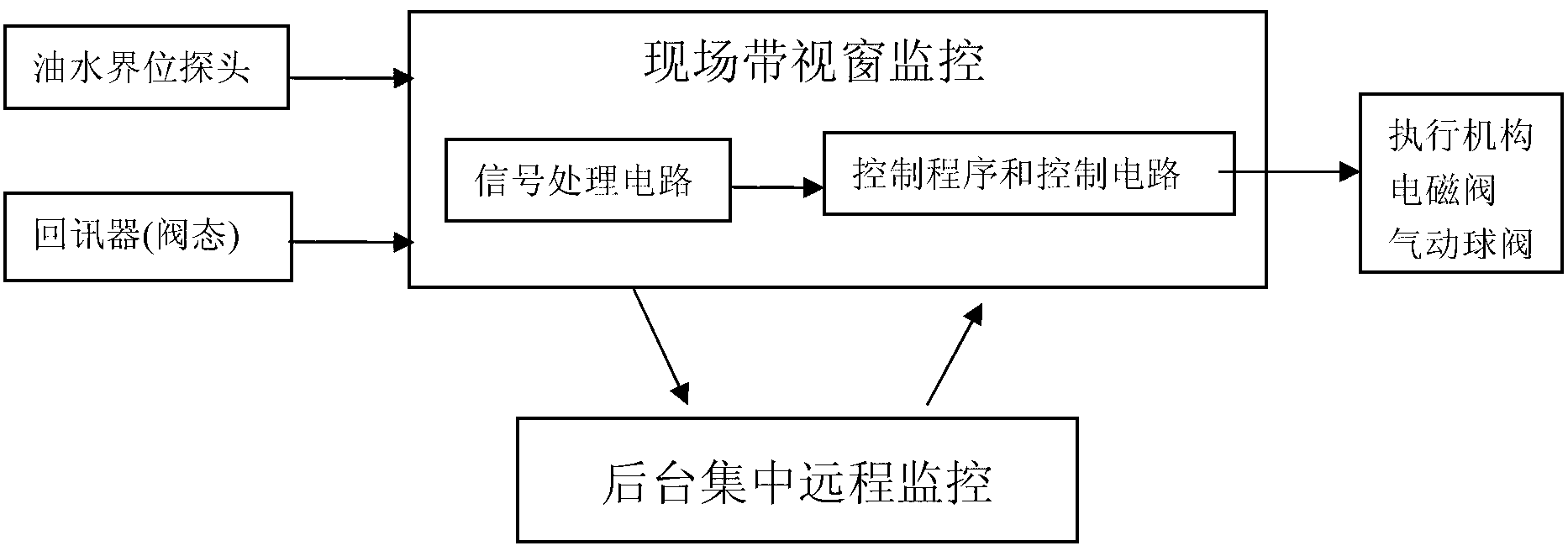

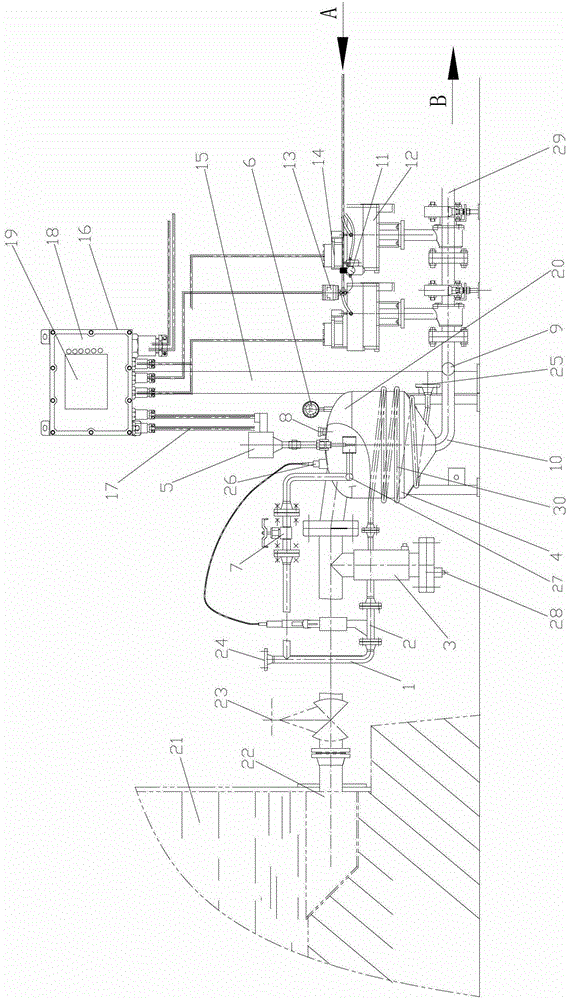

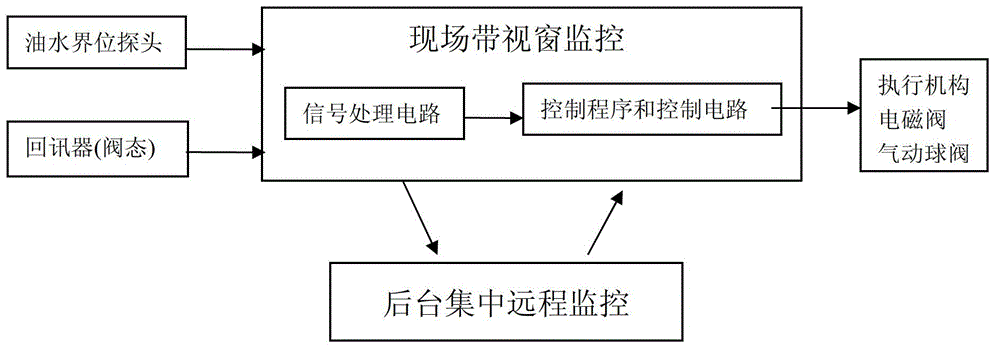

Full-intelligent water draining facility

ActiveCN103279070AGuaranteed zero emissionsCut water safetyTotal factory controlProgramme total factory controlEngineeringPetrochemical

The invention discloses a full-intelligent water draining facility, which consists of an on-site mechanical water draining device, an on-site monitor with a window, and a backstage centralized monitoring system, and is characterized in that improvement measures that a liquid inlet pipe connected with a T-type filter on the upper part of a buffer tank forms an included angle of 8 degree with the horizontal, the T-type filter and the buffer tank are wound with heating coils and the like are taken on the on-site mechanical water draining device; a main control panel circuit of the on-site monitor with the window comprises a power module, a 16-bit microprocessor chip, a universal serial bus (USB) interface circuit, an indicator light, a button and the like; and the backstage centralized monitoring system comprises an active (passive) RS-485 optoelectronic isolation repeater, an industrial grade four-channel RS485 intelligent expander, an active industrial grade RS-232-RS485 bidirectional converter, an industrial personal computer, water draining machine monitoring software and the like. The full-intelligent water draining facility integrates the advantages of the mechanical water draining device and an advanced electronic information technology, and realizes the automation in a tank station of a petrochemical system intelligently, safely and reliably.

Owner:湖北万安环保石化设备有限公司

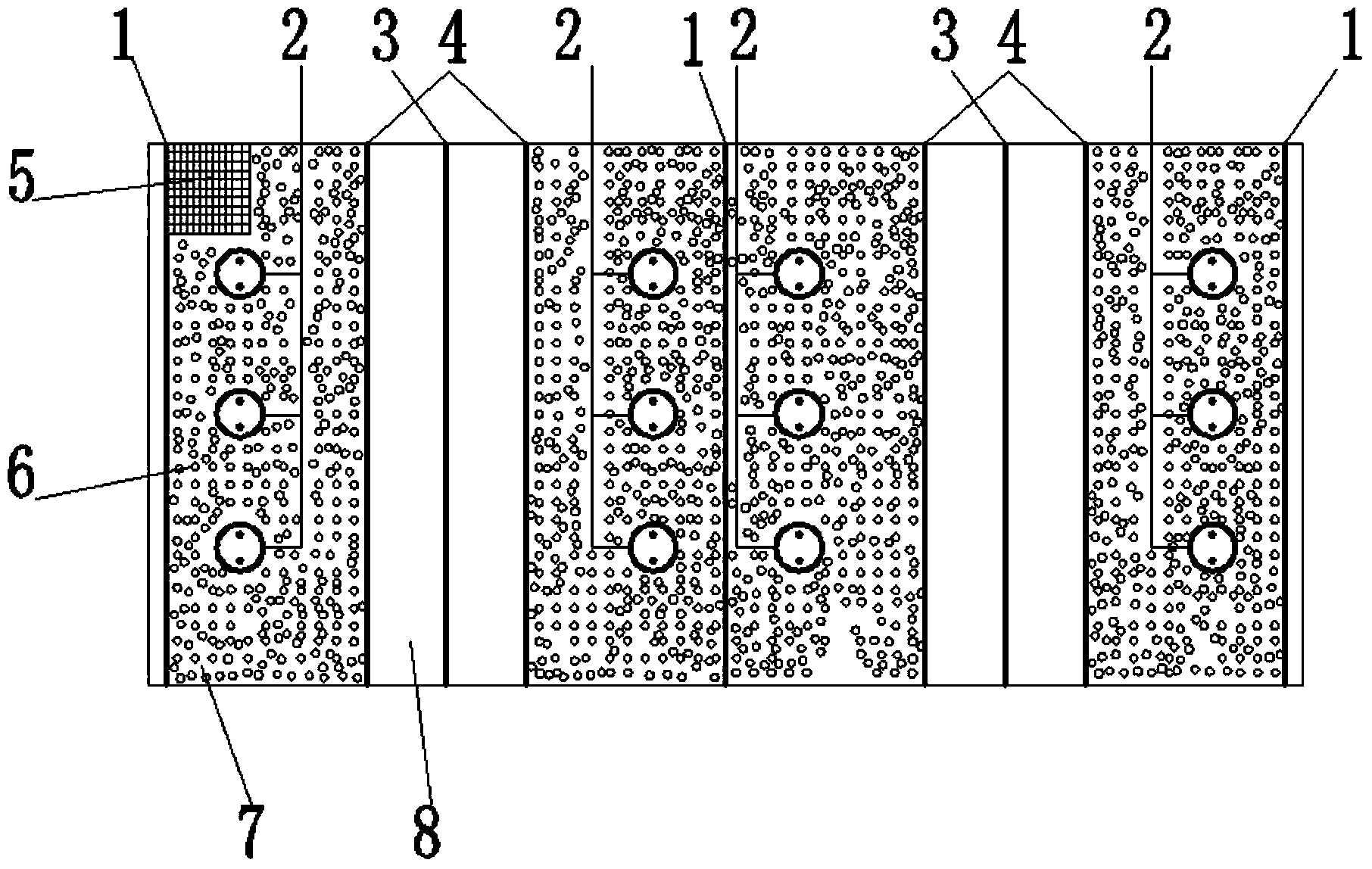

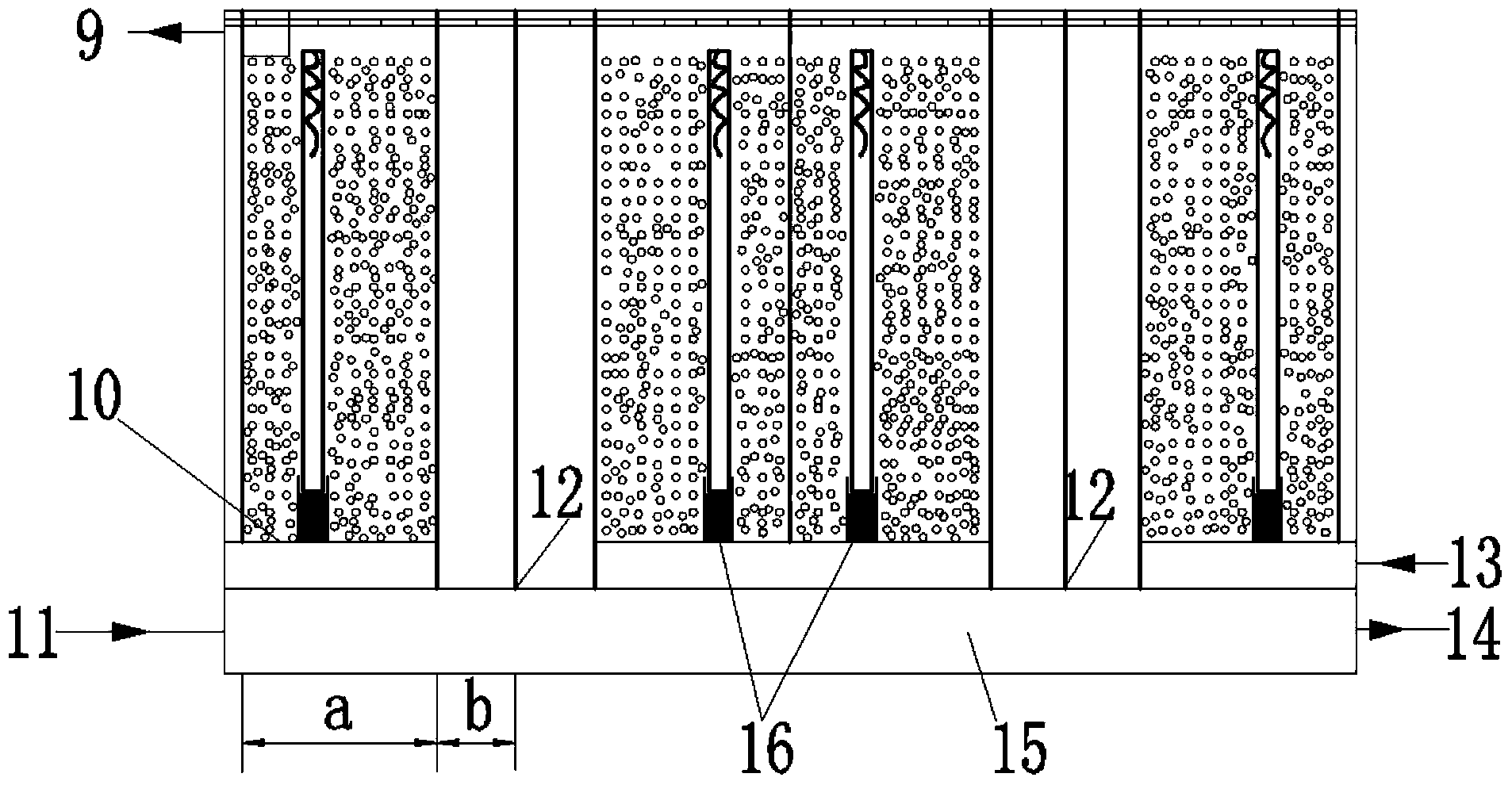

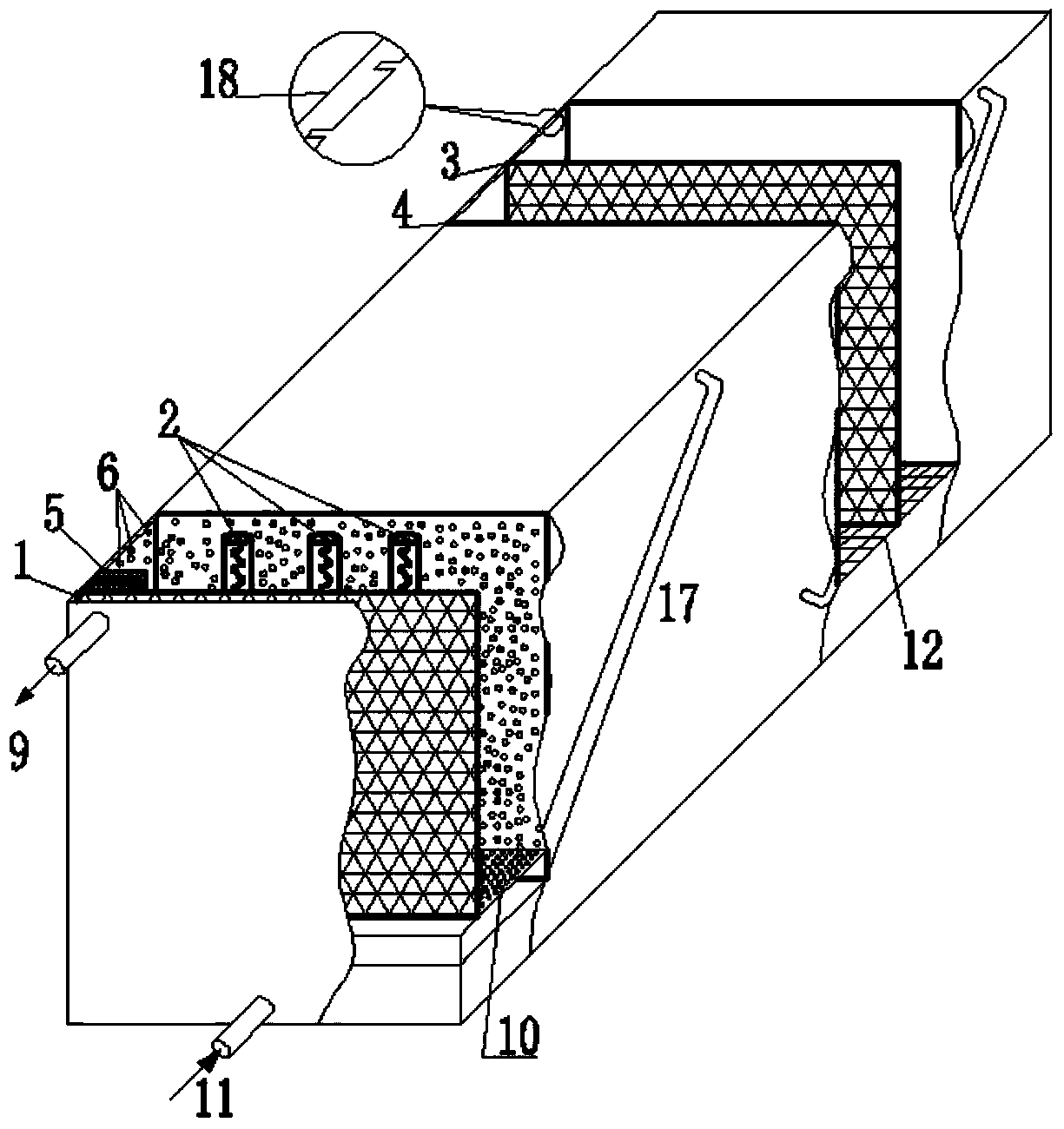

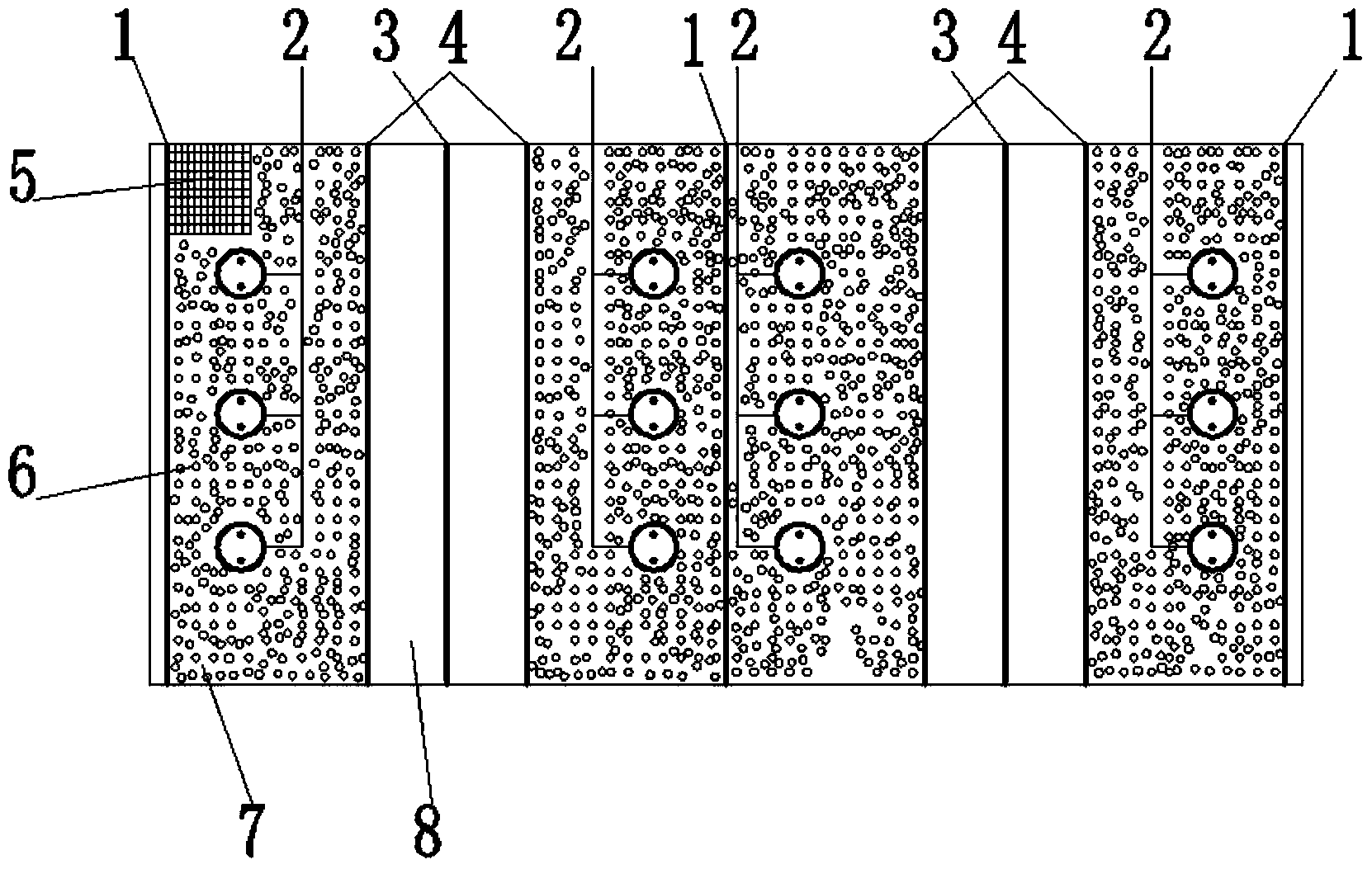

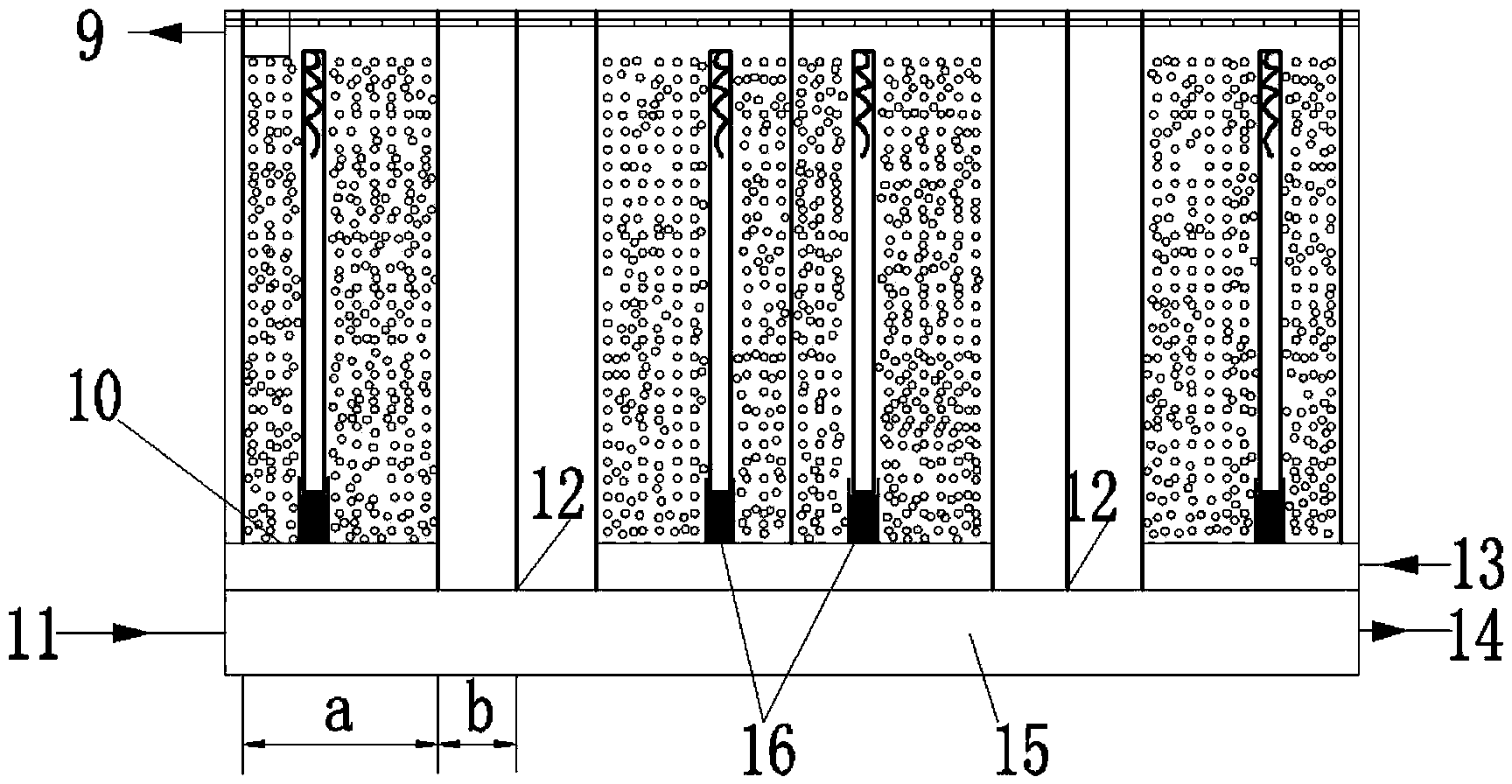

Micro-series-wound photoelectric catalysis oxidation wastewater treatment device

ActiveCN103449564AImprove efficiencyReduce energy consumptionWater/sewage treatment by irradiationWater/sewage treatment using germicide/oligodynamic-processChemistryLight source

The invention provides a micro-series-wound photoelectric catalysis oxidation wastewater treatment device which is characterized by consisting of a plurality of cathode chambers and anode chambers separated by anion selective permeable membranes, wherein the anion selective permeable membranes are located between the cathode plates and the anode plates. The device is internally divided into a plurality of cathode chambers and anode chambers sequentially arranged. A plurality of light sources are arranged inside each anode chamber which is filled with a photoelectric catalyst. The anode chambers are main chambers for wastewater treatment, and adjacent anode chambers are connected through the anode plate, so that all anode chambers in the device are in a micro-series-wound state. Each cathode chamber is filled with a cathode plate anti-scaling liquid, and bottoms of all cathode chambers are intercommunicated. The micro-series-wound photoelectric catalysis oxidation device provided by the invention not only can improve the photoelectric treatment efficiency, but also can effectively solve the problem that the light sources and the plates are hardened when high hardness wastewater is treated, so that frequent cleaning is avoided, and long-term stable operation of the device is guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Efficient energy-saving comprehensive water treatment equipment

InactiveCN108495824AGuaranteed COD valueImprove emission standardsTreatment involving filtrationTreatment with anaerobic digestion processesWater dischargeIndustrial waste water

The invention discloses efficient energy-saving comprehensive water treatment equipment which comprises a domestic sewage pretreatment module, an industrial wastewater pretreatment module and a mixingtreatment module, wherein the domestic sewage treatment module comprises a grid well, an oil separation tank, a comprehensive regulation tank, an anaerobic tank, an oxidation tank and a sedimentationtank; the industrial wastewater pretreatment module comprises a grit chamber, an adjusting tank, a coagulation tank, a flocculation tank, an air floatation tank and a sludge concentration tank; the mixing treatment module comprises a middle water tank, a sand filtration tank, a carban filtration tank, an ultrafiltration device and a reverse osmosis device, wherein the sedimentation tank is communicated with the middle water tank; the anaerobic tank, the oxidation tank and the sedimentation tank are respectively communicated with the sludge concentration tank through a sludge pipeline; the ultrafiltration device and the concentration water tank are respectively communicated with the adjusting tank through a concentrated water return pipeline. The equipment is used for treating industrial wastewater and domestic sewage generated in the production process at the same time. The water treatment efficiency and the water discharge standard rate are improved, the enterprise water treatment cost is reduced, and the method is economical and practical.

Owner:SUZHOU RONGNENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

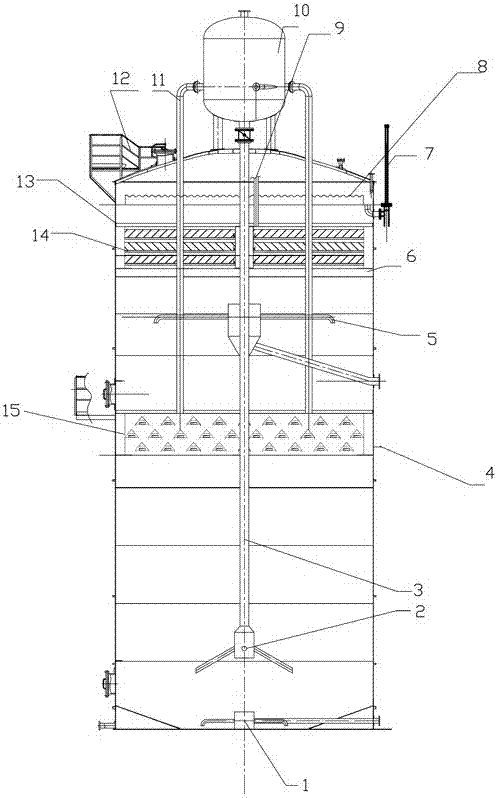

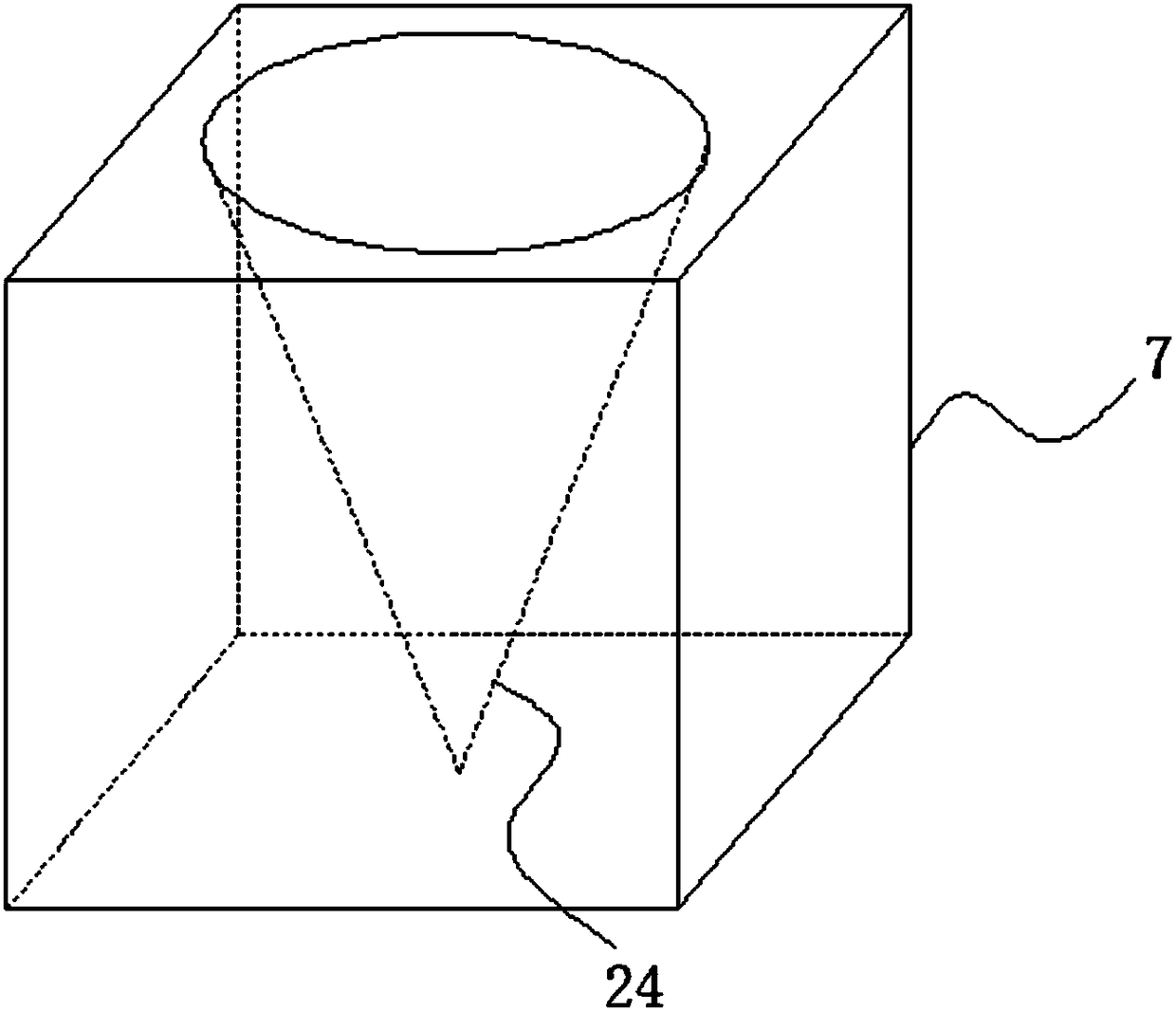

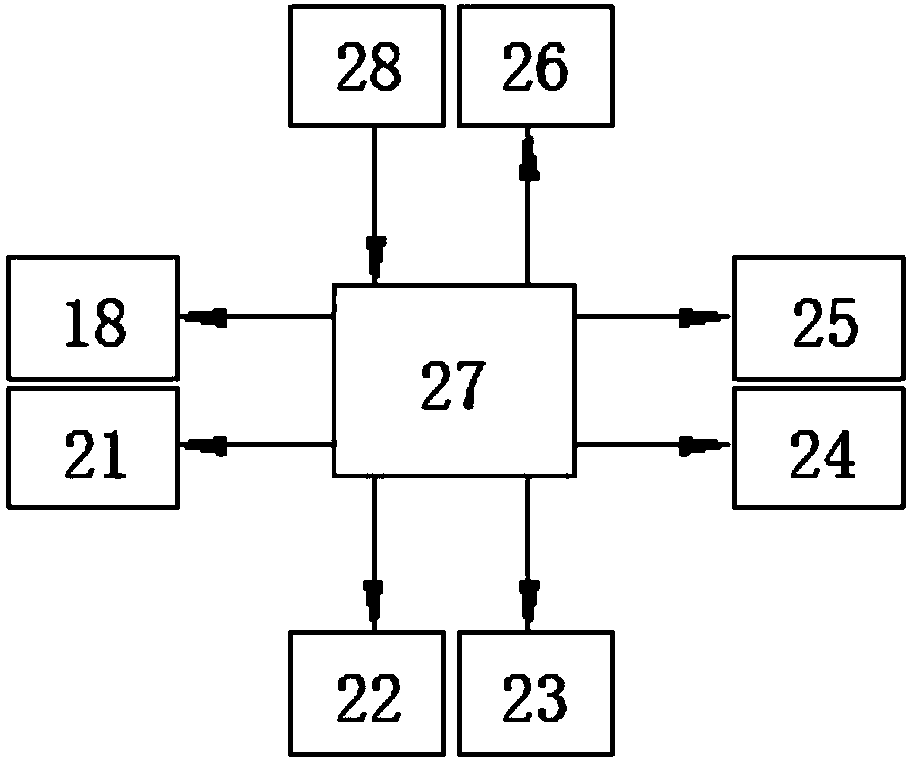

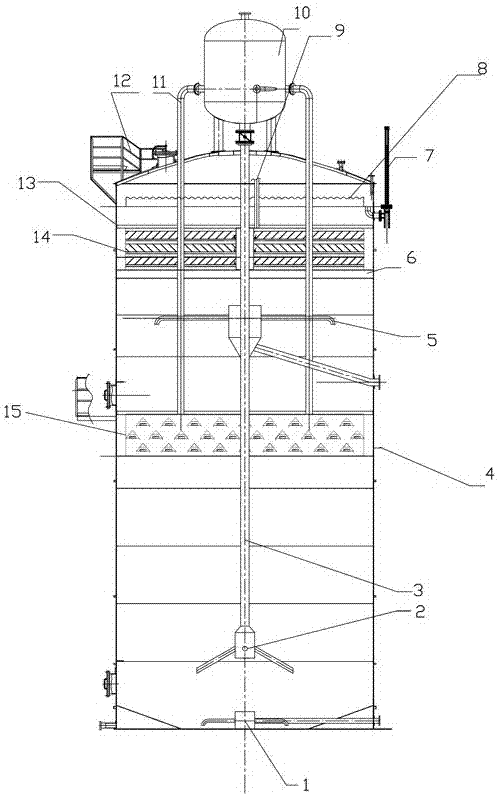

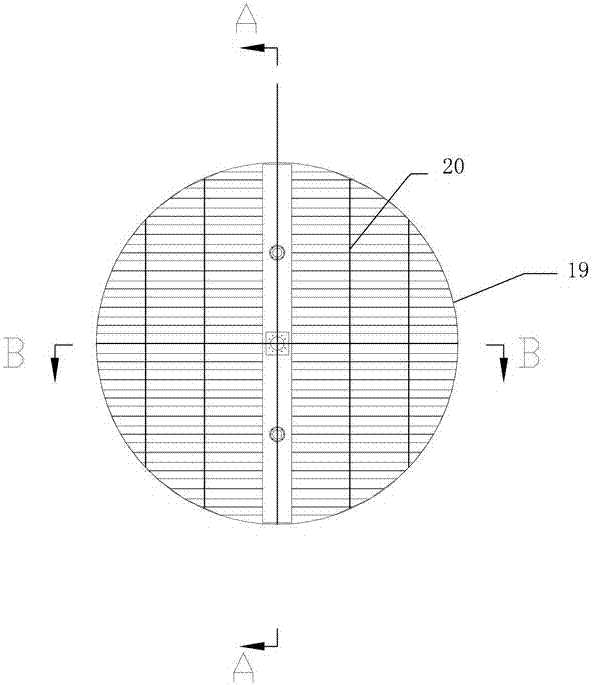

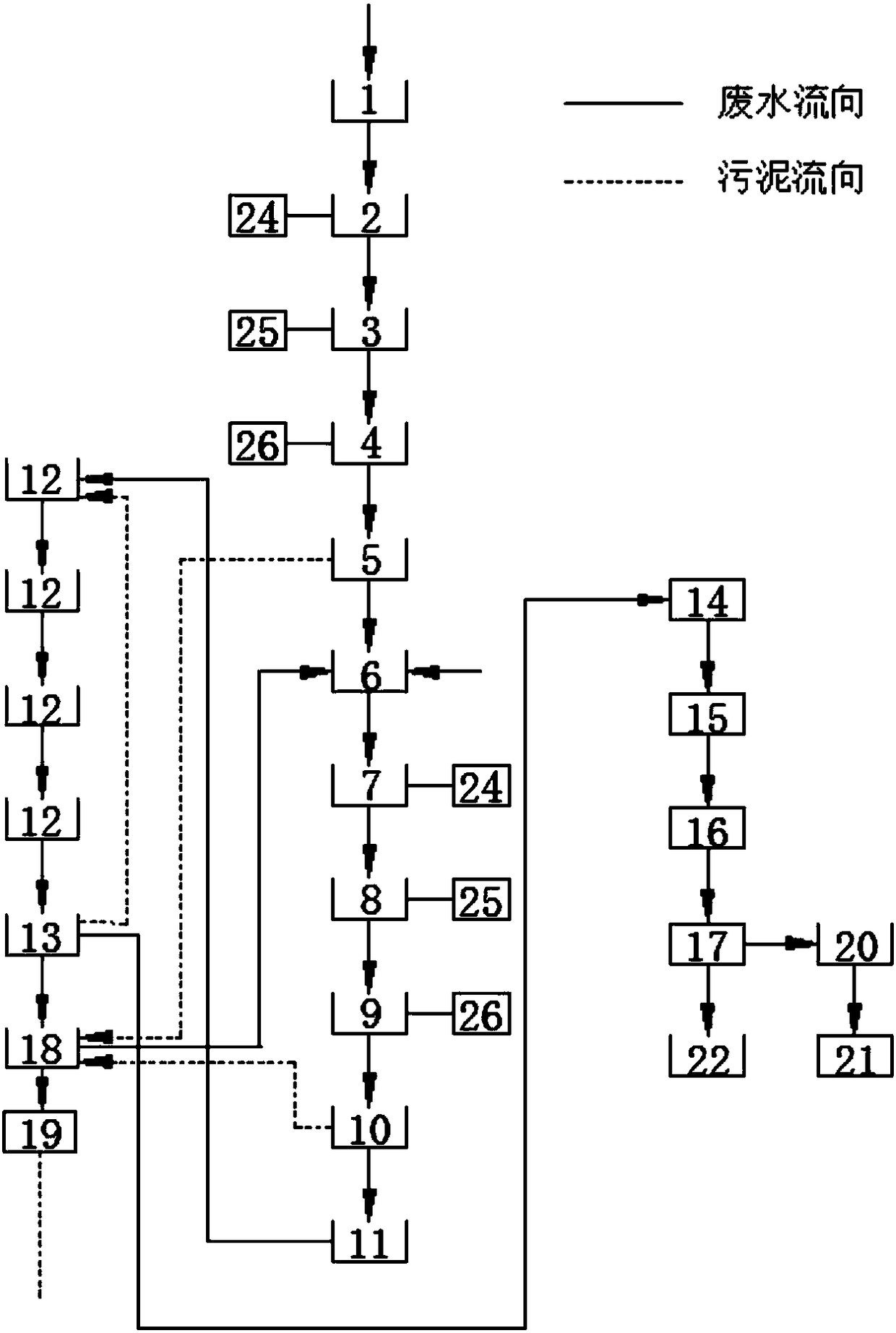

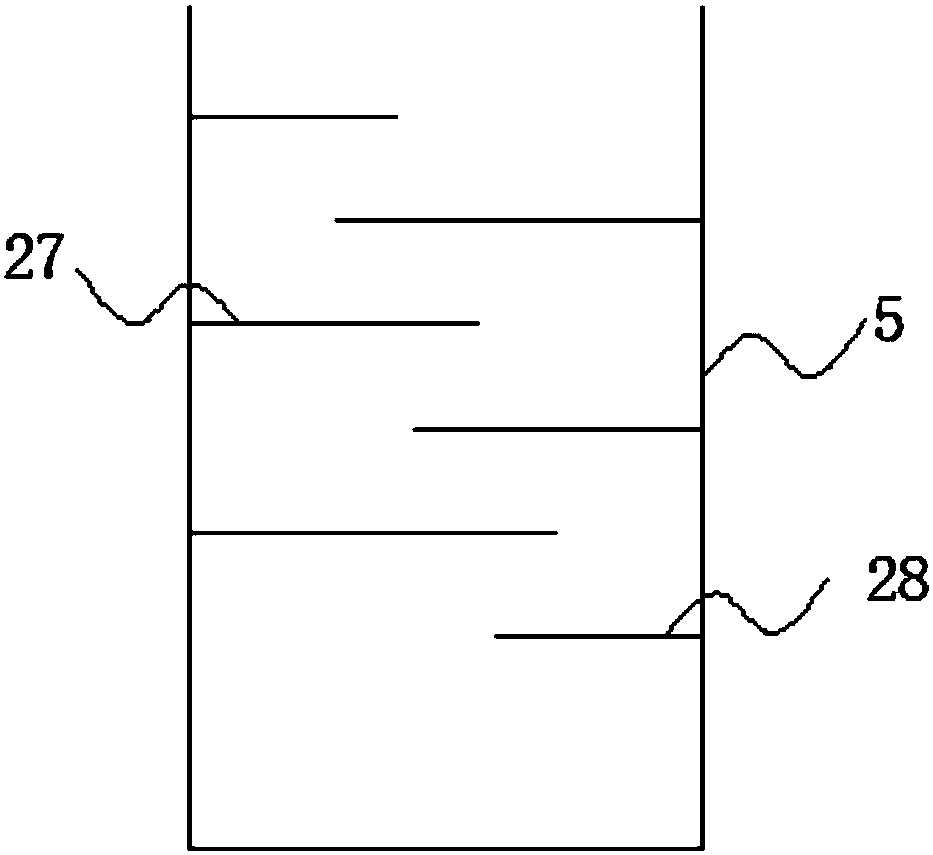

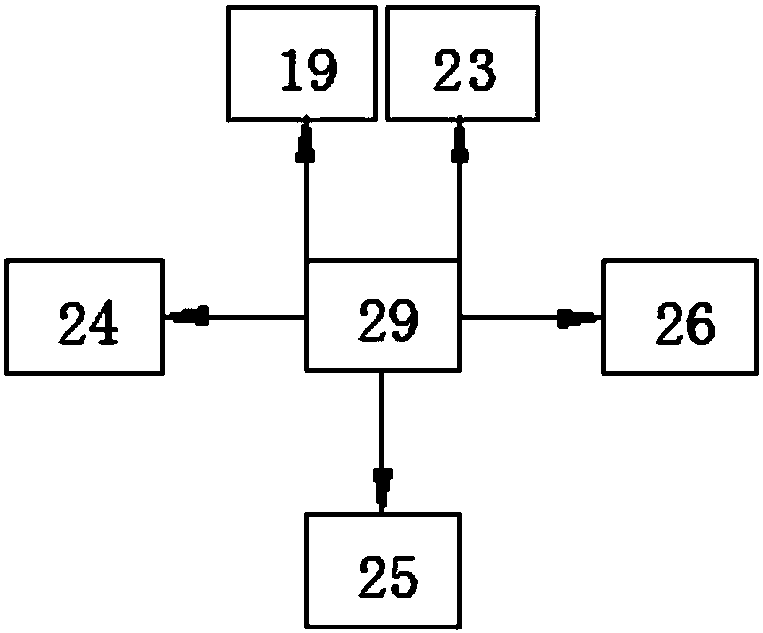

Percolate treating system for garbage incineration power plant

InactiveCN107244782AIncrease water production rateGuaranteed normal consumptionWaste based fuelTreatment with anaerobic digestion processesRefluxPower station

The invention discloses a percolate treating system for a garbage incineration power plant. The percolate treating system comprises an adjusting tank, a medium temperature tank, an anaerobic reactor and a two-stage denitrification / nitrification system. The percolate treating system is characterized by further comprising a sand basin and a filtering system; the sand basin, the adjusting tank, the medium temperature tank, the anaerobic reactor, the two-stage denitrification / nitrification system and the filtering system are sequentially connected through pipelines; the filtering system comprises an outer tubular ultrafiltration membrane system; the sand basin, the anaerobic reactor and the outer tubular ultrafiltration membrane system are connected with a sludge storage tank through pipelines; the sludge storage tank is connected with a sludge dewatering system, a reflux pipeline is arranged between the sludge dewatering system and the adjusting tank, liquid out of the sludge dewatering system can return to the adjusting tank. A water yield of the percolate treating system of the garbage incineration power plant disclosed by the invention is improved, residual concentrated liquid can be completely consumed in the garbage incineration power plant, and the concentrated liquid is prevented from being emitted and seriously polluting environment.

Owner:佛山市银禾工业设计有限公司

Intelligent tail gas photooxygenation pyrolysis device using cavitation liquid technology

PendingCN108014595AEasy to handleImprove processing efficiencyGas treatmentDispersed particle filtrationLiquid wasteMicrocontroller

The invention discloses an intelligent tail gas photooxygenation pyrolysis device using a cavitation liquid technology. A cavitation liquid waste gas washing device is connected with an oil gas purifying electric field device through an air pipe. The oil gas purifying electric field device is connected with a photooxygenation pyrolysis cabinet through an air pipe. A waste gas concentration detecting sensor is installed at the inlet of the photooxygenation pyrolysis cabinet. A certain number of high-energy ultraviolet lamp group modules are installed in the photooxygenation pyrolysis cabinet atcertain intervals. A single-chip microcomputer control system is installed in an intelligent control cabinet. An induced draft fan is installed at the air outlet of the photooxygenation pyrolysis cabinet, and the air outlet of the negative pressure type induced draft fan is connected into a dry method smoke comprehensive processing tank. The single-chip microcomputer control system can control the combined switching on and switching off of the lamp group modules according to information fed back by the waste gas concentration detecting sensor. Energy-saving efficient running of the whole system can be achieved, the service life of the lamp group modules is prolonged, the organic waste gas processing effect is improved, a secondary pollution problem caused by a traditional wet method process is avoided, and super-clean emission is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

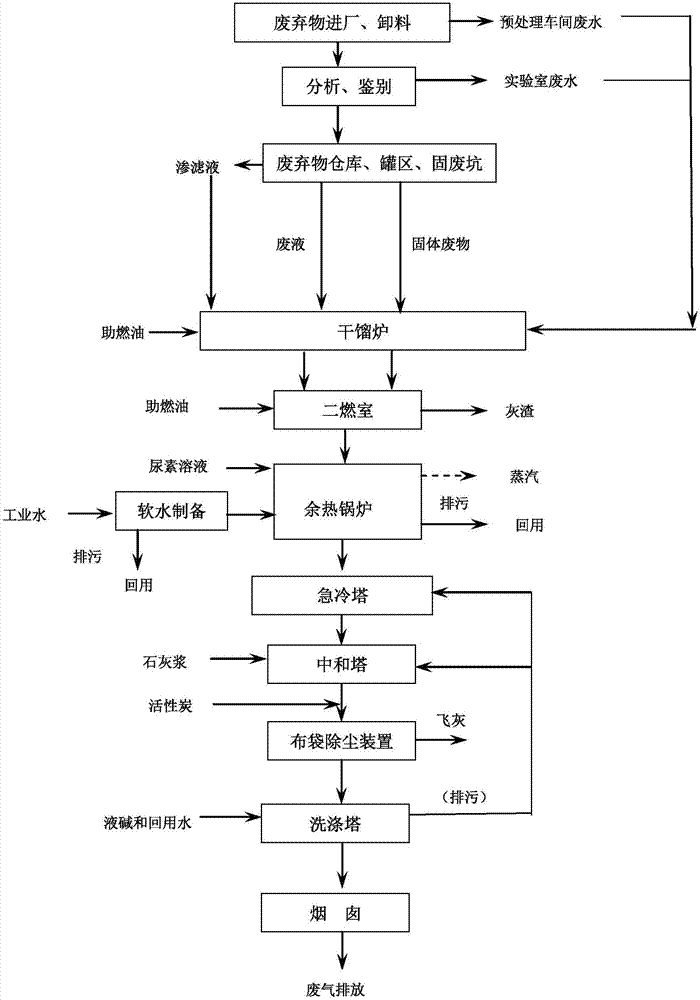

Explosion-proof incineration treatment system for solid waste

PendingCN107246613AAvoid mass productionGuaranteed uptimeIncinerator apparatusCombustion chamberDust control

The invention relates to an explosion-proof incineration treatment system for solid waste. The explosion-proof incineration treatment system for the solid waste comprises solid waste smashing devices, a waste feeding device, a dry distillation device, a secondary combustion chamber, a waste heat boiler, a quenching tower, a neutralizing tower, a cloth-bag dust control device, a washing tower and a chimney which are connected in sequence, wherein the dry distillation furnace and the waste heat boiler are both connected with a water softening device, the washing tower is connected with an alkaline liquor pool, the neutralizing tower is connected with a lime slurry pool, the smoke outlet end of the chimney is connected with one input end of one mixing device, the other input end of the mixing device is connected with a nitrogen storage tank, and the output end of the mixing device is connected with the solid waste smashing devices through smoke return pipelines.

Owner:无锡绿麦环保科技有限公司

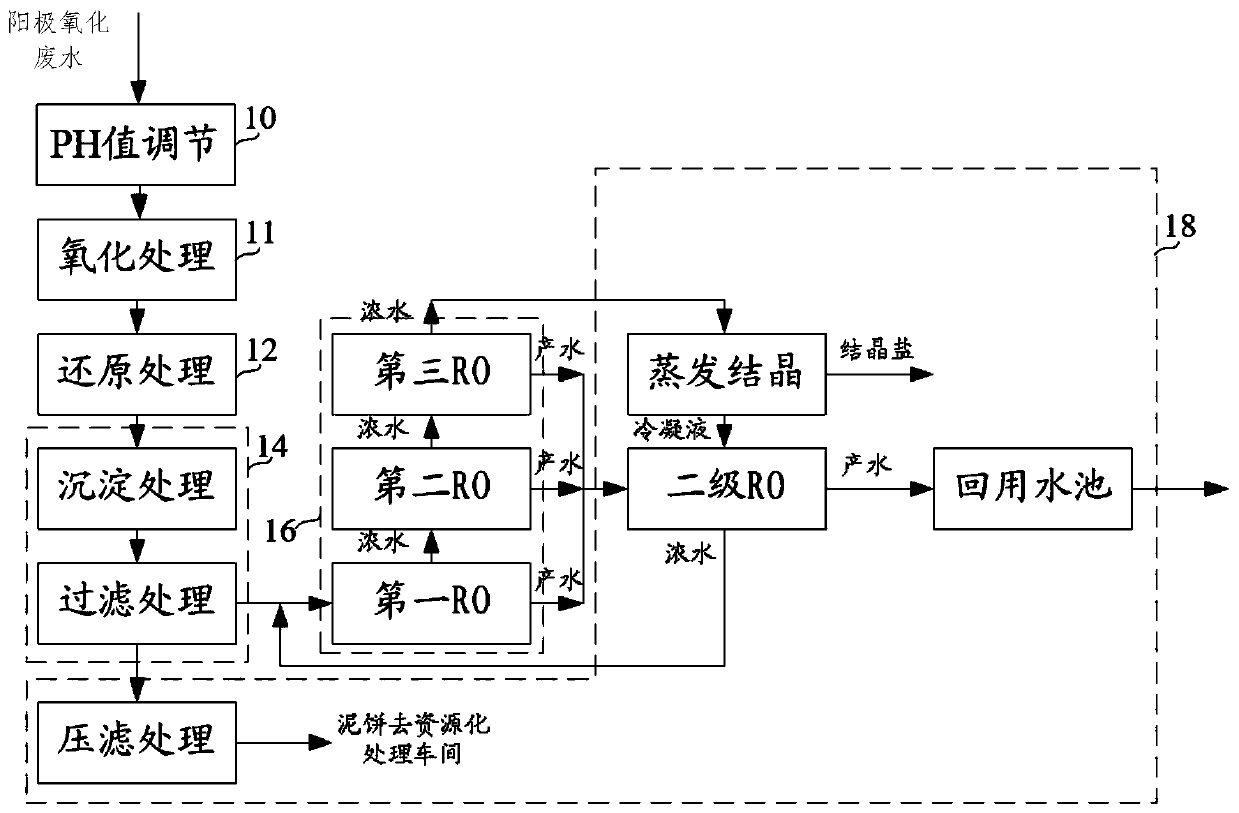

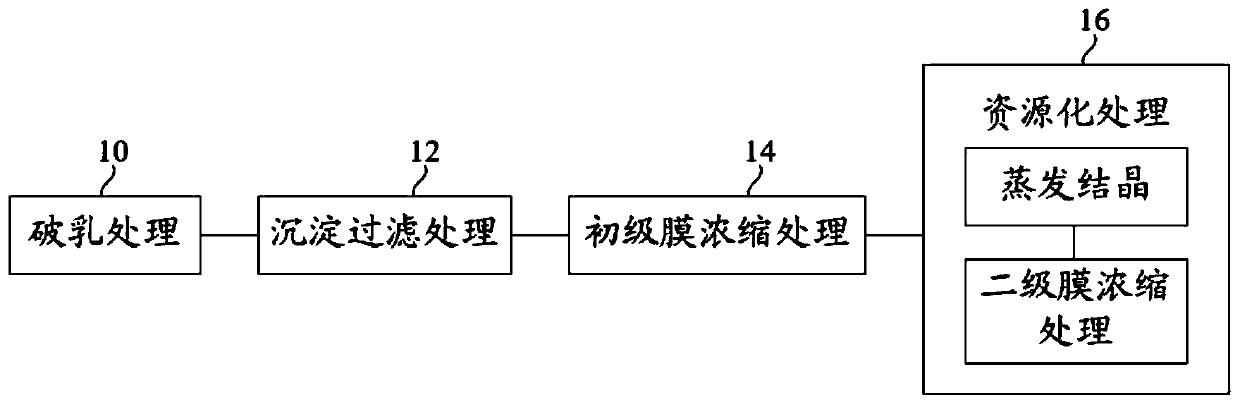

Electroplating wastewater recycling treatment method

InactiveCN110921978AIncrease profitGuaranteed zero emissionsTreatment involving filtrationWaste water treatment from metallurgical processDemulsifierFiltration

An electroplating wastewater recycling treatment method provided by the invention comprises the following steps: demulsification treatment, namely, adding a demulsifier into collected electroplating wastewater in each workshop to remove emulsified oil and floating oil in the electroplating wastewater; precipitation and filtration treatment, namely, adjusting the pH value of the demulsified electroplating wastewater to an alkaline condition; primary membrane concentration treatment, namely, enabling the pretreated wastewater to enter primary reverse osmosis membrane treatment equipment to remove soluble pollutants in the wastewater so as to obtain primary produced water and a primary concentrated solution, the primary produced water entering a produced water mixing tank, and the primary concentrated solution entering a membrane concentrated solution storage tank; and recycling treatment, namely, enabling the primary concentrated solution to enter an evaporative crystallization system tobe subjected to evaporative crystallization treatment to obtain crystalline salt and condensate, mixing the condensate with the primary produced water, carrying out secondary membrane concentration treatment to obtain secondary produced water and a secondary concentrated solution, refluxing the secondary concentrated solution to the primary membrane concentration treatment, and recycling the secondary produced water.

Owner:四川美峰环境治理有限责任公司

Clean production method of 3-chloropropyltrialkoxysilane

ActiveCN104086582AGuarantee product qualityIncrease the rate of esterification reactionGroup 4/14 element organic compoundsAlcoholHigh energy

The invention discloses a clean production method of 3-chloropropyltrialkoxysilane, which aims to solve the technical problems of complex procedure, low efficiency, complex equipment, high energy consumption and high recovery cost in the existing 3-chloropropyltrialkoxysilane production. The method comprises the following steps: a. gasifying alcohol, and delivering into an esterification reaction tower via a booster pump; b. controlling the atmospheric pressure in the esterification reaction tower at 0.15-1 Mpa, and keeping the temperature in the esterification reaction tower at 100-200 DEG C; c. delivering 3-chloropropyltrichlorosilane into the esterification reaction tower, and controlling the mole ratio of the alcohol to the 3-chloropropyltrichlorosilane in the esterification reaction tower at 3.1-10; and d. after the esterification reaction is carried out for 50-80 minutes, detecting the 3-chloropropyltrichlorosilane content in the crude product by using a gas phase chromatograph, finishing the reaction when the content is lower than 0.1%, and carrying out rectification separation treatment on the crude product. The method can enhance the esterification reaction rate and reduce the production procedures, thereby avoiding the discharge of hydrogen chloride and being an environment-friendly closed-cycle production technique.

Owner:江西晨光新材料股份有限公司

Treatment method of chlorine-containing wastewater in rare earth smelting technical process

PendingCN109574174ATo achieve the purpose of dechlorinationRealize closed loopWater contaminantsWater/sewage treatmentSodium bicarbonateEvaporation

The invention discloses a treatment method of chlorine-containing wastewater in a rare earth smelting technical process. The method comprises the following steps of firstly converting the chlorine-containing wastewater generated in the rare earth smelting process into a sodium chloride-containing solution through adding lime and sodium sulfate, then, adding hydrochloric acid used in the rare earthsmelting technical process or introducing a HCl gas into the sodium chloride-containing solution, by utilizing a common ion effect generated by a chlorine ion, impelling sodium chloride in an obtained mixture to precipitate and separate out, or adding sodium carbonate or / and sodium hydrogen carbonate, by utilizing the common ion effect generated by a sodium ion, impelling the sodium chloride in an another obtained mixture to precipitate and separate out, and filtering to obtain a sodium chloride crystal. Without evaporation concentration, chlorine in the chlorine-containing wastewater can beseparated. The method has the advantages of being clean, environment-friendly, economical and efficient, and the like, and is suitable for the industrial application of the treatment of the chlorine-containing wastewater in the rare earth smelting technical process.

Owner:CENT SOUTH UNIV +1

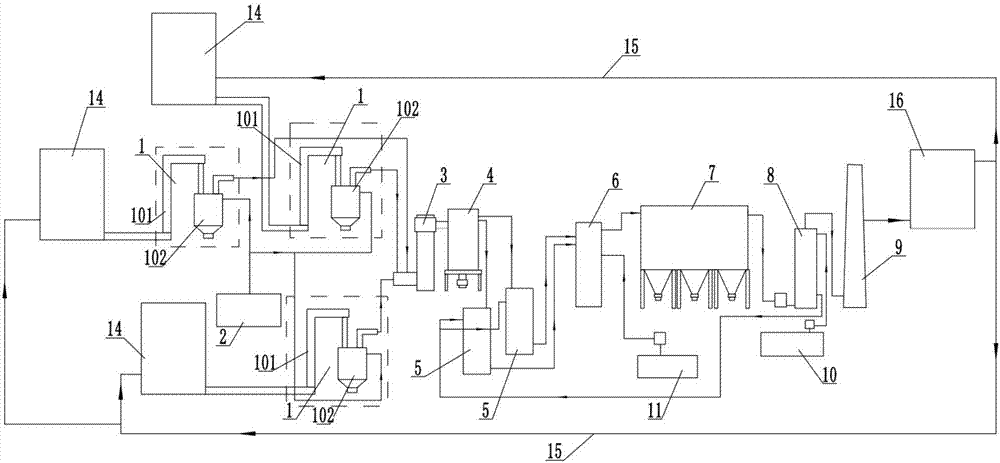

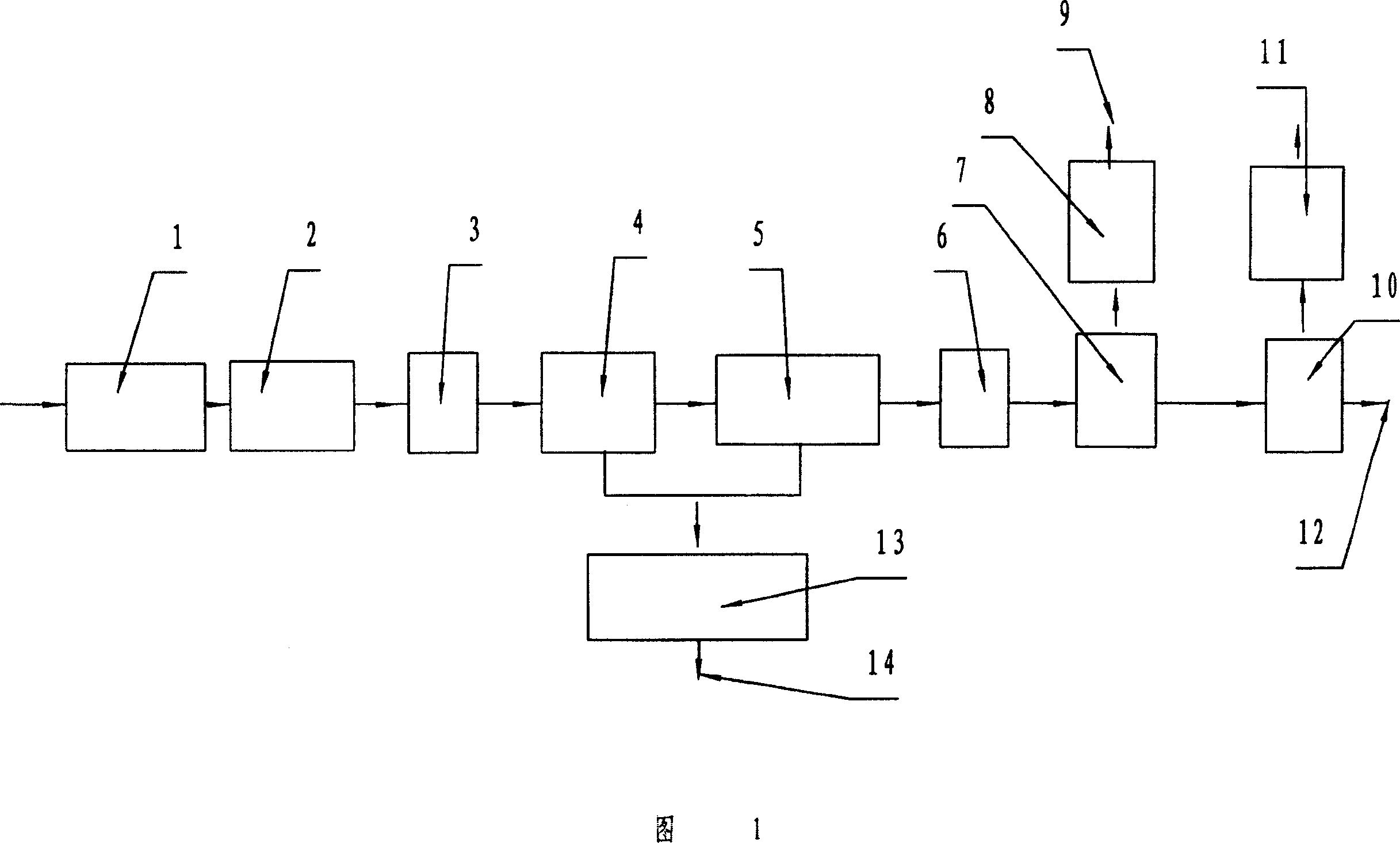

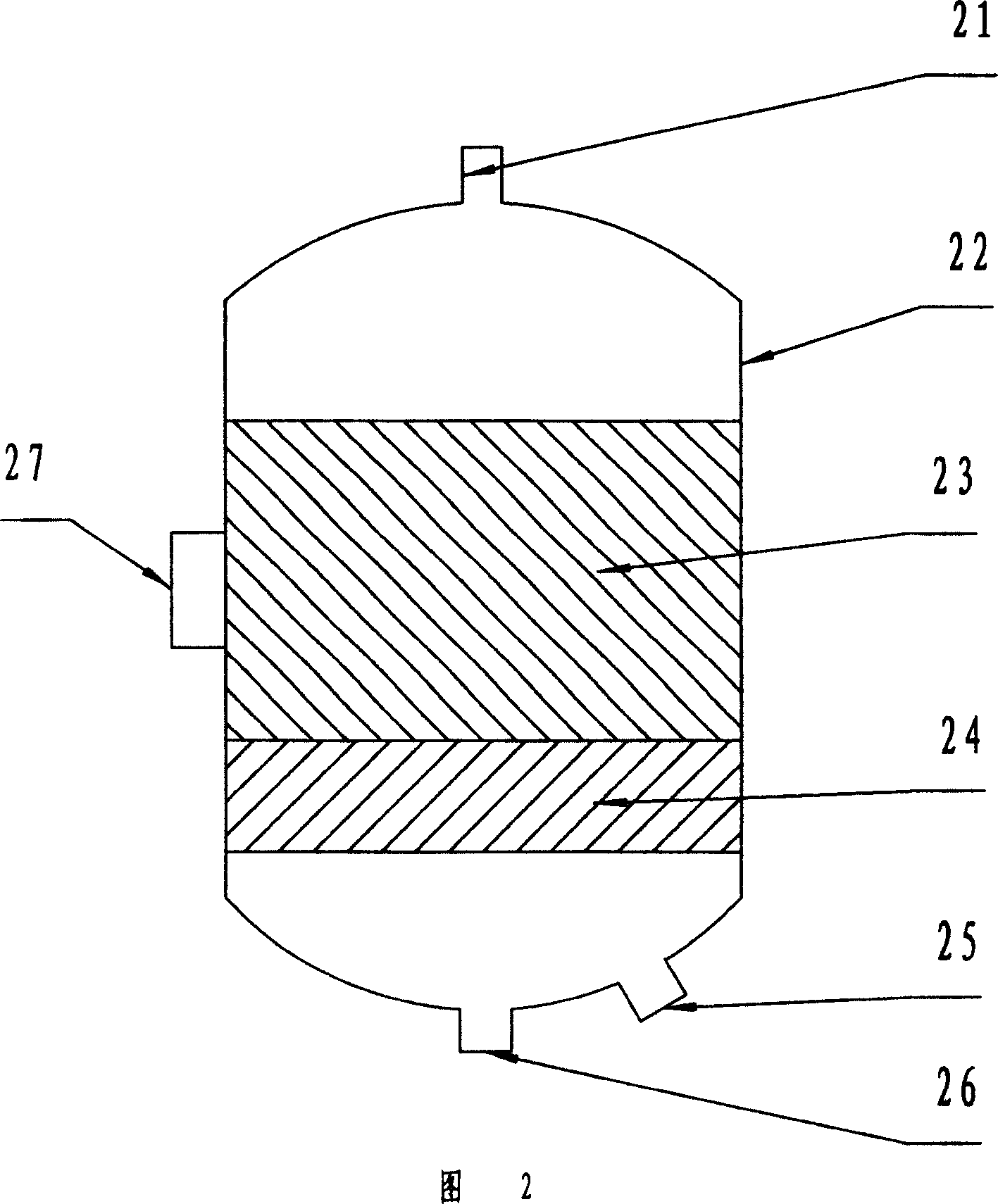

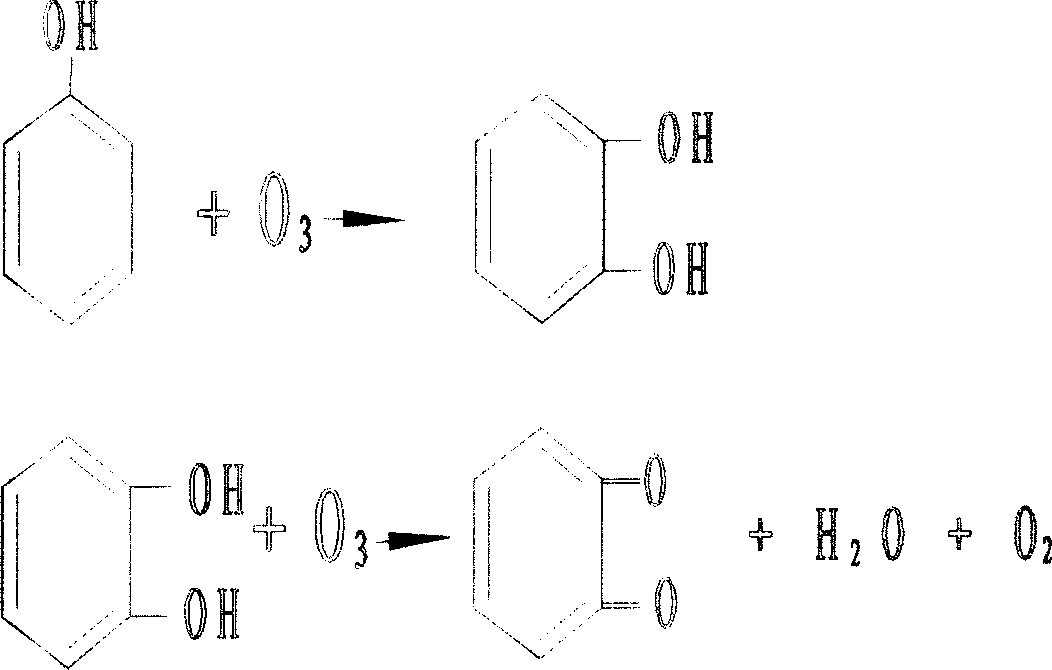

Process for treating coking waste water containing phenol and cyanogen by physical chemistry method and special device therefor

ActiveCN100348519CSimple structureEasy to handleFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWater useChemical treatment

The invention discloses a treatment technology and special equipment of carbonizing phenolic cyanogen waste water by physicochemical method, belonging to the processing technique of waste-water or sewage water, especially the waste-water multistep treatment technique which containing one chemical processing step at least. The technological process of this treatment technology is: air-float de-oiling-ferrum coagulate desulfuration and decyanation-coke adsorption filtration desorption floating precipitate-desorption and stripping NH3-N-ozone oxidation stripping hydroxybenzene and organic matter, the dealed waste-water used as make-up water of coke quenching and coal washing. The treatment technology and special equipment of carbonizing phenolic cyanogen waste water by physicochemical method of this invention has fewer invest and fine dealing effect than traditional treatment scheme, the available resources of waste-water such as tar, ammonia and so on can be reclaimed and utilized effectively, the dealed waste-water is used to coke quenching to reach the dealed waste-water and discharged, the coke quenching discharged gaseous effluent pollutant can reach criterion, not only is the same with waste water disposal of new coke-oven plant, but also is used to the technical betterment of quondam coke-oven factory's waste water disposal system.

Owner:王登富

Water treatment process system for wet desulfurization, and method thereof

ActiveCN108126507AEfficient use ofAvoid wastingGas treatmentDispersed particle separationFlueProcess systems

The invention discloses a water treatment process system for wet desulfurization. The system comprises: a multilayer spray water collector arranged in a desulfurized flue to recover water in flue gas;an evaporative cooling tower, wherein a heat exchange pipeline and a spray pipeline are arranged in the evaporative cooling tower; a first path which communicates the circulating cooling water outletof the desulfurized flue with the heat exchange pipeline inlet of the evaporative cooling tower; a second path which communicates the heat exchange pipeline outlet of the evaporative cooling tower with the circulating cooling water inlet of the desulfurized flue to supply circulating cooling water to the multilayer spray water collector; and a third pass which communicates the wastewater outlet of a wet desulfurization absorption tower with the inlet of the spray pipeline of the evaporative cooling tower. The system can effectively combine the water saving and wastewater treatment effects ofa whole unit, and has a good economical performance and a good market prospect. The invention also provides a water treatment process method for wet desulfurization based on the system.

Owner:FUJIAN LONGKING

Micro-series-wound-internal circulating photoelectric catalysis oxidation wastewater treatment method

ActiveCN103449639AImprove the efficiency of COD degradationReduce processing energy consumptionMultistage water/sewage treatmentOxidative treatmentTemperature and pressure

The invention provides a micro-series-wound-internal circulating photoelectric catalysis oxidation wastewater treatment method which is characterized by comprising the following steps: at normal temperature and pressure, after pretreatment of organic wastewater, wastewater enters into a first anode chamber at the first end of a micro-series-wound photoelectric catalysis oxidation wastewater treatment unit for photoelectric catalysis oxidation treatment; effluent enters into an adjacent anode chamber through an anode communicating pipe for continuous photoelectric catalysis oxidation treatment till the effluent enters into the last anode chamber at the tail end for photoelectric catalysis oxidation treatment so as to obtain treated wastewater, wherein the hydraulic retention time in the whole micro-series-wound photoelectric catalysis oxidation unit device is 0.5-2 hours; gas-liquid separation is carried out on the wastewater after treatment through a micro-series-wound-internal circulating photoelectric catalysis oxidation wastewater treatment post-treatment unit; innocent treatment is carried out on separated tail gases; the effluent separated is discharged with standards. The method provided by the invention can improve the photoelectric treatment efficiency and effectively treat high salinity and high hardness wastewater, and further can effectively solve the problem that the light sources and the plates are hardened when high hardness wastewater is treated.

Owner:CHINA NAT OFFSHORE OIL CORP +2

System and process for realizing zero discharge of gas and steam in iron and steel plants by adopting seawater desalination

ActiveCN102502903BImprove utilization efficiencyGuaranteed zero emissionsGeneral water supply conservationSeawater treatmentEnergy conservationSecondary Energy Resource

The invention discloses a system and a process for realizing zero discharge of gas and steam in iron and steel plants by adopting seawater desalination, which belongs to the technical field of secondary energy comprehensive utilization in iron and steel plants, and particularly relates to converting gas and steam into water resource through low-temperature and multiple-effect seawater desalination. The system comprises a blast furnace gas holder, a coke oven gas holder, a converter gas holder, a gas distributing and pressurizing system, a pure combustion / blending combustion gas station boiler, a steam turbine, an industrial boiler, a steam pipe network, a complementary-energy waste-heat recovery device, a temperature and pressure reduction device, a TVC (thermal vapor compressor) device and an MED (multi-effect distillation) device. Residual gas which can not be consumed in production process of the iron and steel plants is used for a pure combustion / blending combustion gas boiler and / or the industrial boiler, and steam is produced through combustion, which is used in preparing desalinated water through the MED device with steam recovered in the iron and steel plants on the premise of reasonable classification. Compared with the prior art, the system and the process can ultimately recover gas and steam in the iron and steel plants, have good economic effects, and are applicable to the energy conservation and emission reduction of coastal iron and steel plants.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

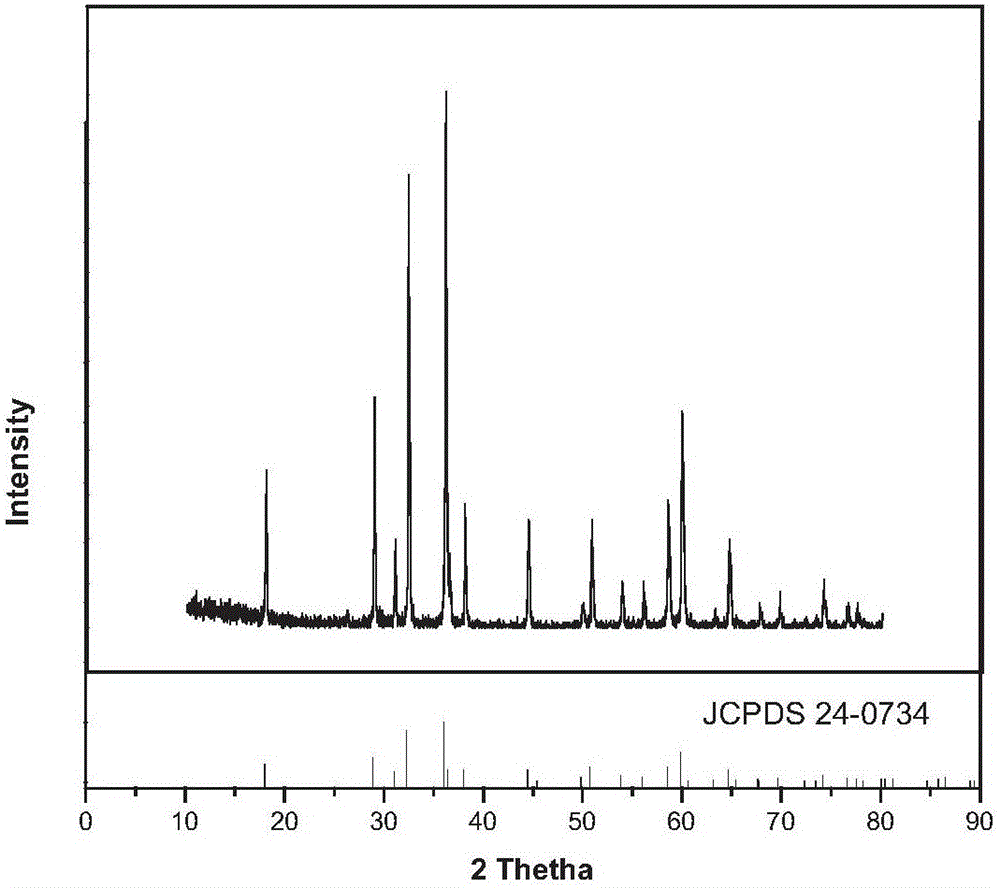

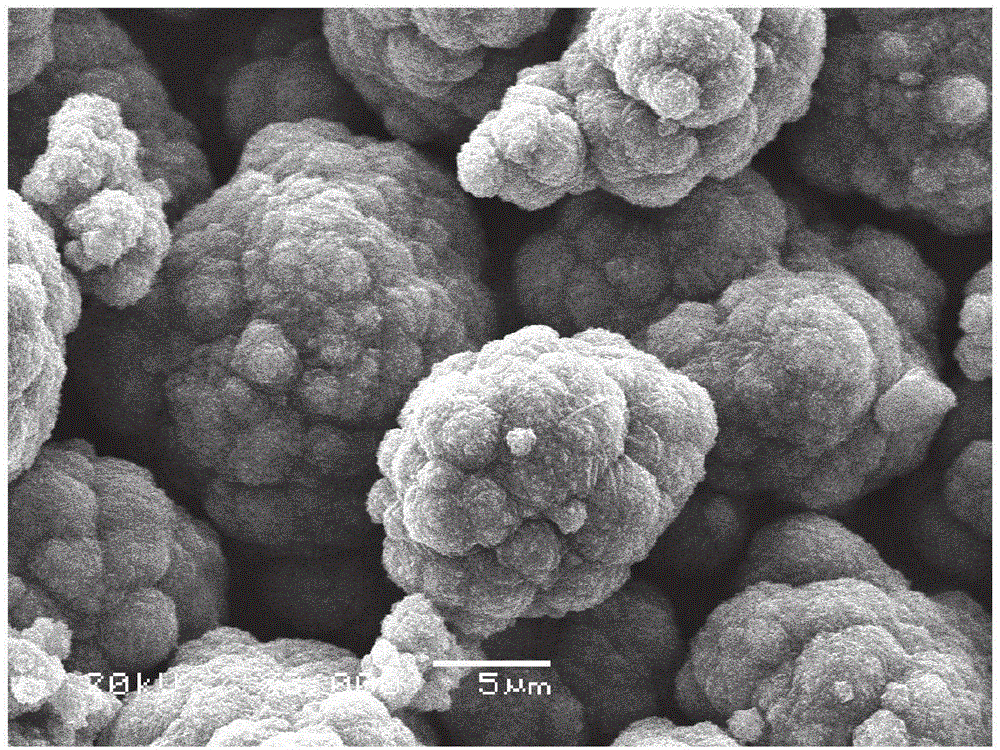

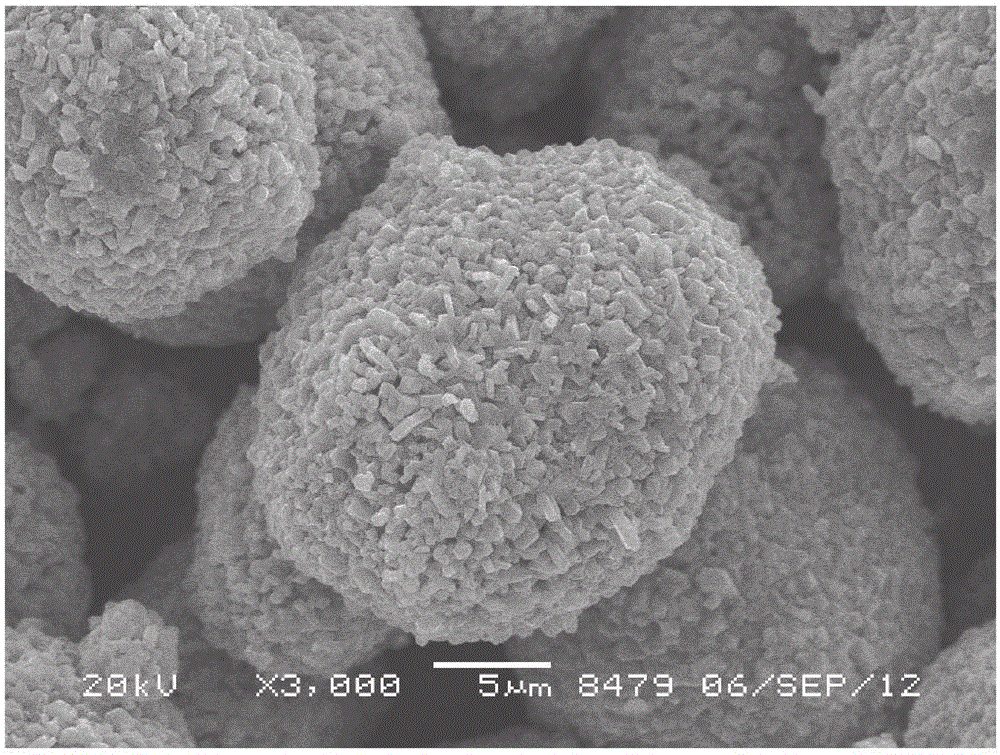

Trimanganese tetraoxide, as well as preparation method and application thereof

ActiveCN105948130AReduce contentParticle regularityCell electrodesSecondary cellsDecompositionParticle-size distribution

The invention discloses a preparation method for trimanganese tetraoxide. The preparation method comprises the following steps: pumping a manganese sulfate solution into a disc granulator, performing crystallization decomposition and rotary granulation under radiation of microwave irradiation, and washing and drying granules obtained by granulation to obtain the trimanganese tetraoxide, wherein the temperature of the microwave irradiation is 900 to 1,200 DEG C; the rotating speed of a disc of the disc granulator is 10 to 30r / min. In addition, the invention further discloses application of the trimanganese tetraoxide prepared by the preparation method to preparation of a cathode material. According to the preparation method and the application, crystallization and granulation are performed under the synergistic action of a rotating parameter of the disc granulator and the microwave radiation, so that preparation of the trimanganese tetraoxide with high purity, large specific gravity and uniform granularity distribution is facilitated, and problems about treatment of ammonium salt wastewater produced by an existing universal process of preparing trimanganese tetraoxide by virtue of a wet manganese sulfate oxidization method are solved; the method is short in process flow, easy to control and suitable for industrial production.

Owner:HUNAN MENGDA NEW ENERGY MATERIALS CO LTD

Environment-friendly mixed wastewater treatment system

InactiveCN108495823AImprove emission standardsGuaranteed zero emissionsSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesFlocculationHigh concentration

The invention discloses an environment-friendly mixed wastewater treatment system, the system comprises a water collecting tank, a first reaction tank, a first coagulation tank, a first flocculation tank. a first sedimentation tank, a comprehensive regulation tank, a second reaction tank, a second coagulation tank, a second flocculation tank, a second sedimentation tank, a middle pool, at least one biochemical pool and a third sedimentation tank, a high-concentration wastewater inlet is arranged on the water collecting tank, and a low-concentration wastewater inlet is arranged on the comprehensive regulation tank; a plurality of upper water fenders are arranged on one side of the first sedimentation tank, one side of the second sedimentation tank and one side of the third sedimentation tank from top to bottom, a plurality of lower water fenders are arranged on the other side of the first sedimentation tank, the other side of the second sedimentation tank and the other side of the thirdsedimentation tank from top to bottom, and the upper water fenders and the lower water fenders are staggered mutually. According to the invention, the system centrally treats high-concentration wastewater and low-concentration wastewater, the structure of the system is simplified, the energy consumption is low, the treatment effect is good, and the system is easy to generalize and implement.

Owner:SUZHOU RONGNENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

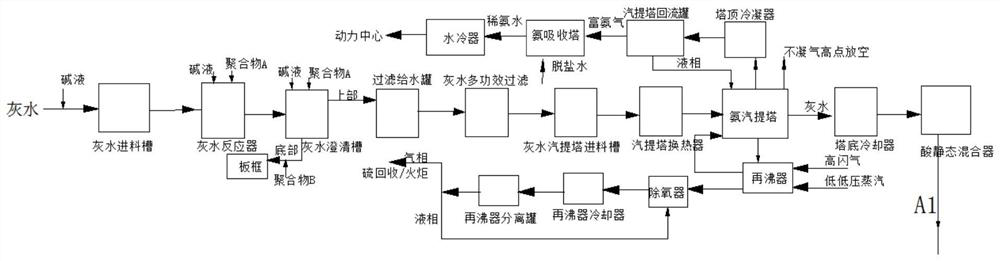

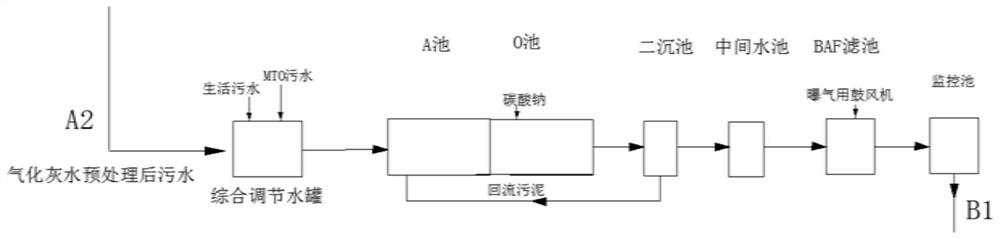

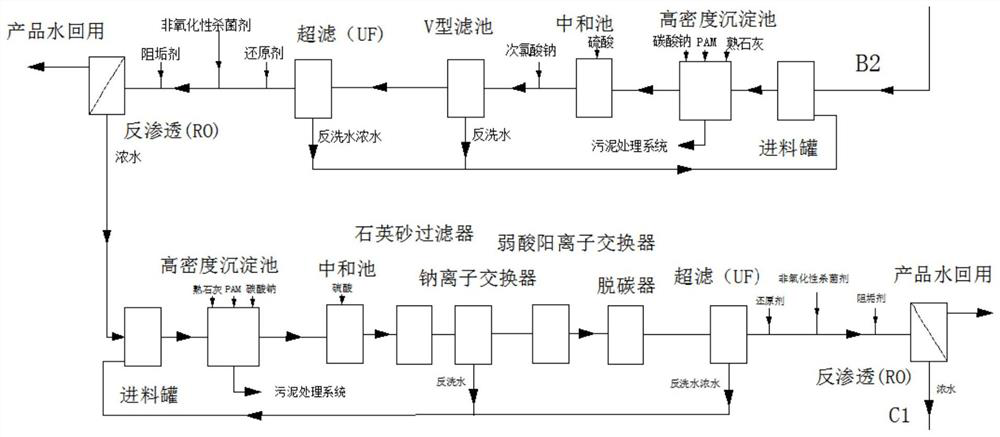

Treatment method of gasification wastewater of coal chemical industry

InactiveCN111620517AGuaranteed zero emissionsEasy to handleTreatment involving filtrationSulfate/bisulfate preparationAmmoniacal nitrogenProcess engineering

Owner:CHINA SHENHUA COAL TO LIQUID & CHEM CO LTD +1

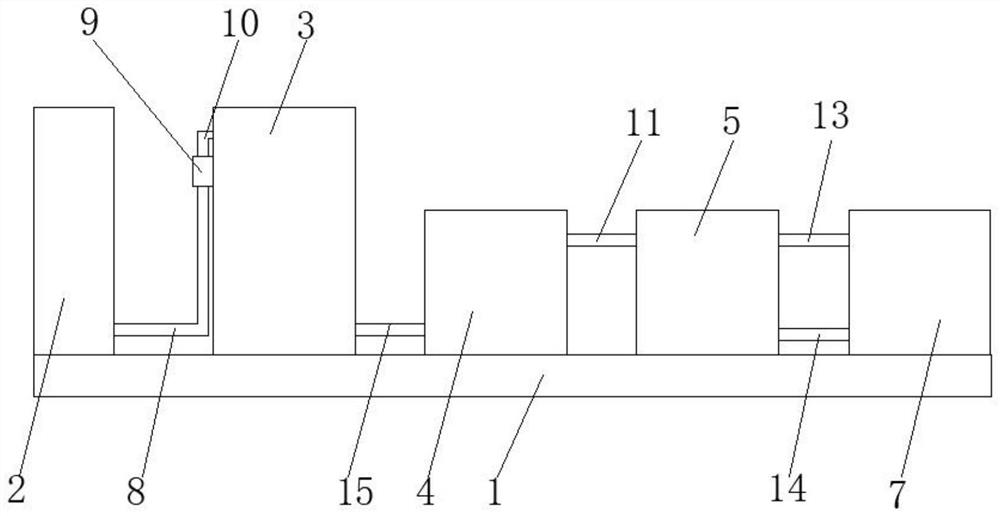

Sewage-zero-discharge process equipment

InactiveCN111606522AEasy to handleImprove processing efficiencyTreatment using aerobic processesTreatment involving filtrationProcess equipmentSewage

The invention provides sewage-zero-discharge process equipment, and relates to the field of sewage treatment. The sewage-zero-discharge process equipmentcomprises a base, wherein the upper surface ofthe base is fixedly connected with a sewage tank, a filtering mechanism, a chemical purification tank, an anoxic treatment mechanism, a superoxide treatment mechanism and an adsorption mechanism; theleft side wall of the filtering mechanism is fixedly connected with a pump body, the input end of the pump body is fixedly connected with a first pipeline, the end, away from the pump body, of the first pipeline is fixedly connected with the side wall of the sewage tank; and the output end of the pump body is fixedly connected with a second pipeline. Through multiple filtering chambers of the equipment and a reasonable treatment process, the equipment can treat sewage all the time, the cleaning process of the equipmentis not hindered, the sewage treatment efficiency of the equipment is furthergreatly improved, the purpose of efficient sewage treatment can be achieved, and then the zero-emission environment-friendly effect is achieved.

Owner:北京盈宝泰科环保科技股份有限公司

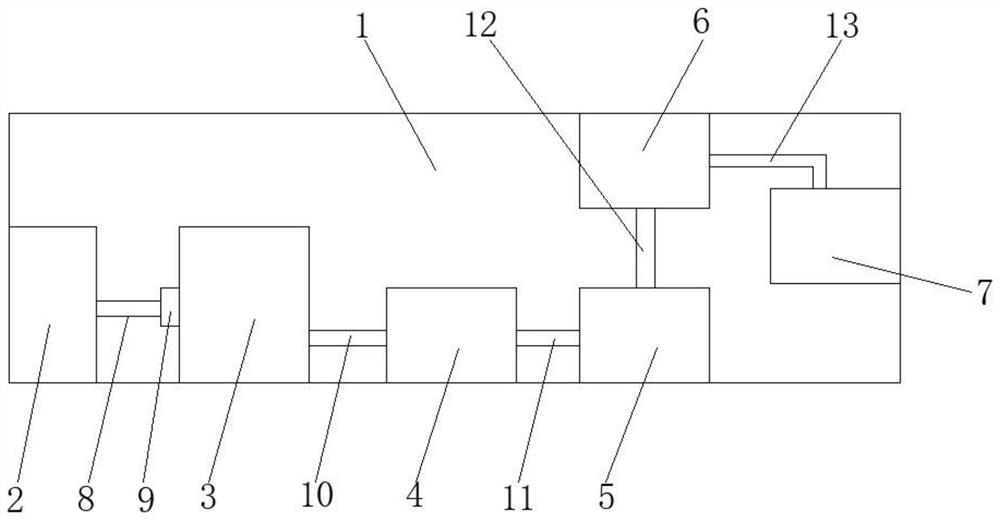

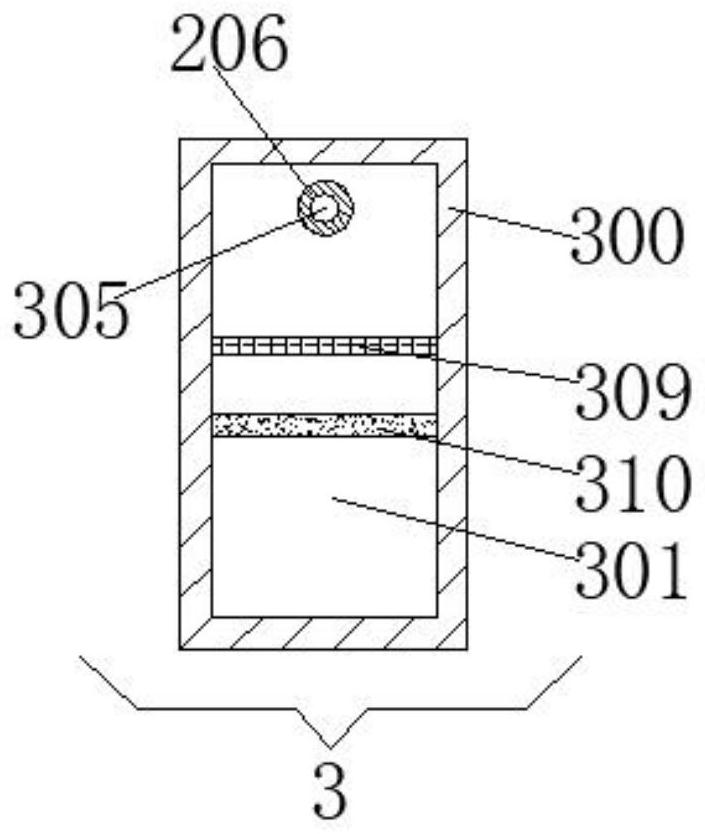

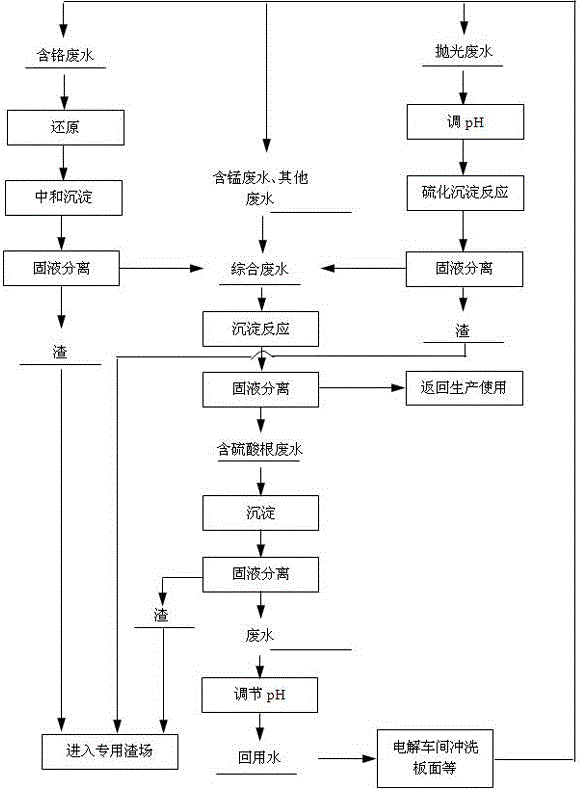

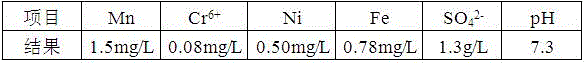

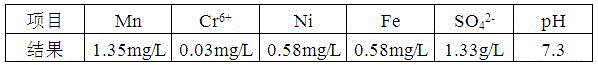

Technique for manganese recycling and comprehensive treatment of waste water and waste gas in electrolytic manganese industrial wastewater

ActiveCN107522324AReduce heavy metal contentEasy to recycleWater contaminantsTreatment involving filtrationSlagManganese

The invention discloses a technique for manganese recycling and comprehensive treatment of waste water and waste gas in electrolytic manganese industrial wastewater. The technique includes steps of disposing chromate wastewater and polishing wastewater; adding reducing agent in the chromate wastewater; reducing Cr6+ to Cr3+; then adding hydroxide to adjust pH, and generating chromic hydroxide sediment; making slag stack at a special slag field after being settled and separated, and making filter fluid enter the manganese wastewater; treating the polishing wastewater; recycling manganese, performing sulfate radical treatment; and others. The technique is segmented in the disposing process, the chromate wastewater and polishing wastewater are treated respectively; the wastewater with heavy metal ion is treated at first, thus the heavy metal content in the manganese carbonate slag is reduced, and the technique is good for recycling the manganese carbonate slag; the main water use in the technical process of the electrolytic manganese production is carried out at the flushing section, and the sulfate radical treatment technique is added to the wastewater treatment, thus the SO42- content is reduced, the sulfate radical is reduced from over 10g / L in the past to about 2g / L; the influence of the sulfate radical on the sulfur containing of the manganese piece in the electrolysis flushing water is reduced greatly.

Owner:GUIZHOU SONGTAO JINRUI MANGANESE INDUSTRY CO LTD

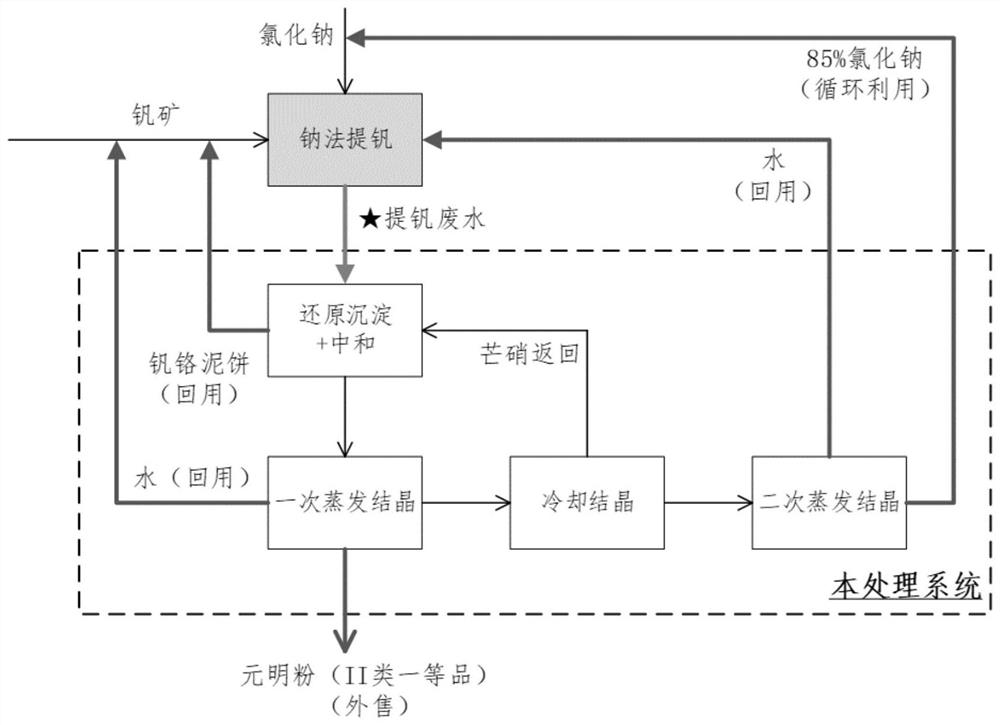

Zero discharge and resource utilization method for vanadium-containing high-salinity wastewater

PendingCN114560587AEasy to handleRealize resourcesWater contaminantsWaste water treatment from metallurgical processReclaimed waterVanadium atom

The invention relates to a method for zero discharge and resource utilization of vanadium-containing high-salinity wastewater, and discloses a method for treating vanadium-containing high-salinity wastewater obtained by sodium-process vanadium extraction, which comprises the following steps: recovering and enriching vanadium ions, chromium ions and other ions through chemical reduction precipitation, and then returning to a sodium-process vanadium extraction process; sodium sulfate and sodium chloride in the salt are separated and recycled through the specific combination of two times of evaporative crystallization and one time of cooling crystallization, evaporation condensate water serves as reclaimed water to be recycled, the separated sodium sulfate can be sold in the form of a sold product, the separated sodium chloride can be returned to the sodium-method vanadium extraction process to be recycled, no impurity salt is discharged, and the method is environmentally friendly. Therefore, efficient green treatment and zero emission of the high-salinity wastewater are realized.

Owner:TIANJIN UNIV +1

Full-intelligent water draining facility

ActiveCN103279070BGuaranteed zero emissionsCut water safetyTotal factory controlProgramme total factory controlEngineeringPetrochemical

The invention discloses a full-intelligent water draining facility, which consists of an on-site mechanical water draining device, an on-site monitor with a window, and a backstage centralized monitoring system, and is characterized in that improvement measures that a liquid inlet pipe connected with a T-type filter on the upper part of a buffer tank forms an included angle of 8 degree with the horizontal, the T-type filter and the buffer tank are wound with heating coils and the like are taken on the on-site mechanical water draining device; a main control panel circuit of the on-site monitor with the window comprises a power module, a 16-bit microprocessor chip, a universal serial bus (USB) interface circuit, an indicator light, a button and the like; and the backstage centralized monitoring system comprises an active (passive) RS-485 optoelectronic isolation repeater, an industrial grade four-channel RS485 intelligent expander, an active industrial grade RS-232-RS485 bidirectional converter, an industrial personal computer, water draining machine monitoring software and the like. The full-intelligent water draining facility integrates the advantages of the mechanical water draining device and an advanced electronic information technology, and realizes the automation in a tank station of a petrochemical system intelligently, safely and reliably.

Owner:湖北万安环保石化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com