Trimanganese tetraoxide, as well as preparation method and application thereof

A technology of trimanganese tetraoxide and manganese sulfate solution, which is applied in the direction of manganese oxide/manganese hydroxide, electrochemical generators, structural parts, etc., and can solve the problem of small particle size, irregular particle shape and uneven particle distribution of trimanganese tetraoxide and other problems, to achieve the effect of uniform particle size distribution, high tap density and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare 5L of manganese sulfate saturated solution (a saturated aqueous solution of manganese sulfate; in this saturated solution, the concentration of manganese sulfate is 393g / L, and the pH is 5.0-6.0), add 5g of Na2S to remove impurities, filter, then add 5g of ascorbic acid to the filtrate to dissolve . Use the feeding pump to add to the disc granulator, turn on and adjust the frequency of the motor, so that the disc rotates at a speed of 15r / min, and at the same time turn on the microwave heating to gradually heat the temperature of the disc to 950°C at 10°C / min and keep it warm 1h, the gas decomposed in the reaction process enters the collection device through the guide tube to prepare dilute sulfuric acid. After the reaction is completed, it is naturally cooled to room temperature. About 16μm spherical trimanganese tetraoxide.

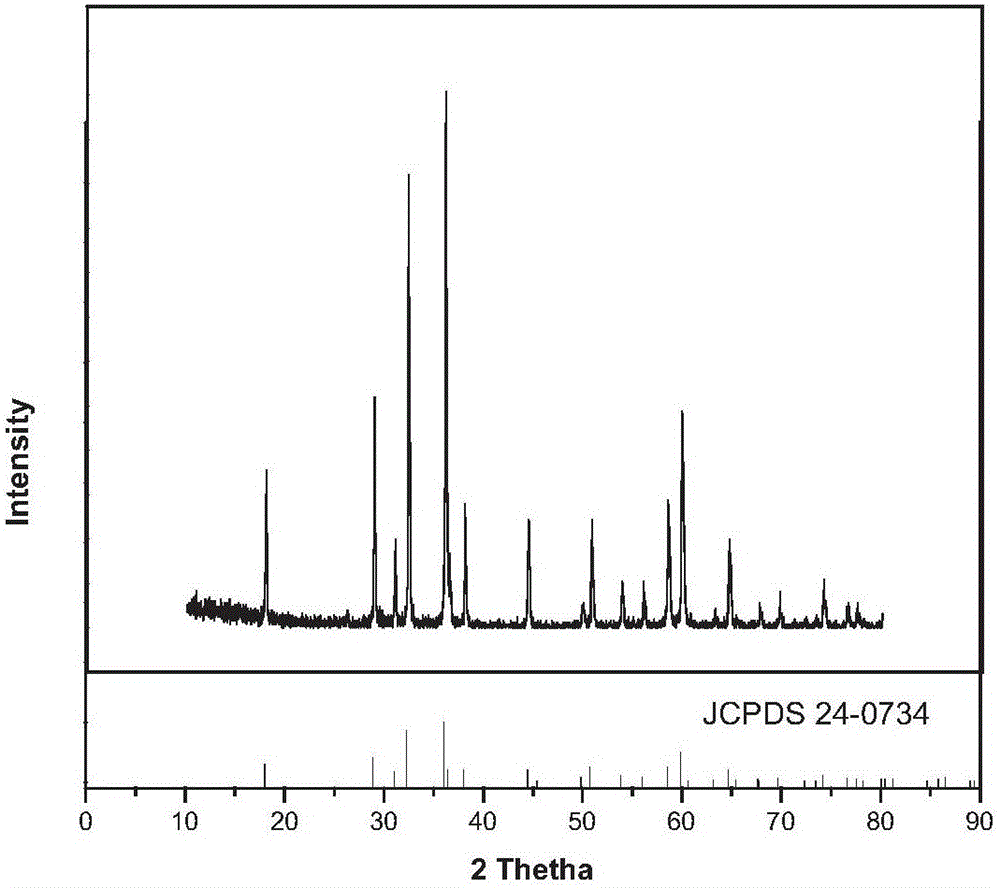

[0041] figure 1 It is the XRD figure of the obtained trimanganese tetraoxide; As can be seen from the figure, all the characteristic p...

Embodiment 2

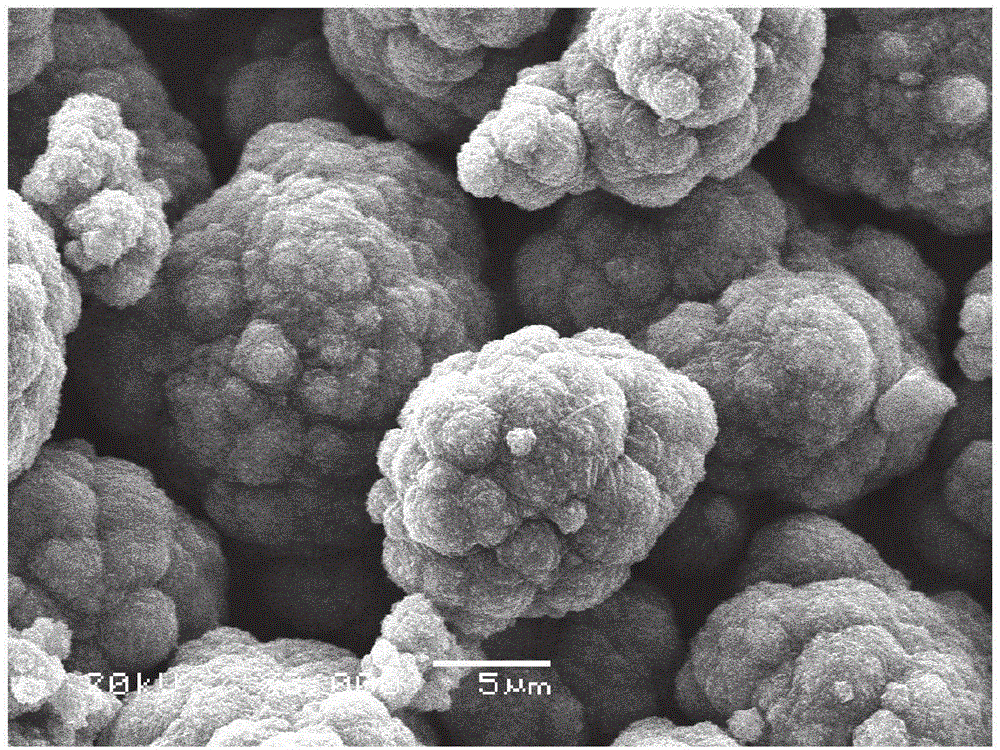

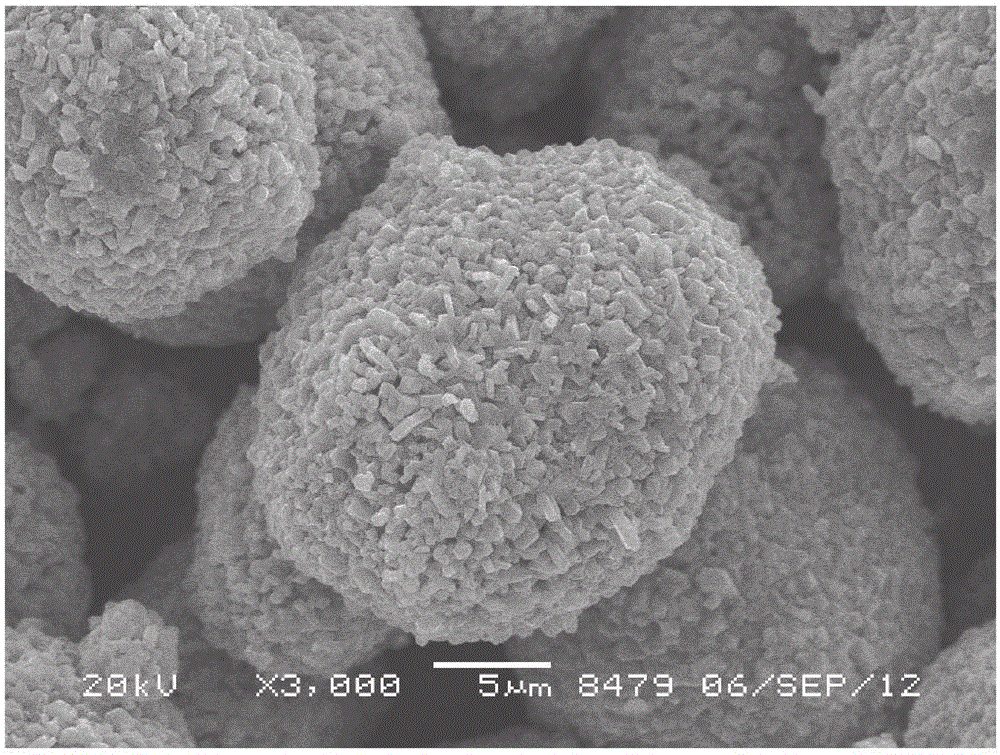

[0044] Prepare 5L of manganese sulfate saturated solution (a saturated aqueous solution of manganese sulfate; in this saturated solution, the concentration of manganese sulfate is 393g / L, and the pH is 5.0-6.0), add 4g of Na2S to remove impurities, filter, then add 3g of ascorbic acid to the filtrate to dissolve . Use the feeding pump to add to the disc granulator, turn on and adjust the frequency of the motor, so that the disc rotates at a speed of 10r / min, and at the same time turn on the microwave heating to gradually heat the temperature of the disc to 1100°C at 20°C / min and keep it warm After 30 minutes, the gas decomposed in the reaction process enters the collection device through the guide tube to prepare dilute sulfuric acid. After the reaction is completed, it is naturally cooled to room temperature, and the trimanganese tetraoxide obtained by the reaction is repeatedly washed and dried to obtain trimanganese tetraoxide; figure 2 This is the SEM image of the obtaine...

Embodiment 3

[0047] Prepare 5L of manganese sulfate saturated solution (a saturated aqueous solution of manganese sulfate; in this saturated solution, the concentration of manganese sulfate is 393g / L, and the pH is 5.0-6.0), add 8g of Na2S to remove impurities, filter, then add 3g of ascorbic acid to the filtrate to dissolve . Use the feeding pump to add to the disc granulator, turn on and adjust the frequency of the motor, so that the disc rotates at a speed of 15r / min, and at the same time turn on the microwave heating to gradually heat the temperature of the disc to 950°C at 10°C / min and keep it warm 1h, the gas generated by decomposition during the reaction enters the collection device through the guide tube to prepare dilute sulfuric acid. After the reaction is completed, it is naturally cooled to room temperature, and the trimanganese tetraoxide obtained by the reaction is repeatedly washed and dried to obtain spherical trimanganese tetraoxide. Using a specific gravity meter to detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com