Electroplating wastewater recycling treatment method

A technology of electroplating wastewater and treatment methods, which is applied in the direction of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., and can solve the problems of non-recyclable condensate, waste of water resources and evaporation costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

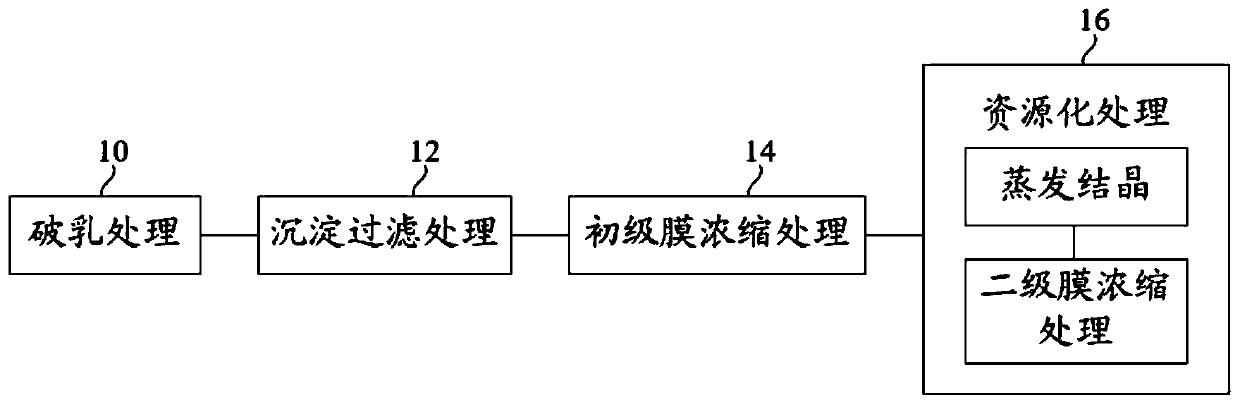

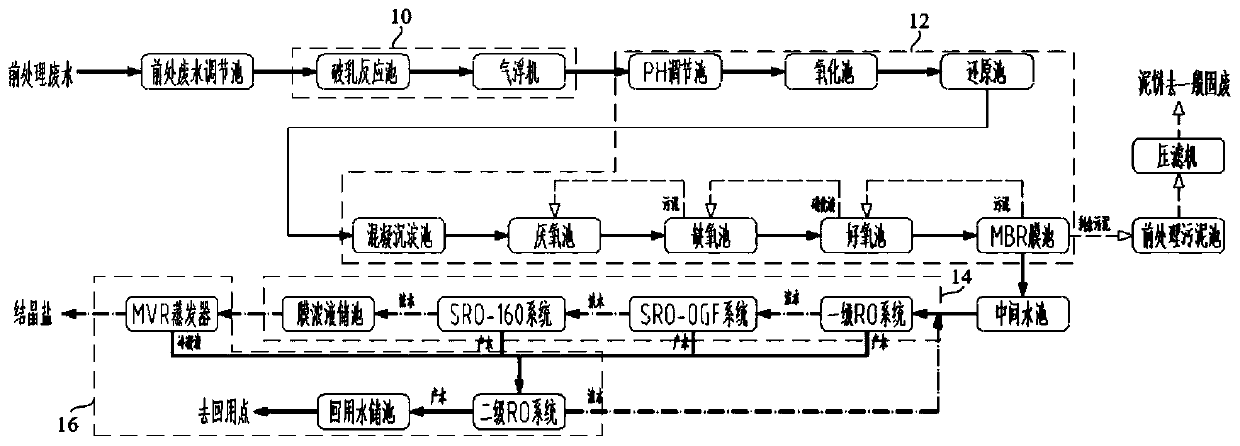

Method used

Image

Examples

Embodiment example

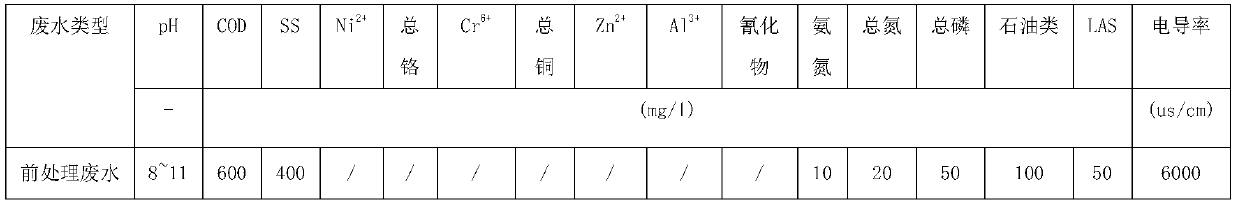

[0099] The total amount of wastewater treatment is 22,000 tons per day, including the main wastewater of the electroplating industry. Influent water quality parameters are as follows:

[0100]

[0101]

[0102] Outlet water quality requirements:

[0103] Test items pH Chroma Turbidity Conductivity unit of measurement dimensionless times NTU us / cm detection value 6~8 ≤3 ≤1 ≤300

[0104] Final hazardous waste generation:

[0105] project Sludge volume (tpd) Electroplating nickel wastewater sludge 0.75 Chemical Nickel Wastewater Sludge 0.08 Chromium-containing wastewater sludge 2.63 Zinc-containing cyanide wastewater, zinc-containing wastewater sludge 0.04 Copper-containing cyanide wastewater, acid copper wastewater, coke copper wastewater sludge 0.85 Anodized Wastewater Sludge 0.08 Integrated Wastewater Sludge 0.05 total 4.47

[0106] Final general industrial solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com