Patents

Literature

54results about How to "Avoid mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

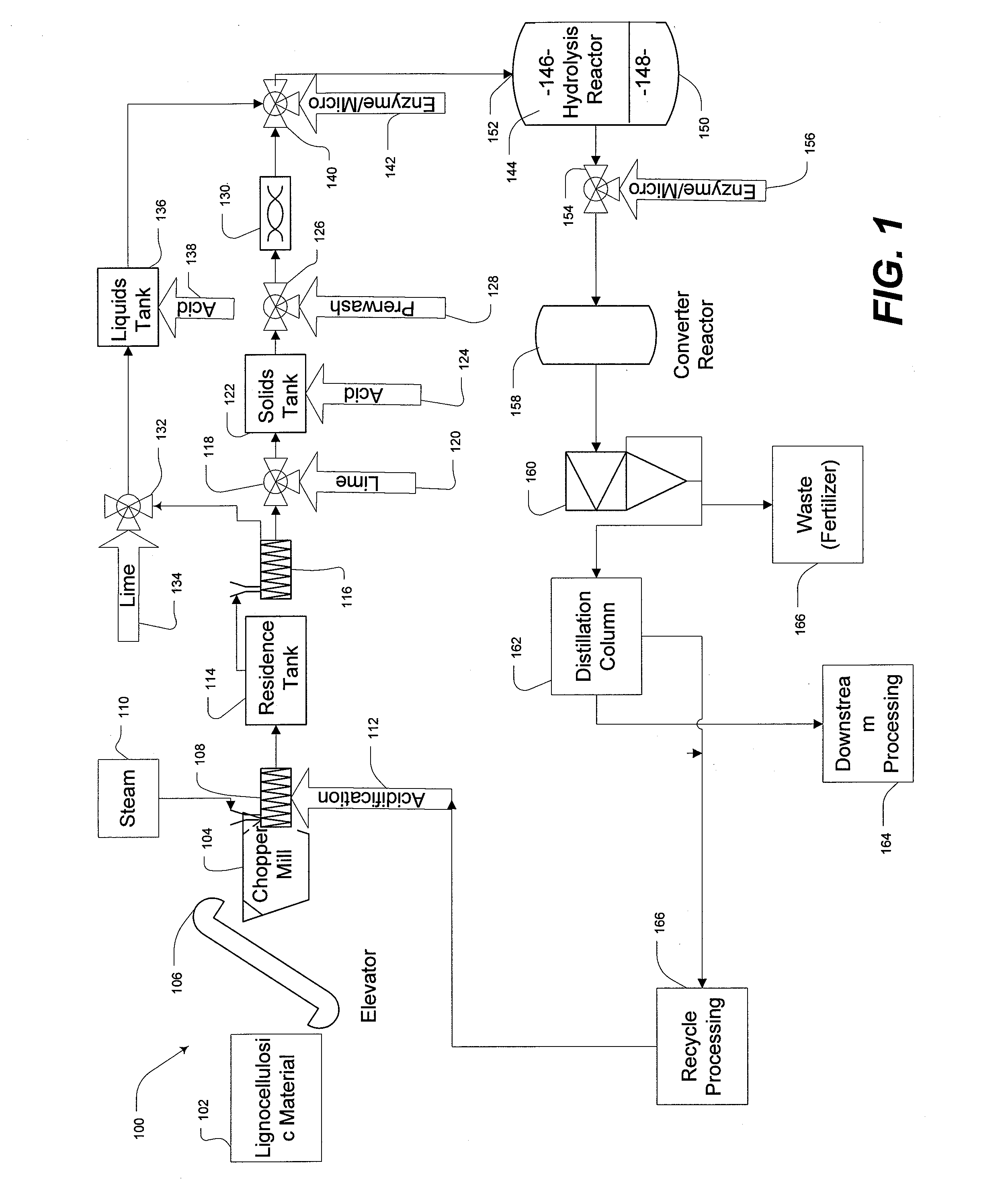

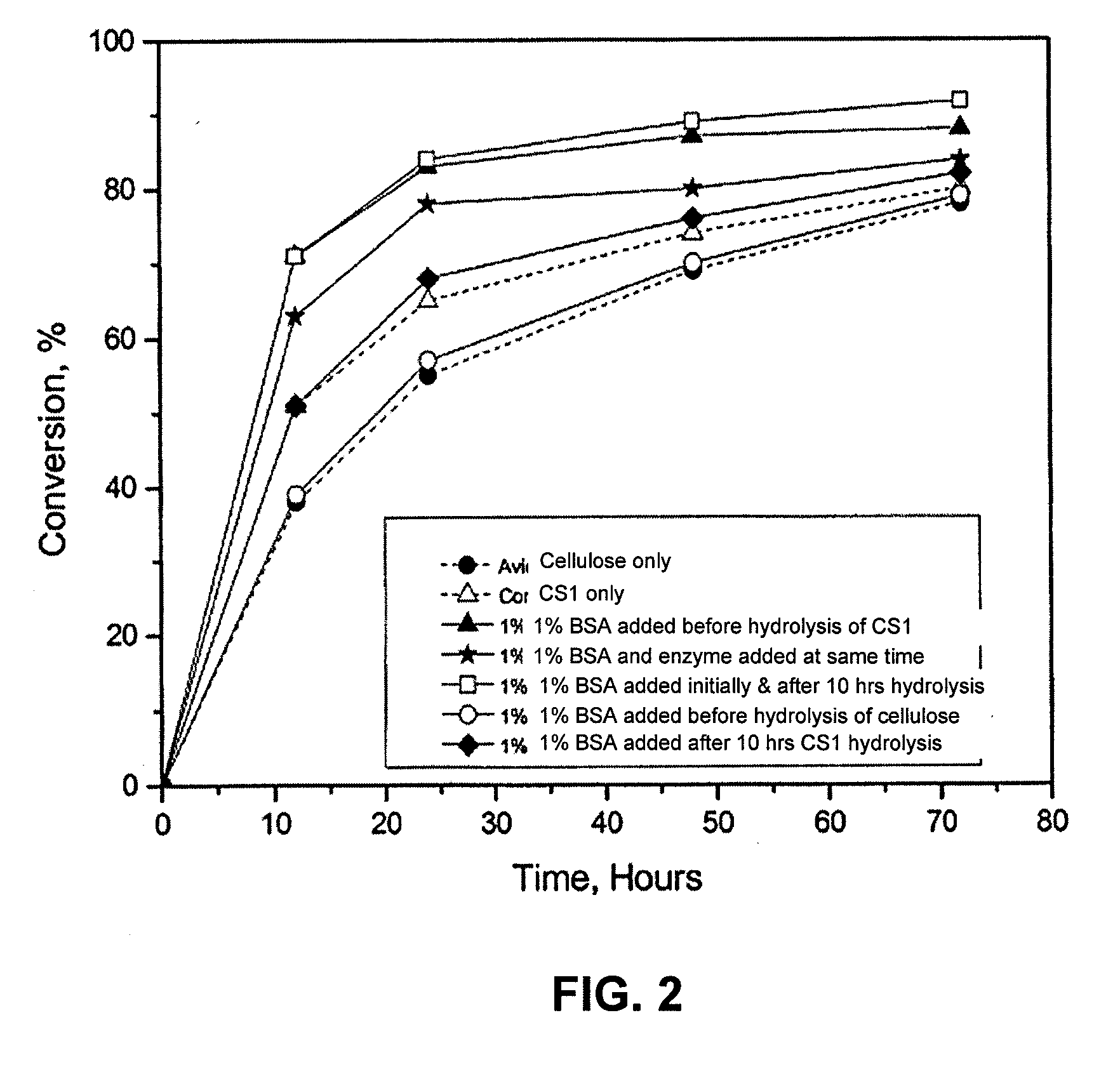

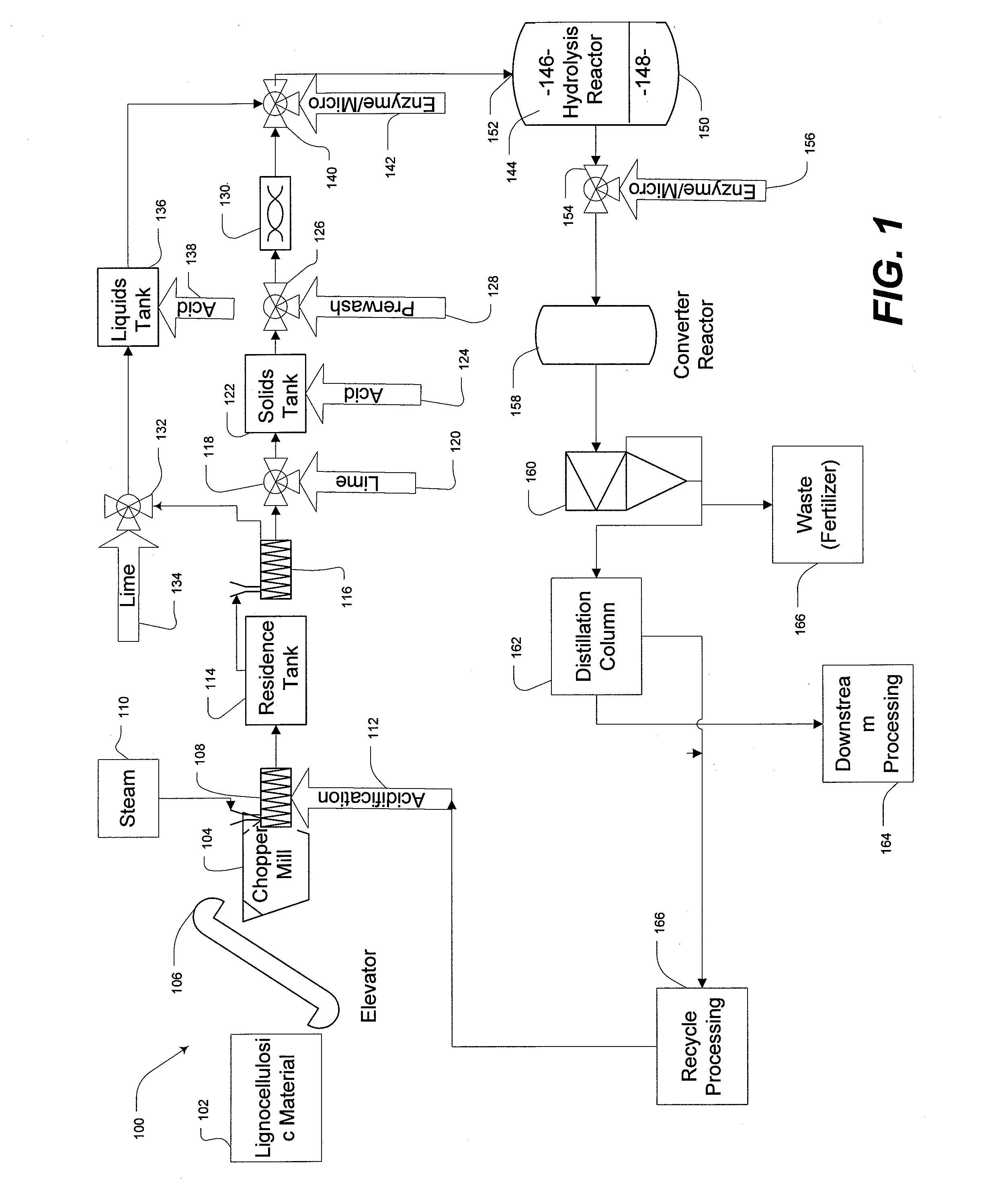

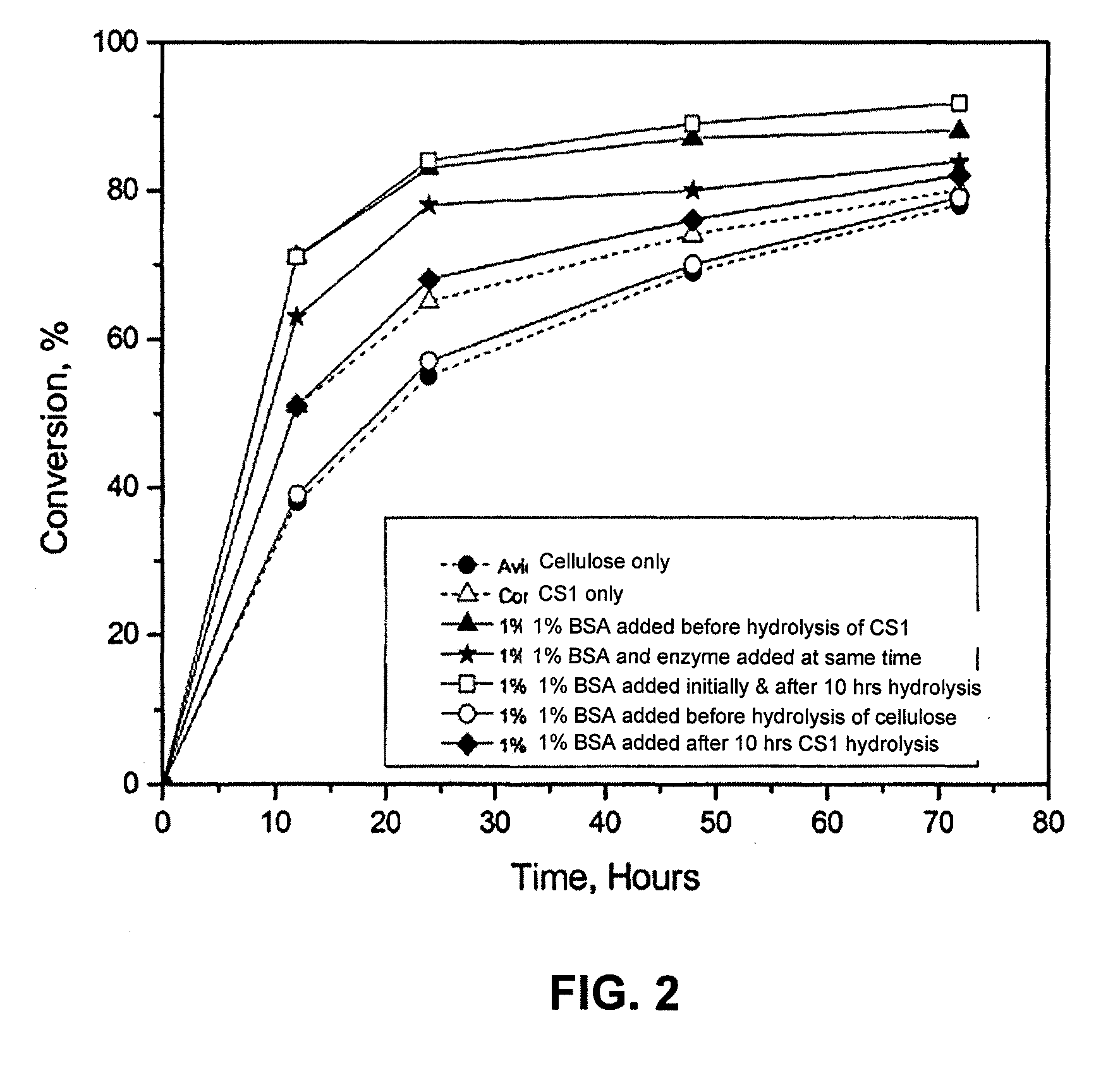

Lignin blockers and uses thereof

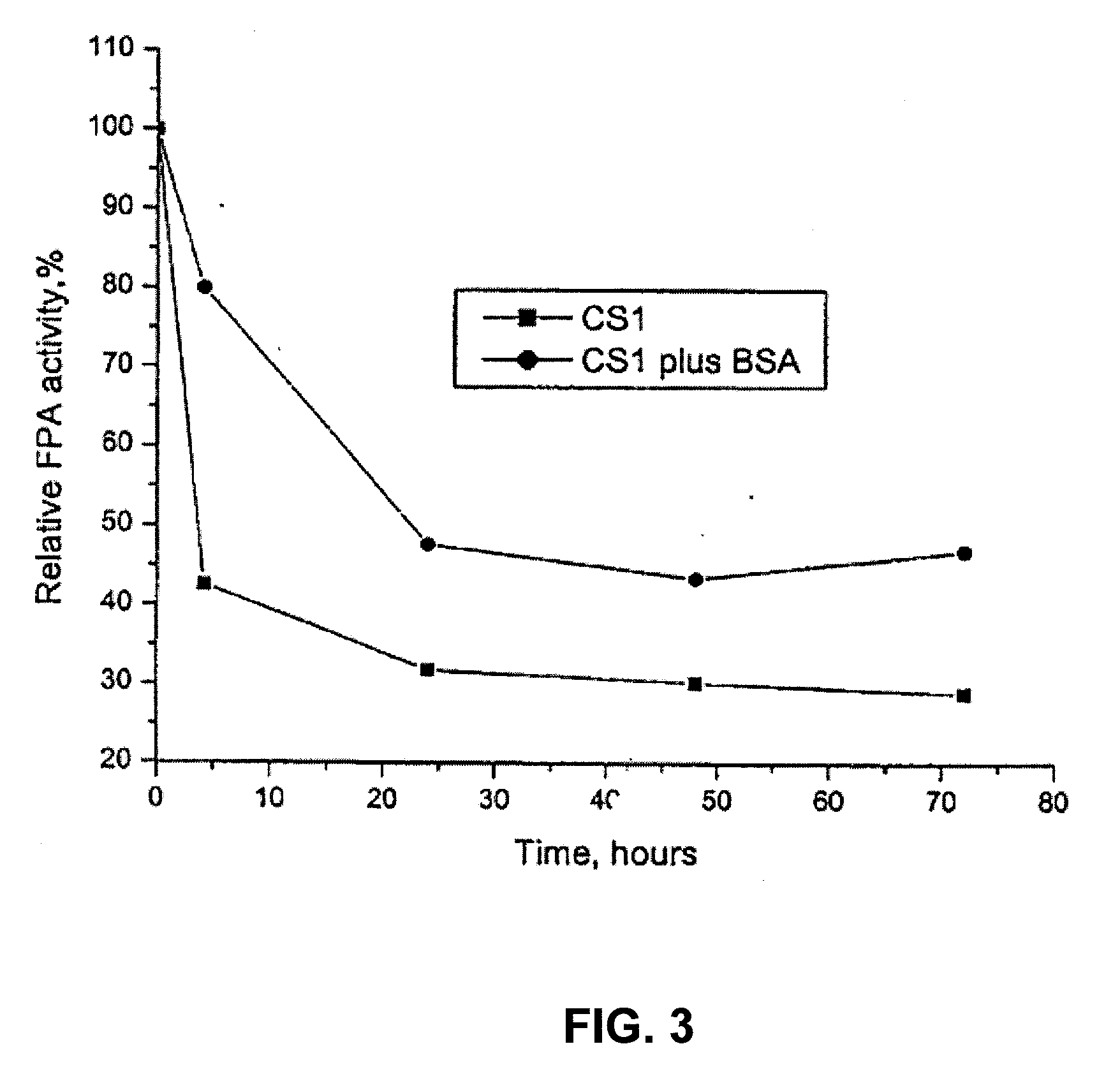

InactiveUS20060088922A1High efficiency in cellulose conversionLess of advantageProtein composition from vegetable seedsBiofuelsLignin degradationLignocellulosic biomass

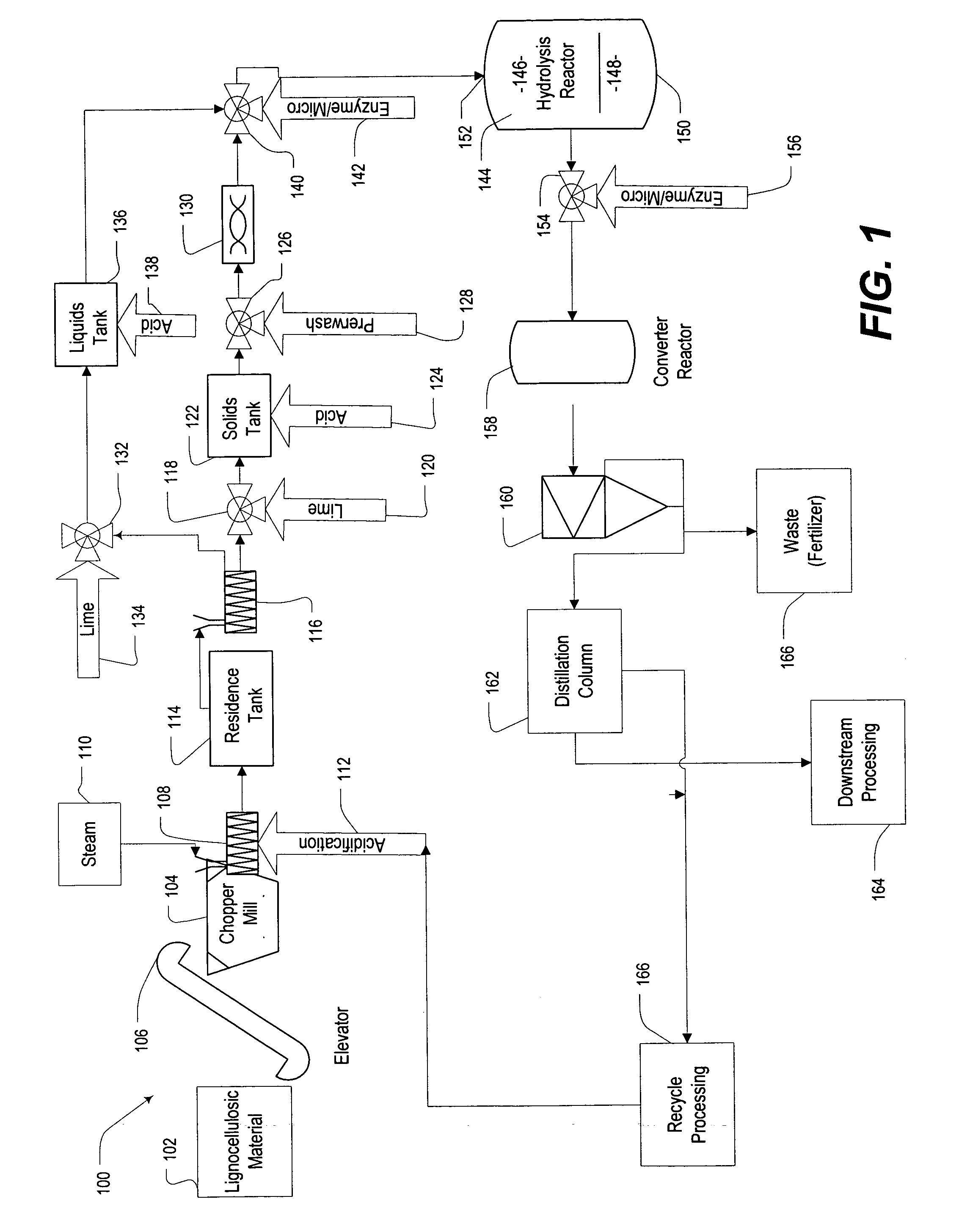

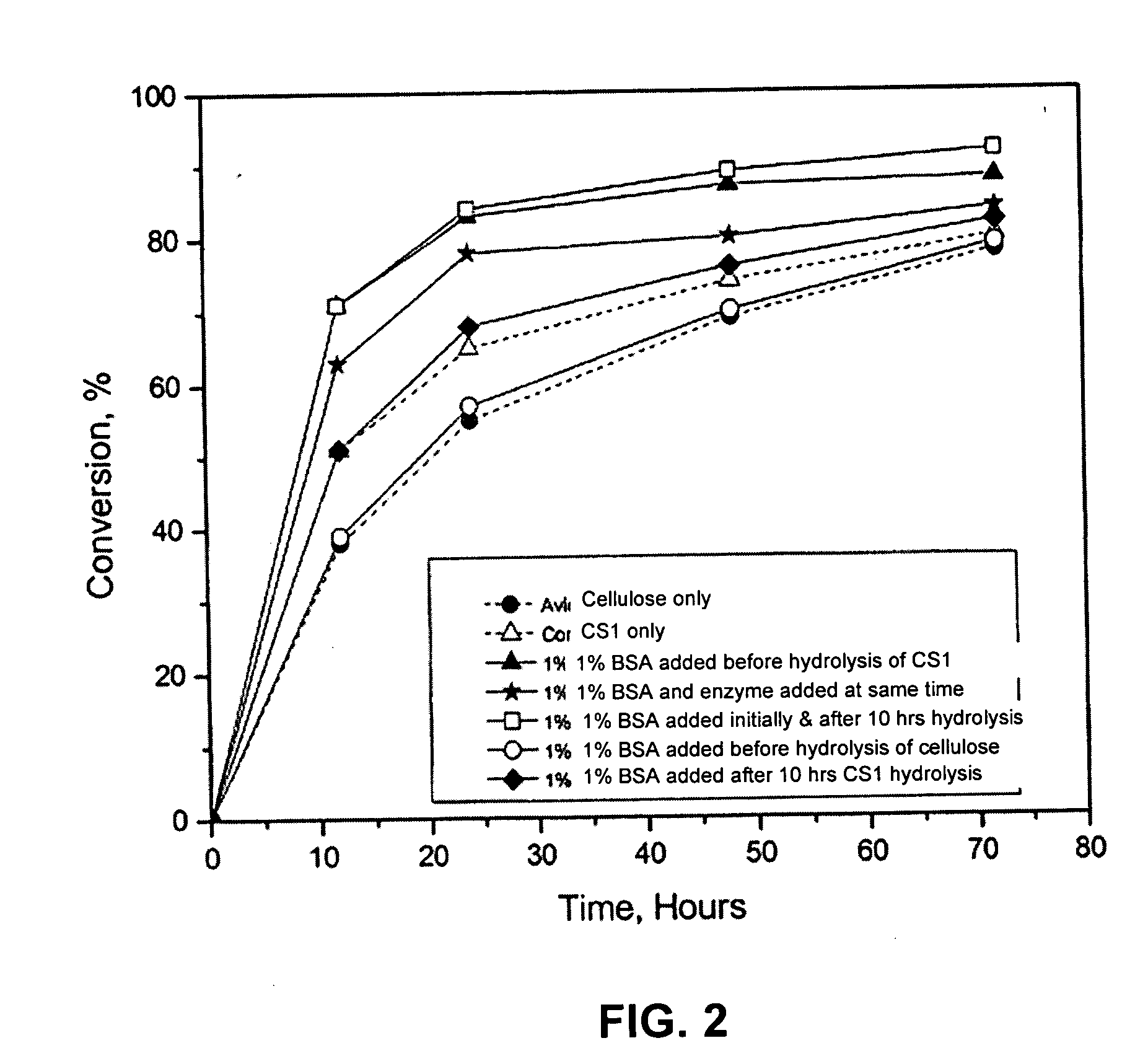

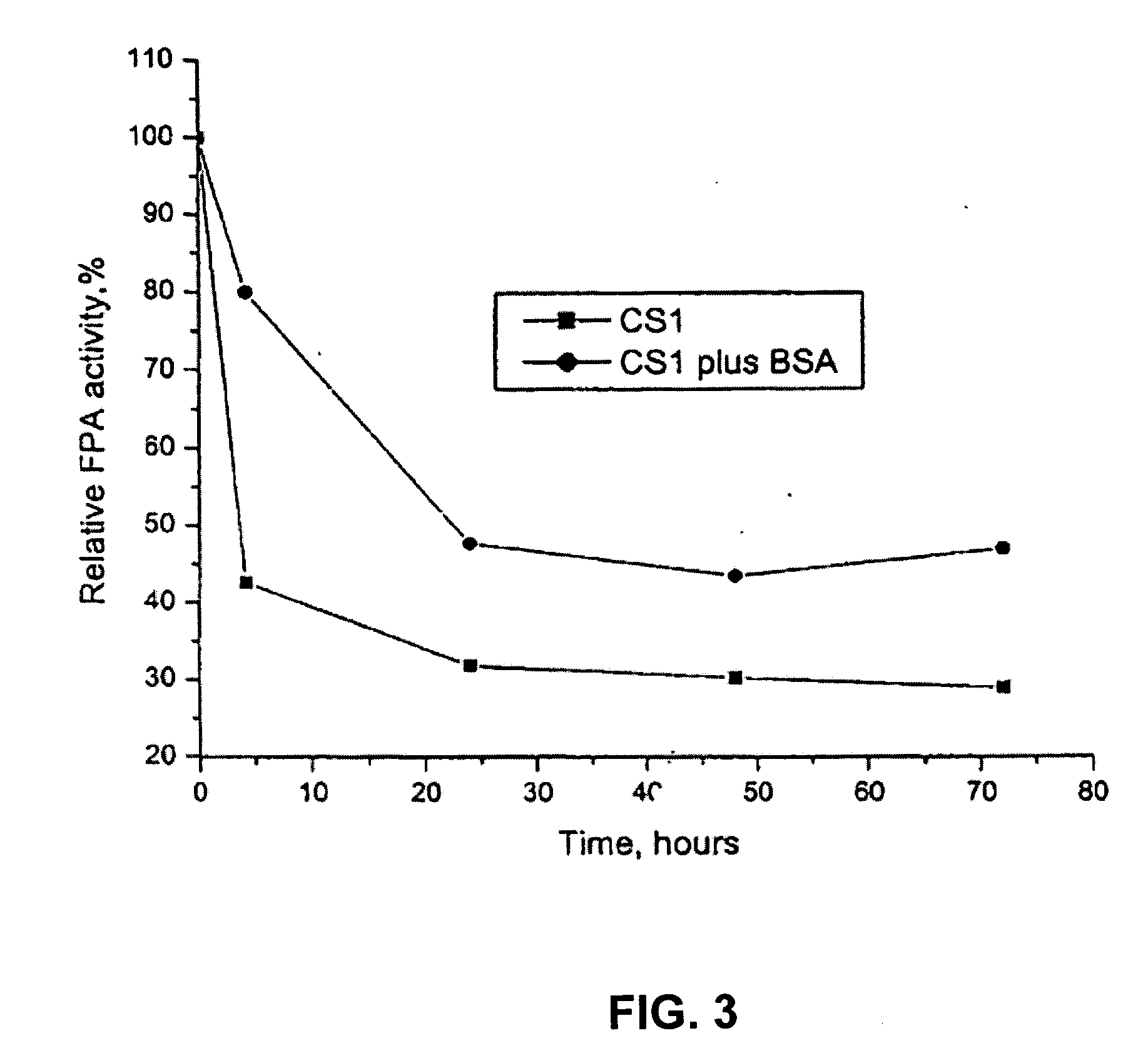

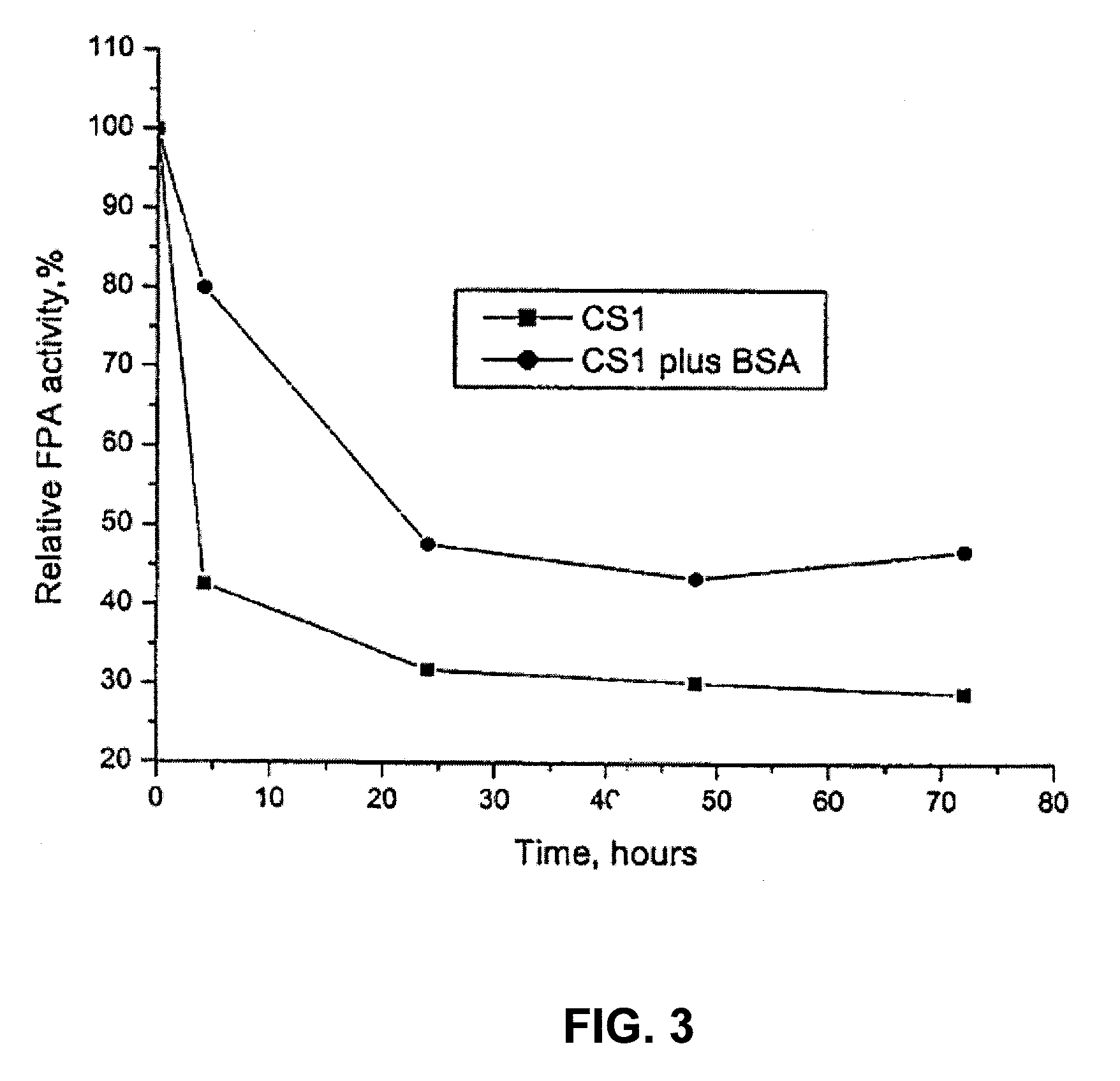

Disclosed is a method for converting cellulose in a lignocellulosic biomass. The method provides for a lignin-blocking polypeptide and / or protein treatment of high lignin solids. The treatment enhances cellulase availability in cellulose conversion and allows for the determination of optimized pretreatment conditions. Additionally, ethanol yields from a Simultaneous Saccharification and Fermentation process are improved 5-25% by treatment with a lignin-blocking polypeptide and / or protein. Thus, a more efficient and economical method of processing lignin containing biomass materials utilizes a polypeptide / protein treatment step that effectively blocks lignin binding of cellulase.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

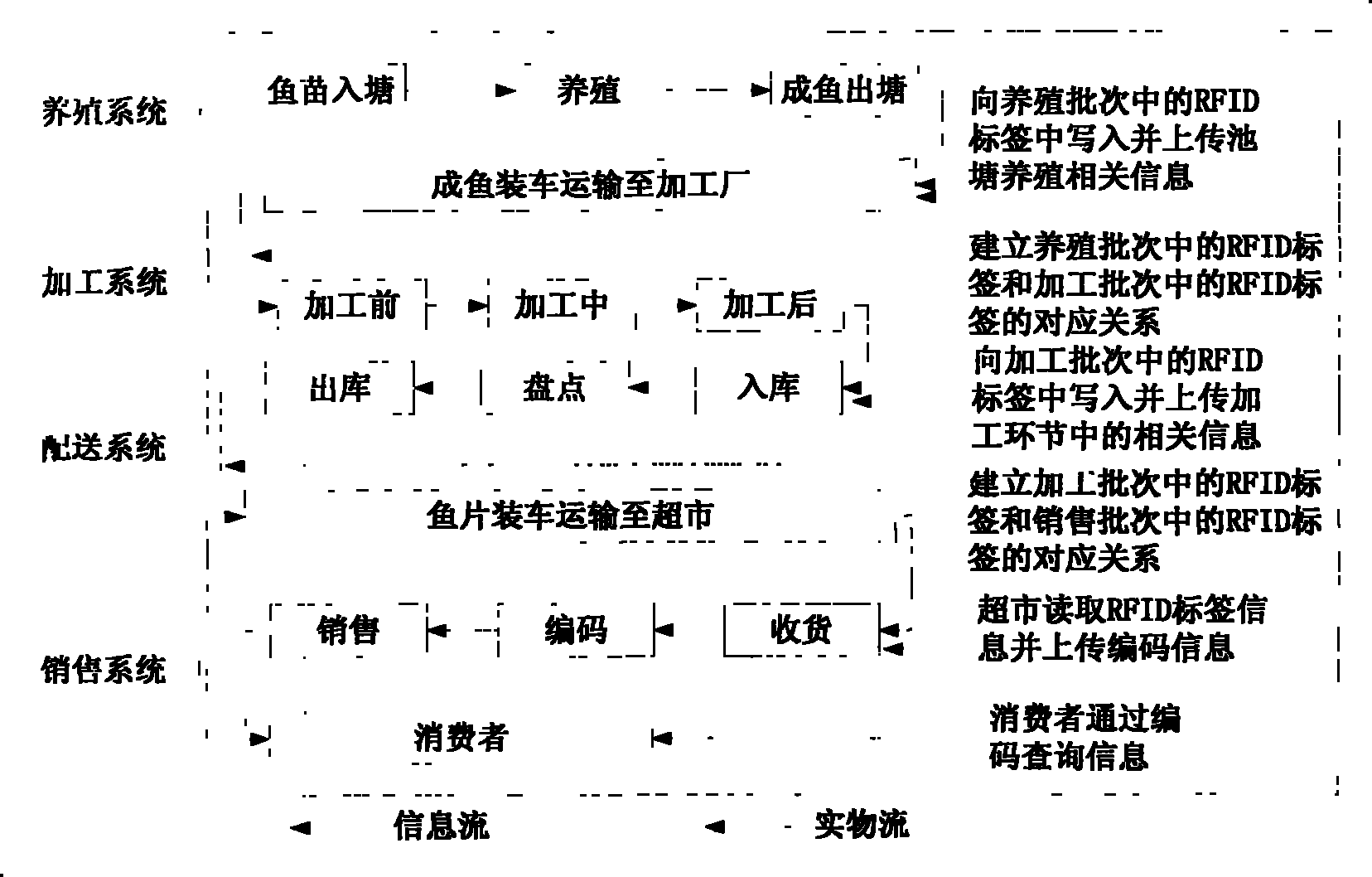

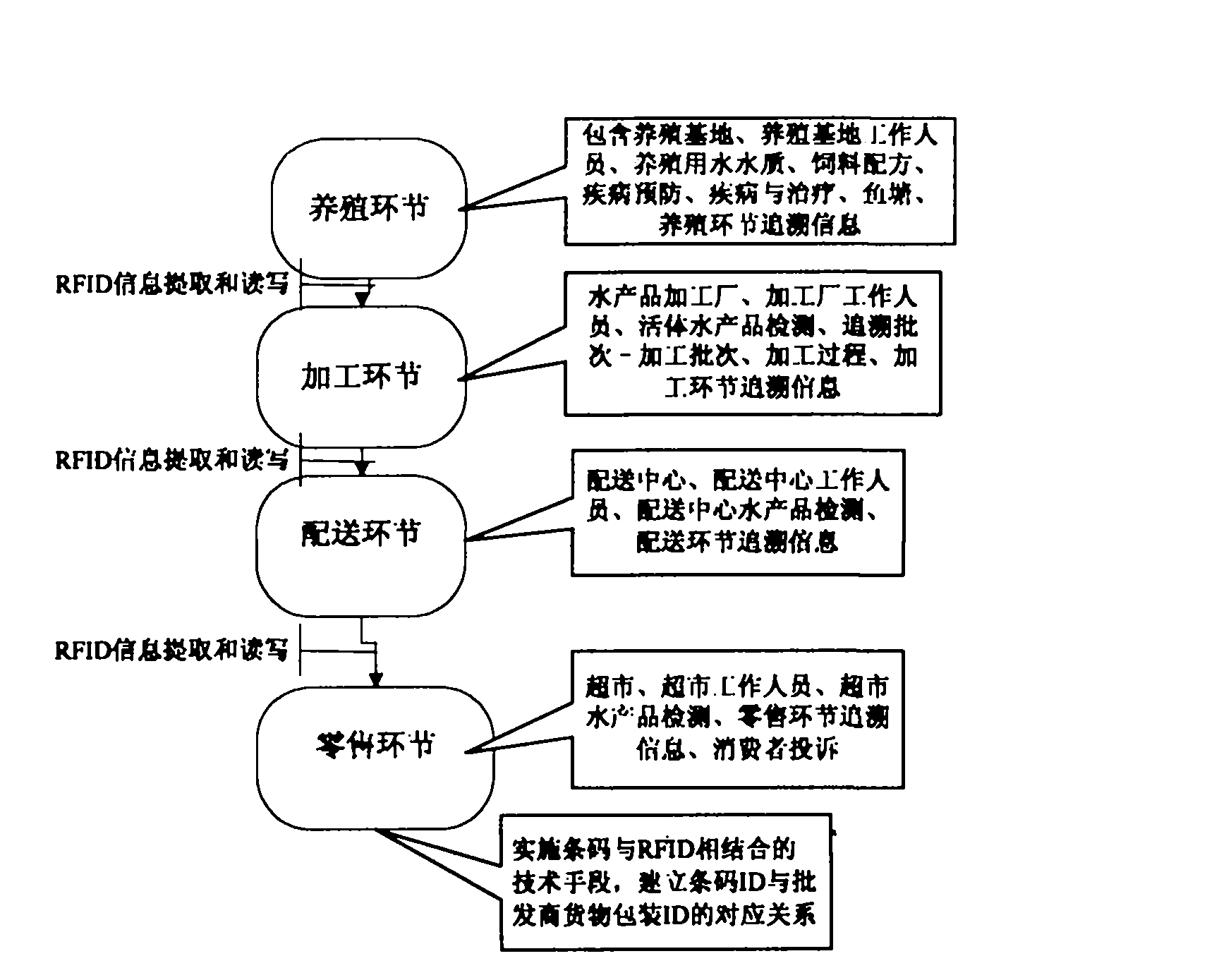

Aquatic product supply chain traceability system based on RFID and bar code technology and method thereof

InactiveCN101840538AHigh implementabilityAvoid defectsCo-operative working arrangementsResourcesCold chainVideo monitoring

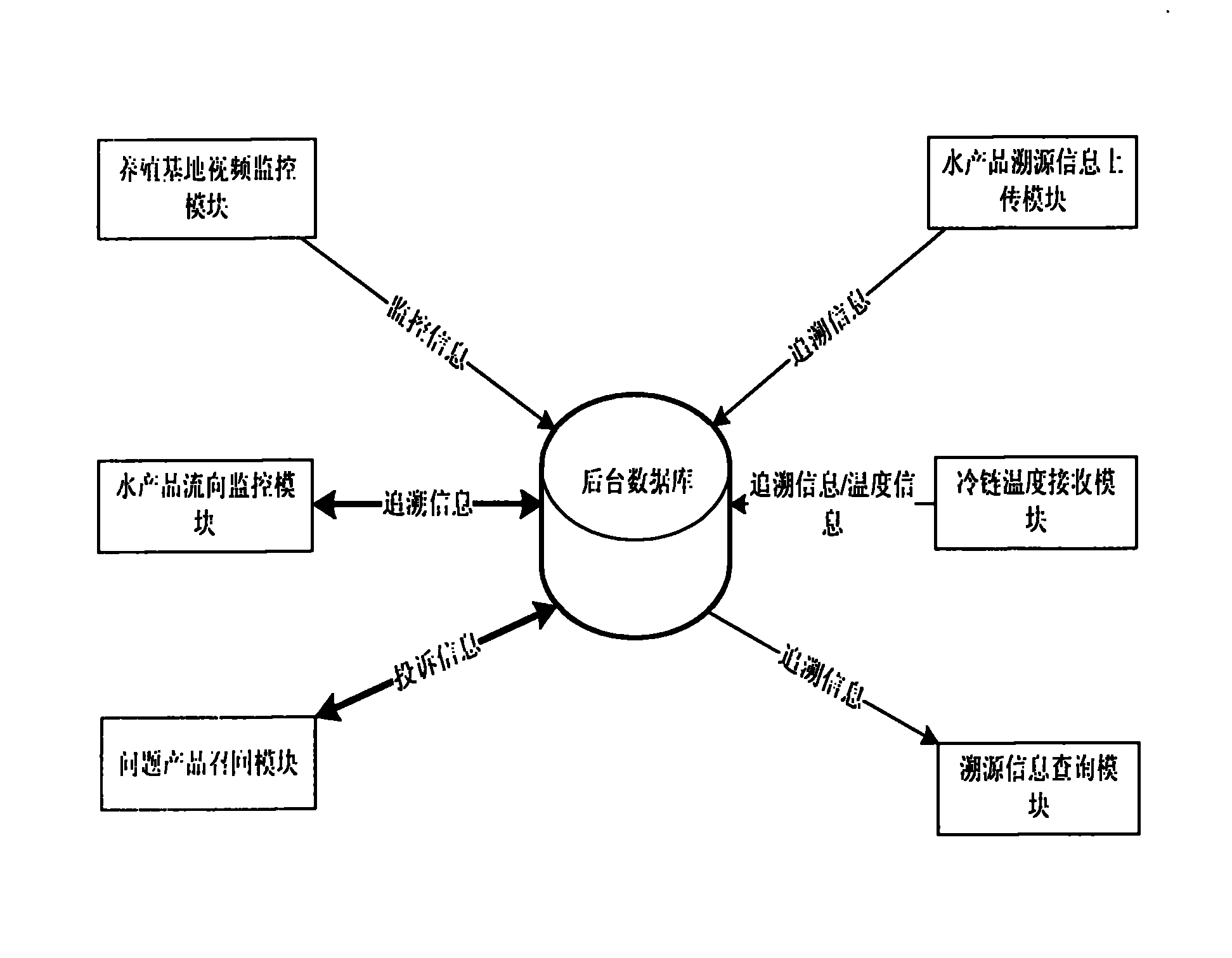

The invention discloses an aquatic product supply chain traceability system based on an RFID and bar code technology and a method thereof. The system comprises a background database, an aquaculture base video monitoring module, an aquatic product tracing information uploading module, an aquatic product flow-direction monitoring module, a cold chain temperature receiving module, a tracing information query module and an unqualified product recalling module. The specific method comprises four parts, i.e. an aquaculture section, a processing section, a delivery section and a retail section, after all processes are finished, the tracing information are uploaded to the background database, or is read from the background database, while the transfer of the tracing information on the supply chain can be realized among all the processes by batch information stored in an RFID electronic tag. By effective combination of the RFID tap and the bar code, the invention really realizes a management mode with descending tracking and ascending tracing and brings great convenience for consumers and enterprises.

Owner:SOUTH CHINA UNIV OF TECH

Processing method of instant seasoning grilled squid strips

The invention relates to a processing method of instant seasoning grilled squid strips, and the method comprises the following steps that fresh squid, or fresh frozen and thawed squid is selected as a raw material and cleaned; the head and the internal organs are removed; then the squid is uniformly mixed with seasoning and cured, dried, aired and baked into grilled dried squid with the water content being controlled to be 17 percent + / - 1 percent; the grilled dried squid is torn into strips; and the grilled squid strips are detected by metal and packaged to obtain finished products. The processing method has reasonable procedures, is simple in preparation, and easily realizes large-scale production. The seasoning for curing is mixed scientifically, so that the freshness and the flavor of the squid product are improved, and the product is not dry, hard and crispy. The seasoning grilled squid strips which are prepared through the method maintain the nutrition of the squid, have golden color, and the special baking aroma of marine food products, and the product has tough texture, is chewy and dainty in saline taste and sweetness, has delicious taste and long storage life, can be eaten conveniently only after a package is opened, and is ideal leisure food.

Owner:RONGCHENG HONGWEI FOOD

Pollution removing medicament for drinking water

InactiveCN1597544ALittle effect of load changesPromote catalytic oxidationWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationCatalytic oxidationManganese

A chemical for removing pollutants from drinking water contains perferrite, permanganate and assistant. It features strong catalytic oxidizing action for destroying oraganic substances.

Owner:HARBIN INST OF TECH

Lignin Blockers And Uses Thereof

InactiveUS20110076725A1Improved yieldIncrease productionProtein composition from vegetable seedsBiofuelsChemistryCellulose

Disclosed is a method for converting cellulose in a lignocellulosic biomass. The method provides for a lignin-blocking polypeptide and / or protein treatment of high lignin solids. The treatment enhances cellulase availability in cellulose conversion and allows for the determination of optimized pretreatment conditions. Additionally, ethanol yields from a Simultaneous Saccharification and Fermentation process are improved 5-25% by treatment with a lignin-blocking polypeptide and / or protein.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

High-purity sodium carboxymethyl starch, preparation method thereof and application thereof

The invention discloses high-purity sodium carboxymethyl starch, a preparation method thereof and application thereof. Mainly during basification and etherification of starch in a reaction kettle, the stable reaction temperature, stirring time and stirring speed are strictly kept; and after an organic solvent is added into the starch, a semi-powder semi-grain product is completely stirred and fully dispersed in the organic solvent, and the solvent is removed to form a powder product. The purity of the prepared sodium carboxymethyl starch is as high as 90 to 99 percent, the substitution value is as high as 1.3 to 1.9, and the application fields of dye printing, spinning, food, papermaking, ceramics, petroleum and the like are enlarged.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

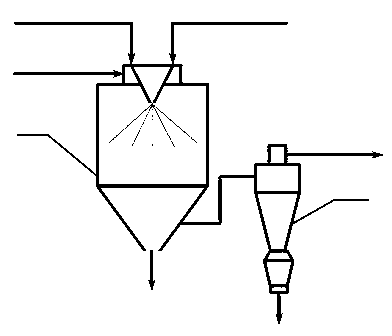

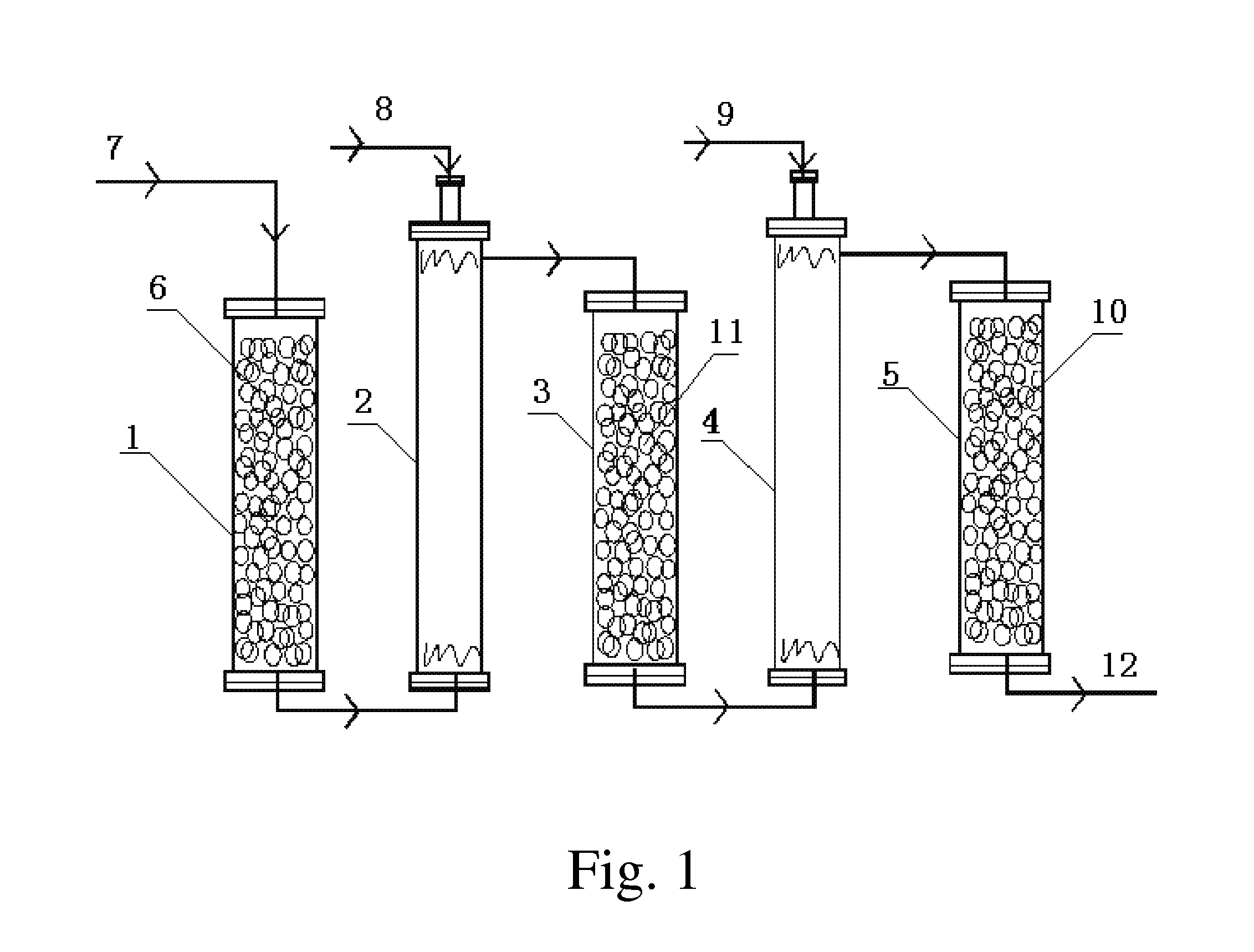

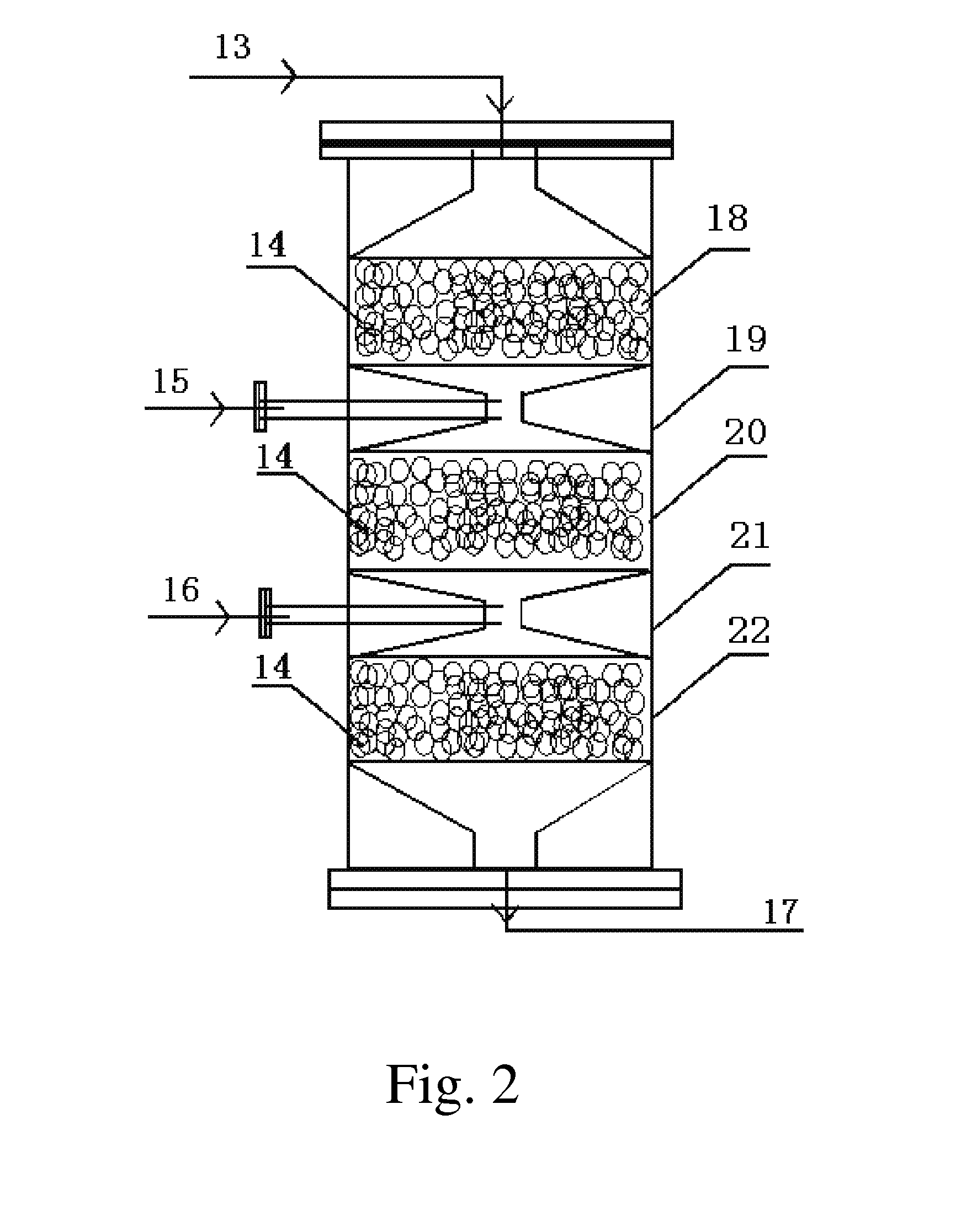

Preparation method of nanometer silver powder with particles controllable

ActiveCN104014804AAvoid cloggingMake up for the lack of concentrationNanotechnologyTowerReducing agent

The invention discloses a preparation method of nanometer silver powder with particles controllable. The method includes the following steps that silver nitrate and dispersants are mixed with water in sequence in proportion so that an oxidizing mixed solution A can be obtained; reducing agents are added into water and stirred to be dissolved, then the pH value of the solution is regulated to range from 7.5 to 13.5 through small molecular amine, and a reducing solution B is obtained after stirring and dissolving; the oxidizing mixed solution A and the reducing solution B are pumped into a spraying nozzle according to the volume ratio ranging from 1:10 to 10:1, the oxidizing mixed solution A and the reducing solution B are sprayed into a spraying drying tower through hot air at the temperature ranging from 35 DEG C to 150 DEG C at the speed ranging from 1 kg / h to 8000 kg / h, and powdery solids are formed and subside to the bottom of the drying tower; powder airflow obtained through the reaction is pumped into a separation tower to be further separated, and finally, silver powder and redundant reducing agents are separated so that the nanometer silver powder can be obtained. The preparation method has the advantages of being simple in process, convenient to operate and capable of achieving mass production fast.

Owner:福建富轩科技有限公司

Preparation method of graphene for heater

InactiveCN106276874AHigh degree of oxidationIncrease layer spacingSingle layer grapheneAfter treatmentHydrogen

The invention relates to the technical field of graphene, in particular to a preparation method of graphene for a heater. The method is characterized in that the graphene is prepared by adopting an oxidation-reduction method and specifically comprises the following steps: firstly, peroxidation of the graphene; secondly, oxidization of graphite, wherein oxidation treatment comprises four stages, namely low-temperature reaction, medium-temperature reaction, high-temperature reaction and after treatment; in the low-temperature reaction and the medium-temperature reaction, an ultrasonic and mechanical stirring combined action is adopted, and hydrogen is introduced into a reaction system; thirdly, preparation of the graphene, wherein a drying mode in the preparation process adopts freeze drying. According to the preparation method of the graphene for the heater, provided by the invention, a production process is controllable, and large-scale production can be realized; nano ions are not easy to agglomerate in the preparation process; a prepared graphene crystal is complete in structure and excellent in conductivity.

Owner:ANHUI NINGGUO TIANCHENG ELECTRICAL APPLIANCES

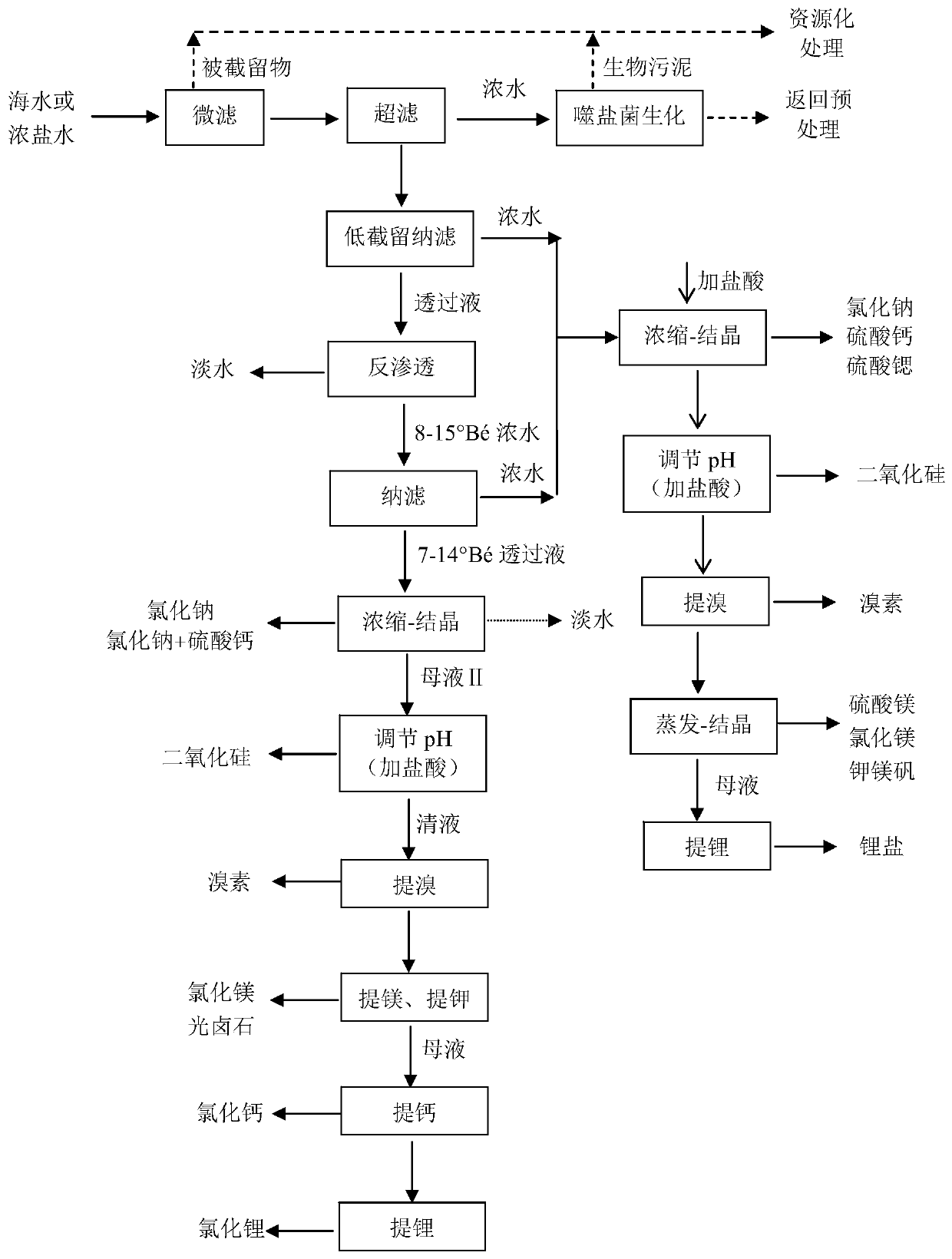

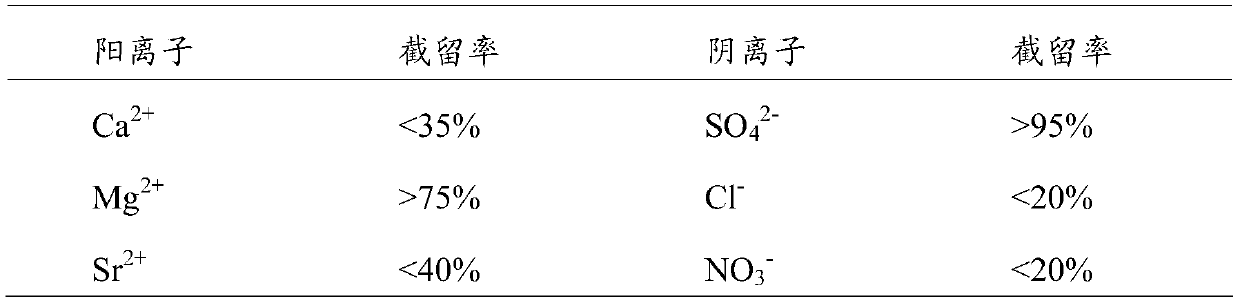

Comprehensive treatment method of seawater or strong brine

ActiveCN111484178AAvoid mass productionIncrease productionGeneral water supply conservationSeawater treatmentReverse osmosisSodium sulfate

The invention relates to a comprehensive treatment method of seawater or strong brine. The comprehensive treatment method comprises the following steps: pretreatment, low-interception nanofiltration separation, low-interception nanofiltration permeate liquid treatment, reverse osmosis concentrated water treatment, nanofiltration osmosis permeate liquid treatment and nanofiltration concentrated water treatment. According to the method, fresh water is completely recycled, the yield of low-value magnesium chloride and calcium sulfate (gypsum) byproducts is greatly reduced, low-value sodium sulfate, magnesium bromide and the like are prevented from being generated, and the yield of high-value products such as high-purity sodium chloride, calcium chloride, potassium sulfate and magnesium sulfate is remarkably increased.

Owner:TIANJIN PURESEA SPRING MEMBRANE TECH CO LTD

High-stability carbon nanometer fluorescence dye

InactiveCN103343005AChanging the luminescence spectrumExtended service lifeLuminescent compositionsFluorescent stainingCarbon nanodots

The invention provides a high-stability carbon nanometer fluorescence dye. The high-stability carbon nanometer fluorescence dye is coated on the surface of a conventional luminescent material, can be used for changing a luminescent spectrum and comprises a carbon nano-dot fluorescent material, a thinning agent, a binding agent and a fluorescent dyeing matter. The high-stability carbon nanometer fluorescence dye is characterized in that the carbon nano-dot fluorescent material is mixed with the thinning agent to form a fluorescent solution containing the carbon nano-dot fluorescent material; the fluorescent solution is uniformly mixed with the binding agent to form a fluorescent binding agent; and the fluorescent binding agent is combined with the fluorescent material. The high-stability carbon nanometer fluorescence dye provided by the invention has the characteristics of transparency, stability, no toxicity, environmental protection, low cost, simplicity in use and the like. The high-stability carbon nanometer fluorescence dye can be widely applied to the fields such as color long afterglow, light emitting display, light conversion agents, anti-fake fluorescent materials and various coatings.

Owner:SHANGHAI DONGZHOU IND

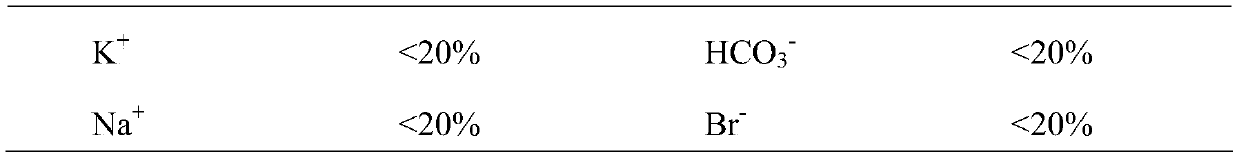

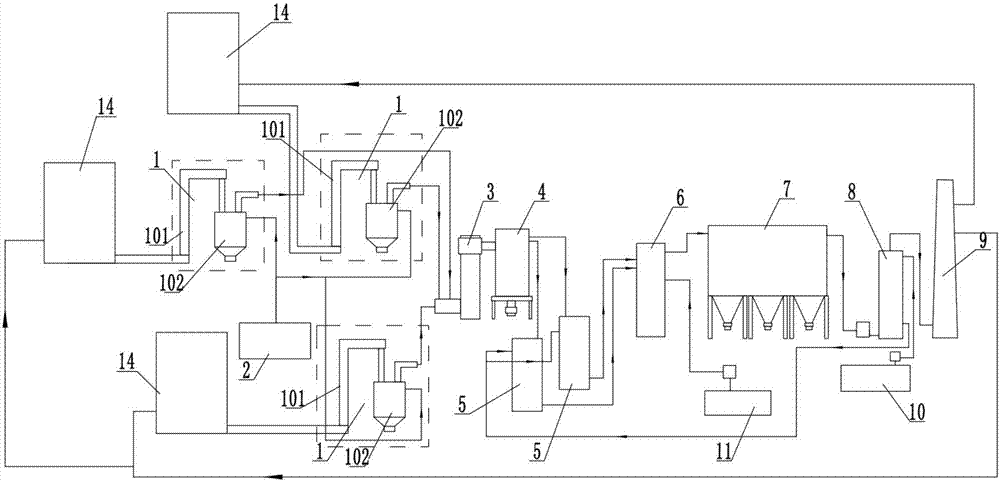

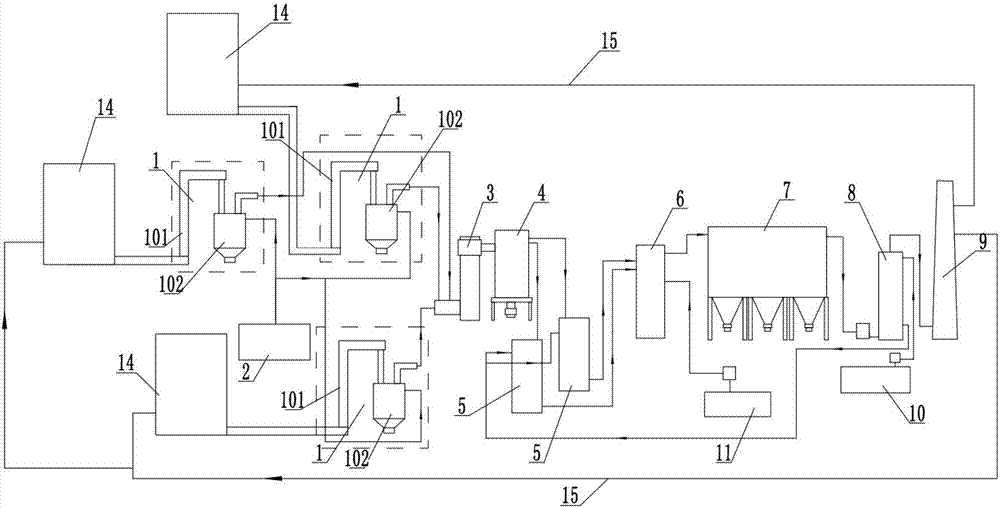

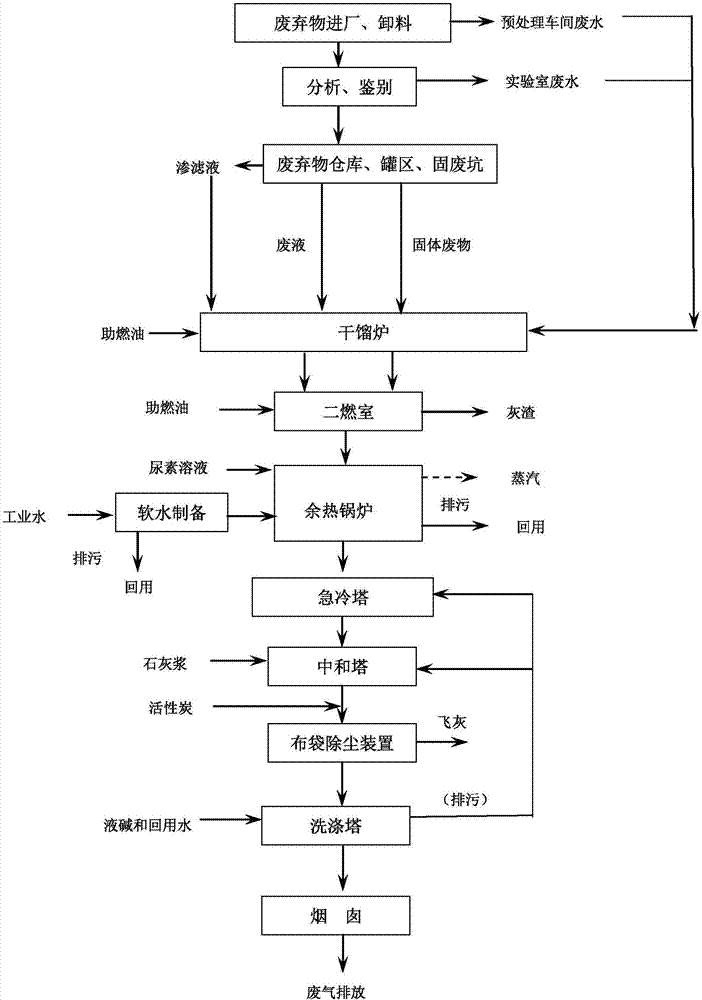

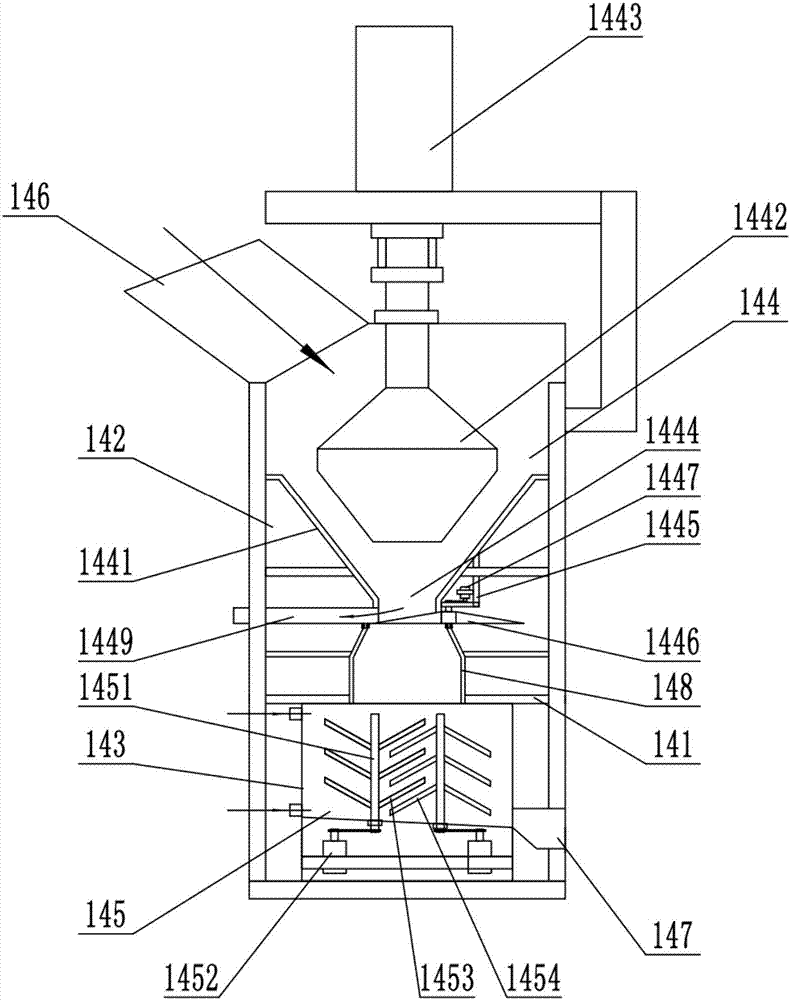

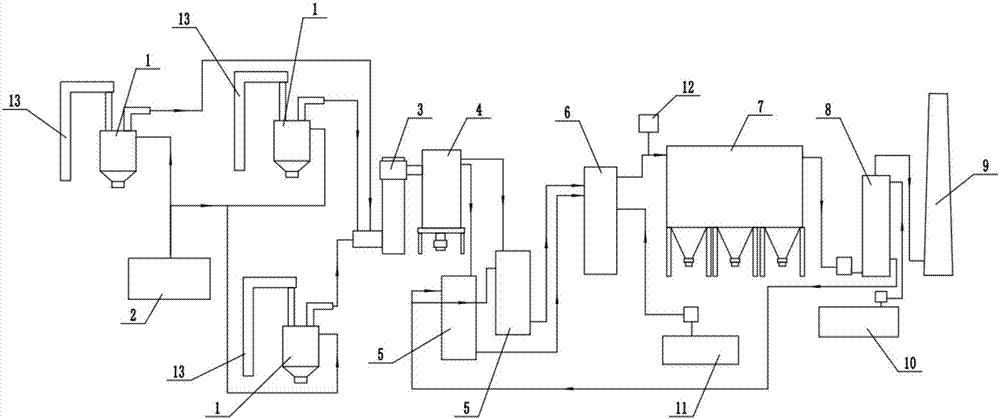

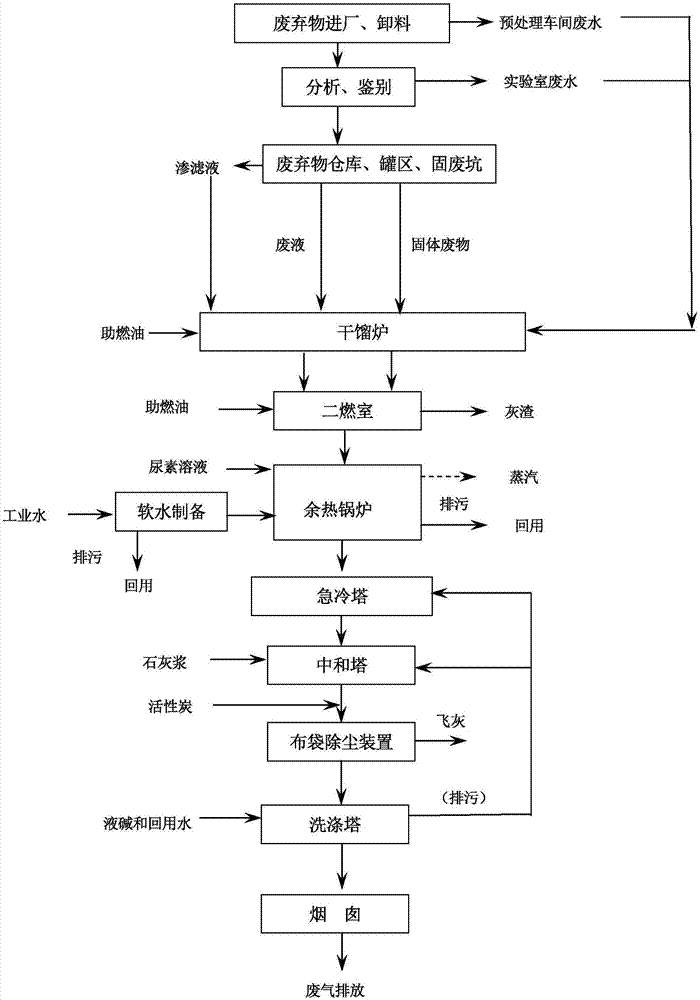

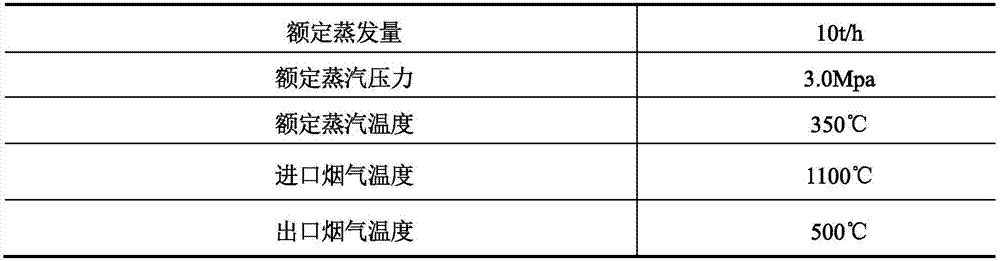

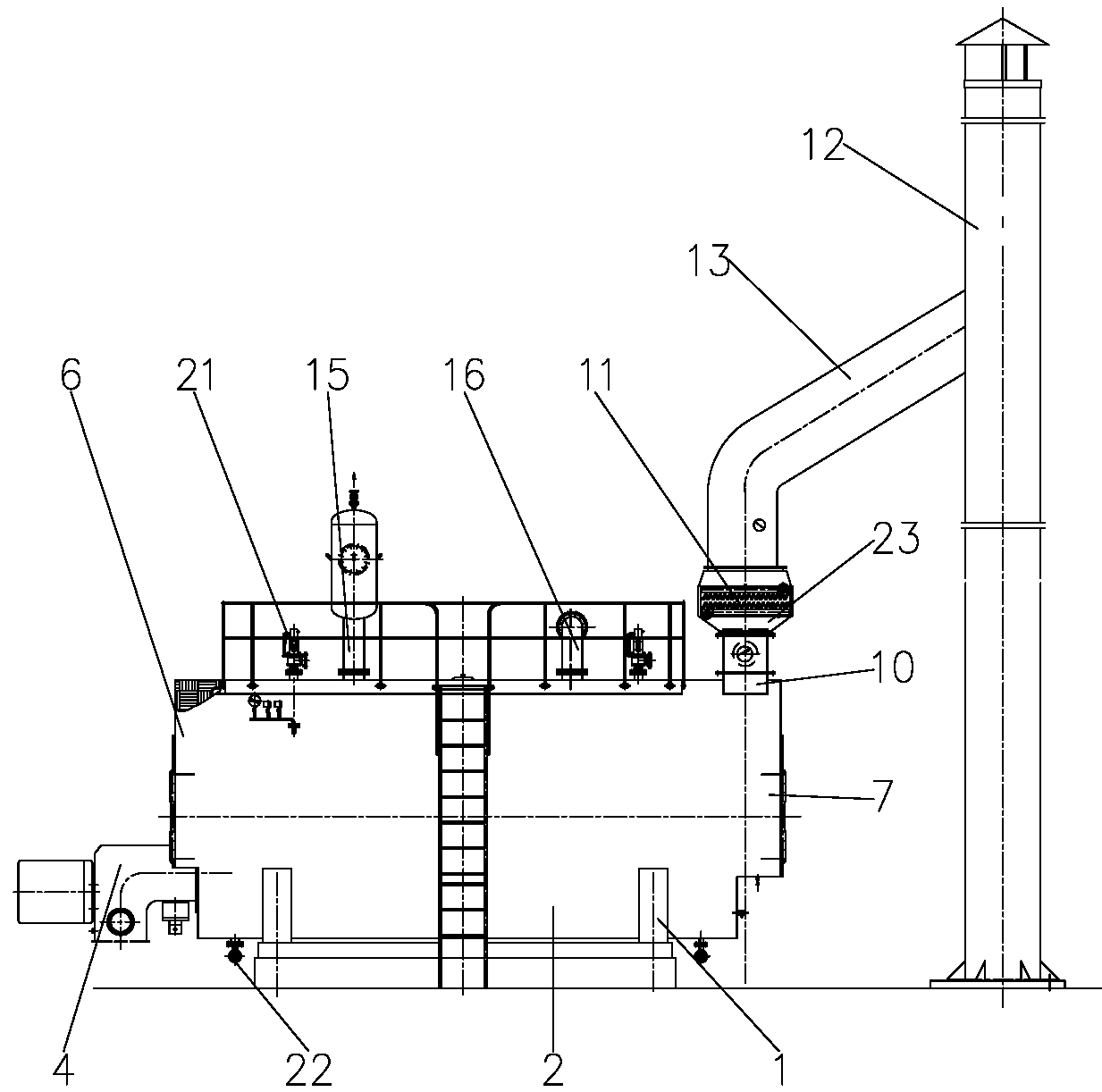

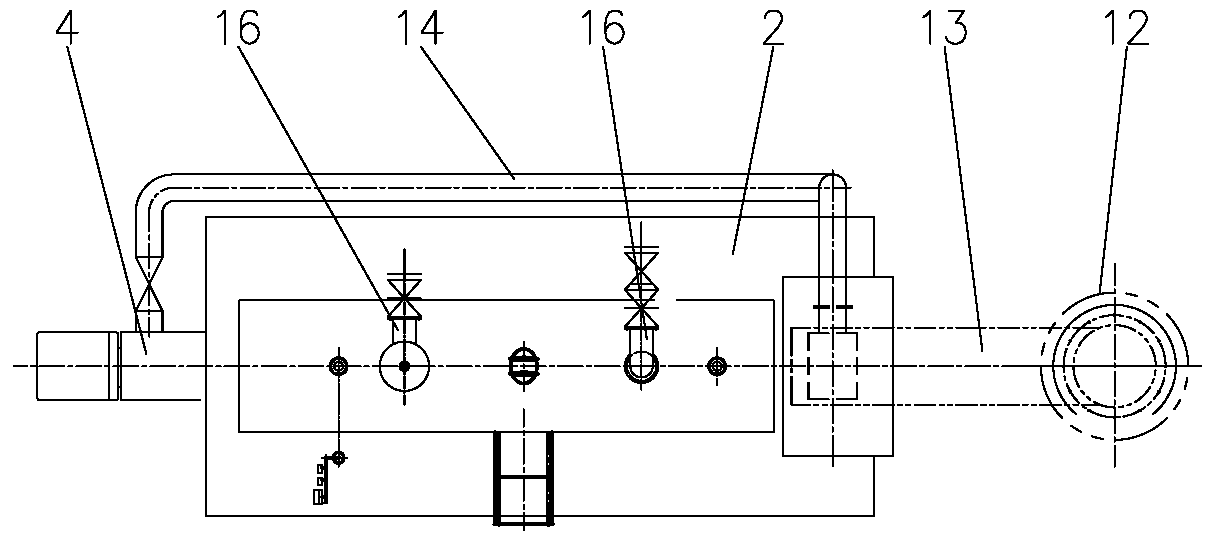

Solid waste incineration treatment system

The invention relates to a solid waste incineration treatment system. The system comprises a waste feeding device, a dry distillation device, a two-combustion form, an afterheat boiler, a quench tower, a neutralizing tower, a cloth bag dust removing device, a washing tower and a chimney; a dry distillation furnace and the afterheat boiler are both connected with a soft water device; the washing tower is connected with an alkali liquid pool; and the neutralizing tower is connected with a lime slurry pool. The semi-dry process deacidification is adopted to combine with the wet process deacidification; on the one hand, zero emission of nitrogen phosphorus after the tail gas treatment can be guaranteed; and on the other hand, generation of a lot of salt in the quench tower is prevented, and the cleaning period is prolonged.

Owner:无锡绿麦环保科技有限公司

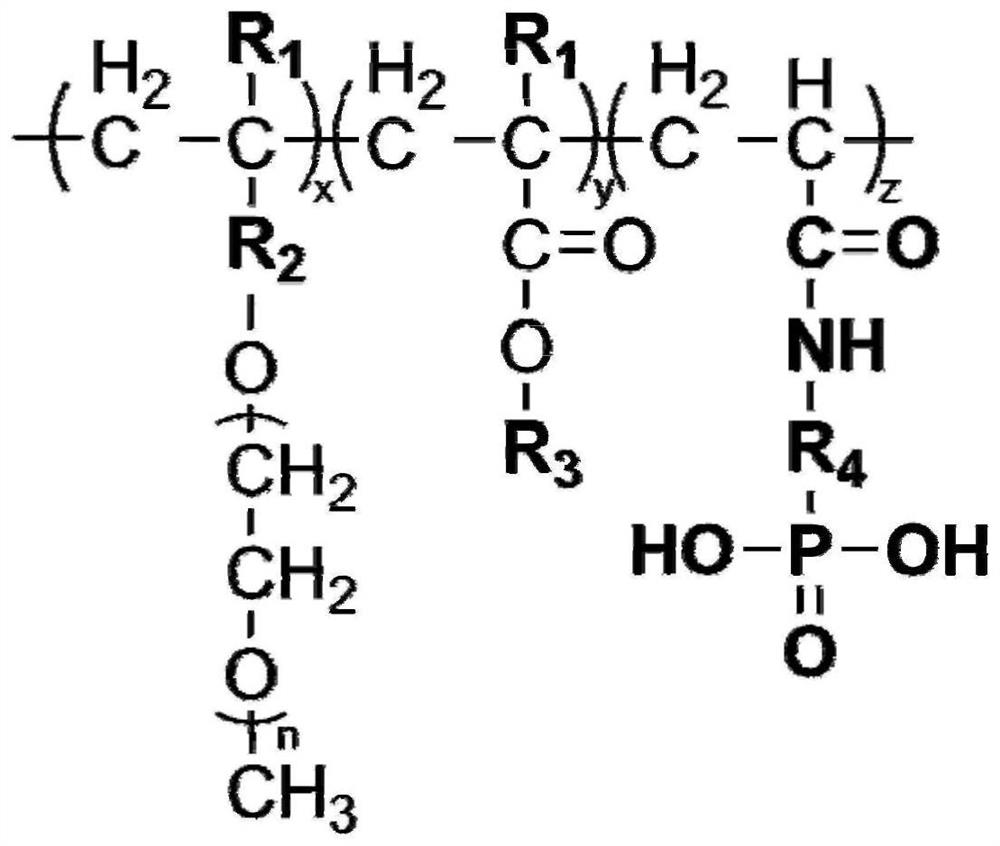

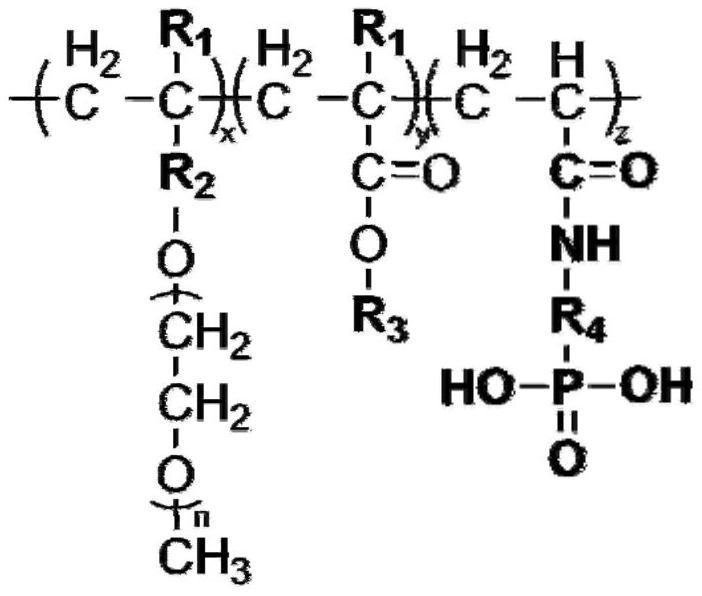

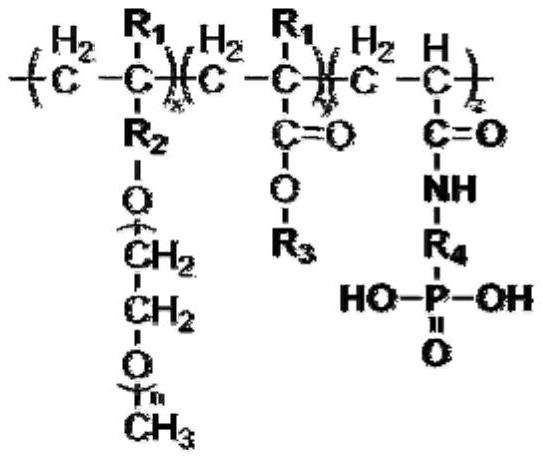

Phosphate-containing high-adaptability early-strength polycarboxylate superplasticizer, and preparation method and application thereof

InactiveCN112745464AImprove stabilitySimple preparation techniquePhosphoric Acid EstersPolymer science

The invention provides a phosphate-containing high-adaptability early-strength polycarboxylate superplasticizer, and a preparation method and application thereof, and relates to the technical field of concrete admixtures. The phosphate-containing high-adaptability early-strength polycarboxylic acid water reducer is prepared by copolymerizing 90 to 110 parts of unsaturated polyether macromonomer, 10 to 20 parts of unsaturated carboxylic acid and 1 to 6 parts of phosphate-containing acrylamide free radical. A polyacrylic acid derivative and a polyether side chain on the molecular chain of the water reducing agent provide dispersing performance, the phosphate ester-containing polyacrylamide improves the adaptability of the water reducing agent due to the existence of a phosphate group on one hand, and amido balances the retarding effect of the phosphate group on the other hand, and also improves the early strength effect of the product. Therefore, the cement early strength agent has better adaptability and early strength effect when being used for mixing different types of cement and high-mud-content aggregate concrete.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

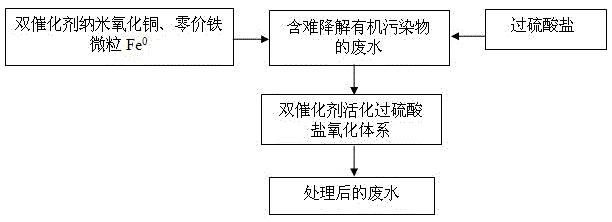

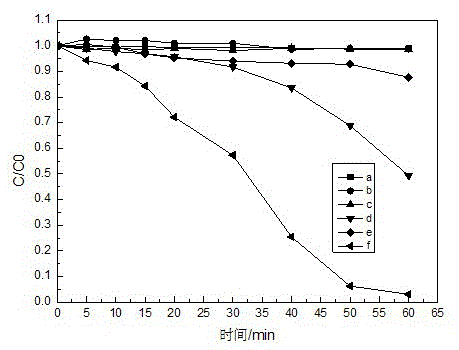

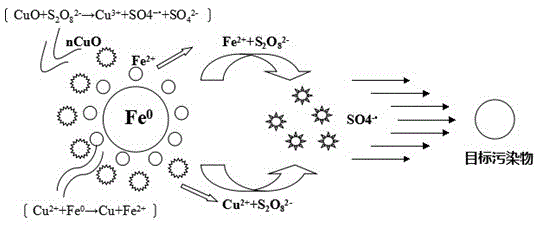

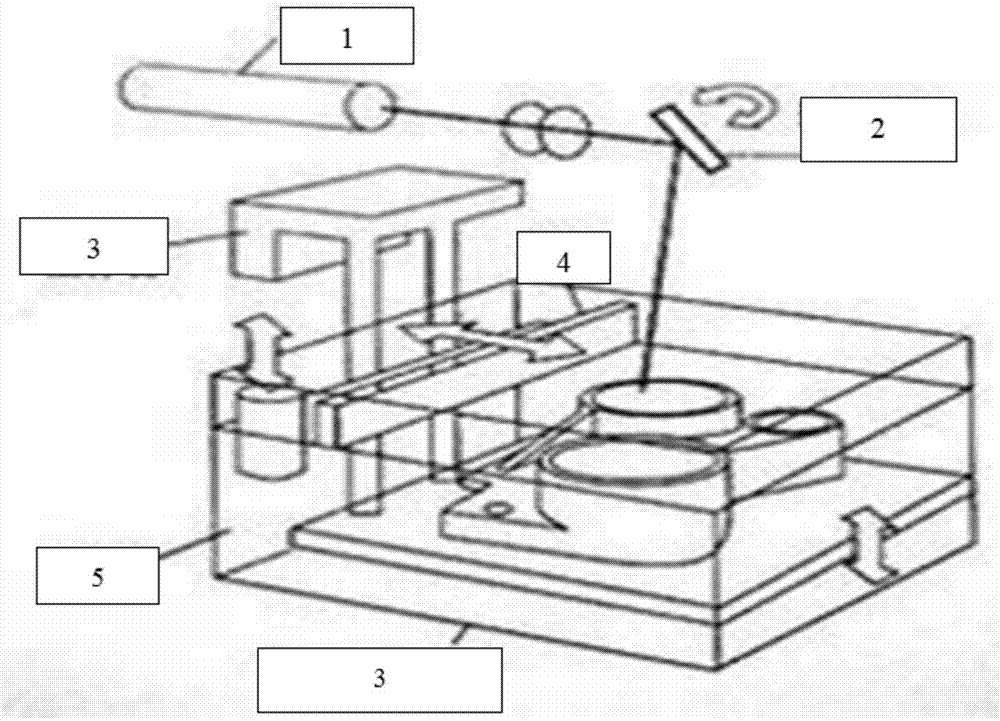

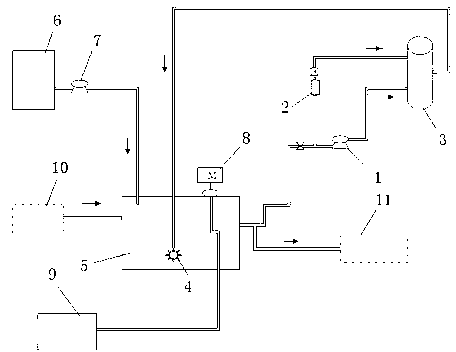

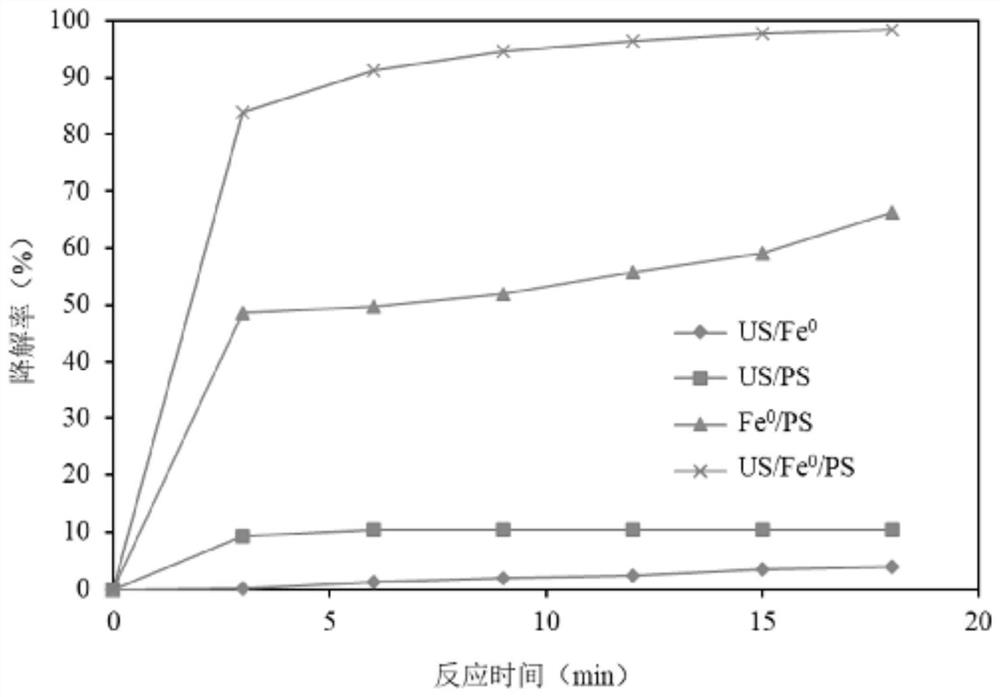

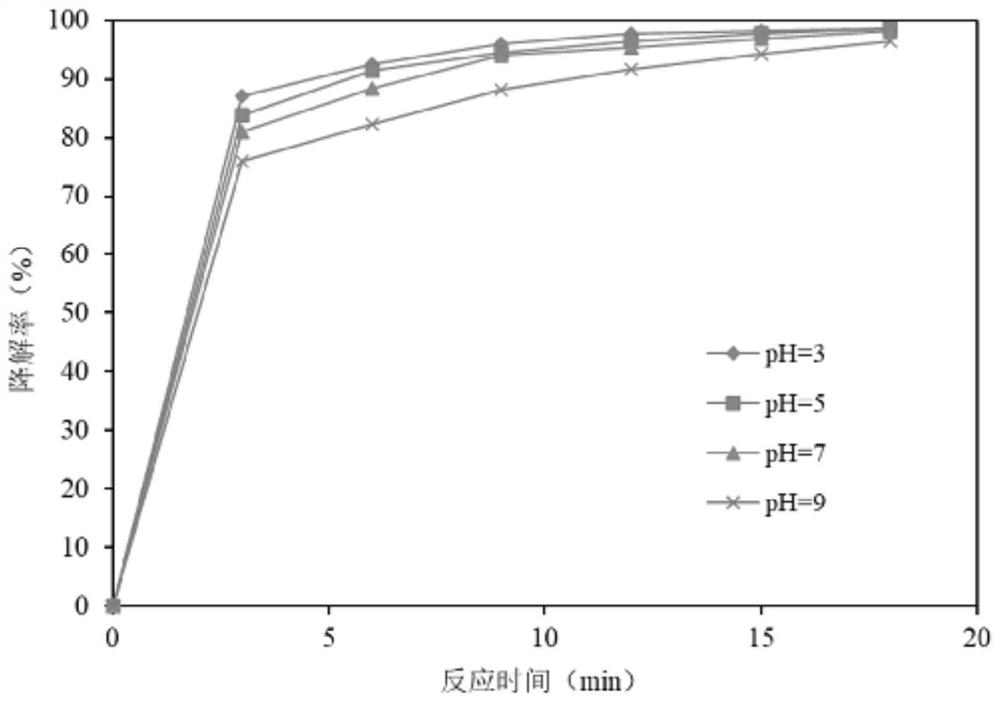

A kind of method utilizing dual catalyst heterogeneous activation persulfate to treat organic waste water

ActiveCN103896388BHigh catalytic activityIncrease profitWater/sewage treatment by oxidationSulfate radicalsBiological activation

The invention discloses a method for treating organic wastewater by using double catalysts to heterogeneously activate persulfates, belonging to the technical field of water pollution control. According to the method, nano copper oxide and zero-valent iron particles are used as a combined catalyst to activate the persulfates to generate free sulfate radicals with strong oxidizing property, so that refractory organics are removed from the wastewater. Compared with a homogeneous persulfate water treatment technology, the method has the advantage that the heterogeneous catalysts can efficiently and continuously activate the persulfates to achieve a heterogeneous activation effect due to the properties of relatively large specific surface area, relatively high catalytic activity and the like. The double-catalyst heterogeneous persulfate activation water treatment technology established by the method disclosed by the invention is applicable to treatment of various kinds of organic wastewater, is high in efficiency, good in durability and convenient in operation, can efficiently remove toxic and harmful pollutants from the wastewater within a relatively wide pH range, provides a broad prospect for treating toxic, harmful and non-biodegradable organic wastewater, and has a great application potential in the field of environmental pollution treatment.

Owner:SOUTH CHINA UNIV OF TECH

High-efficiency separation and conversion method of corn stalk

ActiveCN109880865AHigh yieldReduce damageLignin derivativesFermentationHigh concentrationGLUCOSE LIQUID

The invention provides a high-efficiency separation and conversion method of corn stalk. The method includes the following steps: (1) separation and conversion of hemicellulose; (2) separation and conversion of cellulose; and (3) separation of lignin. The systematic method effectively uses corn stalks as a raw material to produce high value-added energy chemicals and materials. The hemicellulose in the corn stalk is separated and converted into furfural, and the yield of furfural is high; the cellulose is separated and converted into the high-concentration glucose liquid; and the separated lignin has a relatively complete structure through identification. The method can effectively improve the separation efficiency and utilization rate of the three major components, and has great significance for the utilization of corn stalk biomass resources and environmental protection.

Owner:BEIJING FORESTRY UNIVERSITY

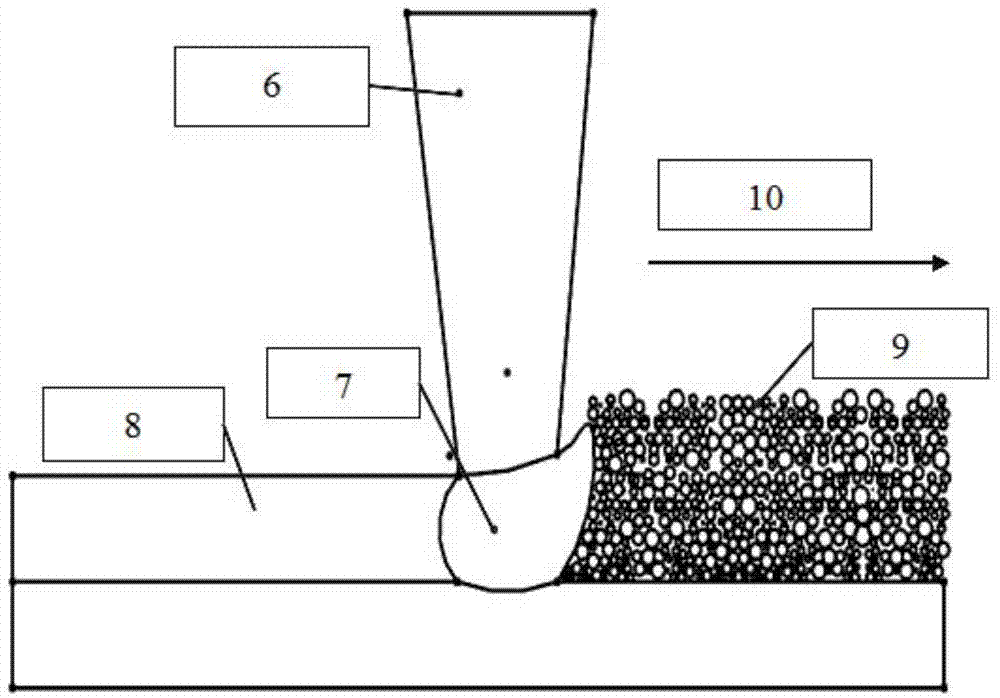

Fiber hairbrush scraper

InactiveCN104498863ASimple structureReduce volumeAdditive manufacturing apparatusMolten spray coatingMicrostructureAdhesive

The invention relates to a fiber hairbrush scraper for paving and conveying powder in a laser rapid forming process. The fiber hairbrush scraper consists of a supporting bracket and a hairbrush part, wherein a hairbrush is attached to the supporting bracket by virtue of an adhesive. In the powder paving process, on the one hand, when powder particles with the grain size being greater than the thickness of a powder paving layer enter between the scraper and a workpiece, the powder particles can be extruded, so that the frictional force between the scraper and the workpiece is increased; on the other hand, a metal solution is easily nodulized in a setting process. Problems on the above two aspects lead to bending deformation or movement of a formed piece in a forming process to affect the powder paving uniformity, so that the processing precision is reduced, or even the workpiece cannot be processed. The carbon fiber hairbrush scraper can be used for effectively solving the problem, and not only is suitable for the processing process of products with relatively great dimension, but also has advantages in processing microstructures. The carbon fiber hairbrush has the advantages of simple manufacturing, low processing cost, strong practicality, long service life and the like, is suitable for massive production and has a great economic benefit.

Owner:BEIJING UNIV OF TECH

Production method of purple yam clear juice beverage and product thereof

InactiveCN105876547AGive full play to the role of health careIncrease the juice yieldFood hydrolysisFood ingredient functionsBiotechnologyMacromolecular Substances

The invention provides a production method of a purple yam clear juice beverage and a product thereof and belongs to the technical field of deep processing of agricultural products. The production method includes: raw material purple yam pretreatment, pulping, amylase enzymolysis, compound enzyme enzymolysis, centrifuging for residue removal, mixing for filling, and sterilizing. A biological enzymolysis method is adopted to decompose ingredients like starch and protein in purple yam, so that juice yield and solid content are increased, and healthcare effect of functional ingredients like rich anthocyanin in the purple yam is brought into full play. Starch is hydrolyzed into sugar, so that only a small amount of sugar or sweetener needs to be added. Through degradation of macromolecular substances like starch and protein and control of acidity and treatment temperature, massive generation of precipitate in the process of production and storage is avoided, and product quality is improved. The product is reasonable in technology and simple in process, and the beverage is bright in color and luster, transparent, fresh and cool in taste and wide in market prospect.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

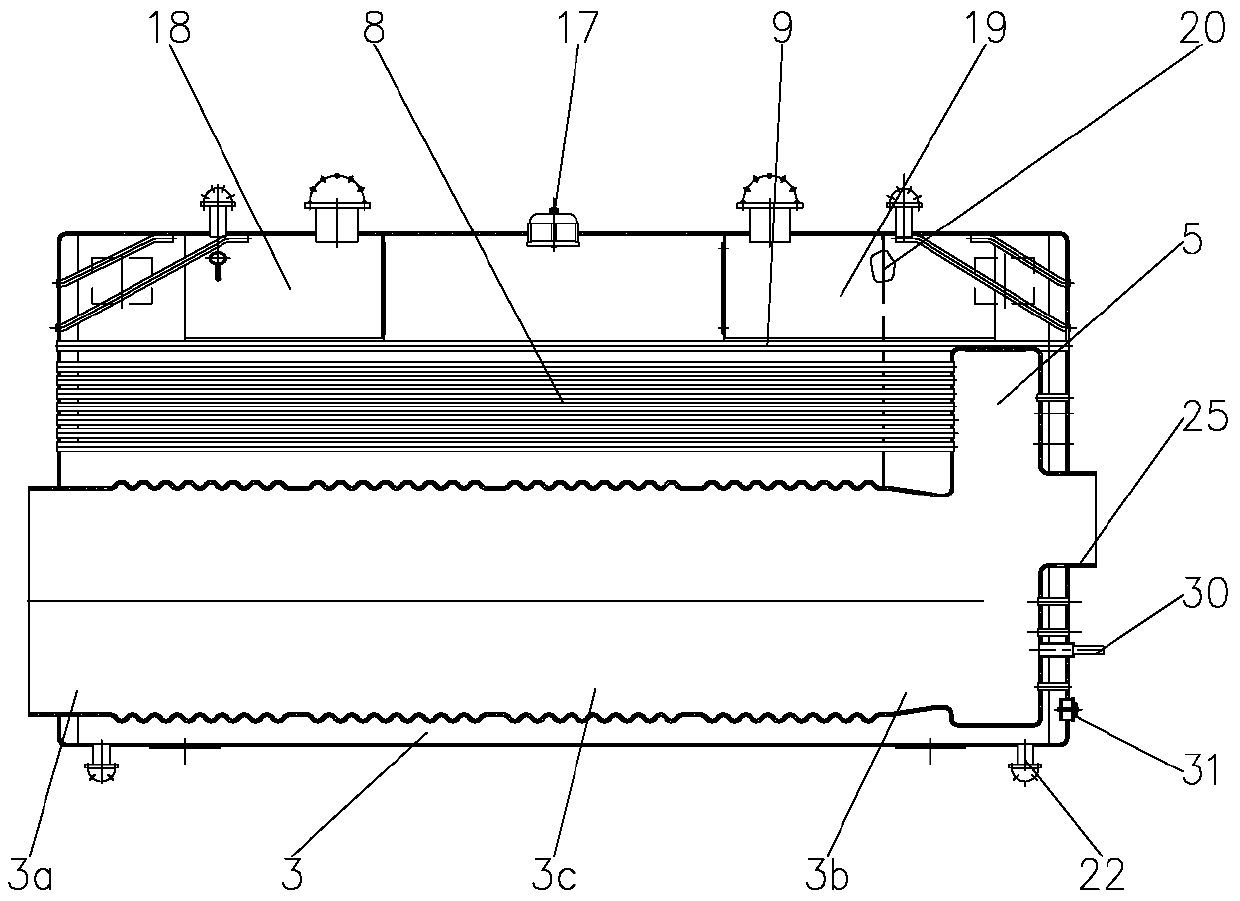

Coking desulfurization waste liquid pretreatment device

ActiveCN103304047AAchieve the purpose of preprocessingEfficient Adsorption SeparationMultistage water/sewage treatmentDissolutionAir bubble

The invention discloses a coking desulfurization waste liquid pretreatment device belonging to the technical field of coking desulfurization waste liquid treatment equipment and being used for rapidly removing sulphur and pigment in a coking desulfurization waste liquid. The technical scheme is as follows: a liquid inlet pipeline of a pressure pump and a liquid inlet pipeline of a water jet machine are respectively connected with a liquid outlet of a flotation tank; a liquid outlet pipeline of the pressure pump and a liquid outlet pipeline of the water jet machine are respectively connected with a liquid inlet of a dissolved air tank; a liquid outlet pipeline of the dissolved air tank is connected with the floatation tank; an infusion pipeline of a dosing tank is connected with the flotation tank through a dosing pump; and a sediment scraper is arranged on the flotation tank. According to the invention, the desulfurization waste liquid containing a surfactant is pressurized and subjected to air dissolution and is released at reduced pressure through an aeration head, then, air bubbles formed by the surfactant can be used for efficiently adsorbing and separating organic matters, suspended solids and metal ions, and dross can be removed by the sediment scraper, so that the aim for pre-treating the waste liquid is achieved. The coking desulfurization waste liquid pretreatment device is low in byproduct yield and capable of avoiding generating a great number of active carbon wastes in an active carbon decoloring technology, and has the advantages of simple structure and good use effect.

Owner:HEBEI IRON AND STEEL

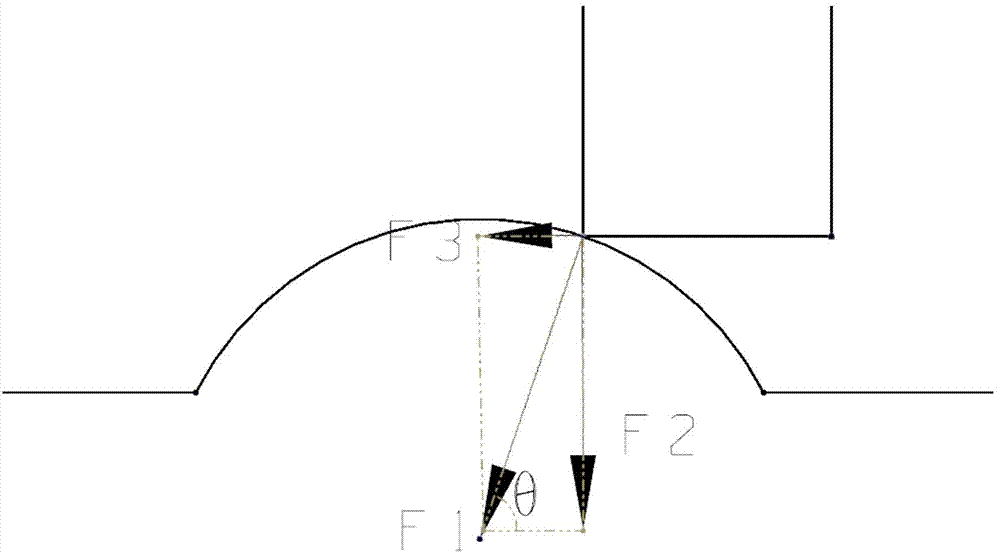

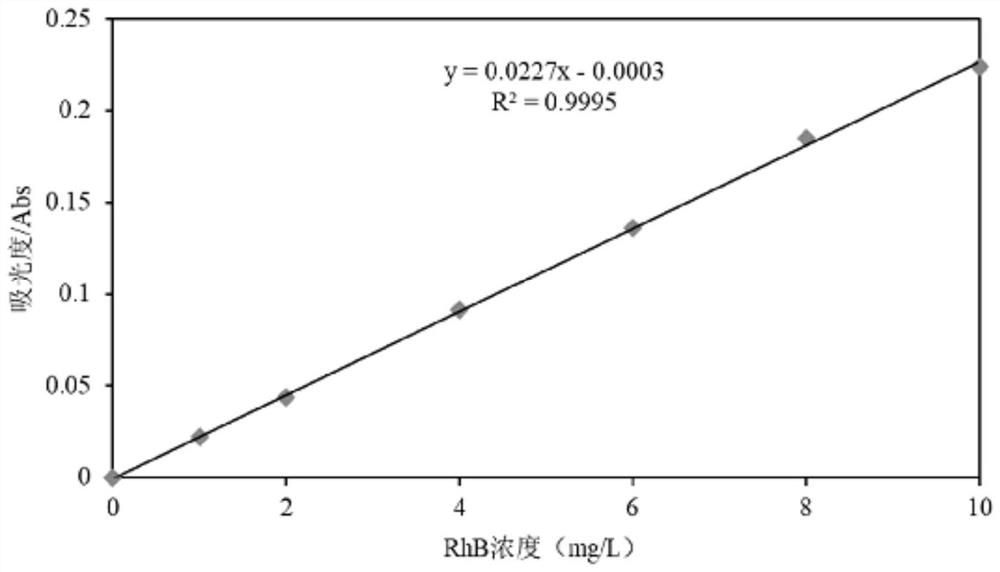

Method for catalytically degrading organic pollutants by zero-valent iron

InactiveCN112079427APromote degradationApplicable treatmentWater/sewage treatment with mechanical oscillationsWater contaminantsIron powderPersulfate

The invention discloses a method for catalytically degrading organic pollutants by zero-valent iron. The method comprises the steps of adding iron powder and persulfate into organic wastewater, and carrying out ultrasonic treatment to degrade the organic pollutants. Some embodiments of the invention have good organic pollutant degradation effects under acidic and alkaline conditions, have a wide application range, and are especially suitable for treatment of printing and dyeing wastewater. Low-cost iron powder is used for catalyzing the advanced oxidation reaction of persulfate, so that a large amount of iron sludge is prevented from being generated, and the treatment cost of the organic wastewater is remarkably reduced.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Lignin blockers and uses thereof

InactiveUS8580541B2Increase productionAvoid mass productionSerum albuminProtein composition from vegetable seedsLignocellulosic biomassCellulase

Disclosed is a method for converting cellulose in a lignocellulosic biomass. The method provides for a lignin-blocking polypeptide and / or protein treatment of high lignin solids. The treatment enhances cellulase availability in cellulose conversion and allows for the determination of optimized pretreatment conditions. Additionally, ethanol yields from a Simultaneous Saccharification and Fermentation process are improved 5-25% by treatment with a lignin-blocking polypeptide and / or protein.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

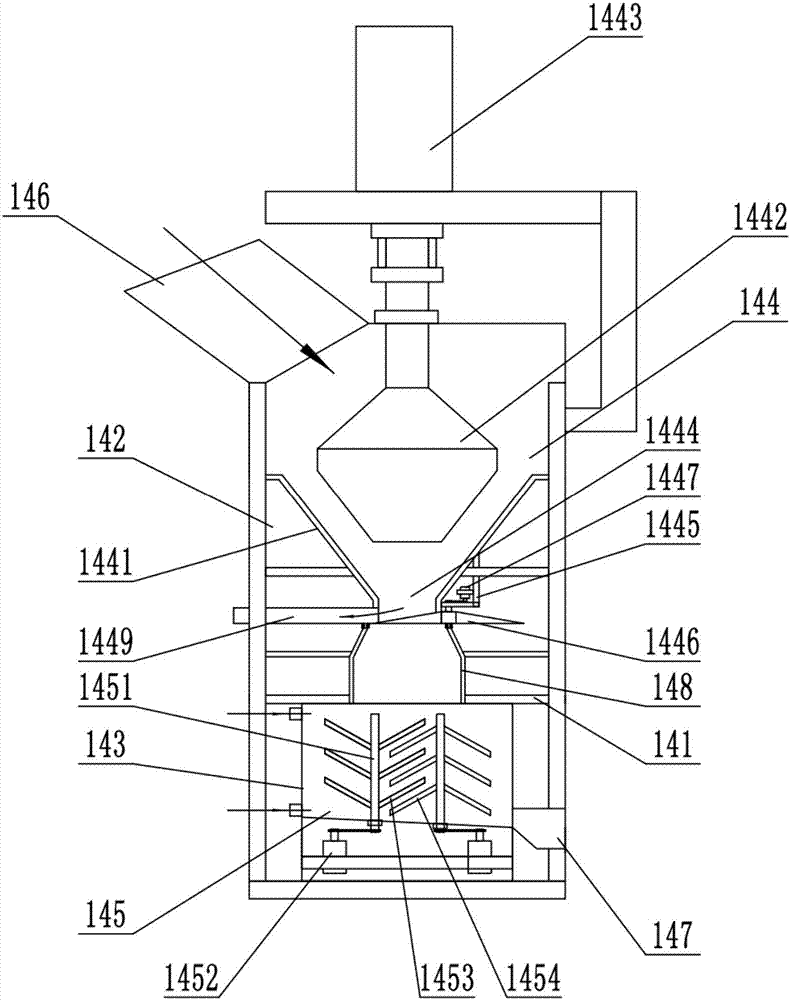

Explosion-proof incineration treatment system for solid waste

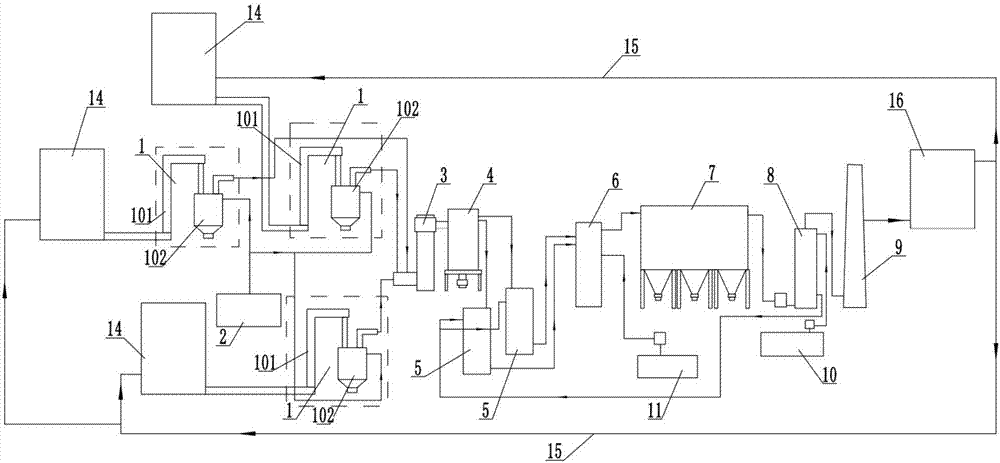

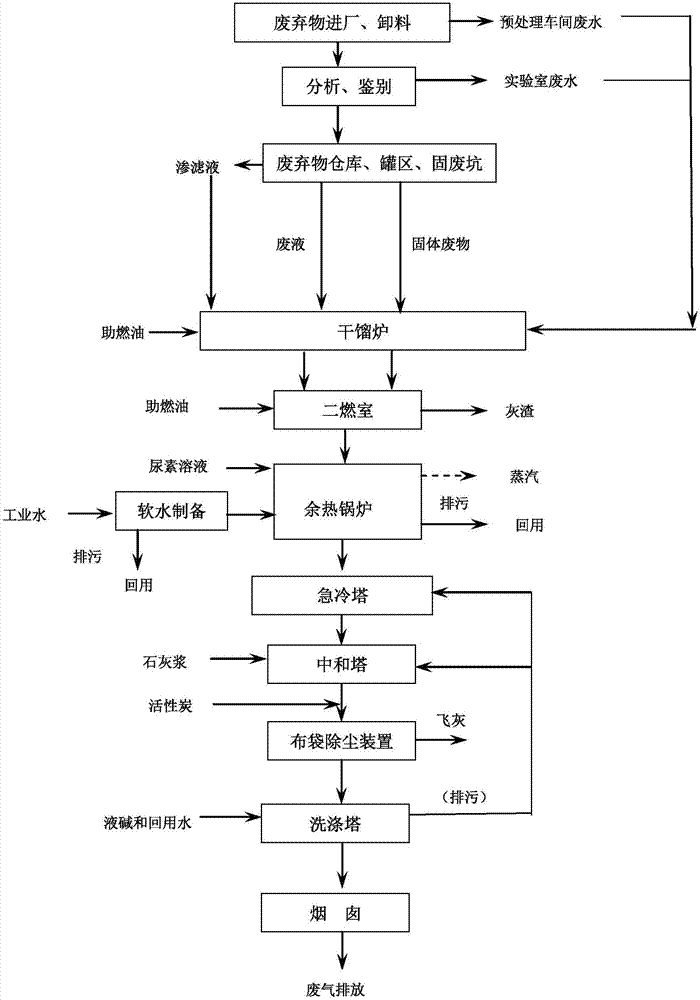

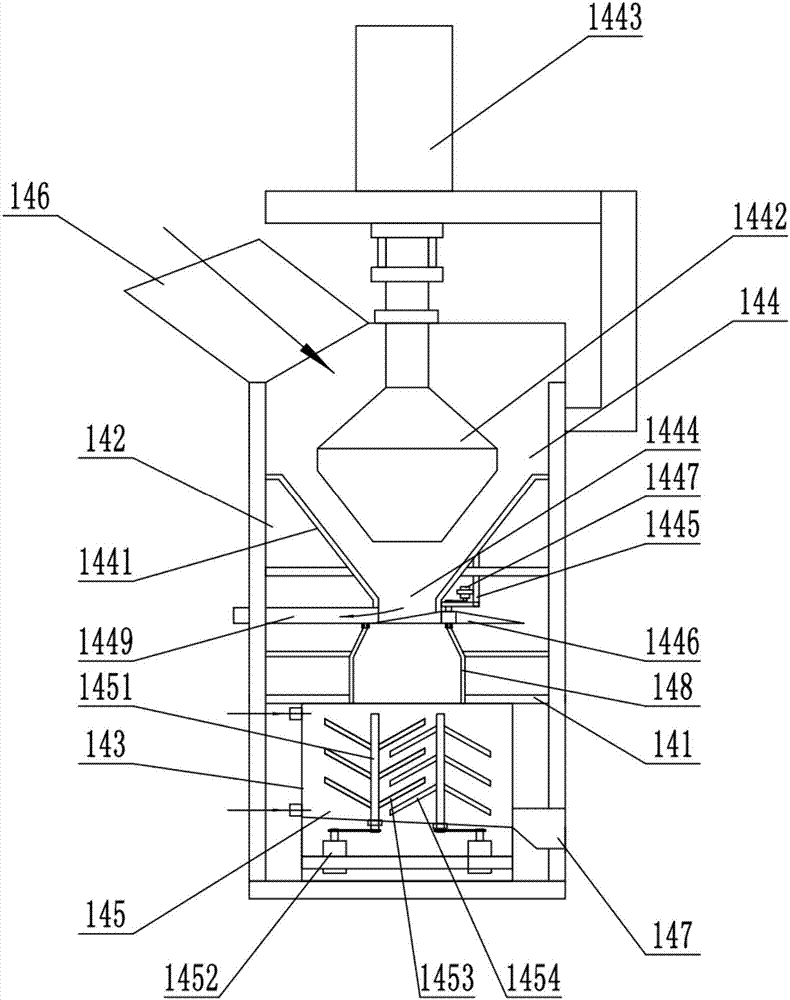

PendingCN107246613AAvoid mass productionGuaranteed uptimeIncinerator apparatusCombustion chamberDust control

The invention relates to an explosion-proof incineration treatment system for solid waste. The explosion-proof incineration treatment system for the solid waste comprises solid waste smashing devices, a waste feeding device, a dry distillation device, a secondary combustion chamber, a waste heat boiler, a quenching tower, a neutralizing tower, a cloth-bag dust control device, a washing tower and a chimney which are connected in sequence, wherein the dry distillation furnace and the waste heat boiler are both connected with a water softening device, the washing tower is connected with an alkaline liquor pool, the neutralizing tower is connected with a lime slurry pool, the smoke outlet end of the chimney is connected with one input end of one mixing device, the other input end of the mixing device is connected with a nitrogen storage tank, and the output end of the mixing device is connected with the solid waste smashing devices through smoke return pipelines.

Owner:无锡绿麦环保科技有限公司

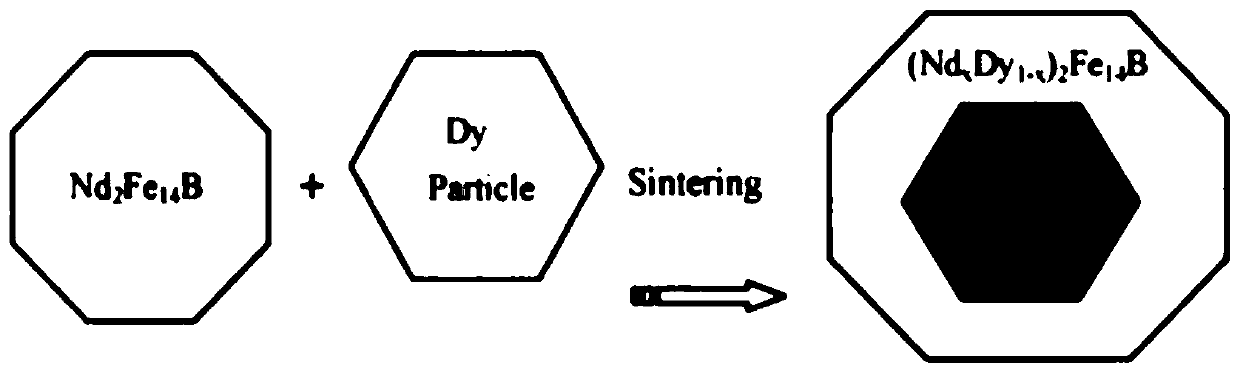

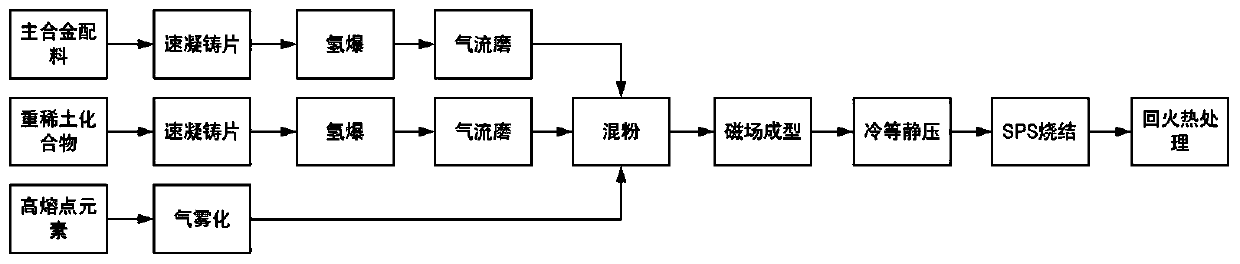

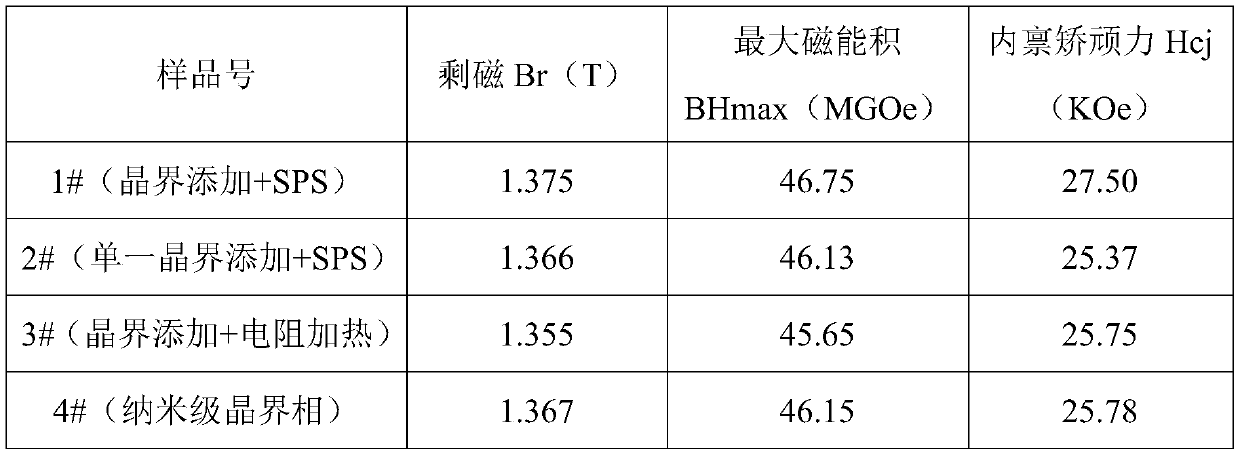

Method for preparing high-performance sintered neodymium-iron-boron magnet based on grain boundary addition

InactiveCN110534280AInhibition of magnetization reversal domain nucleationImprove magnetic propertiesInductances/transformers/magnets manufactureMagnetic materialsGrain boundaryCoercivity

The invention discloses a method for preparing a high-performance sintered neodymium-iron-boron magnet based on grain boundary addition. The method comprises the steps that firstly, main alloy is prepared according to the composition of atomic ratio Nd: Fe: B=2: 14: 1; main alloy and two kinds of grain boundary phase micron powder of a heavy rare earth compound and a high melting point element areprepared by the method of gas atomization or rapid solidification casting, hydrogen explosion and jet milling; three kinds of powder are uniformly mixed by compositely adding the micron-level heavy rare earth compound and a high melting point element regulating grain boundary structure; a flake is acquired through magnetic field molding, cold isostatic pressing and the like; and finally dischargeplasma sintering (SPS) and secondary tempering are carried out to acquire the high-performance sintered neodymium-iron-boron magnet with the maximum magnetic energy product greater than or equal to 45 MGOE and intrinsic coercivity greater than or equal to 25KO. Compared with the prior art, the method provided by the invention has the advantages of high processing efficiency, low production cost and good consistency of magnetic properties, is easy to realize commercial applications, can well meet customer needs, and is very suitable for preparing the high-performance sintered neodymium-iron-boron magnet.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

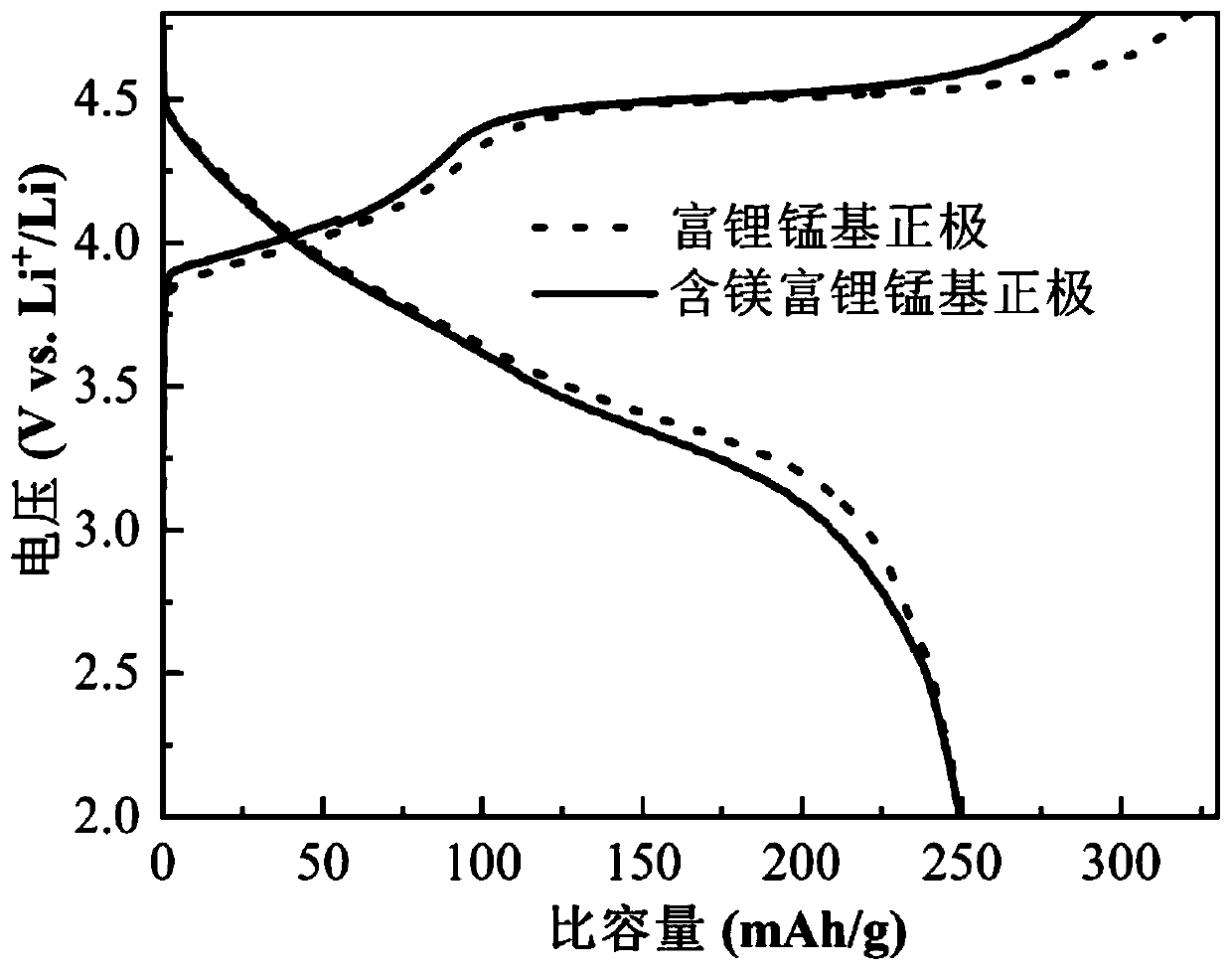

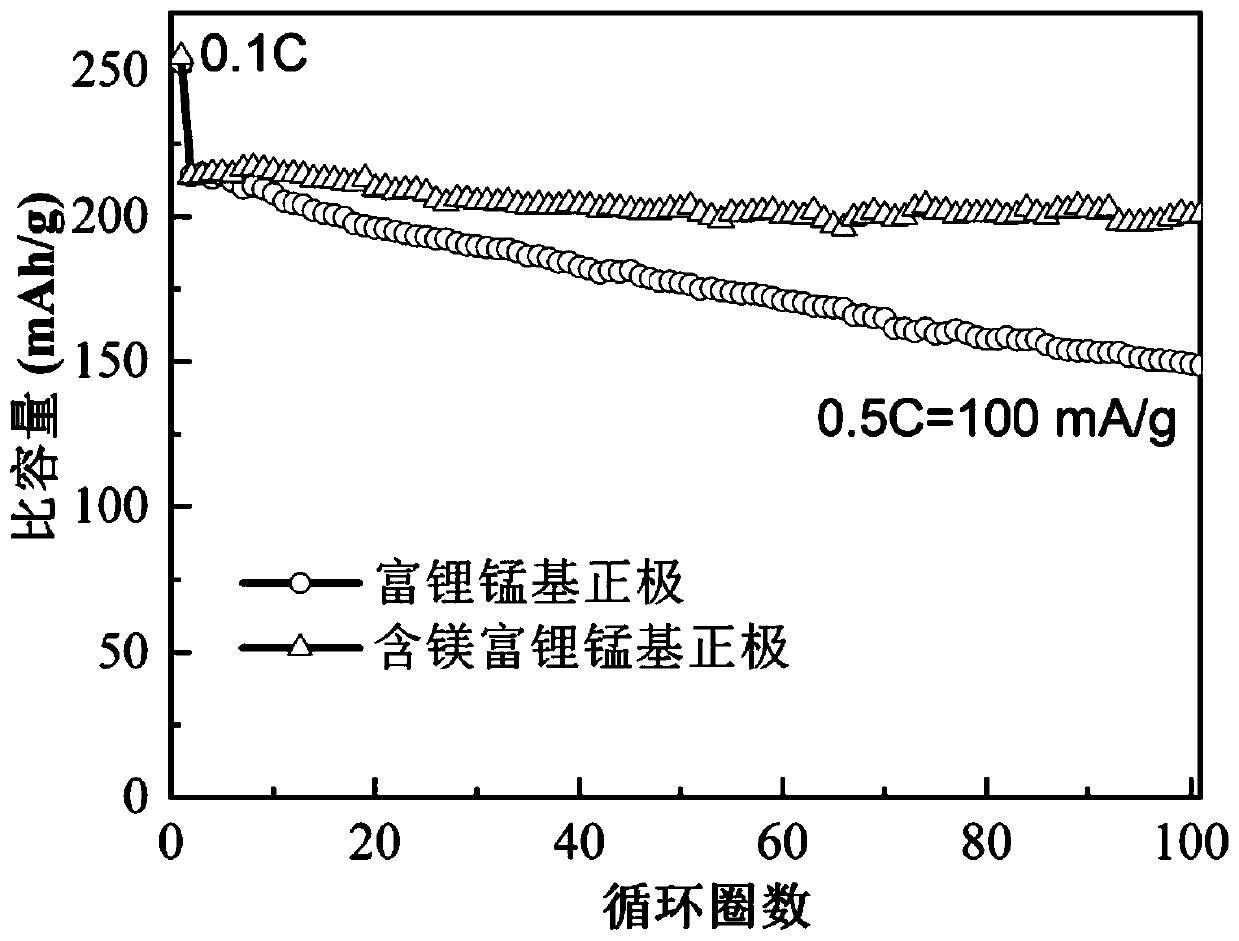

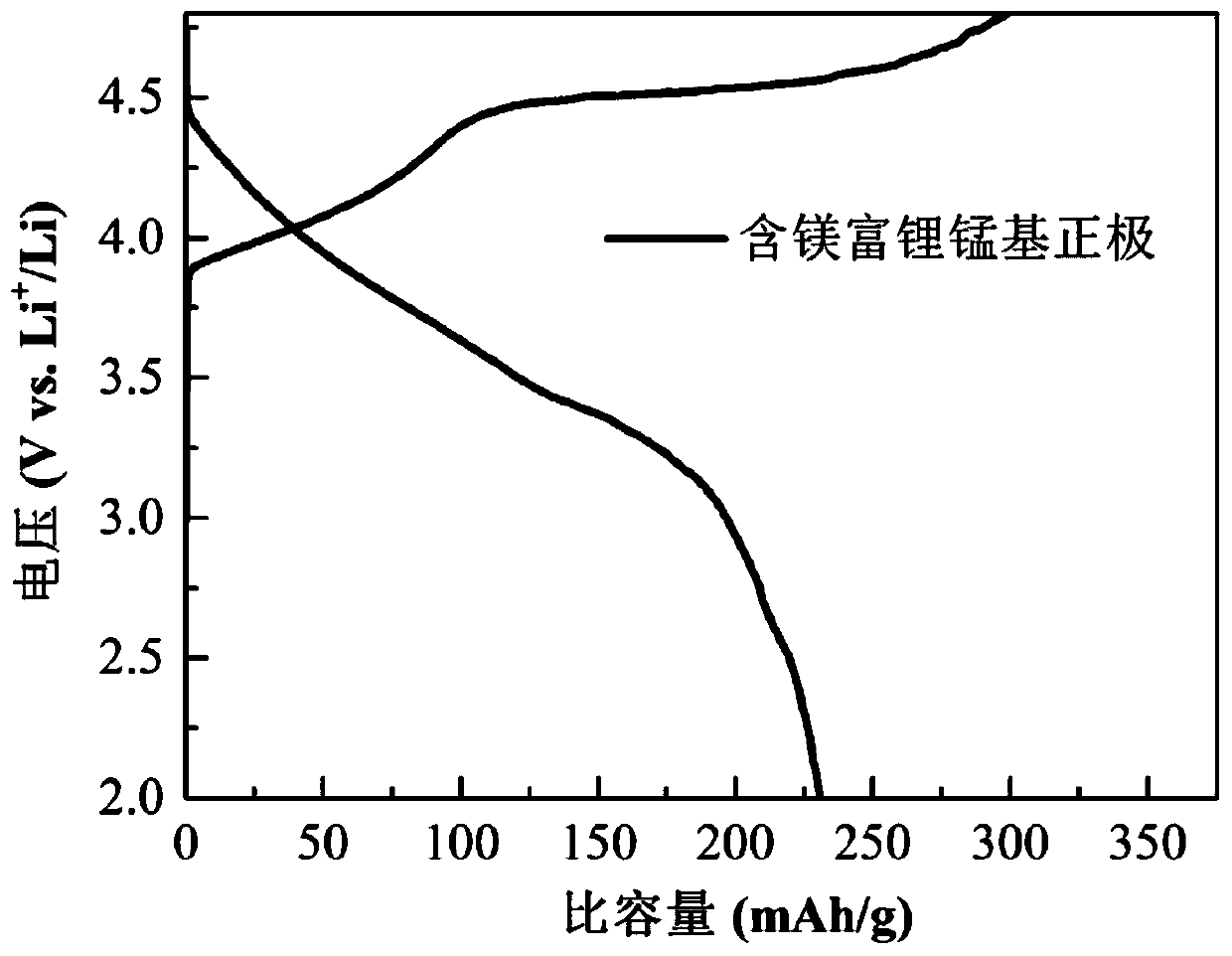

Magnesium-containing lithium-rich manganese-based positive electrode and preparation method thereof

ActiveCN111313008AAvoid irreversible damageEvenly distributedElectrode collector coatingLi-accumulatorsManganeseLithium-ion battery

The invention relates to a magnesium-containing lithium-rich manganese-based positive electrode and a preparation method thereof. The magnesium-containing lithium-rich manganese-based positive electrode comprises a current collector and an active material, the active material is attached to the current collector, the active material comprises a lithium-rich manganese-based positive electrode material xLi2MnO3. (1-x) LiMO2, wherein M is a transition metal element, and x is greater than 0 and less than 1; a magnesium simple substance or a magnesium compound, a conductive agent and a binder, wherein the mass of the magnesium elementary substance or the mass of magnesium in the magnesium compound is 0.1%-10% of the mass of the lithium-rich manganese-based positive electrode material. The activation of the manganese element of the lithium ion battery prepared from the magnesium-containing lithium-rich manganese-based positive electrode is inhibited in the first-circle charging process, andthe lithium ion battery has extremely high cycling stability.

Owner:XIAMEN UNIV

Method for preparing vinyl chloride with acetylene and dichlorethane

ActiveUS20150141713A1Outstanding advantageAvoid mass productionPreparation by hydrogen halide split-offPreparation by halogen halide additionEthane DichlorideHydrogen chloride

Provided is a method for preparing vinyl chloride with acetylene and dichlorethane for large-scale industrial production. Acetylene, dichlorethane vapor and hydrogen chloride gas at a molar ratio of 1:(0.3-1.0):(0-0.20) are mixed; the raw mixed gas is preheated; the preheated raw mixed gas passes through a reactor containing a catalyst and reacts; the resultant mixed gas is cooled to 30-50° C. and pressurized to 0.4-1.0 MPa, and then cooled to ambient temperature, and further frozen to −25-15° C. for liquefaction isolation, and unliquefied gas is recycled and reused; liquefied liquid is sent to a rectifying tower for rectification, and vinyl chloride monomers meeting polymerization requirements are obtained. The present invention has the advantages of eliminating mercury contamination completely, simplifying the reactor structure, recycling hydrogen chloride and acetylene, reducing waterwash process, avoiding mass production of waste acid and improving utilization of chlorine.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Solid waste incineration disposal system and process thereof

InactiveCN107401744AAvoid mass productionGuaranteed uptimeCombustion technology mitigationIncinerator apparatusCombustion chamberNitrogen

The invention relates to a solid waste incineration disposal system. The solid waste incineration disposal system comprises a waste feed device, a destructive distillation device, a secondary combustion chamber, a waste heat boiler, a quench tower, a neutralizing tower, a cloth bag dust removal device, a washing tower and a chimney which are sequentially connected. The destructive distillation furnace and the waste heat boiler are both connected with a waster softening device. The washing tower is connected with an alkali liquor pool. The neutralizing tower is connected with a lime slurry pool. According to the solid waste incineration disposal system, the semi-dry method deacidification and the wet method deacidification are combined; on one hand, it can be ensured that zero nitrogen and phosphorus emission is achieved after tail gas processing; and on the other hand, it is avoided that a large amount of salt is generated in the quench tower, and the cleaning period of the quench tower is prolonged.

Owner:无锡绿麦环保科技有限公司

Solid waste incineration system and process thereof

PendingCN107120657AAvoid mass productionGuaranteed uptimeEmission preventionIncinerator apparatusCombustion chamberNitrogen

The invention relates to a solid waste incineration system and process. The solid waste incineration system comprises a waste feeding device, a dry distillation furnace, a second combustion chamber, a waste heat boiler, a quench tower, a neutralizing tower, a bag-type dust collection device, a washing tower and a stack which are sequentially connected. The dry distillation furnace and the waste heat boiler are both connected with a demineralized water treatment device, the washing tower is connected with an alkali liquor pond, and the neutralizing tower is connected with a lime slurry pond. According to the solid waste incineration system and process, semidry method deacidification and wet method deacidification are combined, on the one hand, zero nitrogen and phosphorus emission after tail gas treatment is conducted can be guaranteed, on the other hand, generation of a large amount of salt in the quench tower is avoided, and the cleaning cycle of the system is prolonged.

Owner:无锡绿麦环保科技有限公司

Environment-friendly energy-saving boiler

The invention provides an environment-friendly energy-saving boiler. The environment-friendly energy-saving boiler comprises a chassis, a boiler body is fixedly installed on the chassis, and the boiler body is internally provided with a boiler furnace and a reversal chamber which is located at the rear end of the boiler furnace; a combustion engine is arranged at the portion, corresponding to theboiler furnace, of the front end of the boiler body, the front end of the boiler body is further provided with a front smoke box, and the rear end of the boiler body is provided with a rear smoke box;and a first smoke tube group is arranged between the reversal chamber and the front smoke box, a second smoke tube group is arranged between the front smoke box and the rear smoke box, and a chimneybase which communicates with the rear smoke box is arranged on the rear smoke box. The environment-friendly energy-saving boiler is characterized in that an energy-saving condenser is installed on thechimney base and provided with a connecting smoke flue which is connected with a chimney; a smoke recirculating tube is arranged between the chimney base and the energy-saving condenser, the other end of the smoke recirculating tube is connected with an air inlet of the combustion engine, the volume of smoke, sucked into the combustion engine, in the smoke recirculating tube accounts for 10%-16%that of the smoke exhausted in the chimney base, and the volume heat load of the boiler furnace ranges from 850 KW / m<3> to 1,050 KW / m<3>. Not only can the using requirement be met, but also the environment-friendly energy-saving boiler is more energy-saving and environment-friendly compared with an existing hot-water boiler.

Owner:CHONGQING ZHONGGUO ENERGY TECH

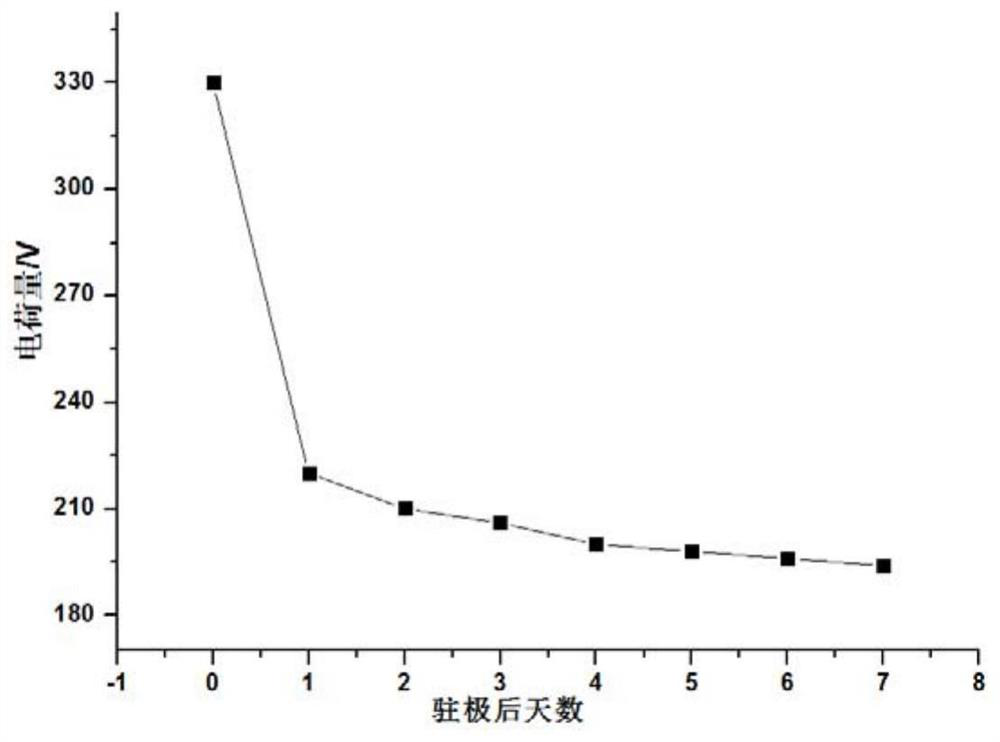

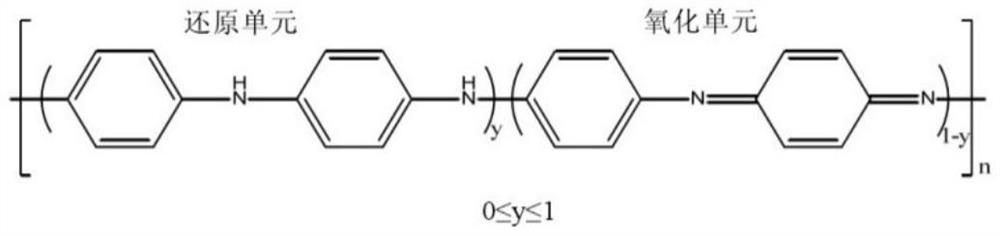

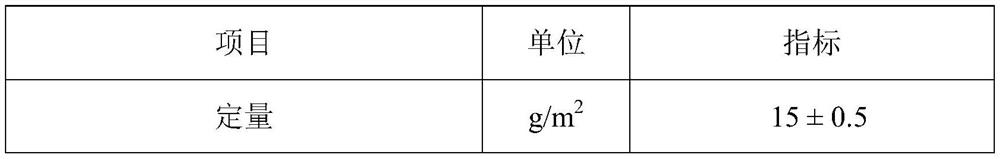

Electret filter base paper based on natural plant fibers as well as preparation method and application of base paper

ActiveCN112323539ASolve the problem of non-electretImprove filtration efficiencyPulp properties modificationOrganic non-cellulose fibresCelluloseConductive polymer

The invention discloses electret filter base paper based on natural plant fibers as well as a preparation method and application of the electret filter base paper, and the preparation method comprisesthe following steps: (1) defibering and dispersing paper pulp cellulose, and adding a conductive polymer material monomer to obtain a first mixed suspension; (2) adding an oxidant into the first mixed suspension, conducting stirring and reacting for 1-3 hours at 0 DEG C in an ice bath, and conducting filtering, washing, drying and defibering to obtain a modified second mixed suspension; (3) adding polylactic acid fibers, a reinforcing agent, SiO2 and nanocellulose into the second mixed suspension, then conducting defibering and uniform mixing, and conducting papermaking to obtain paper; and (4) carrying out electret treatment on the prepared paper to obtain the filter base paper with the surface potential of 300V-400V. According to the method disclosed by the invention, the plant fiber isused as a base material, polyaniline is introduced into the surface of the fiber through a chemical modification method, and the added functional additive has excellent electret stability and good mechanical properties, so that the filtering efficiency of the base paper can be greatly improved.

Owner:QILU UNIV OF TECH +1

Processing method of instant seasoning grilled squid strips

Owner:RONGCHENG HONGWEI FOOD

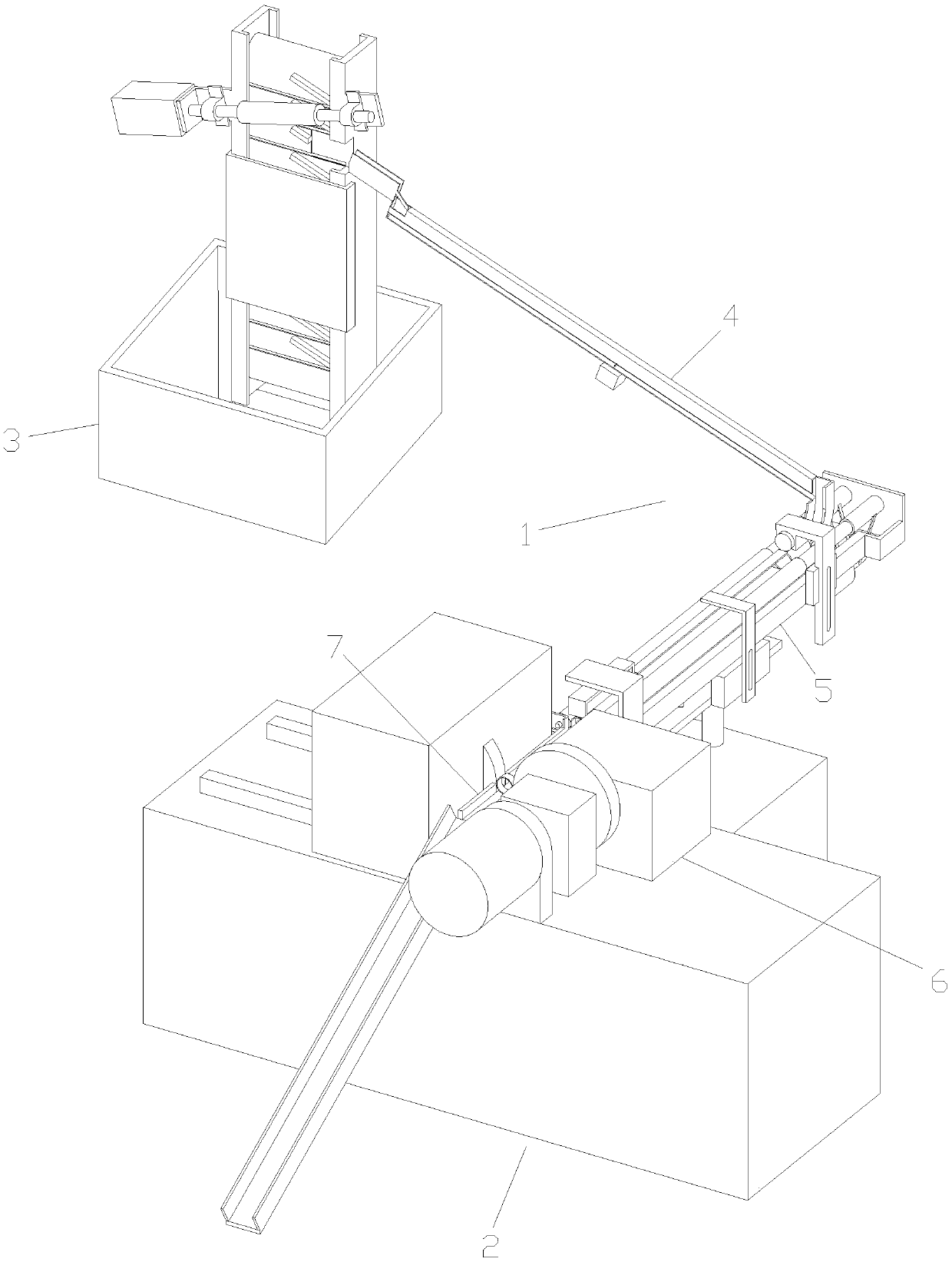

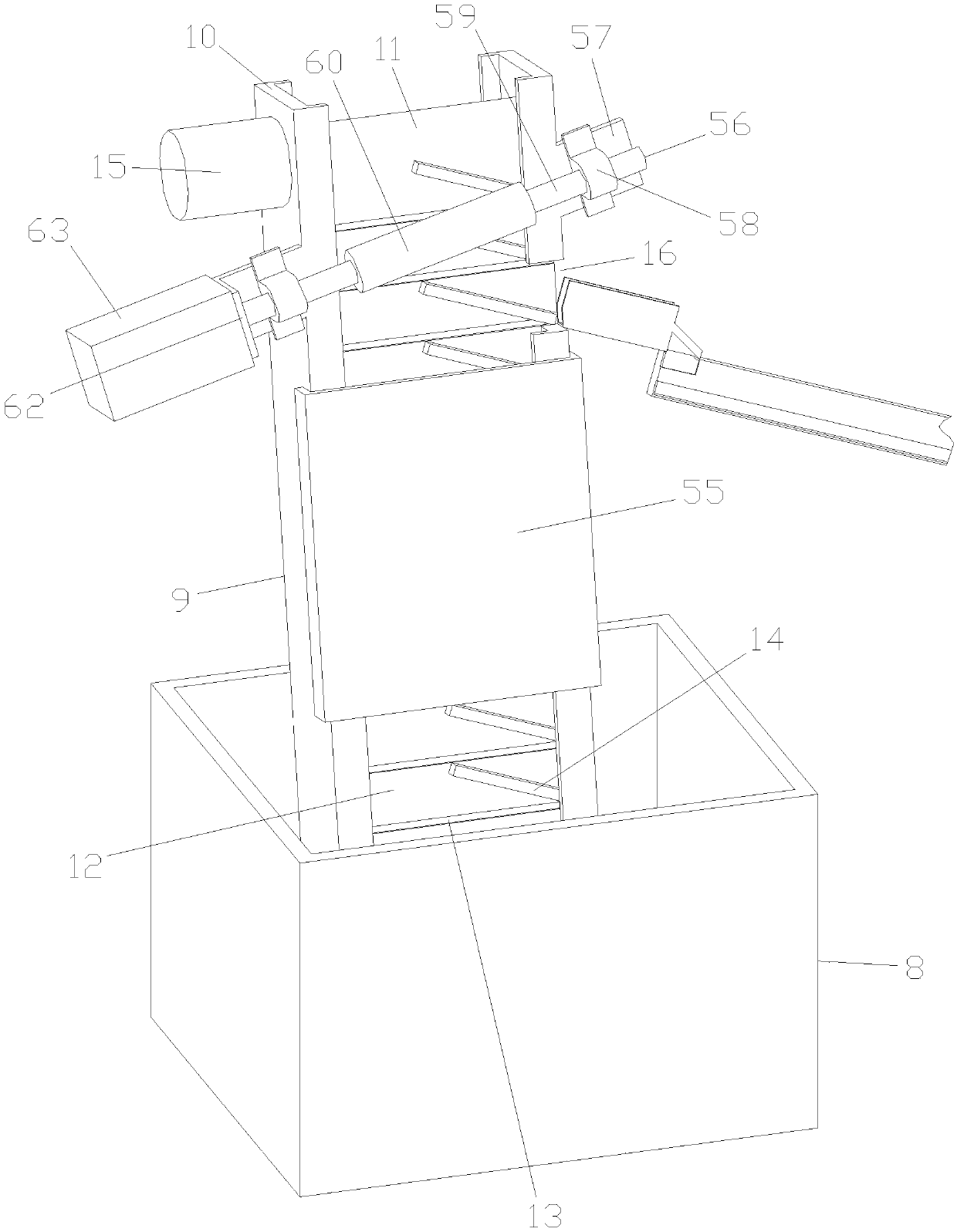

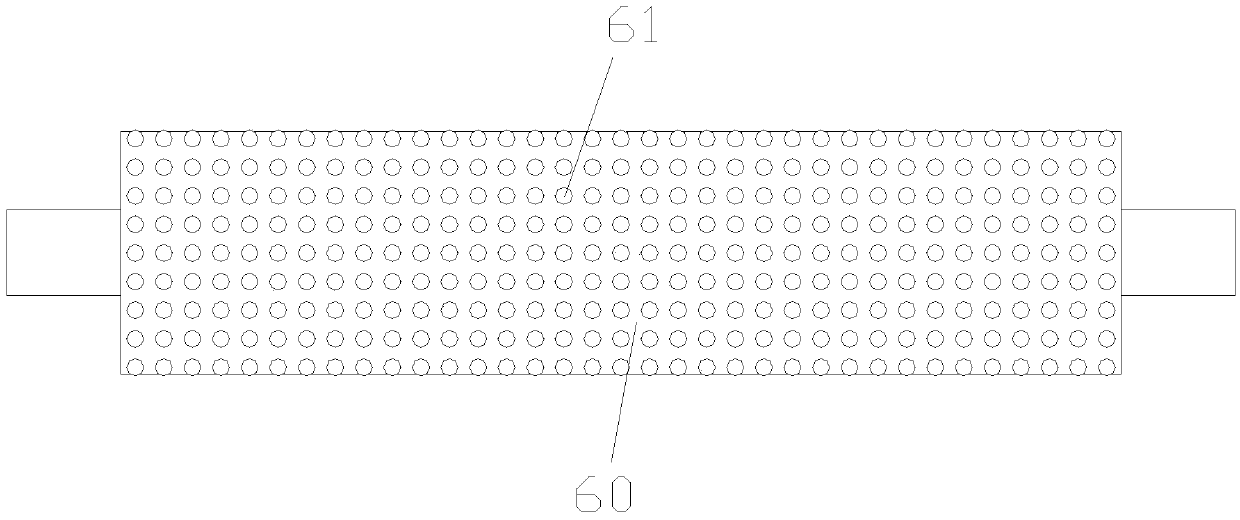

Bearing outer surface grinding and conveying and machining all-in-one machine

PendingCN109531299ASolve the blockageQuick grindingGrinding carriagesRevolution surface grinding machinesEngineeringSurface grinding

The invention discloses a bearing outer surface grinding and conveying and machining all-in-one machine. The bearing outer surface grinding and conveying and machining all-in-one machine comprises a conveying device and a grinding device, the conveying device comprises a vertical conveying unit, a feeding rail arranged at the discharging end of the vertical conveying unit and a material pushing unit connected with the discharging end of the feeding rail, and the grinding device comprises a machining unit and a feeding rail arranged in the machining unit and used in cooperation with the material pushing unit. According to the bearing outer surface grinding and conveying and machining all-in-one machine, the conveying and machining are integrated, the bearing outer surface grinding and conveying and machining all-in-one machine has the advantages of being good in lifting effect and free of noise; the problem of blockage of the bearing is solved, when the bearing is pushed to the machining device, the feeding efficiency is improved by driving the bearing to rotate; due to the bearing cannot be poured, the original placing state is lost, the problem of the feeding process is hindered,the outer peripheral surface of the bearing can be rapidly ground without clamping in the grinding process, and the bearing outer surface grinding and conveying and machining all-in-one machine realizes batch production, is convenient and rapid, and is worthy of popularization.

Owner:浙江景宁精工轴承有限公司

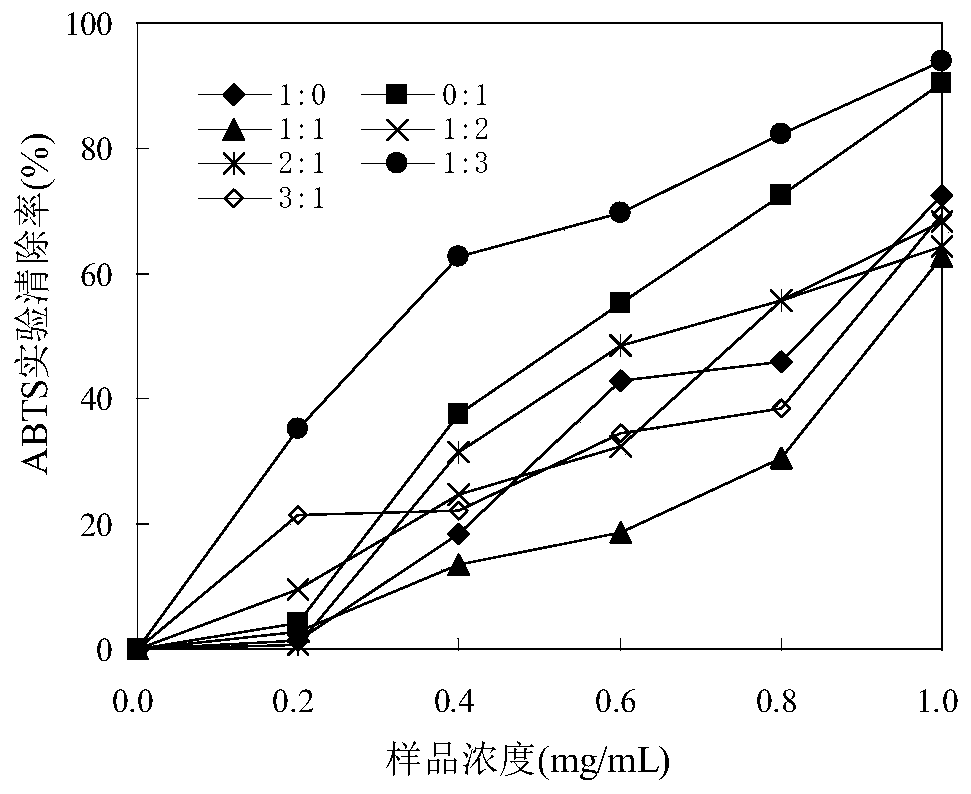

Composite rice soup beverage capable of resisting oxidation and inhibiting lipase and preparation method thereof

PendingCN111528371AUnique material selectionReasonable material selectionOptically investigating flaws/contaminationNatural extract food ingredientsBiotechnologyVitamin C

The invention discloses a composite rice soup beverage capable of resisting oxidation and inhibiting lipase and a preparation method of the composite rice soup beverage, and belongs to the technical field of functional foods. Composite rice soup is prepared from a mulberry-Chinese wolfberry water extract and brown rice soup according to a mass ratio of (1:1)-(1:3), and maltitol accounting for 7-13% of the mass of the composite rice soup, citric acid accounting for 0.02-0.08% of the mass of the composite rice soup and vitamin C accounting for 0.10-0.20% of the mass of the composite rice soup are added into the composite rice soup, wherein the mulberry-Chinese wolfberry water extract is obtained by preparing Chinese wolfberry and mulberries into a Chinese wolfberry-mulberry mixture accordingto a mass ratio of (1:2)-(1:4) and then mixing the Chinese wolfberry-mulberry mixture with distilled water according to a mass ratio of 1:20 for extraction, and the brown rice soup is obtained by mixing germinated brown rice and distilled water according to a mass ratio of 1:10 for extraction. The beverage is unique in formula and controllable in quality, contains nutrients and active substancessuch as protein, vitamin C, polyphenol, polysaccharide and the like, has the effects of resisting oxidation and inhibiting pancreatic lipase activity, and can be drunk by people with obesity, hyperlipidemia or hyperglycemia and the like.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com