Micro-series-wound photoelectric catalysis oxidation wastewater treatment device

A technology for photoelectric catalysis and wastewater oxidation, which is applied in illumination water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. It can solve the problems of ultraviolet light attenuation, electrode life decline, current efficiency decline, etc., and reduce the corrosion rate. , prolong the service life, reduce the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

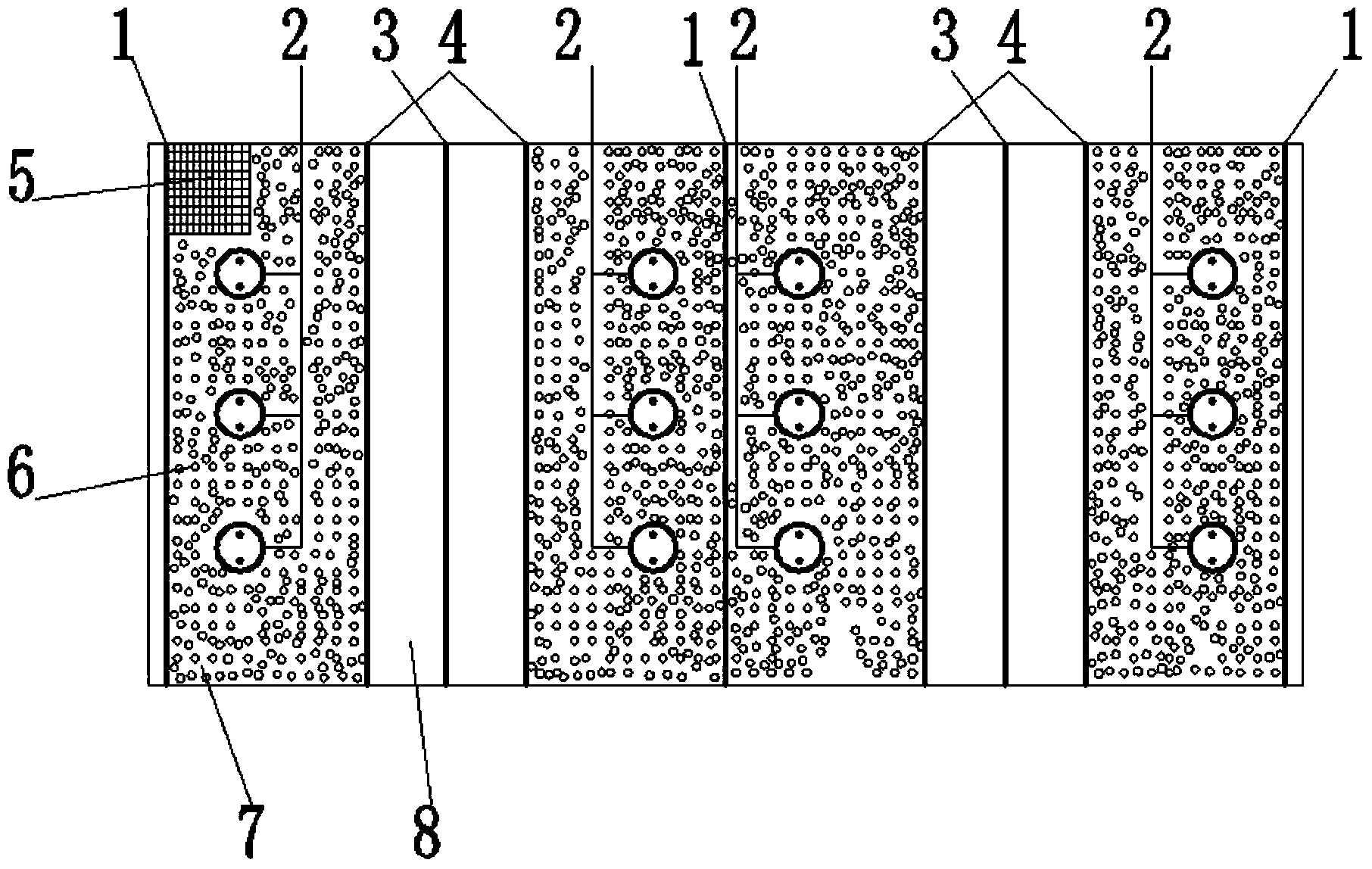

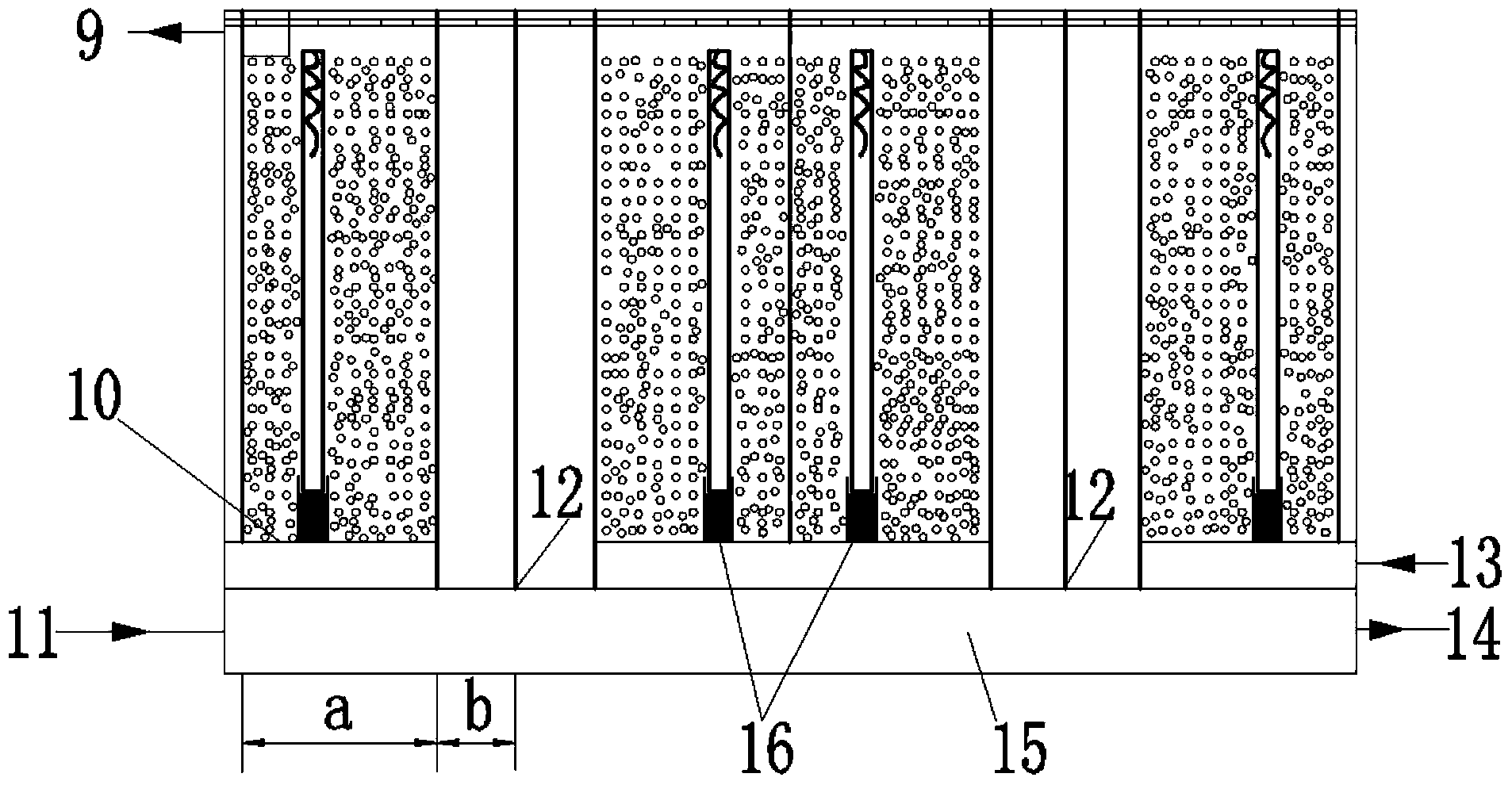

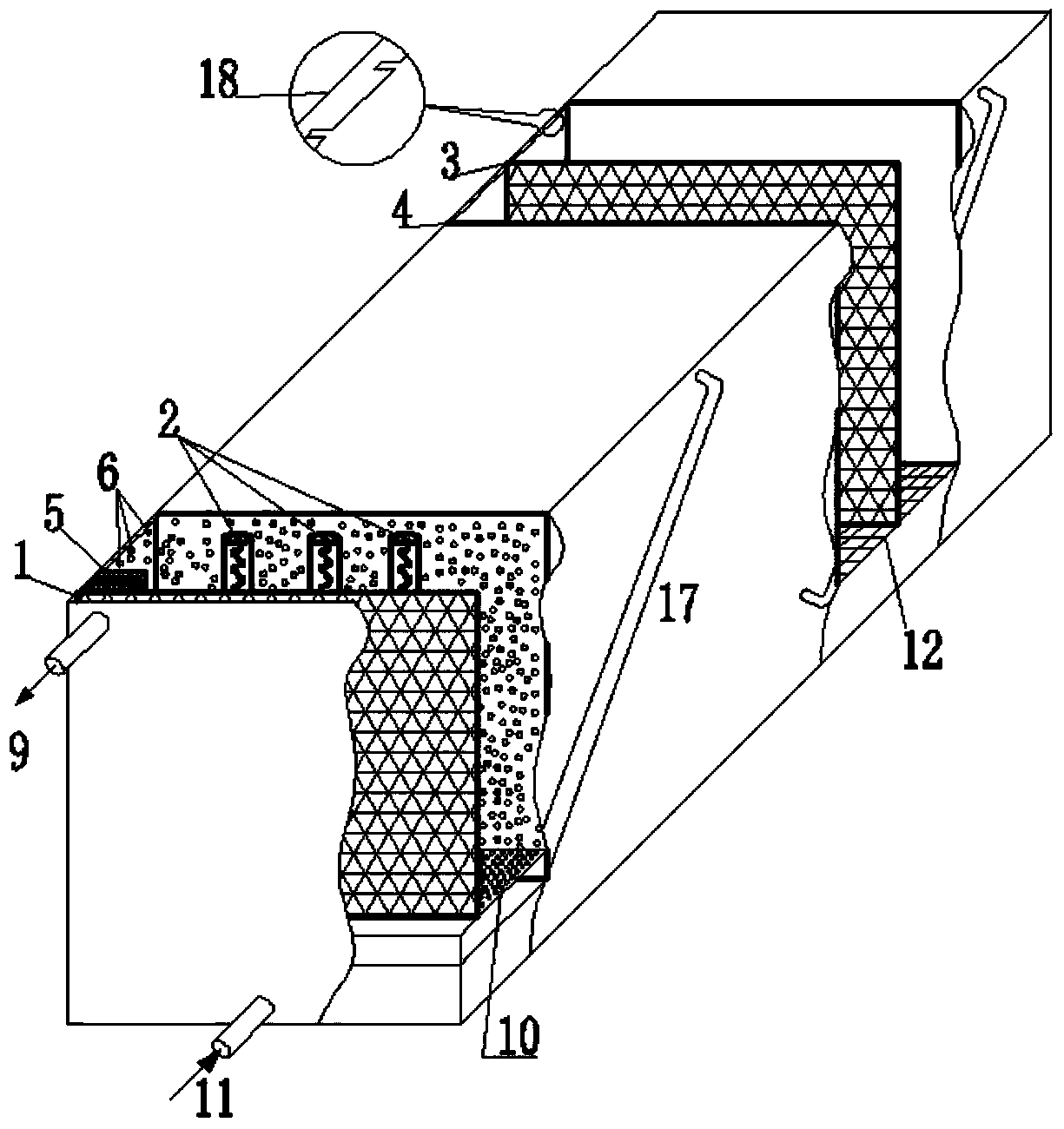

[0045] This embodiment is an embodiment of the structure and composition of the device of the present invention. Such as Figure 1-4As shown, the micro-series photoelectric catalytic oxidation wastewater treatment device of the present invention is seamlessly welded by acid and alkali resistant hard PVC plastic, and the exterior is supplemented by a closed stainless steel plate to make it have a certain pressure resistance. Internally according to anode plate 1, anion selective permeation membrane 4, cathode plate 3, anion selective permeation membrane 4, anode plate 1, anion selective permeation membrane 4, cathode plate 3... anion selectivity Through the sequential arrangement of membrane 4 and anode plate 1, the inner part of the box is divided into 3 anode chambers and 2 cathode chambers (such as Figure 1-2 As shown), in the actual process, according to the different processing capacity, different sets of cathode and anode chambers are set up, preferably 3-10 sets of cat...

Embodiment 2

[0054] It is the actual application embodiment of this device. The concentration of calcium ions in the refining wastewater produced by a petrochemical company in Tianjin is about 1000mg / L, the concentration of chloride ions is 1800mg / L, the conductivity is 8000μs / cm, and the COD after biochemical treatment is 100-200mg / L, which cannot reach the relevant effluent discharge standard. The micro-series photoelectric catalytic oxidation wastewater treatment device and process were used to carry out engineering application research on the high-hard wastewater. The hydraulic retention time in the device was 1 hour, and the CODcr in the final effluent quality was reduced to 40-50mg / L, which met the discharge water quality requirements. .

Embodiment 3

[0056] It is another practical application embodiment of the device. Refining sewage produced by a petrochemical company in Zhejiang will produce a certain amount of concentrated liquid after being treated by an ultrafiltration-reverse osmosis double-membrane system. The reverse osmosis concentrated water has the characteristics of high salt content, complex organic components, and poor biochemical properties. The total hardness is 2300mg / L, the COD is 150-200mg / L, and the conductivity is 19000μs / cm. When using the micro-series-internal circulation photoelectric catalytic oxidation wastewater treatment device and process to treat the company's reverse osmosis concentrated water, the hydraulic retention time in the device For 2 hours, the final effluent CODcr was reduced to 30-40mg / L, meeting the discharge water quality requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com